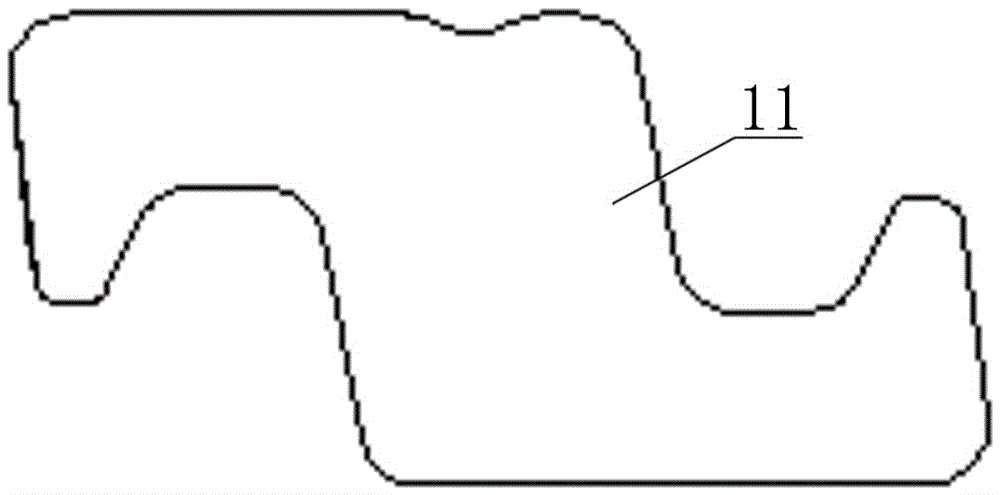

Method for forming irregularly-shaped steel wire with S-shaped cross section

A forming method and cross-section technology, applied in metal rolling and other directions, can solve the problems of inability to achieve comprehensive performance indicators of flexible composite hoses, high cost, easy damage to molds, etc., and achieve excellent comprehensive performance indicators, high production efficiency, and fewer processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

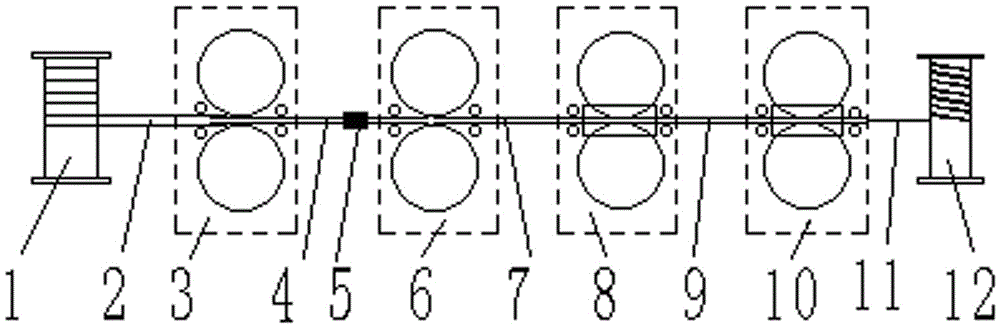

[0027] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

[0028] Such as figure 2 Shown, the molding method of S-shaped cross-section special-shaped steel wire of the present invention comprises the following steps:

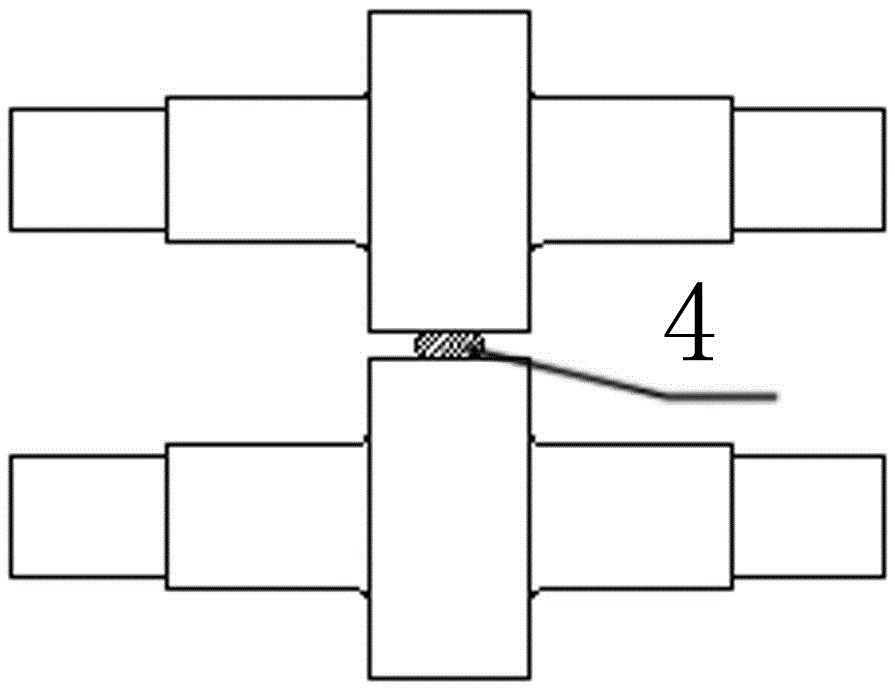

[0029] a. Using the qualified round steel wire 2 unscrewed from the pay-off I-shaped wheel 1 and having a cross-sectional area close to the finished product of the S-shaped cross-section special-shaped steel wire as a raw material, the upper and lower rollers of the first rolling mill 3 are pre-rolled to be parallel to the upper and lower sides First flat wire 4 (see image 3 );

[0030] b, passing the first flat steel wire 4 obtained in step a through the induction coil 5 arranged in front of the entrance of the second rolling mill 6 to be heated, and then entering the upper and lower rolls of the second rolling mill 6 to be rolled into an upper and lower diagonal initial Grooved second flat wire 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com