Patents

Literature

208results about How to "Good anti-ultraviolet aging performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel EVA adhesive film

InactiveCN101353558AStrong free radical capture abilityGeneration of blockingFilm/foil adhesivesElectrical equipmentLight energyAdhesive

The invention provides an EVA adhesive film without adding uvioresistant absorbent, which is prepared mainly by the raw materials according to the mass ratio as follows: ethylene-vinyl acetate copolymer, 100 parts; peroxide type crosslinking agent 0.1 to 10 parts, phenolic or phosphite type antioxidant 0.05 to 5 parts; and hindered amine light stabilizer, 0.01 to 5 parts. As the ultraviolet absorbent is not used, the EVA adhesive film obtained does not produce ultra-violet cut-off, leads the solar modules to receive UV district light energy, thereby having higher photoelectric conversion efficiency and excellent uvioresistant anti-aging property, and guaranteeing the service life of PV modules.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Compounded latex retardant for preventing coal spontaneous combustion and preparation method thereof

InactiveCN102392674AEasy to sprayEasy to operateOther chemical processesDust removalCoal spontaneous combustionFire retardant

A compounded latex retardant for preventing coal spontaneous combustion belongs to the technical field of retardants, and comprises the following components by weight ratio: 20 to 80 polymer emulsion, 10 to 90 organic modified clay, and 0.5 to 60 retardant, as well as 1 to 50 dispersant in a concentration of 0.1 to 10wt%. The preparation method comprises the following steps: adding the clay into silane coupling agent solution; performing ultrasonic or stirring dispersion by 30mins; dissolving the dispersant into water of a certain weight ratio, and stirring under 20 to 90 DEG C to get a dispersant solution in a concentration of 0.1 to 10wt%; and adding the organic modified clay and the prepared dispersant solution into the polymer emulsion, fully stirring, adding the retardant, and stirring to achieve uniform concentration. The retardant provided by the invention can not corrode metal equipment during use, harmful gas the wastes can not be generated, no pollution is caused to coal mine environment, and adverse effects and side effects to human body are prevented. Therefore, the retardant is environmental-friendly.

Owner:BEIJING UNIV OF TECH +1

Nano silicon dioxide (SiO2) improved fluorocarbon coating and preparation thereof

InactiveCN103131275AImprove stain resistanceGood anti-ultraviolet aging performanceCoatingsSilver pasteAcrylic resin

The invention relates to a preparation method of nano silicon dioxide (SiO2) improved fluorocarbon coating. The preparation method of the nano SiO2 improved fluorocarbon coating is characterized in that the nano SiO2 improved fluorocarbon coating comprises the following components, by mass, 1% to 5% of nano SiO2, 40% of acrylic resin with solid contents, 25% to 28% of polyvinylidene difluoride, 24% to 27% of fumed SiO2, 0.4% of silver paste, 6% of cellulose acetate, 4% of dispersing agent, 2% to 5% of mixed solvent, and allowance. nano SiO2 is added into the fluorocarbon coating, thus improving contamination corrosion resistance, ultraviolet aging resistance, corrosion resistance and the like of the fluorocarbon coating, and the preparation method of the nano SiO2 improved fluorocarbon coating belongs to the technical field of processing of coatings.

Owner:CHANGZHOU UNIV

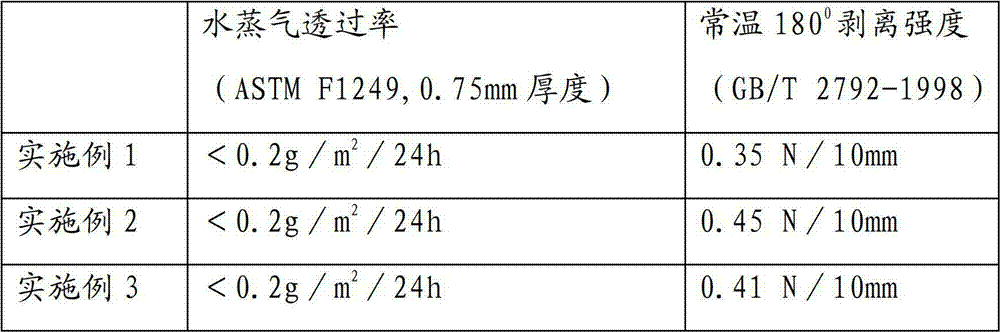

Butyl hot melt adhesive tape and preparation method thereof

InactiveCN102816535AImprove adhesionHigh bonding strengthFilm/foil adhesivesAldehyde/ketone condensation polymer adhesivesPolymer scienceAntioxidant

The invention relates to a butyl hot melt adhesive tape and a preparation method thereof. The preparation method comprises the following steps: 1) adding polyisobutylene into a vacuum kneader, rising the temperature, and conducting a first stirring; then adding a plasticizer, an antioxidant, a modified phenolic resin, a carbon 5 resin, a homogenizing tackifier and a polyethylene wax, and conducting a second stirring to obtain a mixture A; 2) sequentially adding EVA and a butyl rubber into the mixture A obtained in the step 1), and conducting a third stirring to obtain a mixture B; 3) adding carbon black into the mixture B obtained in the step 2), and conducting a fourth mixing to obtain an adhesive material; and 4) heating the adhesive material obtained in the step 3), and then pressing and cutting to obtain the butyl hot melt adhesive tape.

Owner:YANTAI DARBOND TECH

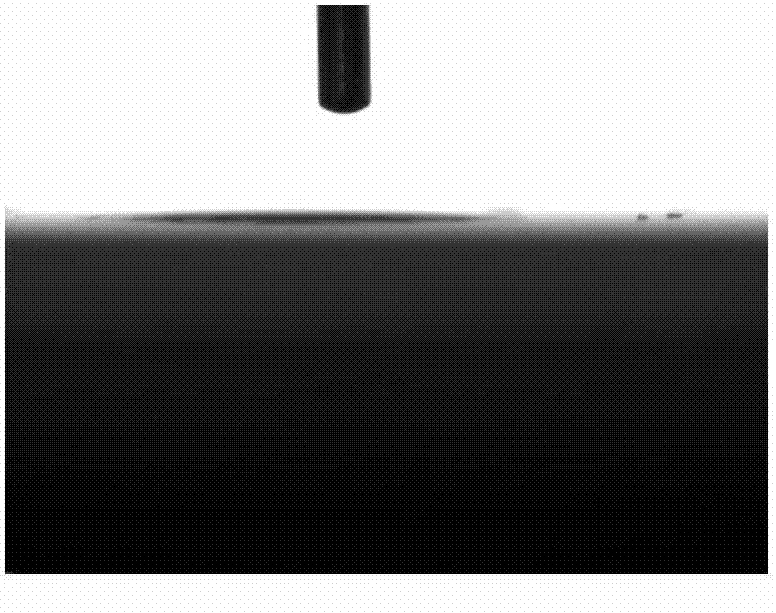

Preparation method of anti-reflection self-cleaning coated glass

The invention discloses a preparation method of anti-reflection self-cleaning coated glass, which comprises the steps of preparing a SiO2-TiO2 composite sol firstly, then carrying out film coating by using a pulling method, and forming a coarse nano thin film layer on the surface of a glass substrate through the SiO2-TiO2 composite sol; and finally, carrying out low-temperature post-treatment on the obtained product so as to obtain coated glass. By using the preparation method disclosed by the invention, the visible light transmittance of the prepared coated glass can be improved, the light transmittance is increased by 2-3%, and the prepared coated glass can achieve a photocatalytic self-cleaning effect. The preparation method disclosed by the invention is simple, a glass substrate is not required to be subjected to complex pretreatment, and coated glass is not required to be subjected to high-temperature baking. The coated glass prepared by using the method disclosed by the invention has excellent ultraviolet aging resistance; and because a coated layer is a nano film, and the surface of the nano film has a proper roughness, the nano film can achieve a physical hydrophilic effect, so that the coated layer on the surface of the glass substrate also can have a super-hydrophilic self-cleaning performance under the condition of no light.

Owner:上海圣元新能源科技有限公司

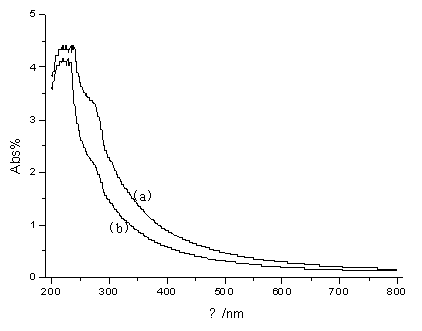

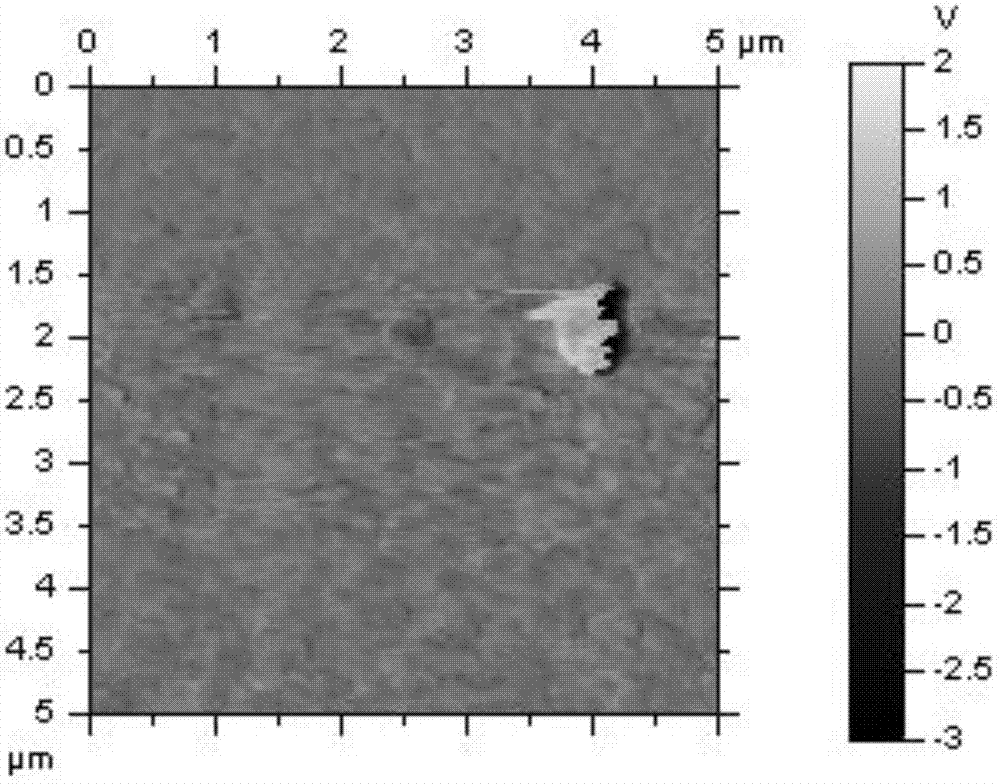

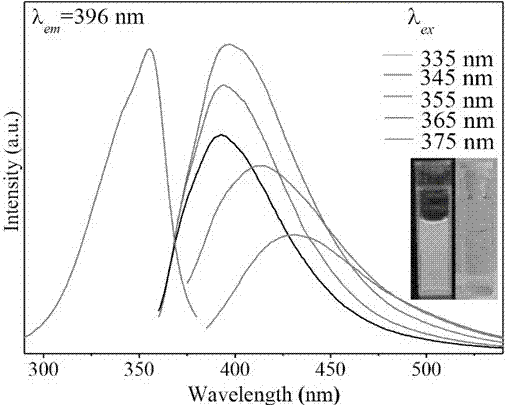

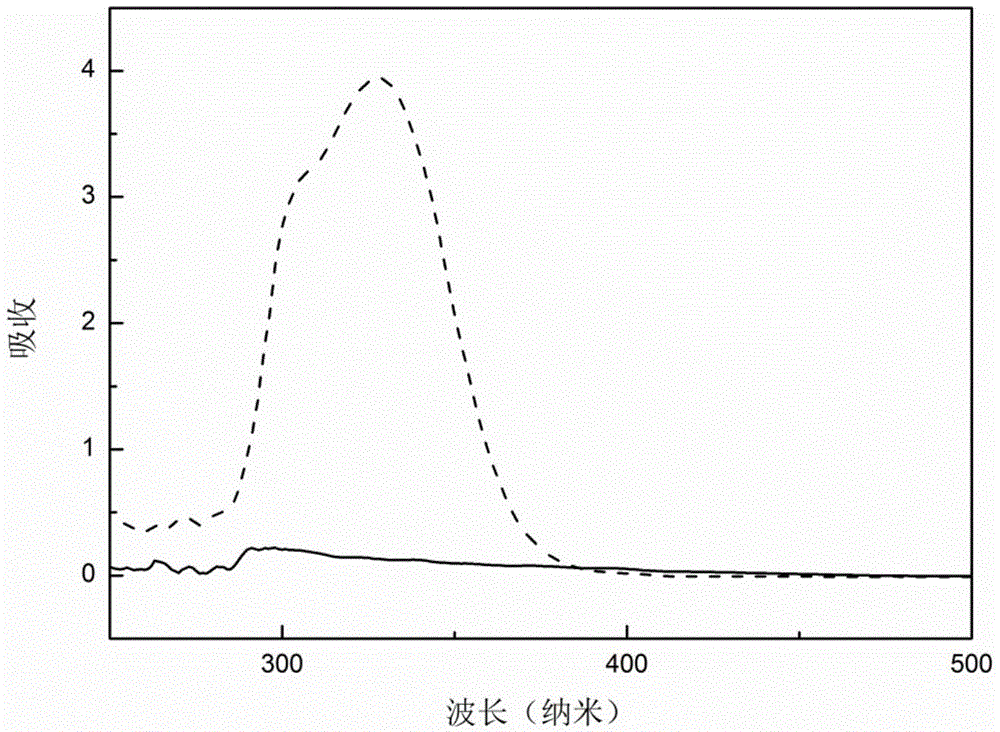

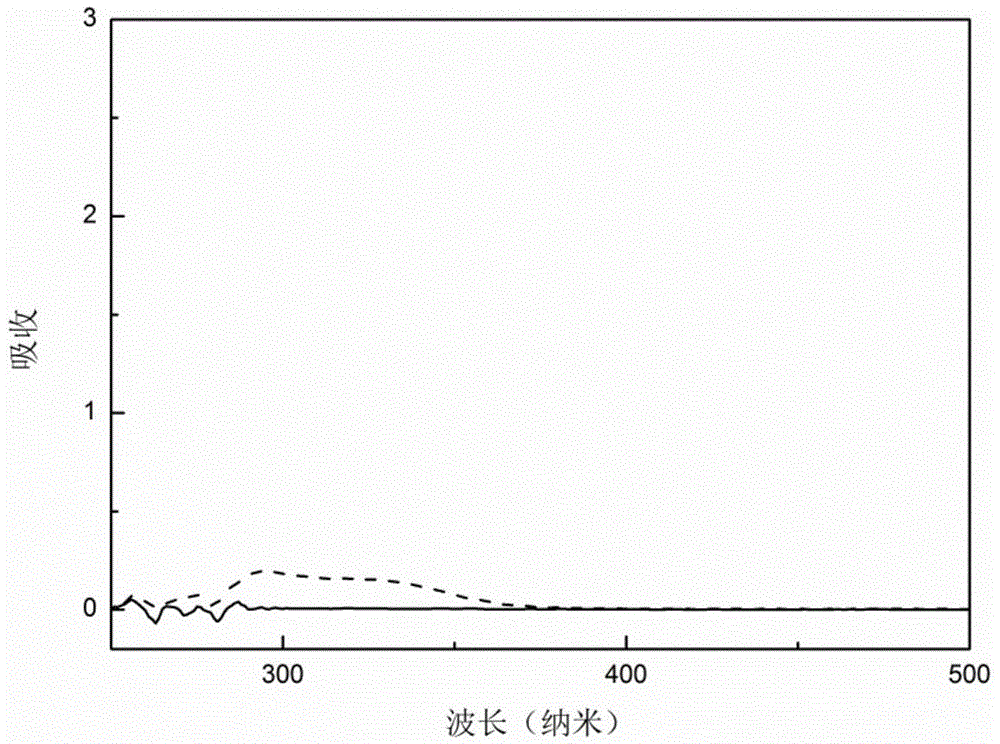

Oil-solubility carbon quantum dots (OCDs), PMMA-coated OOCDs, and preparation method and application thereof

