Building outer wall solar heat reflecting energy-saving coating and preparation method thereof

A technology for building exterior walls and energy-saving coatings, applied in the field of materials, can solve problems such as difficulty in popularization and application, weak impact resistance of coatings, and construction affected by seasons and climates.

Inactive Publication Date: 2013-03-27

BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] ③ The drying cycle is long, and the construction is greatly affected by the season and climate;

[0009] ⑤ The bonding strength to the wall is low, so as to cause a large area of hollowing, etc.

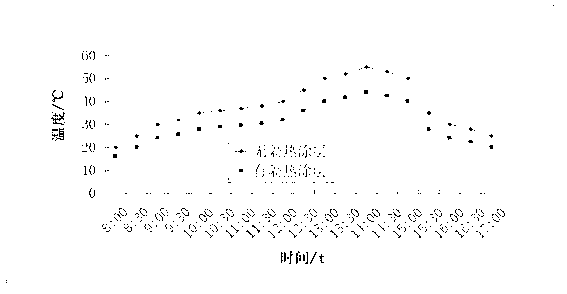

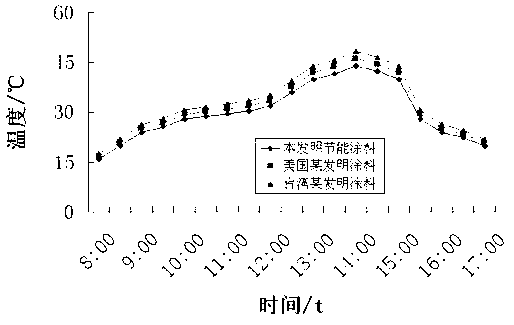

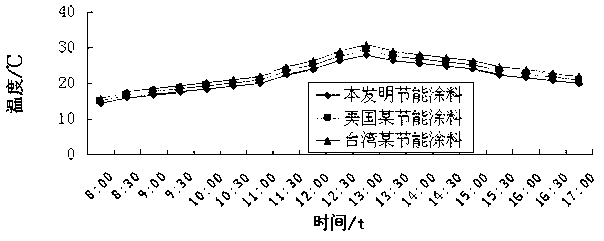

[0010] Foreign products, such as an environmentally friendly and energy-saving product produced by Liquid Ceramic International, Inc., which was introduced into China in August 2005 - liquid ceramic thermal insulation coatings, filled the gap in my country's building thermal insulation coatings , which provides an effective way to meet the current high building energy-saving standards; Taiwan's energy-saving coatings - Ruyi heat-insulating adhesives are also being introduced, but these imported building heat-insulating coatings are very expensive and difficult to promote and apply in the domestic market

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0031]

Embodiment 2

[0033]

[0034]

Embodiment 3

[0036]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a building outer wall solar heat reflecting energy-saving coating which consists of the following components in parts by mass based on 100 parts: 10-15 parts of water, 0.5-1.5 parts of dispersing agent, 0.1-0.5 part of wetting agent, 0.1-0.5 part of antifoaming agent, 0.05-0.15 part of preservative, 0.05-0.15 part of pH regulator, 1-3 parts of propylene glycol, 0.05-0.15 part of cellulose, 5-15 parts of triple superphosphate, 10-30 parts of titanium dioxide, 40-60 parts of emulsion, 4-6 parts of film forming aid, 0.3-0.7 part of mould inhibitor and 0.1-0.5 part of thickening agent. The building outer wall solar heat reflecting energy-saving coating disclosed by the invention can effectively reduce the surface temperature of the outer wall and the indoor environment temperature, reduce the energy consumption of a building, save cost and increase economic benefits.

Description

technical field [0001] The invention relates to a material, in particular to a solar heat-reflecting energy-saving paint for building exterior walls. Background technique [0002] Poor thermal insulation performance of buildings is the main factor for high energy consumption and heavy energy burden in summer. At present, polystyrene, extruded plastic and other materials commonly used are used to insulate buildings through mounting technology. Although these materials can also play a role in heat insulation, they are flammable, pollute the environment, and the construction process is complicated. Disadvantages such as short service life. [0003] In the 1990s, foreign countries have invested more in the research and development of building thermal insulation coatings. Some high-efficiency thin-layer building thermal insulation coatings, such as multi-functional high-efficiency thin-layer thermal insulation coatings, thin-layer vacuum thermal insulation coatings, nanoporous ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D127/12C09D201/00C09D5/33C09D5/00

Inventor 陈铁鑫郭岳峰李旺龙

Owner BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com