Stabilizer for PVC sheets and preparation method thereof

A technology of stabilizer and main stabilizer, which is applied in the field of stabilizer for PVC sheets and its preparation, can solve the problems of increasing the cost of material manufacturers, hazards to human health, and polluting the on-site environment, so as to overcome poor processing performance, Low cost, high transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

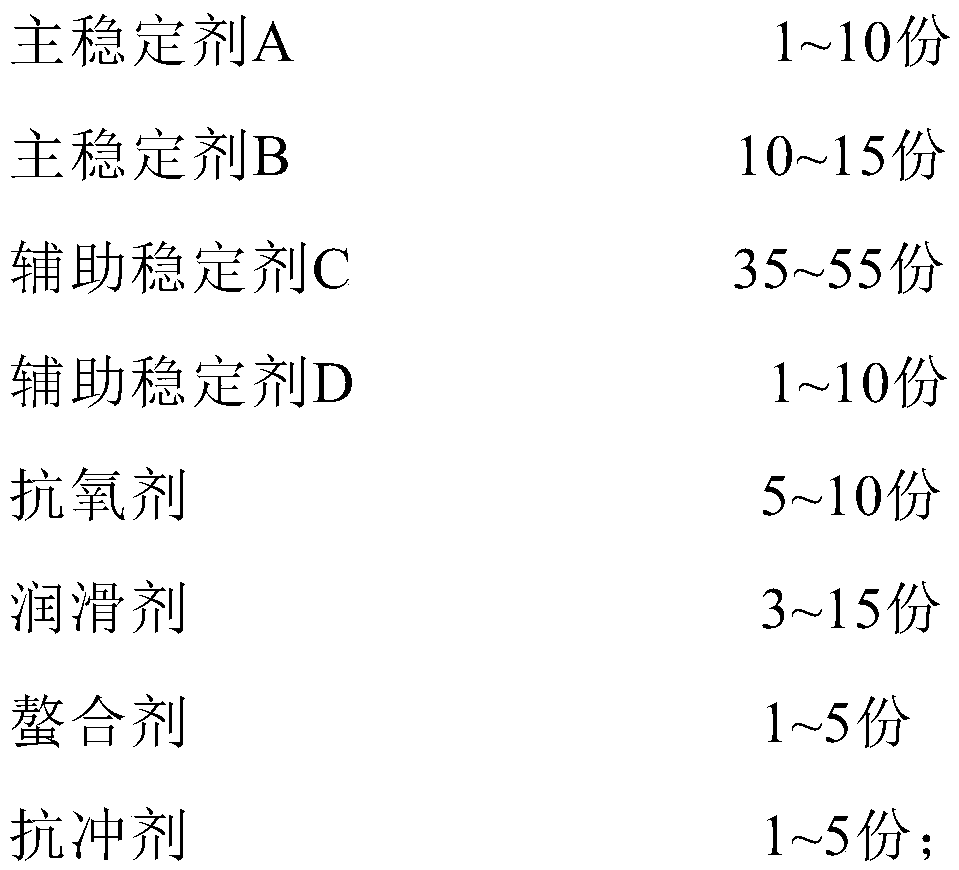

Method used

Image

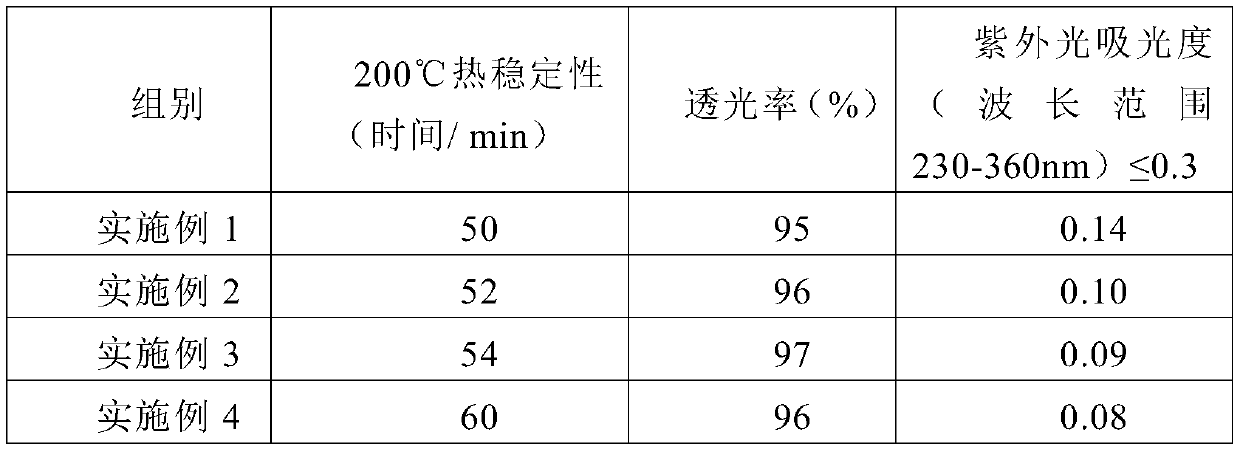

Examples

Embodiment 1

[0040]Take by weighing 10kg calcium stearate, 15kg zinc stearate, 45kg magnesium aluminum hydrotalcite, 10kg dibenzoylmethane, 5kg benzoyl acetone, 5kg anti-impact agent (nano boron fiber: glass fiber: carbon fiber=2:1: 1) Put them into the high-speed mixer one by one. The mixer runs at 1200rpm, and mixes at 45°C for 15 minutes; Alcohol ester, mixed for 10 minutes at the same speed and temperature; finally, 15kg of high-density oxidized polyethylene wax was added, mixed for 5 minutes at the same speed and temperature, and the product described in the present invention was obtained by cooling the material to 35°C.

Embodiment 2

[0042] Take by weighing 10kg calcium stearate, 15kg zinc stearate, 45kg magnesium aluminum hydrotalcite, 10kg dibenzoylmethane, 5kg benzoyl acetone, 5kg anti-impact agent (nano boron fiber: glass fiber: carbon fiber=2:1: 1), 5kg of 2,2,4-trimethyl-1,3-pentanediol diisobutyrate were successively put into the high-speed mixer, the mixer was operated at 1200rpm, and mixed at 45°C for 15min; then put 10kg β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, mixed for 10min under the same rotating speed and temperature conditions; finally put 15kg of high-density oxidized polyethylene wax, The product described in the present invention can be obtained by mixing for 5 minutes under the condition of temperature and temperature, and cooling the material to 35°C.

Embodiment 3

[0044] Take by weighing 10kg calcium stearate, 15kg zinc stearate, 45kg magnesium aluminum hydrotalcite, 10kg dibenzoylmethane, 5kg benzoyl acetone, 5kg anti-impact agent (nano boron fiber: glass fiber: carbon fiber=2:1: 1), 5kg of acetyl tributyl citrate was put into the high-speed mixer in turn, the mixer was run at 1200rpm, and mixed for 15min at 45°C; then 10kg of β-(3,5-di-tert-butyl-4-hydroxybenzene Base) n-octadecanyl propionate, mixed for 10 minutes at the same speed and temperature; finally put 15kg of high-density oxidized polyethylene wax, mixed for 5 minutes at the same speed and temperature, and cooled the material to 35°C to obtain this product invented the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com