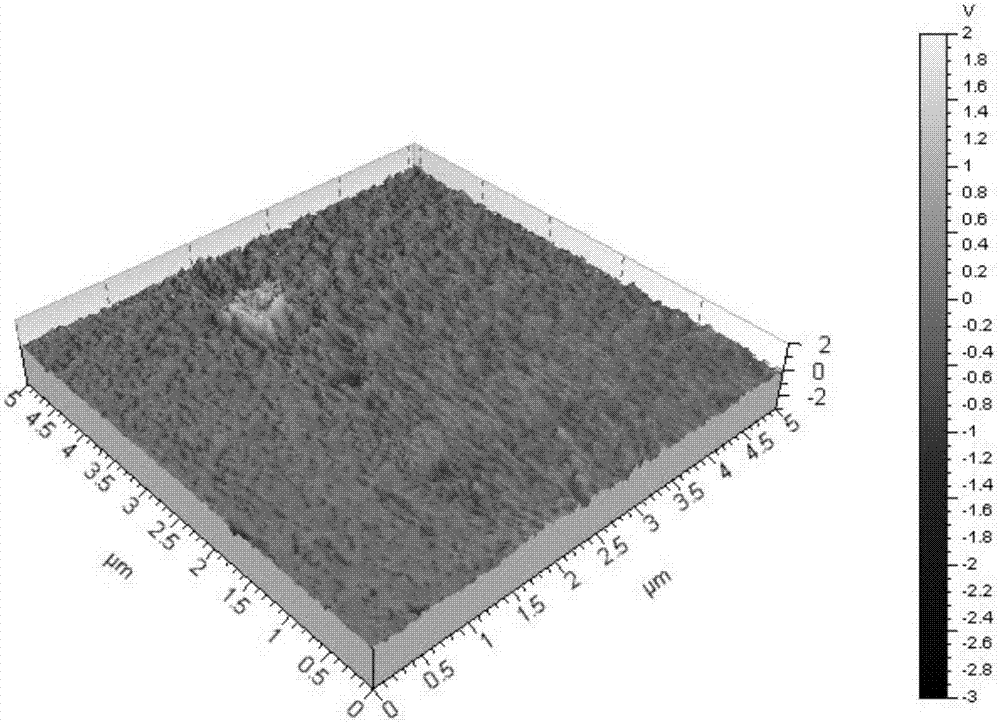

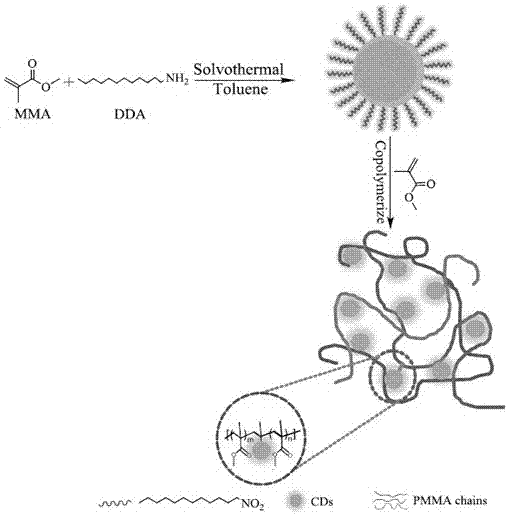

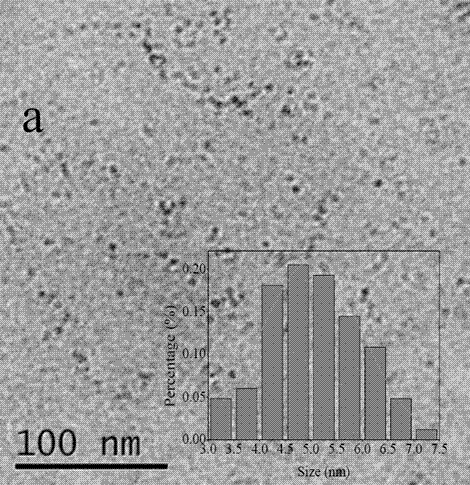

InactiveCN106916587ASmall sizeHigh luminous intensityMaterial nanotechnologyNanoopticsTransmittanceIn situ polymerization

The invention relates to oil solubility carbon quantum dots (OCDs), PMMA-coated OOCDs, and a preparation method and an application thereof. The particle size of the oil solubility carbon quantum dots is 1-10 nm, and the surface non-saturated carbon bond contains 20-50%. The oil solubility carbon quantum dots synthesized by the method has good dispersibility and luminescence performance, can be taken as an age-proof probe of PMMA, a composite material obtained by in-situ polymerization of the oil solubility carbon quantum dots and the PMMA has excellent optical transparency (the transmittance can reach as high as more than 85%), the anti-ultraviolet aging performance of the PMMA can be increased by more than 10 times, the method solves the problems that the application of carbon quantum dots is existed in all-solid-state illumination in the prior art, and solves the problem that the PMMA cannot be widely used due to poor aging performance.

Owner:SHANGHAI UNIV

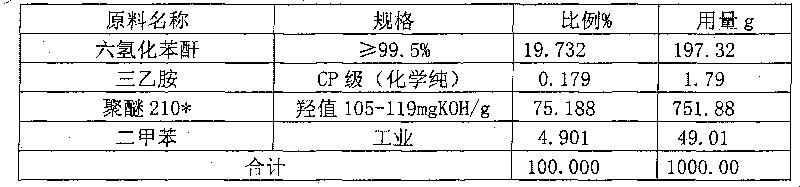

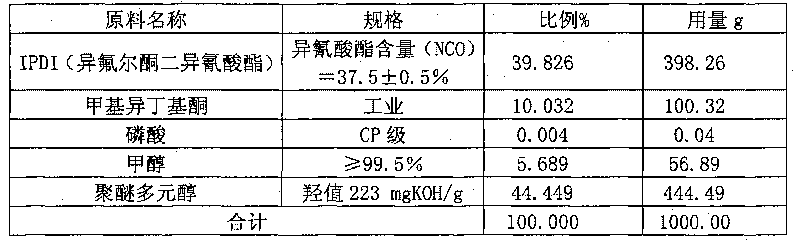

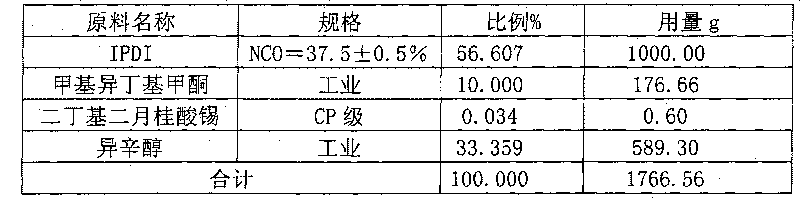

Cathode electrophoretic coating composition and preparation method thereof

InactiveCN101760126AGood anti-ultraviolet aging performanceImprove supporting yellowingPolyurea/polyurethane coatingsPaints for electrolytic applicationsAlcoholEmulsion

The invention relates to a cathode electrophoretic coating composition and a preparation method thereof, wherein the cathode electrophoretic coating composition contains the following components of: a component A comprising water-dispersing emulsion in which cycloaliphatic resin is added, wherein the water-dispersing emulsion accounts for 70-90 parts of the total weight of the composition; and a component B comprising colorant in which cycloaliphatic resin is added, wherein the colorant accounts for 10-30 parts of the total weight of the composition; and the cycloaliphatic resin is selected from an esterified reaction product of hexahydro-anhydride and C1-10 alkyl alcohol or alcohol ether and a closure of isophorone diisocyanate. The invention also provides a method for preparing the cathode electrophoretic coating composition.

Owner:上海金力泰化工股份有限公司

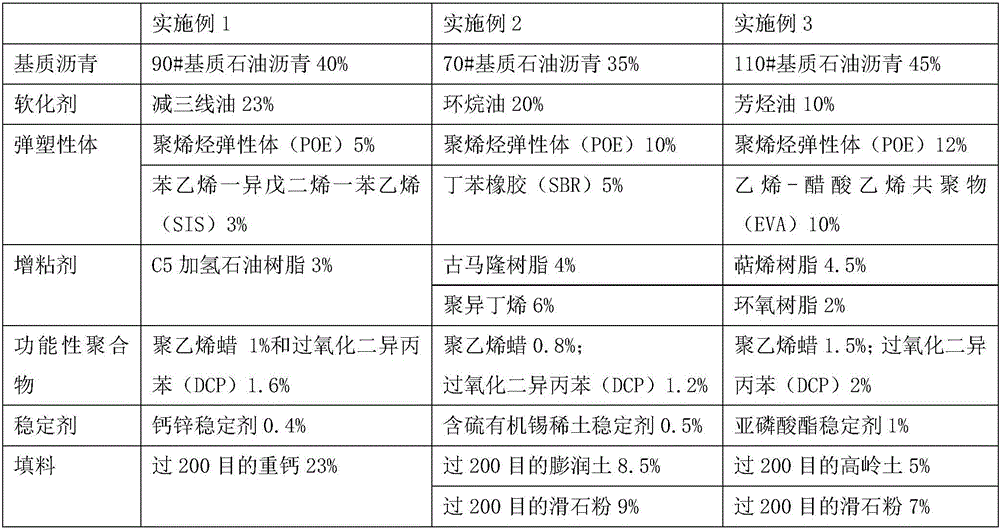

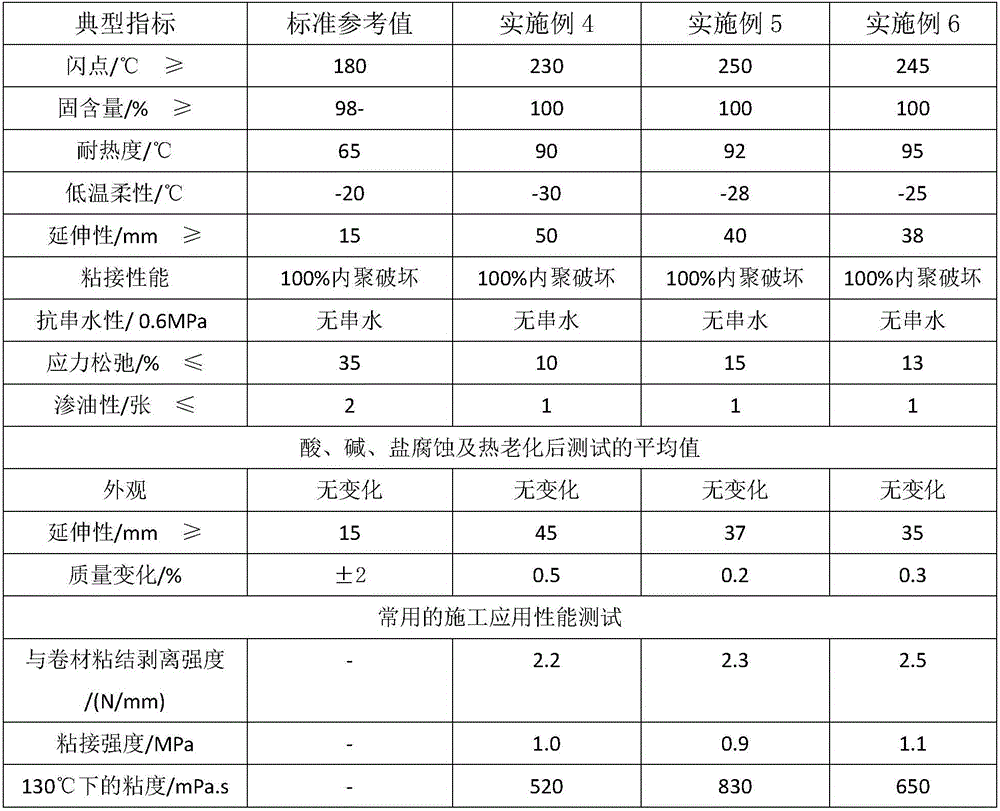

Non-cured rubber asphalt waterproof paint and preparation method thereof

InactiveCN106634602ANot affected by adhesive propertiesImprove thermal stabilityBituminous coatingsBituminous waterproofingPolymer science

The invention discloses a non-cured rubber asphalt waterproof paint and a preparation method thereof. The preparation method comprises the following steps: 1) weighing a matrix asphalt, a softener, an elastic plastic body, an adhesion agent, a functional polymer, a stabilizing agent and a filling material; 2)injecting the matrix asphalt to a reaction vessel, heating the materials, stirring the materials, adding the softener, and stirring the materials; 3) adding the obtained mixture and the elastic plastic body in a colloid grinder, growing the materials, opening the colloid grinder, grinding the materials, and continuously growing the materials; 4) adding an adhesion agent and a functional polymer, continuously stirring the materials; 5) adding a filling material and stirring the materials; and 6) adding a stabilizing agent, and stirring the material. The paint has high heat resistance, good construction property, good thermostability, chemical stability and anti-ultraviolet aging capability, bond property is not influenced due to extraneous environment, the paint has construction property for a wet basic layer, can increase the interfacial affinity interaction with the wet basic layer, and construction quality and progress can be effectively guaranteed, and the paint is environmentally friendly.

