Process method for preparing magnesium alloy through electro-slag remelting

A technology of electroslag remelting and process method, which is applied in the field of magnesium alloy production, can solve the problems of coarse grain and poor performance of magnesium alloy, and achieve the effect of fine grain, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

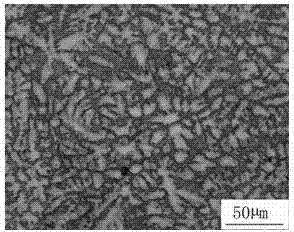

Image

Examples

Embodiment 1

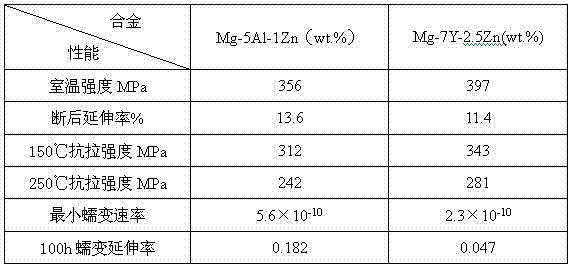

[0021] Pure magnesium, pure aluminum and pure zinc are mixed according to the mass percentage of 94%, 5% and 1%, and then in SF 6 +CO 2 - Melted in a crucible furnace at 850°C under the protection of mixed gas to make a consumable electrode rod; the mass percentage is 12%CaO, 10%Al 2 o 3 , 16% MgO, 62% CaF 2 Mix evenly, keep warm at 800°C for 6 hours as electroslag material, and keep it in the oven until it is taken out before electroslag remelting to ensure dryness; put the consumable electrode rod into the electroslag furnace for smelting, electroslag The working voltage of the furnace is 30V, the working current is 1.5kV, the arc starting block is pure aluminum block, and the arc starting slag is CaF 2 , the smelting process in SF 6 +CO 2 -Proceed under the protection of mixed gas. During the smelting process, electroslag material is added as needed until the electroslag process is completed; the magnesium alloy ingot after electroslag smelting is annealed at 500°C for...

Embodiment 2

[0023] Mix pure magnesium, pure yttrium and pure zinc according to the mass percentage of 90.5%, 7% and 2.5% in SF 6 +CO 2 - Melted in a crucible furnace at 880°C under the protection of mixed gas to make a consumable electrode rod; the mass percentage is 10%CaO, 15%Al 2 o 3 , 20% MgO, 55% CaF 2 Mix evenly, keep warm at 800°C for 6 hours as electroslag material, and keep it in the oven until it is taken out before electroslag treatment to ensure drying; put the consumable electrode rod into the electroslag furnace for smelting, and the electroslag furnace The working voltage is 35V, the working current is 2.0kV, the arc starting block is pure aluminum block, and the arc starting slag is CaF 2 , the smelting process in SF 6 +CO 2 -Proceed under the protection of mixed gas. During the smelting process, electroslag material is added as needed until the electroslag process is completed; the magnesium alloy ingot after electroslag smelting is annealed at 520°C for 5 hours, and...

Embodiment 3

[0027] A kind of electroslag remelting prepares the technological method of magnesium alloy, and its technological step is as follows:

[0028] (a) First mix the magnesium alloy raw materials to be prepared in SF 6 +CO 2 - Melted in a crucible furnace at 800°C to 900°C under the protection of a mixed gas to make a consumable electrode rod. In this embodiment, according to the mass percentage of aluminum in the magnesium alloy being 1%, 3% or 5%, the Pure magnesium and pure aluminum are mixed and smelted in a vacuum induction furnace at 800°C, 850°C or 900°C to make consumable electrode rods;

[0029] (b) Put the consumable electrode rod into the electroslag furnace for electroslag smelting. The working voltage of the electroslag furnace is 25-40V, the working current is 0.8-5kA, the arc starting block is pure aluminum block, and the arc starting slag is CaF 2 , the smelting process in SF 6 +CO 2 -Proceed under the protection of mixed gas. During the smelting process, add e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com