Shear thickening gel and preparation method and anti-fragmentation fabric with shear thickening effect

A technology for thickening gels and fabrics, used in textiles and papermaking, fiber processing, fiber types, etc., can solve problems such as inability to prevent prevention, achieve excellent anti-ultraviolet aging performance, improve impact/puncture resistance, and meet large-scale requirements. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] (2) The preparation method of the above-mentioned shear thickening gel, comprising the following steps: adding boric acid and white carbon black to a, w-dihydroxypolydimethylsiloxane, under pressure of 13-14kPa, temperature is 140 Dehydration and mixing in a kneader at -180°C for 1-3 hours to prepare a base material; then dissolve the base material in a solvent to form the shear thickening gel.

[0034] The solvent is simethicone or isopropanol.

[0035] The ratio between the base material and the solvent is that 10-50 g of base material is added to every 100 mL of solvent.

[0036] (3) An anti-fragment fabric with shear thickening effect, made by the following method:

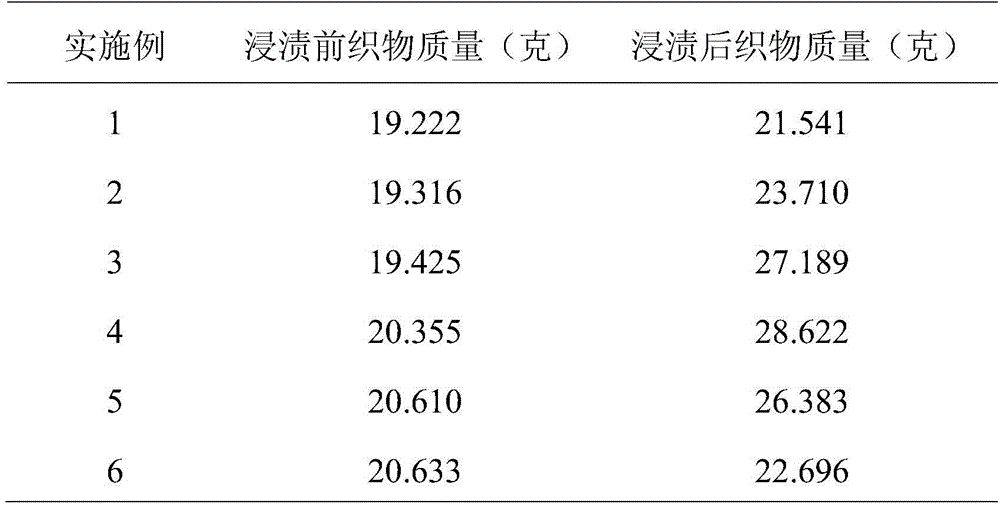

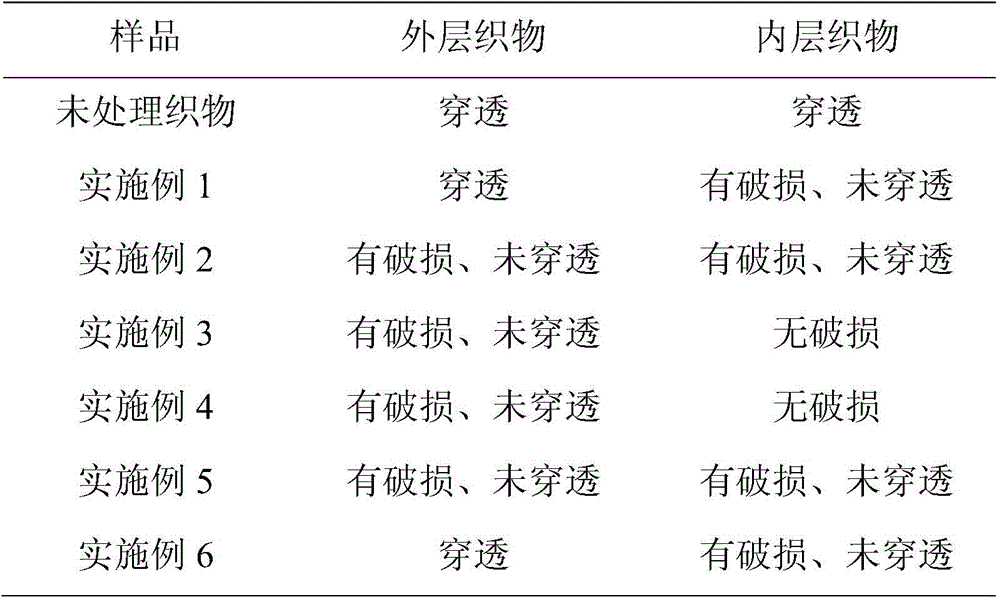

[0037] To prepare the above shear thickening gel, treat 800-1200cm per 100mL shear thickening gel 2 Proportion of polyester fabric Put the polyester fabric into the shear thickening gel and soak it for 30-60 minutes. drying the dipped polyester fabric at 50-80° C. for 1-3 hours to obtain the anti-fra...

Embodiment 1

[0042] The shear thickening gel of the present invention is composed of the following raw material components in mass percentage:

[0043] a,w-Dihydroxypolydimethylsiloxane 100g

[0044] Boric acid 3g

[0045] Silica 5g

[0046] Wherein, the white carbon black is hydrophobic white carbon black with an average particle diameter of 50 nanometers.

[0047] The preparation method of this shear thickening gel is as follows: 3g boric acid and 5g white carbon black are added in the a of 100g, w-dihydroxy polydimethylsiloxane, and then pressure is 13kPa, and temperature is 140 ℃ Dehydration mixing was carried out in a kneader for 1 hour to form a base. Weigh 100mL of simethicone, add 10g of base material into it, and mix well to form a shear thickening gel.

[0048] The anti-fragmentation fabric with shear thickening effect of the present invention is made by the following method:

[0049] Weigh 100mL shear thickening gel and put it in a beaker, put 800cm 2 The polyester fabric ...

Embodiment 2

[0051] The shear thickening gel of the present invention is composed of the following raw material components in mass percentage:

[0052] a,w-Dihydroxypolydimethylsiloxane 100g

[0053] Boric acid 4g

[0054] Silica 10g

[0055] Wherein, the white carbon black is hydrophobic white carbon black with an average particle diameter of 200 nanometers.

[0056]The preparation method of this shear thickening gel is as follows: 4g of boric acid and 10g of white carbon black are added in 100g of a, w-dihydroxypolydimethylsiloxane, and then the pressure is 13kPa, the temperature is 160 ℃ The base was prepared by dehydration mixing in a kneader for 1.5 hours. Weigh 100mL of isopropanol, add 30g of base material into it, and mix well to form a shear thickening gel.

[0057] The anti-fragmentation fabric with shear thickening effect of the present invention is made by the following method:

[0058] Weigh 100mL shear thickening gel and put it in a beaker, put 1000cm 2 The polyester fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com