Owner:LOGISTICS UNIV OF CAPF

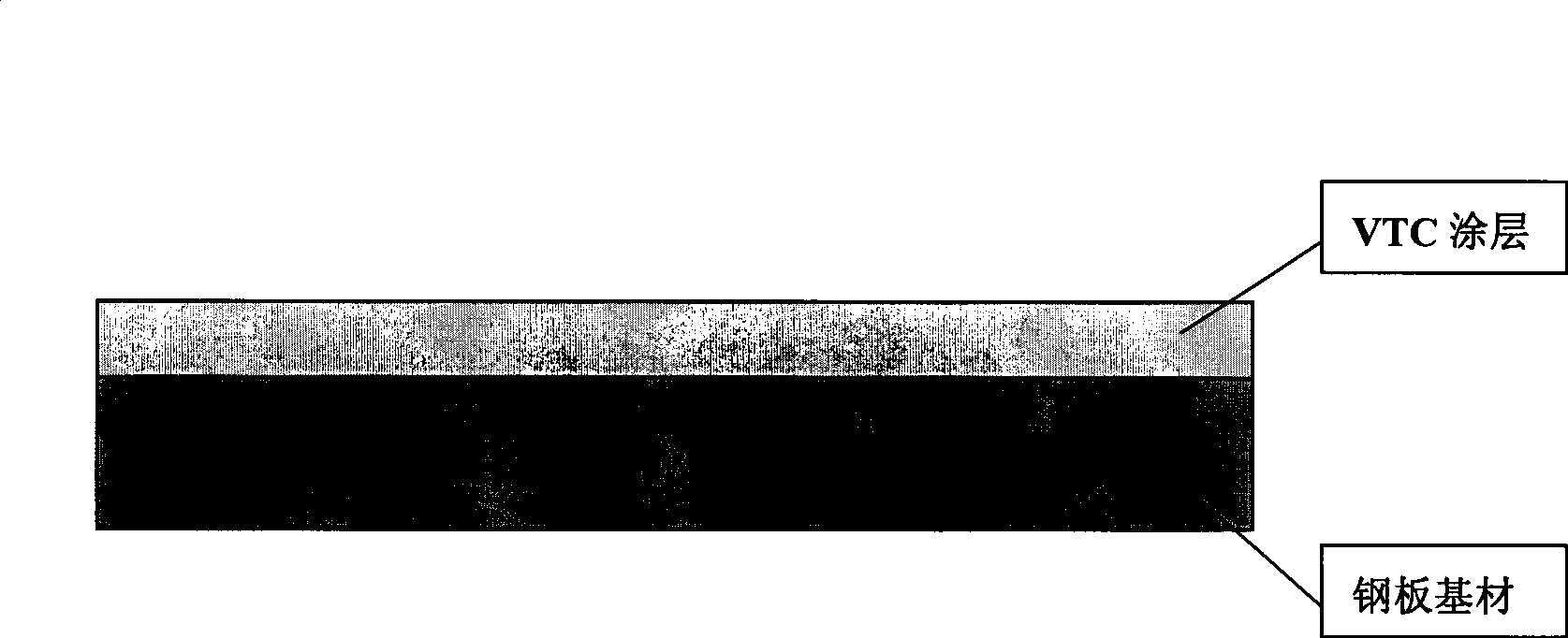

VCI-containing flake cold-plating zinc and aluminum protective coating on steel structure surface and preparation method thereof

ActiveCN101397413AHarsh salt spray resistanceGood anti-ultraviolet aging performanceAnti-corrosive paintsEpoxy resin coatingsCoating systemZinc

A squama type cold galvanizing aluminum coating used on the surface of steel structure and containing VCI (Vapor corrosion inhibitor). Besides, the invention also provides a VCI squama type cold galvanizing aluminum complex coating system on the surface of steel structure and prepared from the coating.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

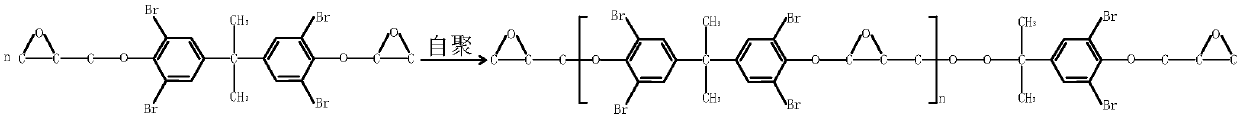

Anti-ultraviolet copolyester and preparation method thereof

InactiveCN105482085AThe phenomenon of reunion is obviousImprove mechanical propertiesUltraviolet absorptionCopolyester

The invention provides an anti-ultraviolet copolyester and a preparation method thereof, and belongs to the field of copolyester preparation. A reaction of an ultraviolet absorption group-containing monomer reacts with a diacid and a diol to prepare the copolyester, and the molecular weight of the copolyester is 1*10<3>-1*10<6>. The preparation method comprises two steps of esterification and vacuum polycondensation. The anti-ultraviolet copolyester is obtained through fusion polycondensation of the ultraviolet absorption group-containing polymerizable monomer, the diacid and the diol. The anti-ultraviolet copolyester prepared in the invention has no compatibility problem of addition type ultraviolet screeners or polymer matrixes, and solves the problem of outward migration of additives existing in the use process of organic micro-molecular anti-ultraviolet additives. The anti-ultraviolet copolyester prepared in the invention has good mechanical performances and excellent ultraviolet ageing resistance.

Owner:TSINGHUA UNIV

Ultraviolet aging resisting fiber-reinforced polymer base composite

The invention relates to an ultraviolet aging resisting fiber-reinforced polymer base composite which comprises the following raw materials in parts by weight: 0.1-10 parts of a compound ultraviolet aging resisting agent, 40-90 parts of matrix resin, 5-60 parts of reinforced fiber and 3-30 parts of a curing agent and an accelerating agent together. Through the addition of the compound ultraviolet aging resisting agent and the reinforced fiber, the ultraviolet aging resisting fiber-reinforced polymer base composite has good ultraviolet aging resisting performance and excellent mechanical performance, can be used for manufacturing outdoor large-sized composite products, and can effectively improve the weather resistance of the products and prolong the service life of the products; when the composite is irradiated under ultraviolet rays for 1000 h, the falling range of the mechanical strength is less than 3%.

Owner:孙仁华

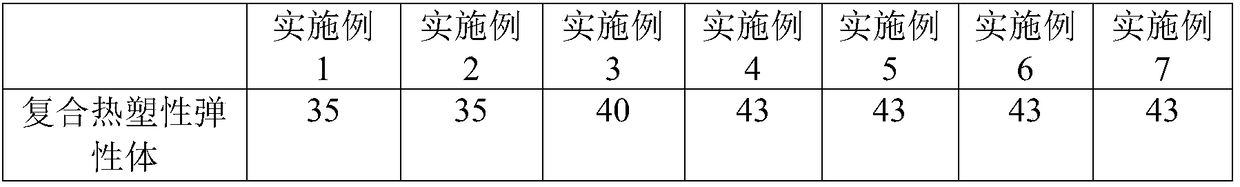

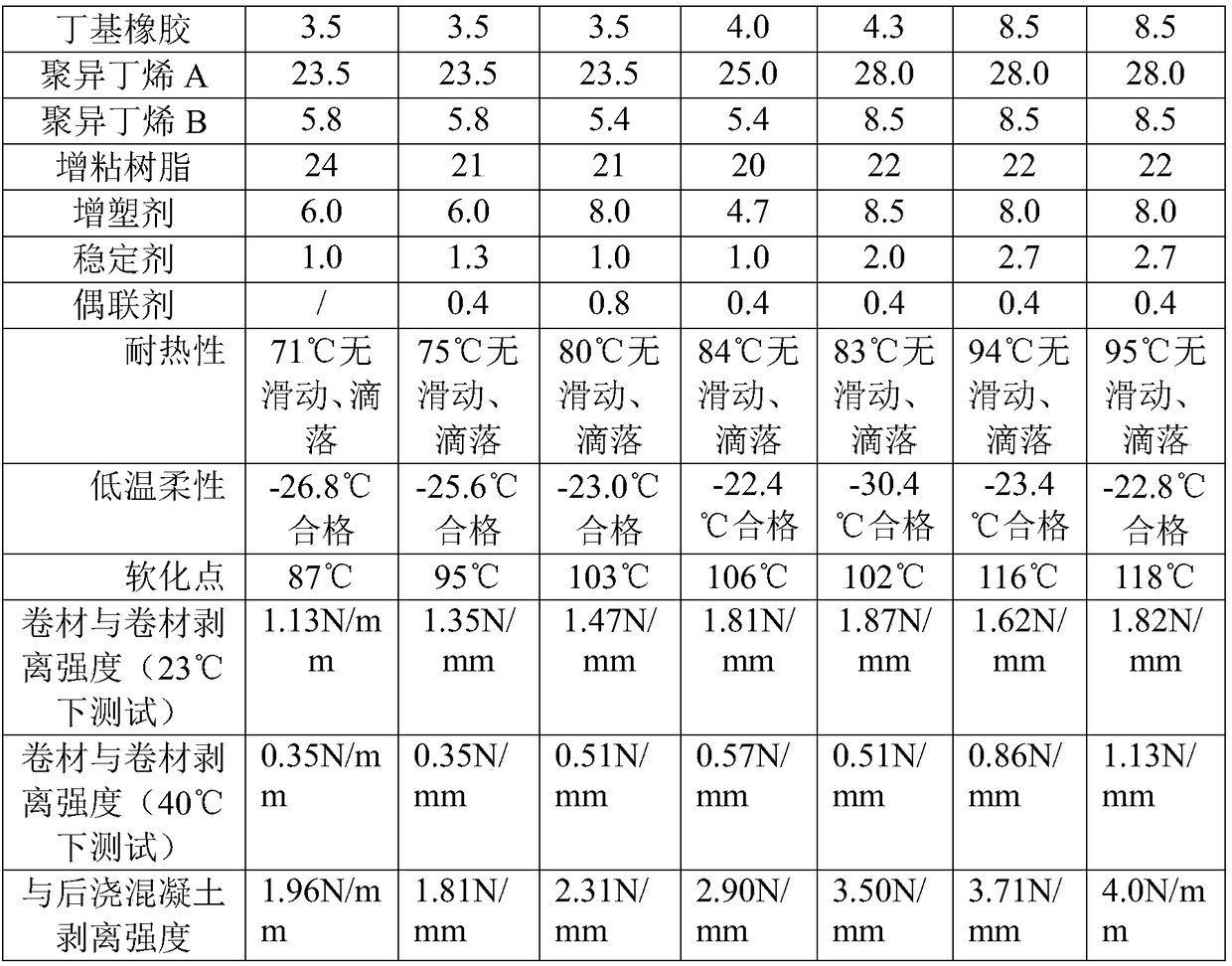

Hot-melt pressure-sensitive adhesive with high heat resistance for macromolecular waterproof roll and preparation method thereof

ActiveCN109233707ASimple production processEasy production coatingNon-macromolecular adhesive additivesMacromolecular adhesive additivesPlasticizerThermoplastic elastomer

The invention discloses a hot-melt pressure-sensitive adhesive with high heat resistance for a macromolecular waterproof roll and a preparation method thereof. The hot-melt pressure-sensitive adhesiveis prepared from the following raw materials by weight percent: 30%-40% of compound thermoplastic elastomer, 3%-10% of butyl rubber, 20%-25% of polyisobutene A, 5%-10% of polyisobutene B, 20%-26% oftackifying resin, 3%-8% of plasticizer, 0.8%-2% of stabilizer and 0.5%-1% of coupler. The hot-melt pressure-sensitive adhesive disclosed by the invention has the characteristics of high viscidity, high peeling strength under high temperature, excellent thermo-oxidative aging and ultraviolet aging resistance and simple production process.

Owner:江苏雨中情防水材料有限责任公司

Wind prevention, sand fixation and water retention afforestation method

ActiveCN105918056AStrong molecular adsorptionExcellent adhesionClimate change adaptationAfforestationSoil sciencePlastic mulch

The invention discloses a wind prevention, sand fixation and water retention afforestation method and belongs to the technical field of environmental protection engineering. The method comprises steps as follows: a curing agent is prepared from sodium carboxymethylcellulose, anionic polyacrylamide, ferrous chloride and water; the curing agent and sand are blended to form cured sand; deep holes for tree planting and shallow trenches for grass planting are dug in the sand land, water collecting hoppers are drilled in the deep holes, the deep holes and the shallow trenches are filled with the cured sand, and the cured sand form deep hole sand fixation and water absorption layers in the deep holes and form shallow trench sand fixation and water absorption layers in the shallow trenches; saplings are planted in the deep holes, the roots of the saplings extend into the mouth parts of the water collecting hoppers, and grass seeds are scattered in the deep holes and the shallow trenches; the grass seeds are covered with a mulching film for maintenance, and small ventilation holes are formed in the mulching film. The curing agent and the sand soil are blended, inside gaps of soil particles can be filled with the blended curing agent and sand soil, the cured sand particles don't easily disperse and jump, sufficient water can be continuously provided for plants, and the long-time wind prevention, sand fixation and water retention effects are achieved.

Owner:裴向军 +1

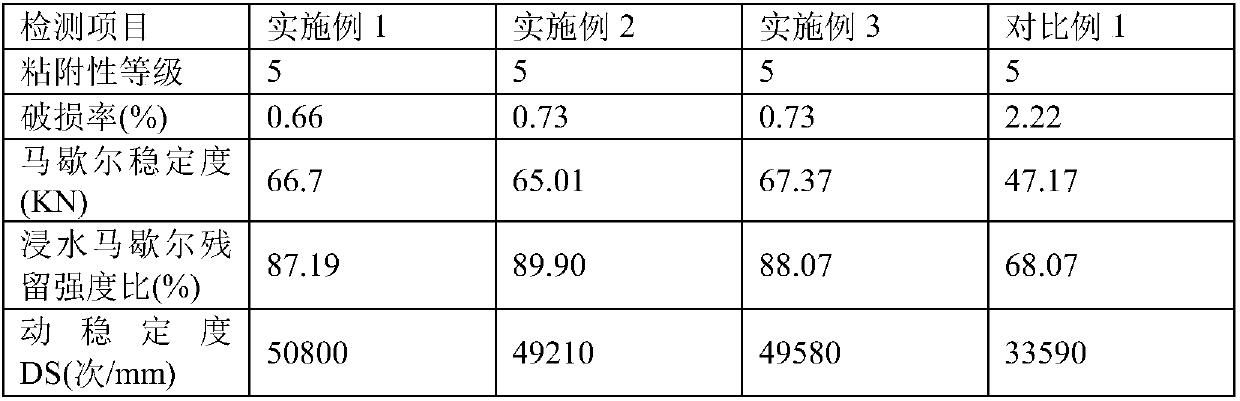

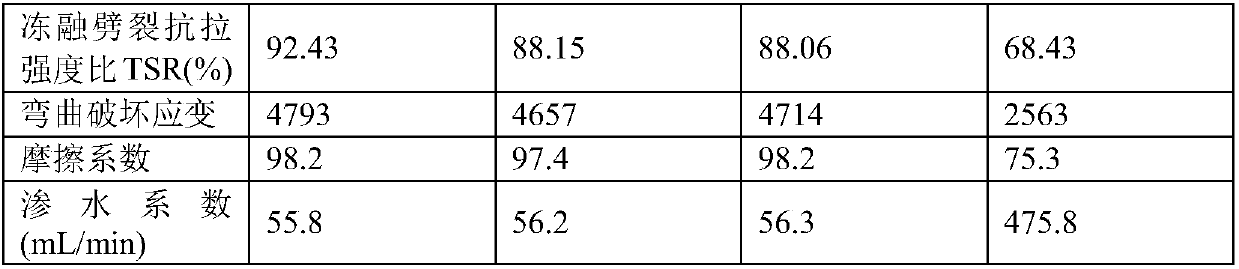

Cold mix and cold laid asphalt concrete and preparation method thereof

The invention relates to cold mix and cold laid asphalt concrete and a preparation method thereof. The cold mix and cold laid asphalt concrete comprises 25-35wt% of emulsified asphalt and 65-75wt% ofaggregate, wherein the emulsified asphalt comprises the following raw materials in parts by weight: 50-60 parts of SBS (Styrene-Butadiene-Styrene) modified asphalt, 35-40 parts of water, 1.2-4.3 partsof an emulsifier, 5-10 parts of a reaction type resin and 0.005-0.1 part of a curing agent. The preparation method comprises the following steps: (1) uniformly dispersing the emulsifier in water of 55-65 DEG C, and adjusting the pH value to 1.5-3.0 for later; (2) putting the SBS modified asphalt into an emulsifier solution, and grinding by using a colloid mill; (3) putting the reaction type resininto the mixed material of the step (2), and grinding by using the colloid mill; (4) shearing the mixed material of the step (3) at a speed of 6000-7000r / minute for 30-60 minutes; (5) putting the aggregate and the curing agent into the mixed material of the step (4), and uniformly mixing. The cold mix and cold laid asphalt concrete provided by the invention has the advantages of good constructionpeaceability and relatively high strength.

