Butyl hot melt adhesive tape and preparation method thereof

A butyl heat and butyl rubber technology, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., can solve the problems of large equipment investment, high defective rate of finished products, and low initial adhesion of tapes. , to achieve good sealing effect, high adhesion and bonding strength, low water vapor transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

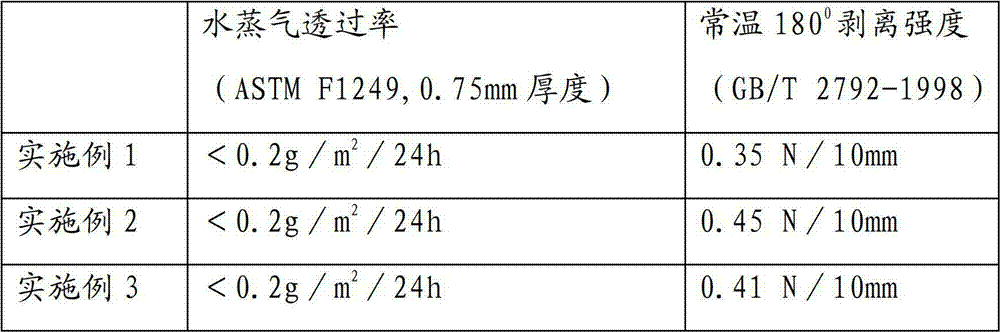

Embodiment 1

[0032] Put 30 parts of polyisobutylene B5000 into a vacuum kneader, raise the temperature to 160°C, and stir for 0.8 hours under a vacuum condition of 0.09-0.094MPa; 1 part of resin, 2 parts of uniform tackifier, 3 parts of polyethylene wax and stir for 0.6 hours; then add 10 parts of EVA and 10 parts of butyl rubber and stir for 1.0 hour; finally add 5 parts of carbon black and stir for 0.5 hours; at 0.09~0.094 Stir under MPa vacuum condition for 0.5 hour and discharge after passing the inspection. Heat the rubber material to 110°C, press it to a thickness of 0.7mm on a coating machine, and then cut it into a tape with a width of 10mm on a cutting machine.

Embodiment 2

[0034] Put 50 parts of polyisobutylene B500 into a vacuum kneader, raise the temperature to 180°C, and stir for 1.5 hours under a vacuum condition of 0.09-0.094MPa; 5 parts of resin, 7 parts of uniform tackifier, 6 parts of polyethylene wax and stir for 1.5 hours; then add 20 parts of EVA and 20 parts of butyl rubber and stir for 1.5 hours; finally add 10 parts of carbon black and stir for 1 hour; Stir under 0.094MPa vacuum condition for 1.0 hour and discharge after passing the inspection. Heat the rubber material to 110°C, press it to a thickness of 0.7mm on a coating machine, and then cut it into a tape with a width of 10mm on a cutting machine.

Embodiment 3

[0036] Put 505 parts of polyisobutylene B5 into a vacuum kneader, raise the temperature to 170°C, and stir for 1.0 hour under the vacuum condition of 0.09-0.094MPa; 3 parts of resin, 5 parts of uniform tackifier, 4.5 parts of polyethylene wax and stir for 1.2 hours; then add 15 parts of EVA and 16 parts of butyl rubber and stir for 1.3 hours; finally add 8 parts of carbon black and stir for 0.8 hours; at 0.09~0.094 Stir under MPa vacuum condition for 0.7 hours and discharge after passing the inspection. Heat the rubber material to 110°C, press it to a thickness of 0.7mm on a coating machine, and then cut it into a tape with a width of 10mm on a cutting machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com