Owner:北京国创通畅路桥养护有限公司

Coupling agent modified silicon dioxide doped cycloaliphatic epoxy resin LED packaging adhesive

InactiveCN102838957AExtended service lifeReduce absorptionNon-macromolecular adhesive additivesOther chemical processesAntioxidantAdhesive

The invention relates to a coupling agent modified silicon dioxide doped cycloaliphatic epoxy resin LED packaging adhesive. The adhesive is characterized in that: it is composed of component A and component B that are mixed in a ratio of 1: (0.9-1) for construction. Specifically, the component A consists of cycloaliphatic epoxy resin, an active diluent, a transparent blue-violet purple dye color paste, a defoaming agent and a softening agent. The component B consists of a curing agent, an accelerator, a silane coupling agent modified nano-ultraviolet absorbent, polyol and an antioxidant. The nano-silicon dioxide doped cycloaliphatic epoxy resin LED packaging adhesive provided in the invention has the advantages of good ageing resistance, strong binding power, fast curing, low viscosity and moisture absorption, so that employment of organosilicone with a high cost can be avoided. Meanwhile, the defects of high moisture absorption, poor ultraviolet resistance and low shortwave transmittance and the like of existing bisphenol A type epoxy resin can be overcome. The LED packaging adhesive provided in the invention is more suitable to be used as a high-end LED packaging adhesive, a high power LED packaging adhesive or an ultraviolet light-based white light and blue light LED packaging adhesive.

Owner:JIANGSU TETRA NEW MATERIAL TECH

Method of high-value comprehensive utilization of bamboo remainders

InactiveCN101619547AImprove liquidityGood storage stabilityAldehyde/ketone condensation polymer adhesivesPaper material treatmentAlcoholSeparation technology

The invention discloses a method of high-value comprehensive utilization of bamboo remainders. The method comprises the following steps: selective liquefaction working procedure, filtering separation working procedure and glue-making working procedure. Compared with the prior art, the invention has the advantages that firstly, due to the adoption of the milder selective liquefaction working procedure condition, the liquefaction is performed to the hemicellulose, the lignin and the partial cellulose (mainly amorphous part) which are easier to be liquefied in the bamboo material, the application performances (viscosity, fluidity and storage stability ) of the liquefaction solution are enhanced, the high-purity bamboo cellulose miropowder is also obtained and the high-value and full utilization of the bamboo remainders are realized; secondly, the poisonous eluting solvent is not required to be used for the obtained liquefaction solution, and the obtained liquefaction solution can be directly used for resinified synthesization; the treatment is performed to the liquefaction residuals by adopting hot water and ethyl alcohol to obtain the bamboo cellulose miropowder with high-value utilization; and the liquefaction and separation technology is simpler, more convenient and more environmental-friendly, the energy consumption is greatly reduced and the process is economical and feasible.

Owner:HUANGSHAN UNIV

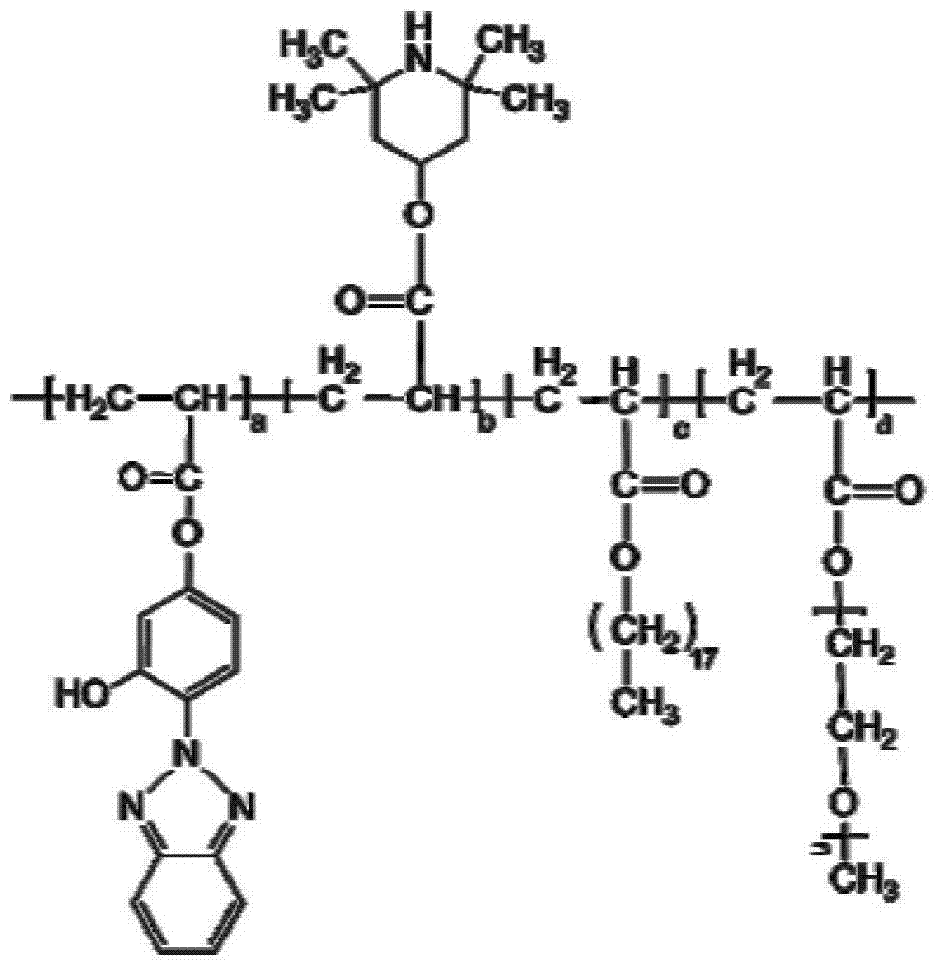

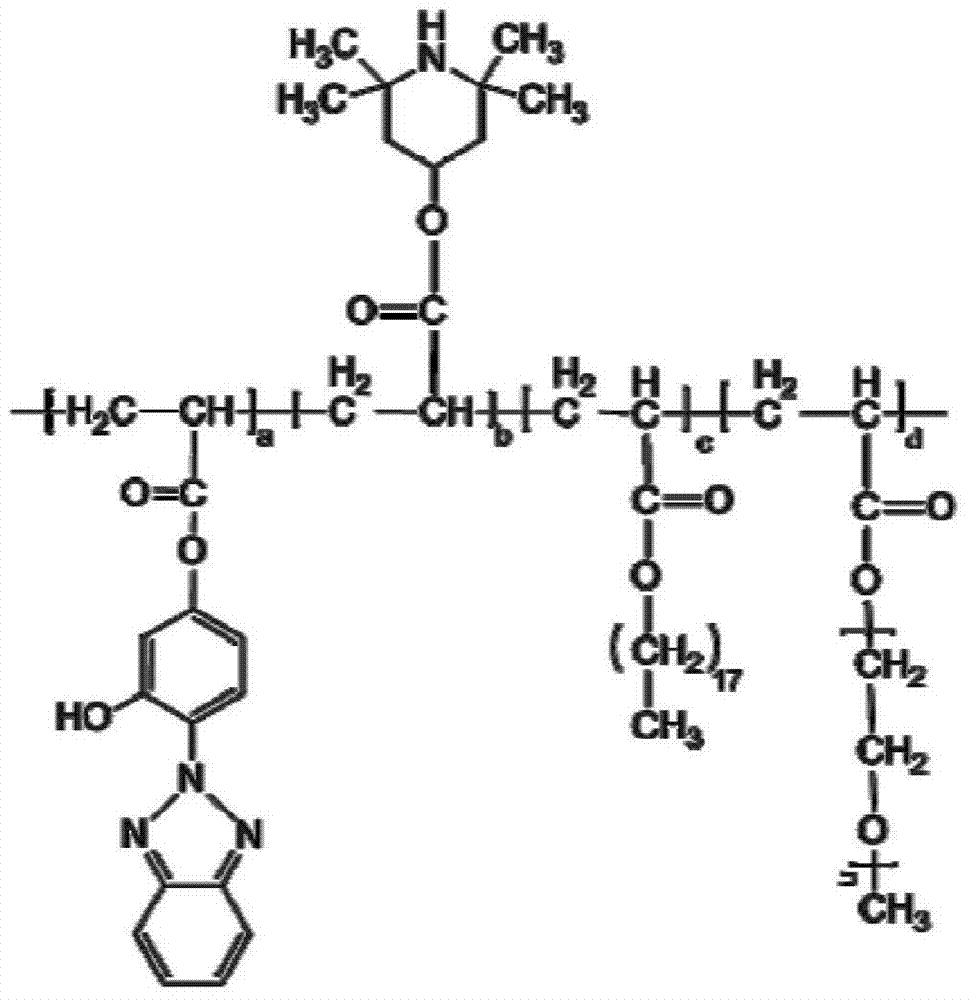

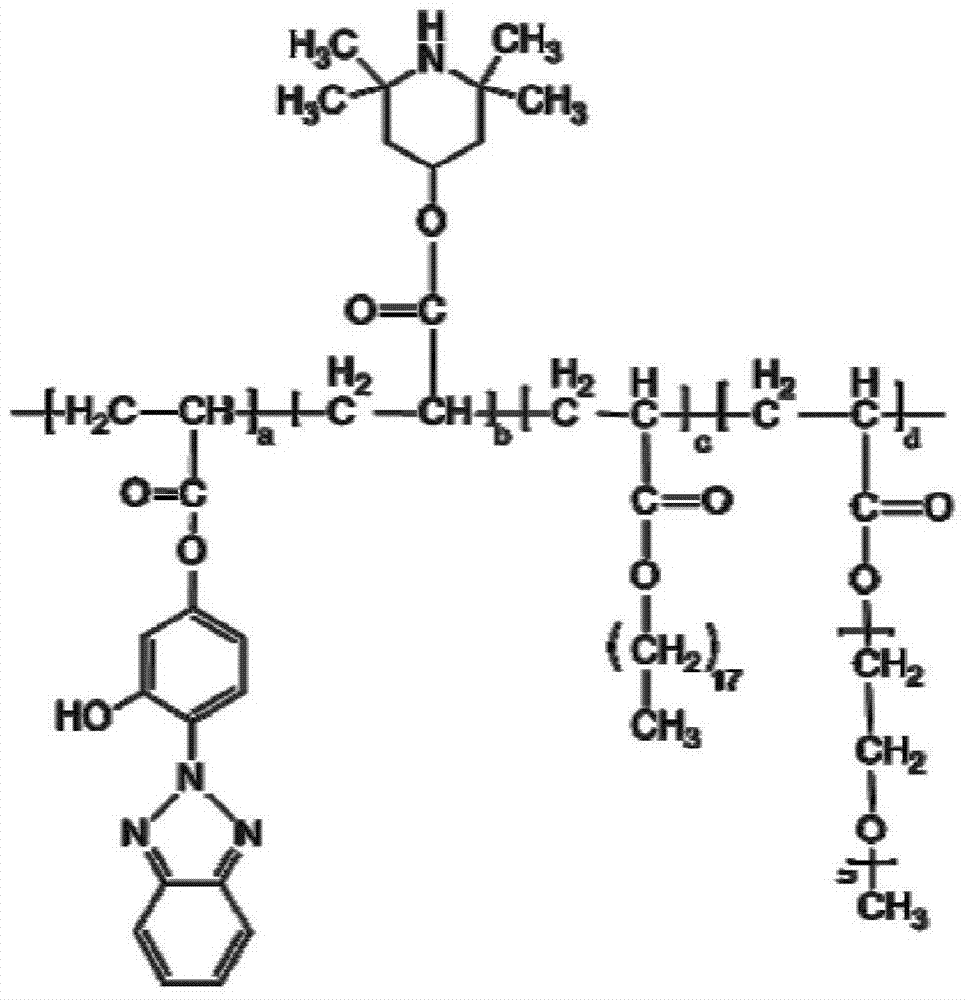

Preparation methods of anti-aging wood-plastic composite and light stabilizer

InactiveCN104844971AHas dual protection against photoagingPhotostabilizationVegetal fibresPlasticizerPolyvinyl chloride

The invention discloses preparation methods of an anti-aging wood-plastic composite and a light stabilizer. The wood-plastic composite is prepared from the following raw material components in parts by weight: 100 parts of polyvinyl chloride, 20-40 parts of sisal fibers, 1-5 parts of a heat stabilizer, 1-8 parts of a lubricating agent, 0.5-2 parts of an antioxidant, 6-10 parts of a plasticizer and 0.5-5 parts of a light stabilizer shown as the short chemical formula: P(HAPBT-co-MTMP-co-AEG-cp-OA). Due to the addition of the specific light stabilizer, the ageing-resistant effect of the wood-plastic composite is favorably improved; in addition, the composite has relatively good physical and mechanical properties and processability, so that the application field of the wood-plastic composite is further widened, and the wood-plastic composite not only can be applied to some indoor wood materials, but also can be applied to outdoor materials such as architectural decoration, transportation, municipal administration and gardens.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Poly(p-phenylene benzobisoxazole) composite fiber containing nano-TiO2 preparation method

InactiveCN101613892AExcellent UV aging resistanceSuitable for industrial manufacturingSpinning head liquid feederWet spinning methodsChemistryMechanical property

The invention relates to a poly(p-phenylene benzobisoxazole) (PBO) composite fiber containing nano-TiO2 preparation method, comprising the following steps: dissolving 4,6-diaminoresorcinol hydrochloride and terephthalic acid and a certain number of phosphorus pentoxide in equal molar ratio in polyphosphoric acid, removing hydrogen chloride gas, heating and polymerizing to obtain poly(p-phenylene benzobisoxazole), then adding poly(p-phenylene benzobisoxazole) and phosphoric acid solution containing nano-TiO2 in a double-screw extruder and obtaining PBO composite fiber containing nano-TiO2 by dry-jet wet spinning; the invention uses nano-TiO2 particles with ultraviolet shielding property and utilizes the strong shearing and high effective blending of the double-screw extruder to prepare the composite fiber; compared with pure PBO fiber, the ultraviolet aging resistance property is effectively improved while the mechanical properties are not reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

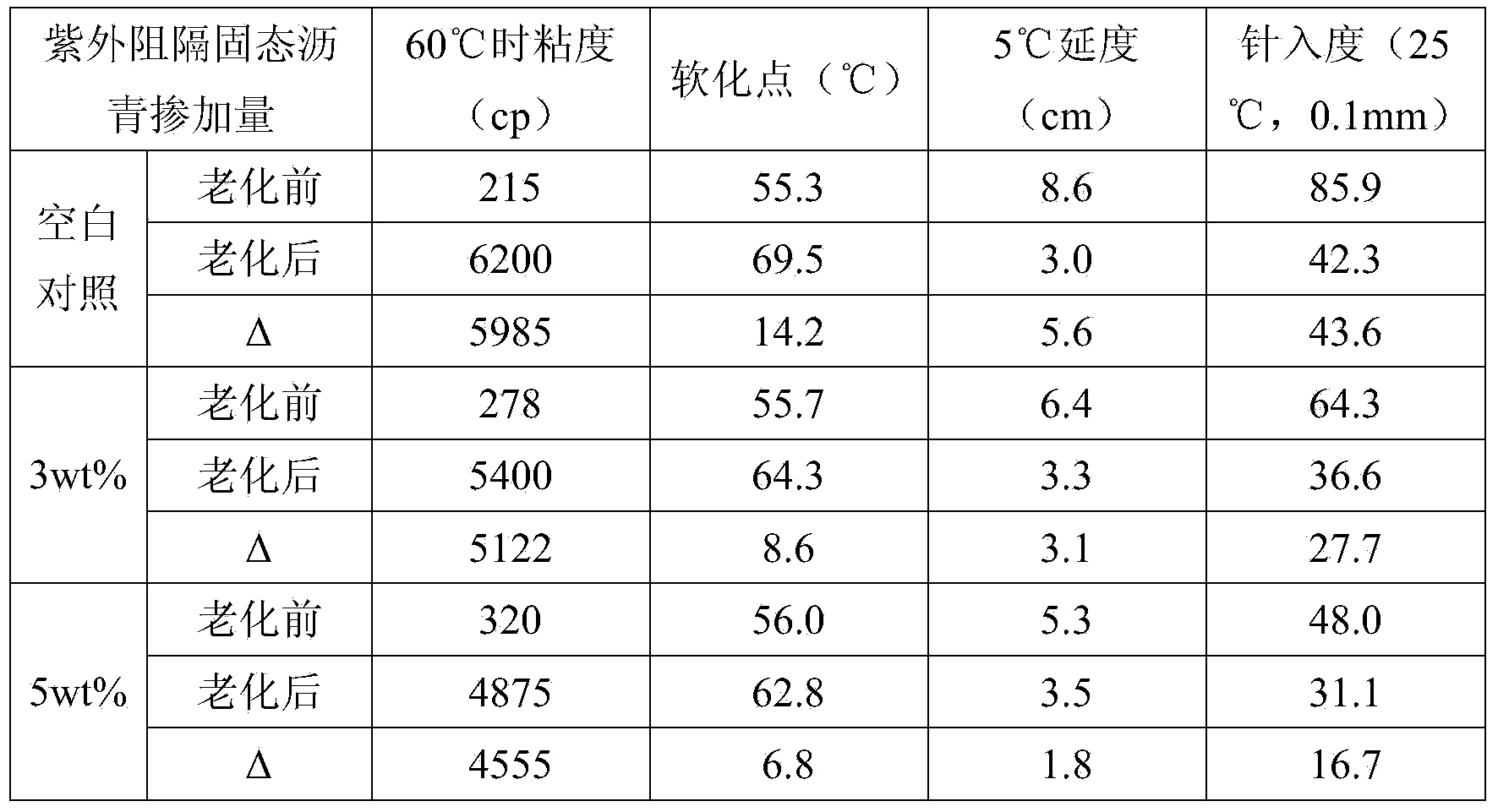

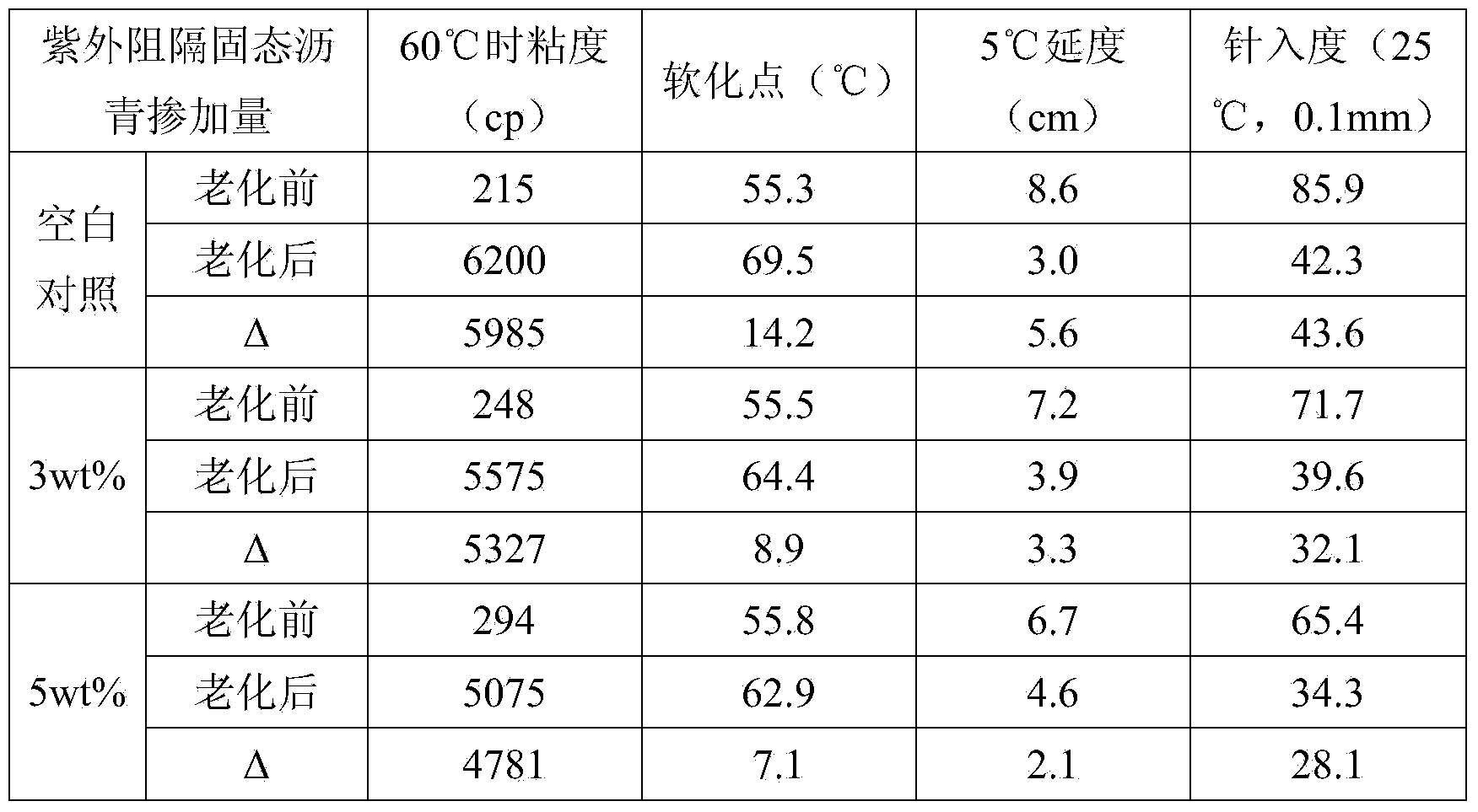

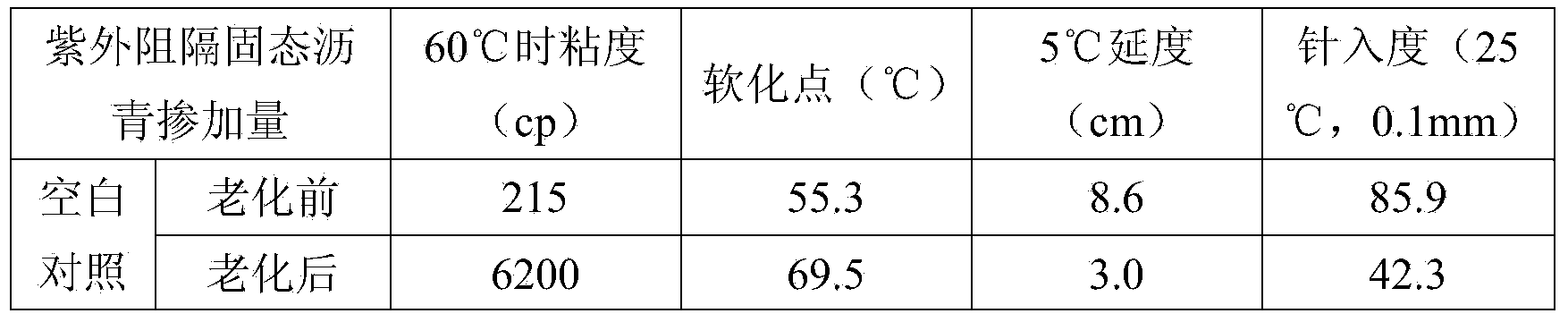

Ultraviolet-rejected solid asphalt, preparation and application thereof

ActiveCN103881403AEasy to store and transportExcellent UV blocking effectIn situ pavingsBuilding insulationsSolventMagnesium

The invention discloses ultraviolet-rejected solid asphalt, preparation and application thereof. The ultraviolet-rejected solid asphalt is prepared by mixing asphalt, magnesium-aluminum-based layered double hydroxide and a cosolvent and is solid-particle-shaped. The ultraviolet-rejected solid asphalt comprises the following components in percentage by weight: 50%-65% of asphalt, 30%-45% of magnesium-aluminum-based layered double hydroxide and 1%-10% of cosolvent. The ultraviolet-rejected solid asphalt is solid-particle-shaped (or powder-shaped) under the normal temperature, and compared with common asphalt which needs insulation for storage and needs to be loaded and unloaded in time in the process of production and use, the solid-particle-shaped (or powder-shaped) asphalt is stable in property and is more convenient in transportation and storage; simultaneously, the ultraviolet rejection action is excellent, the ageing resistance of the road asphalt is obviously improved, the use performances of rutting resistance and water stability of asphalt mixture can be effectively improved and the service life of asphalt roads can be prolonged.

Owner:WUHAN UNIV OF TECH

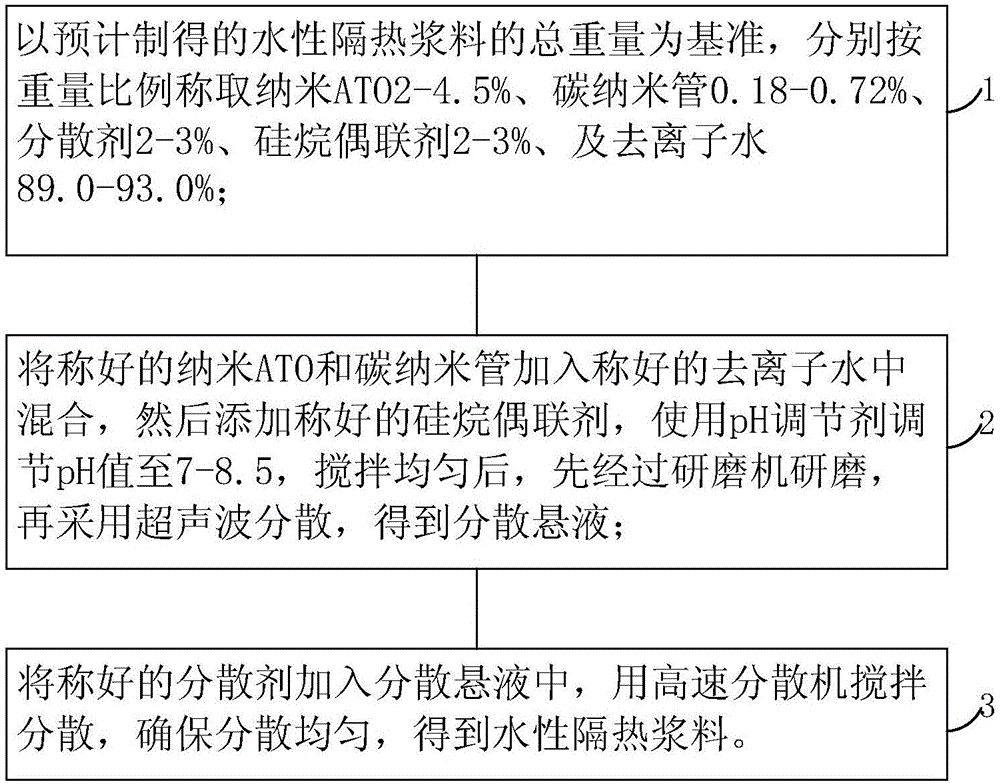

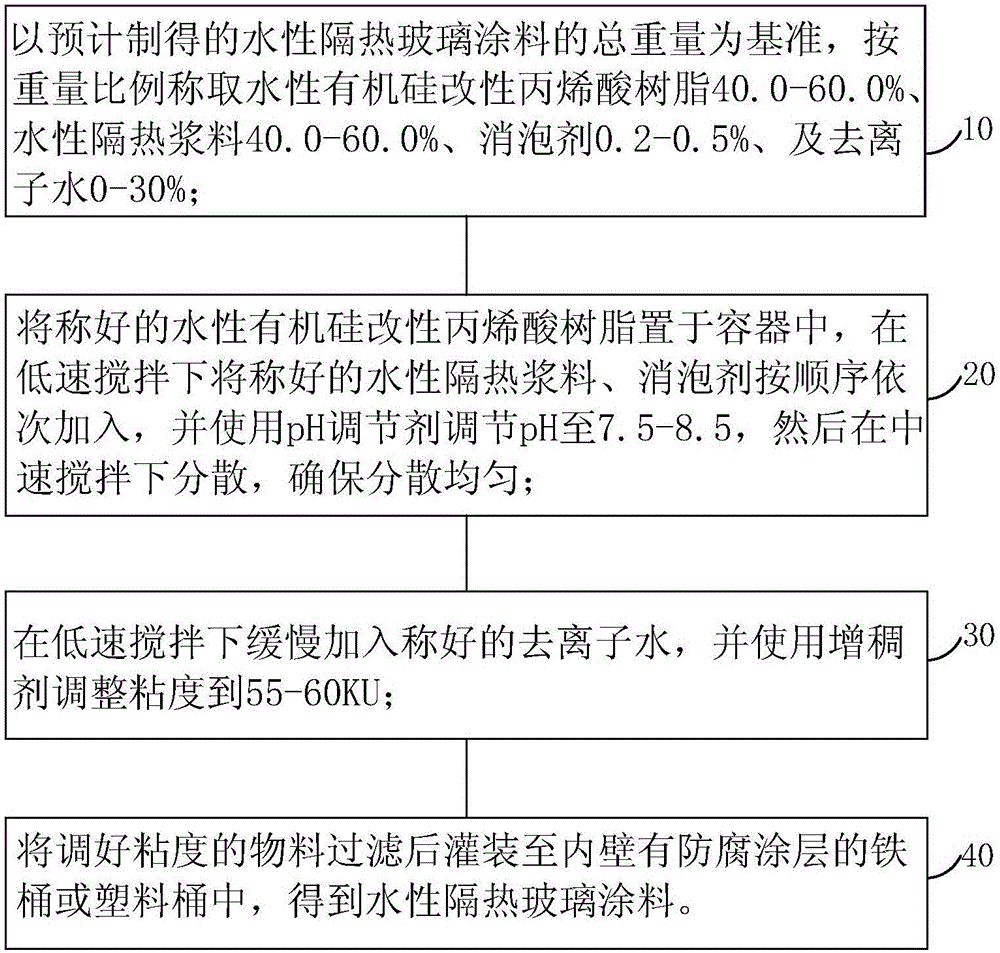

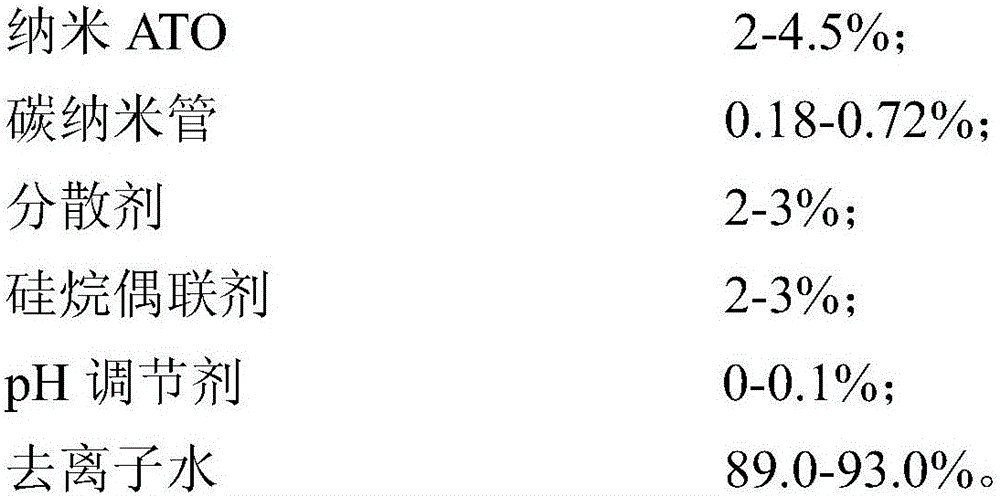

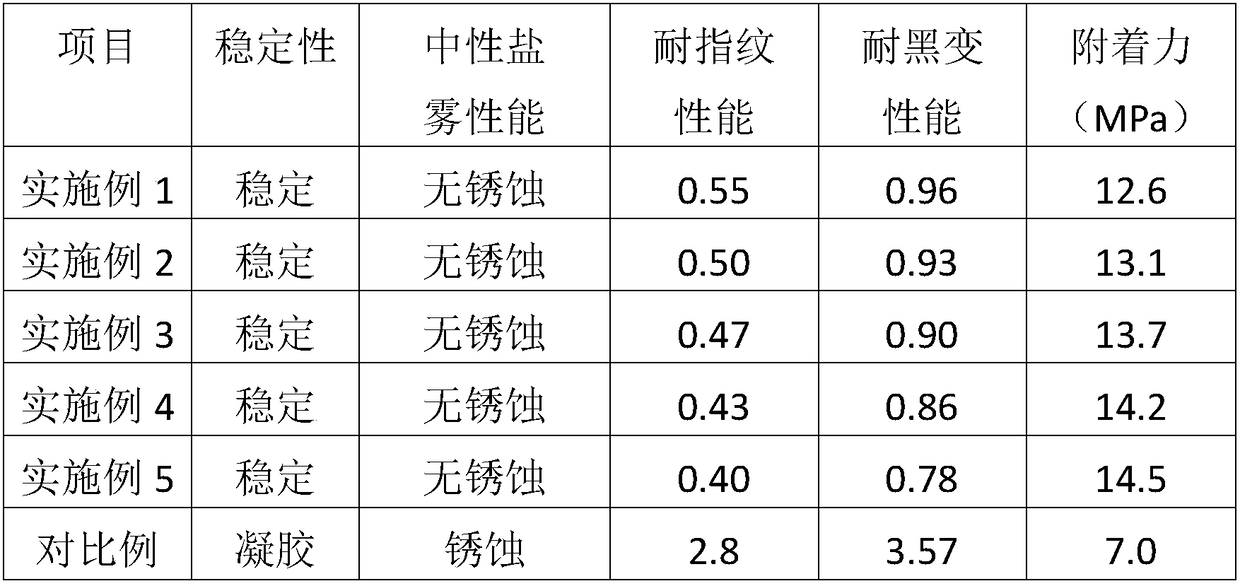

Waterborne heat-insulating slurry and preparation method thereof, as well as waterborne heat-insulating glass coating and preparation method thereof

ActiveCN106752237AImprove insulation efficiencyEasy to operateReflecting/signal paintsWeather resistanceAcrylic resin

The invention provides waterborne heat-insulating slurry and a preparation method thereof, as well as a waterborne heat-insulating glass coating and a preparation method thereof. The waterborne heat-insulating slurry is prepared by selecting nano-ATO and carbon nano-tubes as main heat-insulating materials, the specific optical performance of the nano-ATO is utilized, the long-wave part of an infrared region and an ultraviolet region have a high rejection rate, and a visible region has high transmittance; the carbon nano-tubes with specific carbon atomic arrangement structure have durable high heat-insulating efficiency and ultraviolet aging resistance under near-infrared and ultraviolet irradiation, so that irradiation reflection of the infrared region can be effective reinforced, the defects that the nano-ATO has insufficient partial heat insulating performance and insufficient ultraviolet aging resistance for the near-infrared short-wave part can be overcome. The waterborne heat-insulating glass coating prepared from the heat-insulating slurry and waterborne organic silicone modified acrylic resin can be used for solving the problems of insufficient transparency, poor heat-insulating performance and weak weather resistance of existing coating, and can be kept durable, stable and uniform.

Owner:SHENZHEN SUNRISE NEW ENERGY CO LTD

Chrome-free fingerprint-resistant environment-friendly coating and preparation method thereof

InactiveCN108117835ARaw materials are easy to getLow priceFireproof paintsAnti-corrosive paintsEpoxyPhosphate

The invention discloses a chrome-free fingerprint-resistant environment-friendly coating. The coating contains the following components in parts by weight: 40-50 parts of a film-forming condensation polymer, 5-8 parts of aminopropanol ascorbic acid phosphate modified graphene oxide, 15-20 parts of epoxy resin, 1-4 parts of a dispersing agent, 1-4 parts of a flatting agent, 1-4 parts of a defoamingagent and 20-40 parts of water. The invention further discloses a preparation method of the chrome-free fingerprint-resistant environment-friendly coating. The preparation method comprises the stepsof adding the film-forming condensation polymer into water, uniformly stirring, adding other components, stirring at a rotation speed of 800r / min-1300r / min for dispersion for 50-60 minutes, and filtering, so as to obtain a finished product. The chrome-free fingerprint-resistant environment-friendly coating has relatively excellent corrosion resistance, stability and alkali blackening resistance and is safe and environment-friendly in use.

Owner:SHENZHEN DA QUAI CHEM CO LTD

Shear thickening gel and preparation method and anti-fragmentation fabric with shear thickening effect

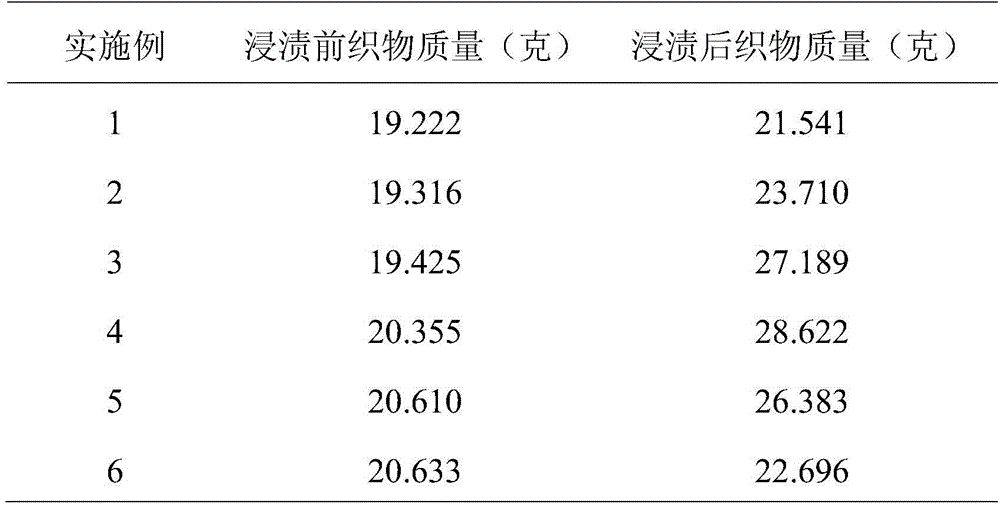

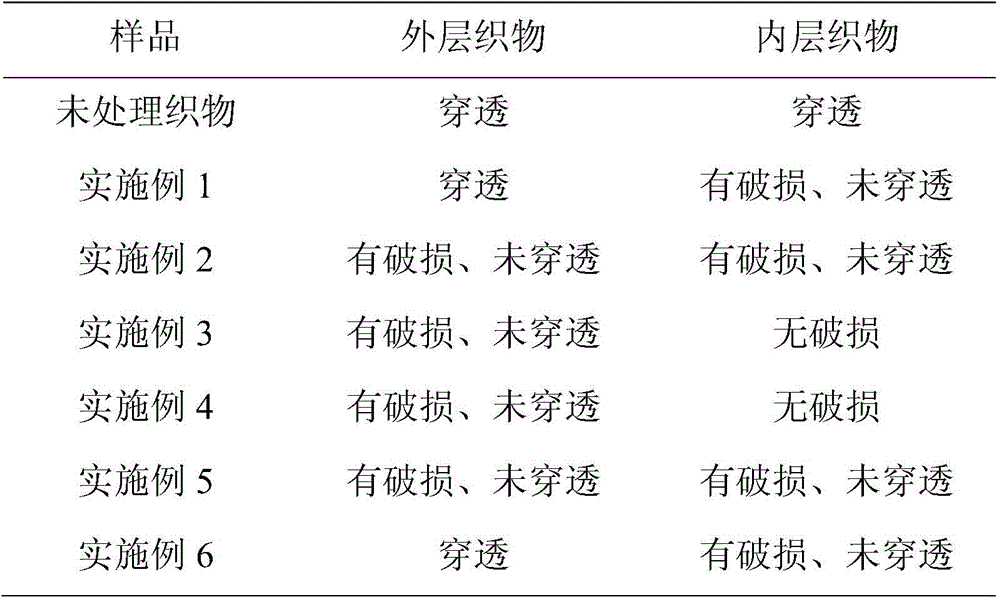

ActiveCN104862975BImproved impact/puncture resistanceImpact resistanceFibre typesPolyesterGel preparation

The invention belongs to the technical field of a polymer based composite, and relates to shear thickening gel, preparation methods and splinterproof fabric with a shear thickening effect. The shear thickening gel comprises components of raw materials in percentage by mass as follows: 78%-92% of a, w-dihydroxy polydimethylsiloxane, 3%-6% of boric acid and 5%-16% of white carbon black. The preparation method of the shear thickening gel comprises steps as follows: the boric acid and the white carbon black are added to a, w-dihydroxy polydimethylsiloxane, the mixture is dehydrated and mixed in a kneading machine for 1-3 h under the pressure of 13-14 kPa at the temperature of 140-180 DEG C, and a base material is prepared; the base material is dissolved in a solvent to obtain the shear thickening gel. The preparation method of the splinterproof fabric with the shear thickening effect comprises steps as follows: polyester fabric is placed in the shear thickening gel for immersion treatment, and the polyester fabric after immersion treatment is dried for 1-3 h at the temperature of 50-80 DEG C to obtain the splinterproof fabric.

Owner:XI AN PEAK XUANKAI NEW MATERIAL CO LTD

High-strength wicking-resistance polyester industrial yarn and preparation method thereof

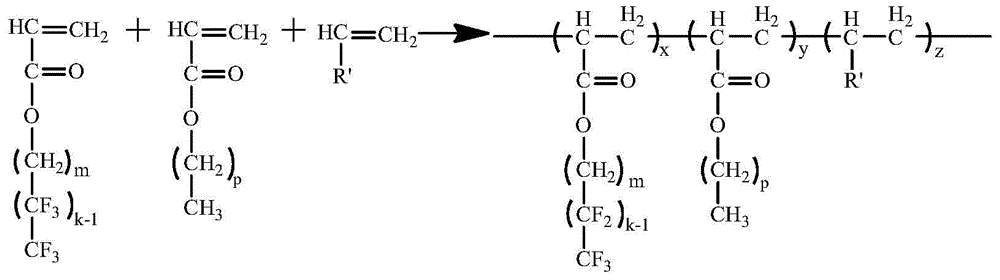

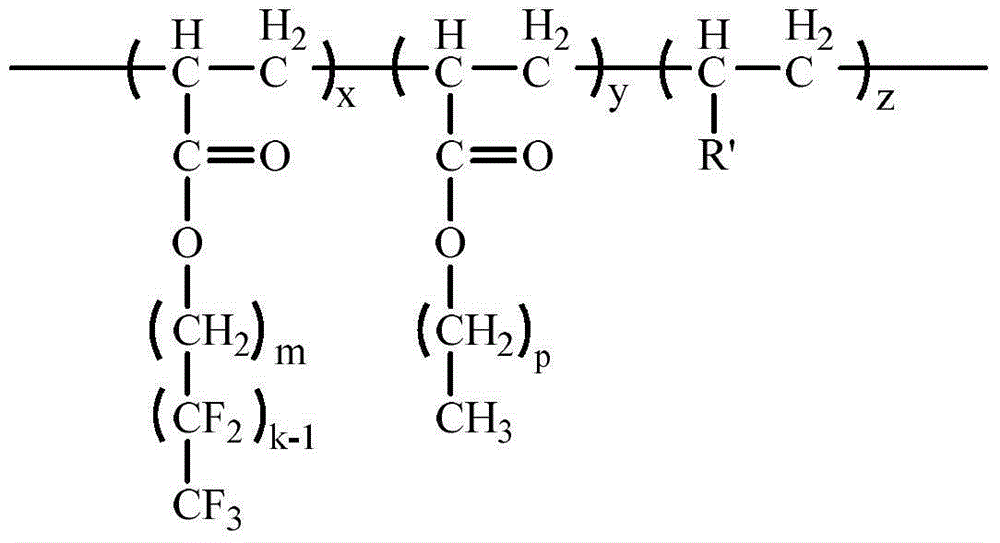

ActiveCN104480566AImprove hydrophobicityImprove waterproof performanceElectroconductive/antistatic filament manufactureOrganic compound preparationAging resistanceFatty acid

The invention relates to a high-strength wicking-resistance polyester industrial yarn and preparation method thereof. The high-strength wicking-resistance polyester industrial yarn is prepared by taking modified polyester viscosity-increasing chips as the raw material, melting, spinning and performing post-treatment; the modified polyester is prepared from polyester and amino fatty acid glycol ester, the amino fatty acid glycol ester is dispersed among molecular chains of the polyester, and the molecular chains of the amino fatty acid glycol ester and the polyester have hydrogen-bonding interaction, so that the relative positions of the molecular chains of the amino fatty acid glycol ester and the polyester are fixed; a wicking-resistance agent comprises perfluoroalkyl methacrylate, non-ternaryfluoroalkyl methacrylate and ternary block copolymer containing ultraviolet resistance groups. The prepared high-strength wicking-resistance polyester industrial yarn has the characteristic of inherent high breaking strength of a high-strength polyester industrial yarn, also has excellent hydrophobic property and ultraviolet aging resistance, can be widely applied to outdoors, and has widely application prospect in the field of high-grade light box advertising cloth, waterproof cloth and fabrics for a swimming pool.

Owner:JIANGSU HENGLI CHEM FIBER

Transparent waterproof encapsulating material

InactiveCN105969287AImprove adhesionImprove stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAcrylic resinPlasticizer

This case discloses a transparent waterproof potting material, including the following materials: polyurethane prepolymer; α, ω-dihydroxypolydimethylsiloxane; alkoxysilane; Polymer; Triethylenediamine; Plasticizer; Structural aid; Silane coupling agent. The invention provides a transparent waterproof potting material. Polyurethane and acrylic resin are used to modify organic silicon to obtain a transparent waterproof potting material with strong adhesion, excellent electrical insulation performance, ultraviolet resistance and high corrosion resistance.

Owner:苏州市奎克力电子科技有限公司

Modified nano zinc oxide doped cycloaliphatic epoxy resin light-emitting diode (LED) packaging adhesive

InactiveCN102719213AGood dispersionExtended service lifeNon-macromolecular adhesive additivesOther chemical processesChemistryAdhesive

The invention relates to a modified nano zinc oxide doped cycloaliphatic epoxy resin light-emitting diode (LED) packaging adhesive. The modified nano zinc oxide doped cycloaliphatic epoxy resin LED packaging adhesive is characterized by being composed of a component A and a component B, the component A and the component B are mixed according to the ratio of 1: (0.9-1.0), and then the packaging adhesive is used for construction. The component A is composed of a cycloaliphatic epoxy resin, a reactive diluent, transparent royal purple dye color paste, an antifoaming agent and a softening agent, and the component B is composed of a curing agent, an accelerating agent, a silane coupling agent modified nano ultraviolet absorption agent, polyatomic alcohol and an antioxidant. The modified nano zinc oxide doped cycloaliphatic epoxy resin LED packaging adhesive is high in transparency, good in ultraviolet aging resistance performance, high in adhesive power, rapid in solidification and low in viscosity; and according to the packaging adhesive, high-cost organosilicone isn't used, defects that existing bisphenol A epoxy resins are high in moisture absorption, poor in ultraviolet resistance performance and low in short-wave transmissivity are overcome, and the modified nano zinc oxide doped cycloaliphatic epoxy resin LED packaging adhesive can be used as a high-end LED packaging adhesive, a high-power LED packaging adhesive or an LED packaging adhesive based on white light and blue light of ultraviolet light.

Owner:JIANGSU TETRA NEW MATERIAL TECH

High-temperature-resistant self-adhesive waterproofing coiled material and preparation method thereof

InactiveCN107216823ASimple preparation processRaw materials are easy to getNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolymer science

The invention discloses a high-temperature-resistant self-adhesive waterproofing coiled material and a preparation method thereof. The high-temperature-resistant self-adhesive waterproofing coiled material is formed by sequentially compounding five layers of an isolating membrane layer, a high-temperature-resistant self-adhesive waterproofing glue layer, a carrier film layer, the high-temperature-resistant self-adhesive waterproofing glue layer and the isolating membrane layer from top to bottom, wherein the high-temperature-resistant self-adhesive waterproofing glue is prepared from the following raw materials of epichlorohydrin rubber, a softening agent, benzotriazole-modified zinc oxide, polyformaldehyde, organic silicon elastomers for daily use, petroleum asphalt and natural asphalt; the benzotriazole-modified zinc oxide is prepared by adopting a special preparation method; the total thickness of the waterproofing coiled material is 1.5 to 5.0mm; the thickness of the carrier film layer is 1.0 to 3.5mm. The waterproofing coiled material disclosed by the invention has the advantages of excellent waterproofing property, excellent high temperature resistance and excellent ageing resistance.

Owner:ZHEJIANG DIHENG IND CO LTD

Ultraviolet-resistant nano titanium dioxide doped cycloaliphatic epoxy resin LED (light emitting diode) packaging glue

InactiveCN102690620ANo penetrationGood anti-ultraviolet aging performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesAntioxidantUltraviolet

The invention relates to an ultraviolet-resistant nano titanium dioxide doped cycloaliphatic epoxy resin LED (light emitting diode) packaging glue which is characterized by comprising a component A and a component B, wherein the components A and B are mixed according to the proportion of 1: (0.9-1.0) and then used for construction; the component A comprises cycloaliphatic epoxy resin, a reactive diluent, a transparent bluish violet dye color paste, a defoaming agent and a flexibility agent; and the component B comprises a curing agent, an accelerating agent, a nano ultraviolet absorbing agent, polylol and an antioxidant. The ultraviolet-resistant nano titanium dioxide doped cycloaliphatic epoxy resin LED packaging glue has the characteristics of high transparency, good ultraviolet ageing resistance, strong binding power and low moisture absorption, avoids adopting organic silicon with high cost, overcomes the defects of high moisture absorption, poor ultraviolet resistance, low short wave transmissivity and the like of the traditional bisphenol A epoxy resin, and is more suitable for being used as an ultraviolet-based white light and blue light LED packaging glue. The ultraviolet-resistant nano titanium dioxide doped cycloaliphatic epoxy resin LED packaging glue has the advantages of good performance, low cost and simple process, and is suitable for industrial massive production.

Owner:SHANGHAI ZHONGXIN YUXIANG CHEM

Anti-aging polypropylene material based on fiber reinforcement and preparation method thereof

The invention discloses an anti-aging polypropylene material based on fiber reinforcement and a preparation method of the anti-aging polypropylene material. The anti-aging polypropylene material comprises the following components: polypropylene, polyethylene, ethylene propylene diene monomer, an anti-aging agent, an auxiliary agent, a light stabilizer and the like. The anti-aging agent comprises wood fibers, carbon fibers, carbon nanotubes, dopamine, modified zinc oxide and other components; when the modified zinc oxide is prepared, zinc oxide is synthesized by a solvothermal method, components such as zinc acetate, sodium hydroxide, glycerol and the like are used for reaction, and the synthesized zinc oxide is petal-shaped or rod-shaped; the invention discloses the anti-aging polypropylene material based on fiber reinforcement and the preparation method thereof, the process design is reasonable, the component proportion is proper, the prepared polypropylene material not only has excellent mechanical properties and tensile strength, but also has further improved ultraviolet aging resistance, the service life is greatly prolonged, and high practicability is achieved.

Owner:卞培培

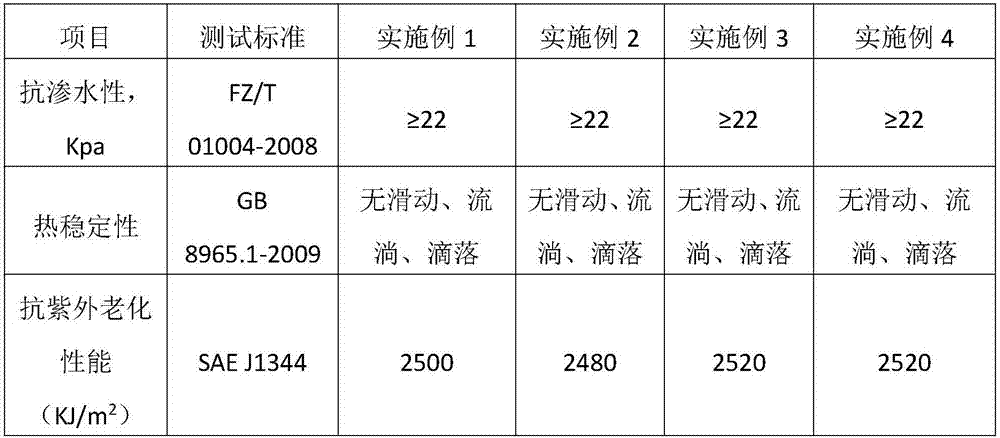

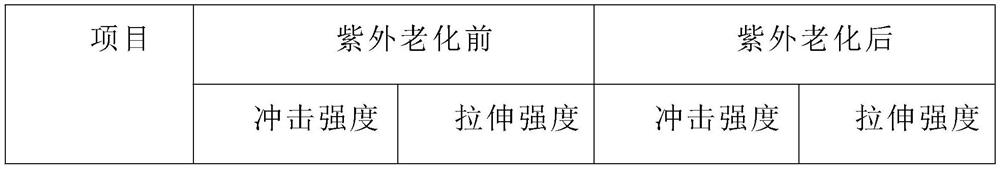

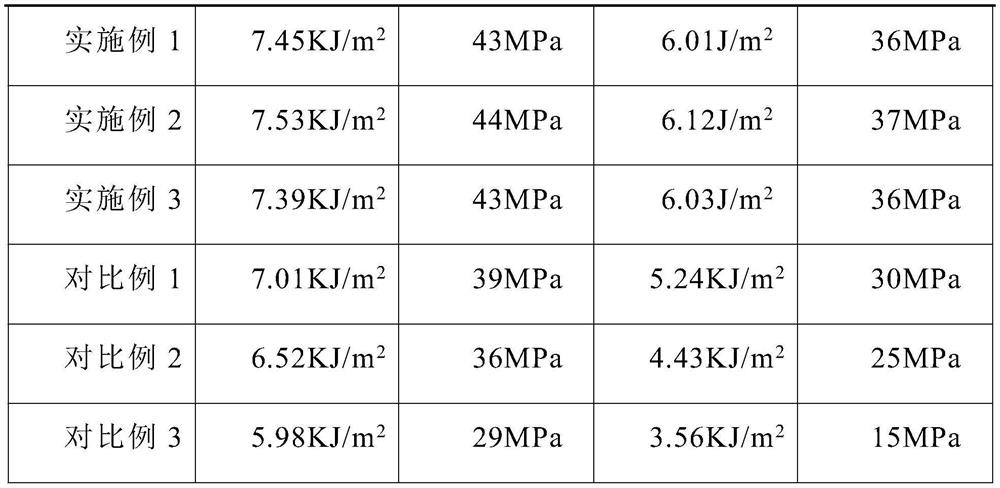

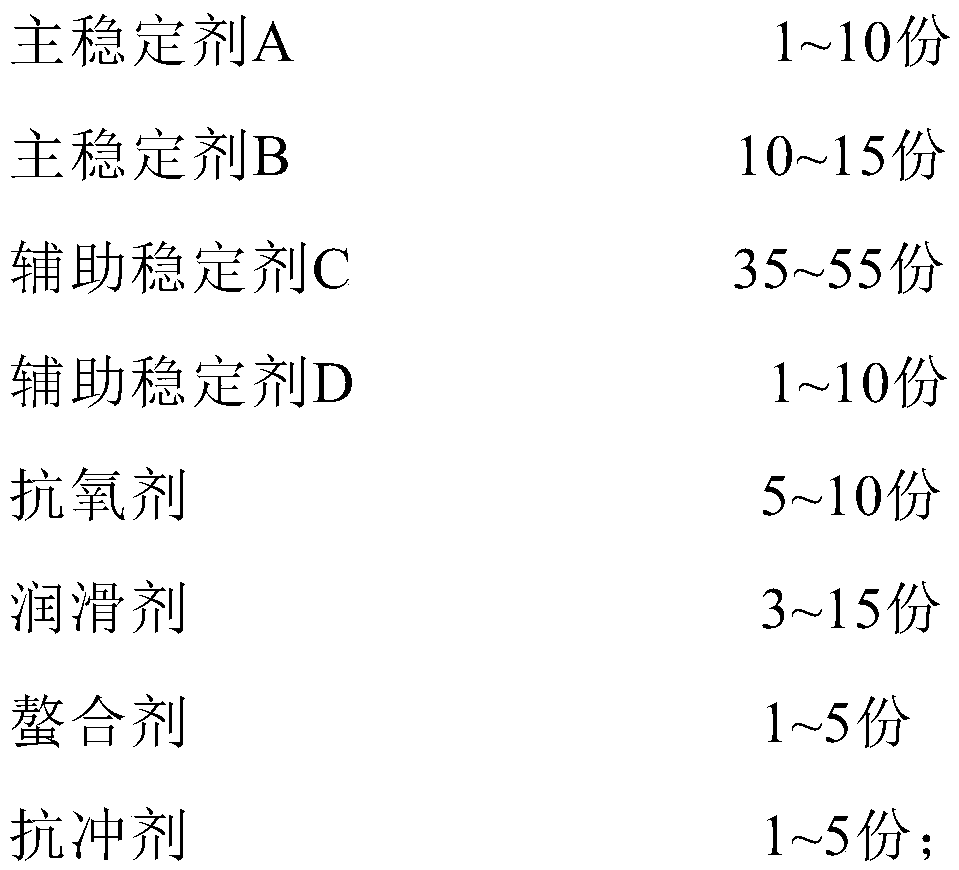

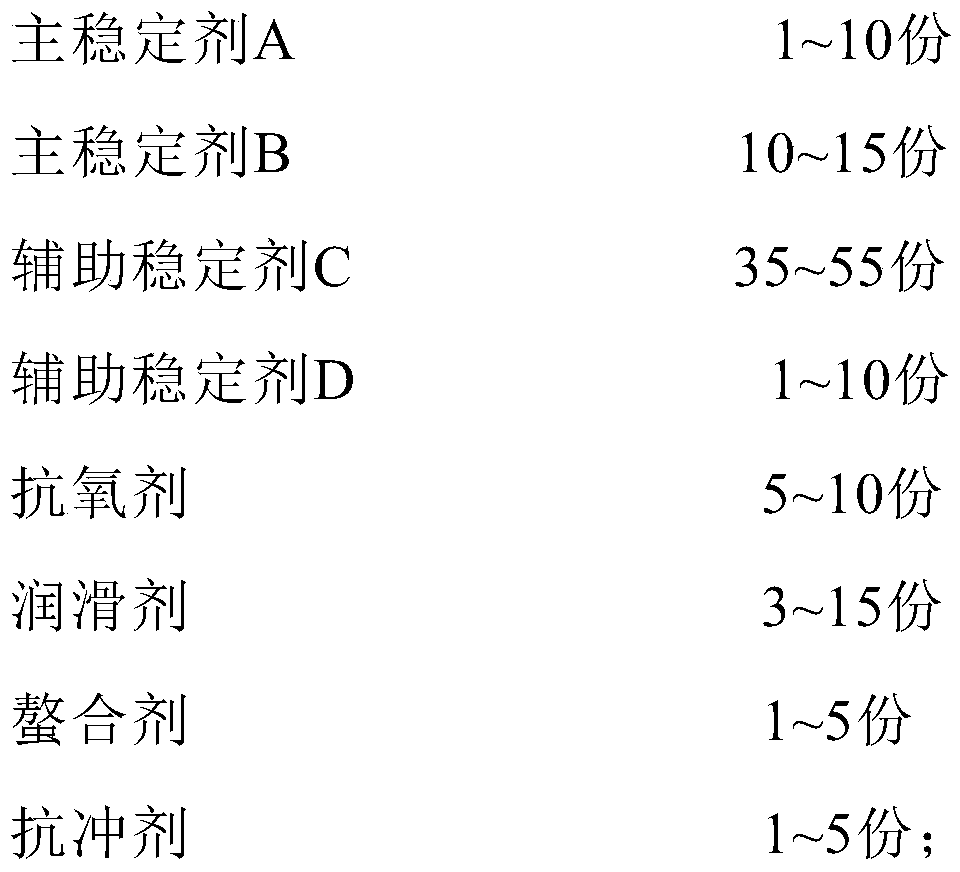

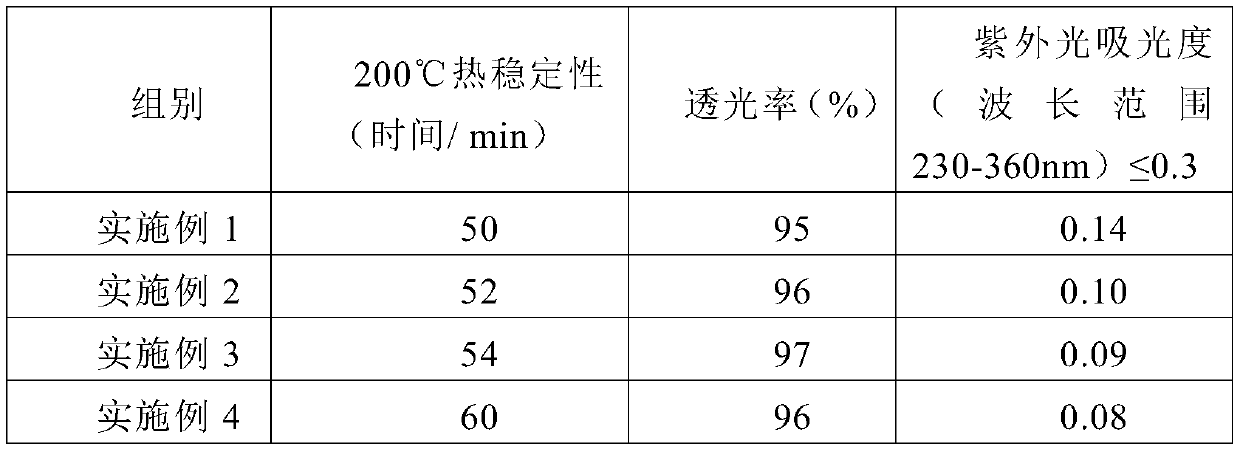

Stabilizer for PVC sheets and preparation method thereof

The invention discloses a stabilizer for PVC sheets and a preparation method thereof. The stabilizer for PVC sheets is prepared from the following raw materials by weight: 1-10 parts of a main stabilizer A, 10-15 parts of a main stabilizer B, 35-55 parts of an auxiliary stabilizer C, 1-10 parts of an auxiliary stabilizer D, 5-10 parts of an antioxidant, 3-15 parts of a lubricant, 1-15 parts of a chelating agent, and 1-5 parts of an impact resistant agent. Specifically, the main stabilizer A is at least one of calcium stearate, strontium stearate and calcium benzoate; the main stabilizer B is at least one of zinc stearate, lanthanum stearate and zinc benzoate; the auxiliary stabilizer C is at least one of magnesium-aluminum hydrotalcite and magnesium-aluminum-zinc hydrotalcite; and the auxiliary stabilizer D is at least one of dibenzoyl methane, stearoyl benzoyl methane and dodecyl dihydropyridine diformate. The stabilizer prepared according to the invention has the advantages of no toxicity, environmental protection, no odor, fast plasticization, high product transparency, good weather resistance and good ultraviolet aging resistance.

Owner:DONGGUAN SUNVO NEW MATERIAL CO LTD

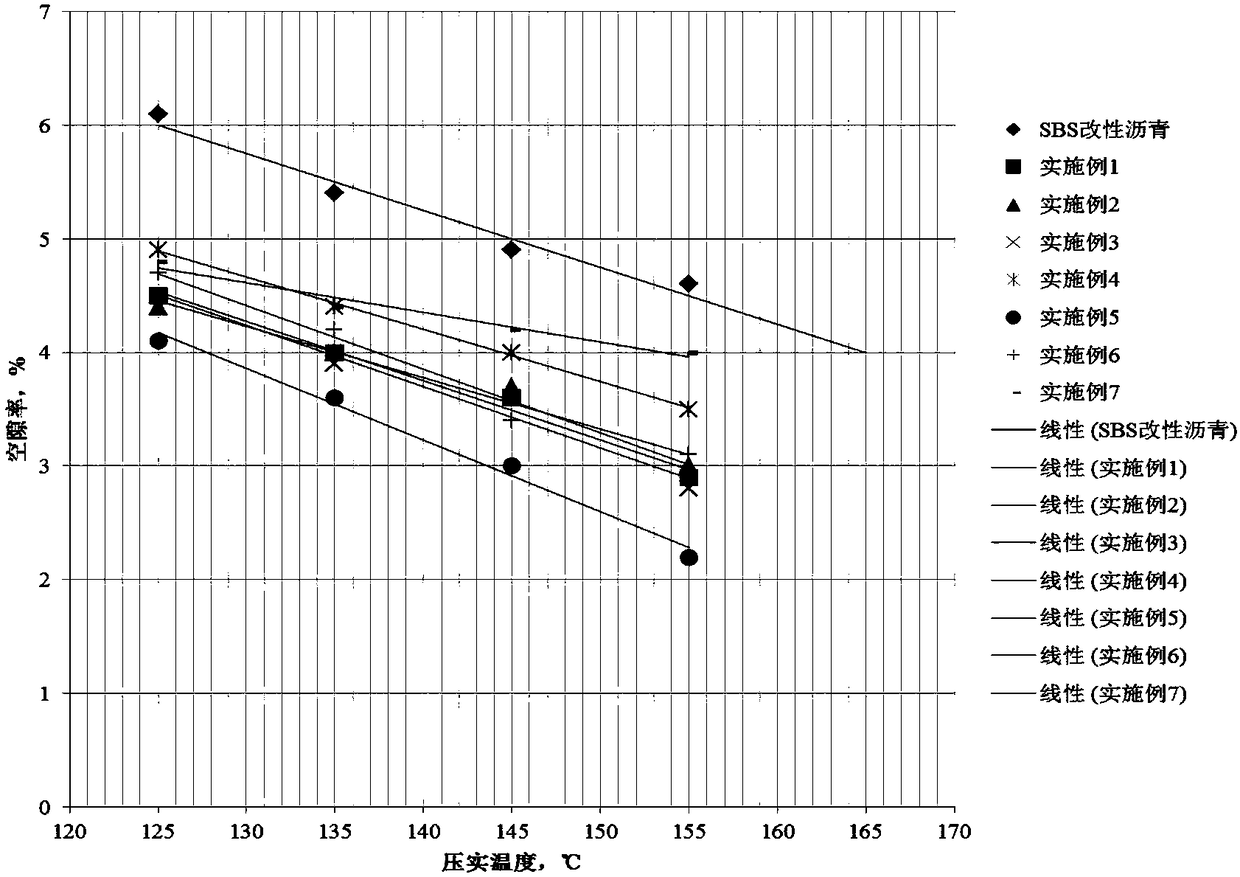

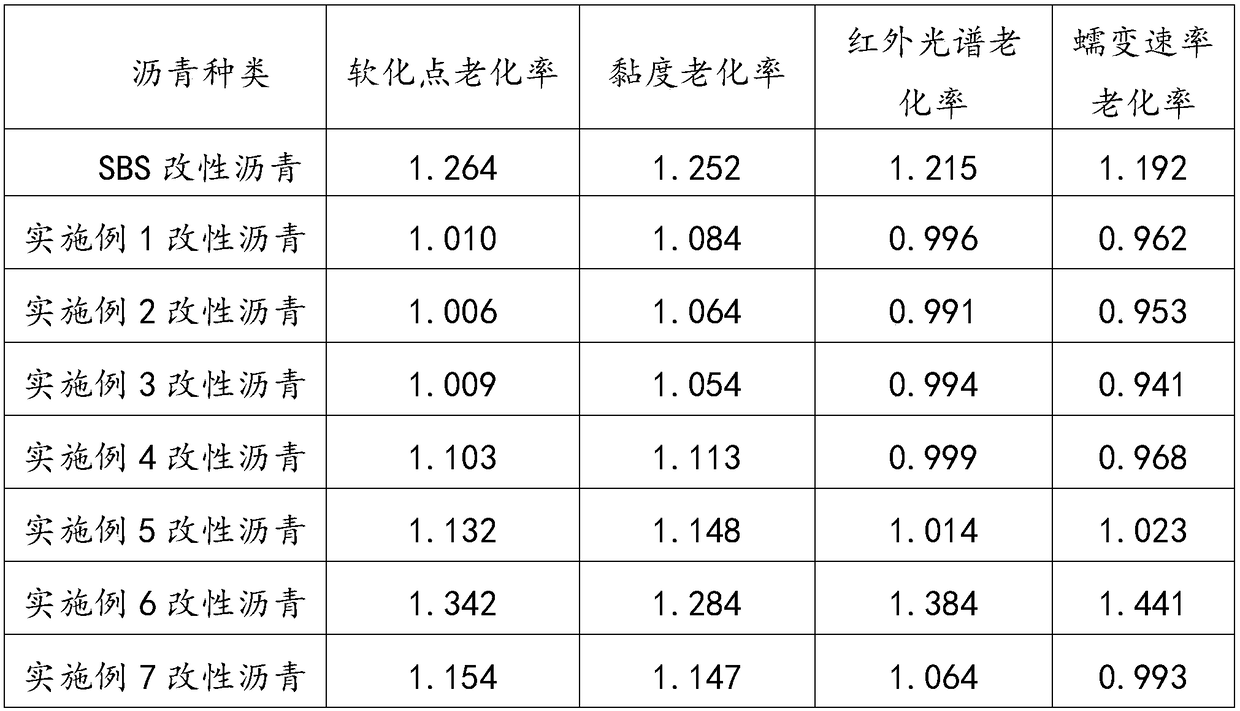

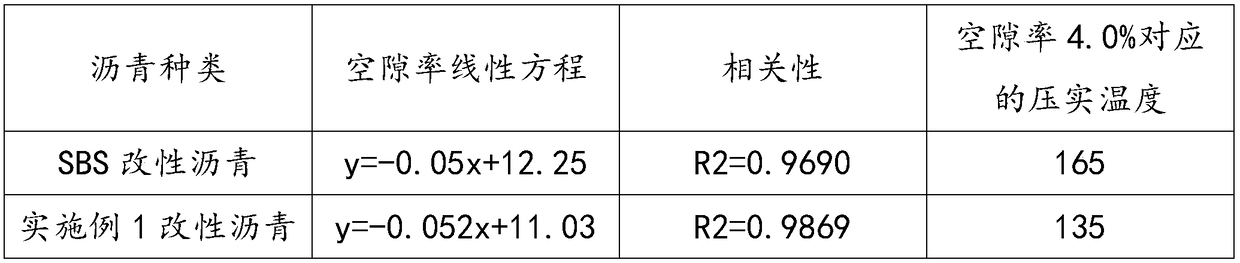

Warm-mixing anti-ultraviolet aging asphalt and preparation method thereof

ActiveCN108276788AGood anti-ultraviolet aging performanceImprove high temperature resistanceClimate change adaptationBuilding insulationsButadiene-styrene rubberAsphalt

The invention discloses warm-mixing anti-ultraviolet aging asphalt and a preparation method thereof. The asphalt is prepared from the following raw materials in parts by weight: 100 parts of SBS (Styrene-Butadiene-Styrene) modified asphalt, 1 to 4 parts of light stabilizing agent, 0.1 to 0.5 part of absorbent and 0.5 to 2.5 parts of warm-mixing agent. The warm-mixing anti-ultraviolet aging asphaltprepared by the preparation method of the warm-mixing anti-ultraviolet aging asphalt has remarkable anti-ultraviolet aging performance and also has good high-temperature-resisting performance and low-temperature anti-cracking performance; the service life of an asphalt road surface can be greatly prolonged and the construction temperature also can be effectively reduced; in a construction process, energy source consumption is saved and the environment protection is facilitated.

Owner:PETROCHINA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com