Patents

Literature

446results about How to "Impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

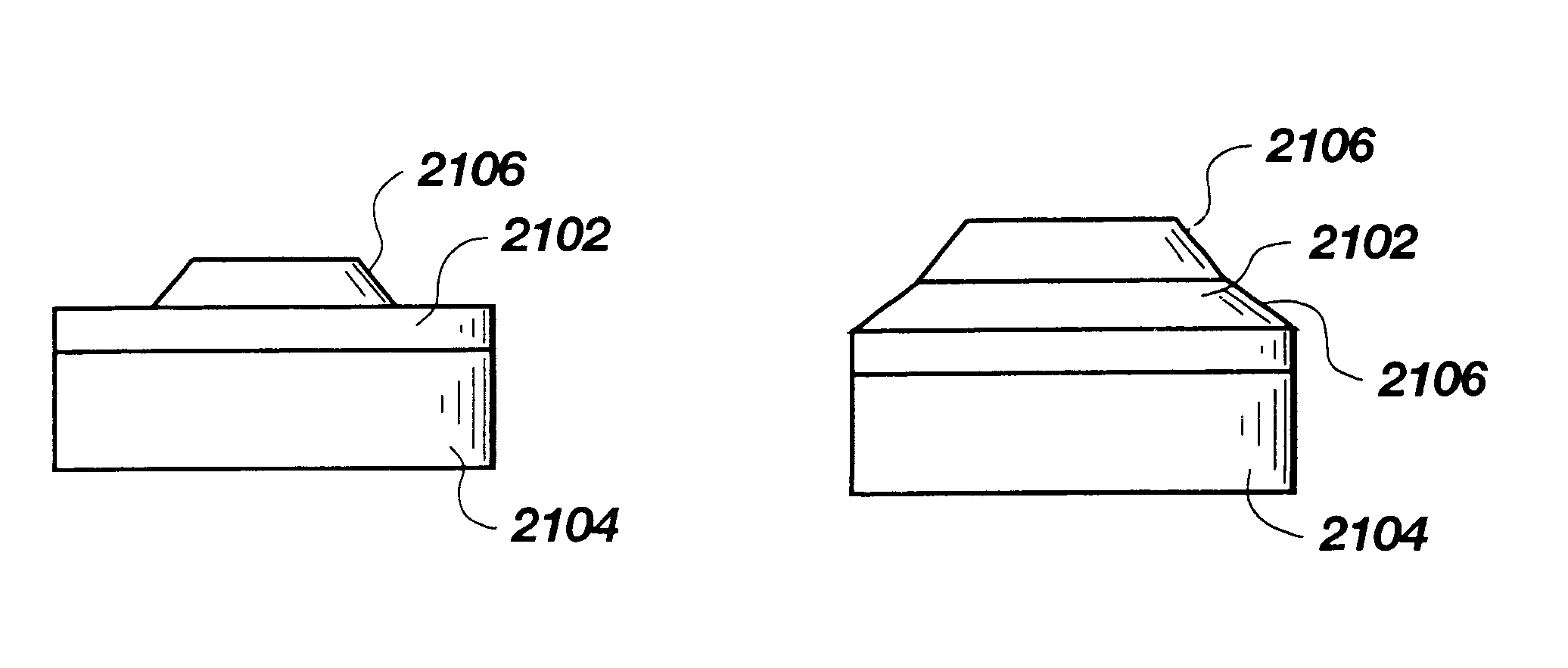

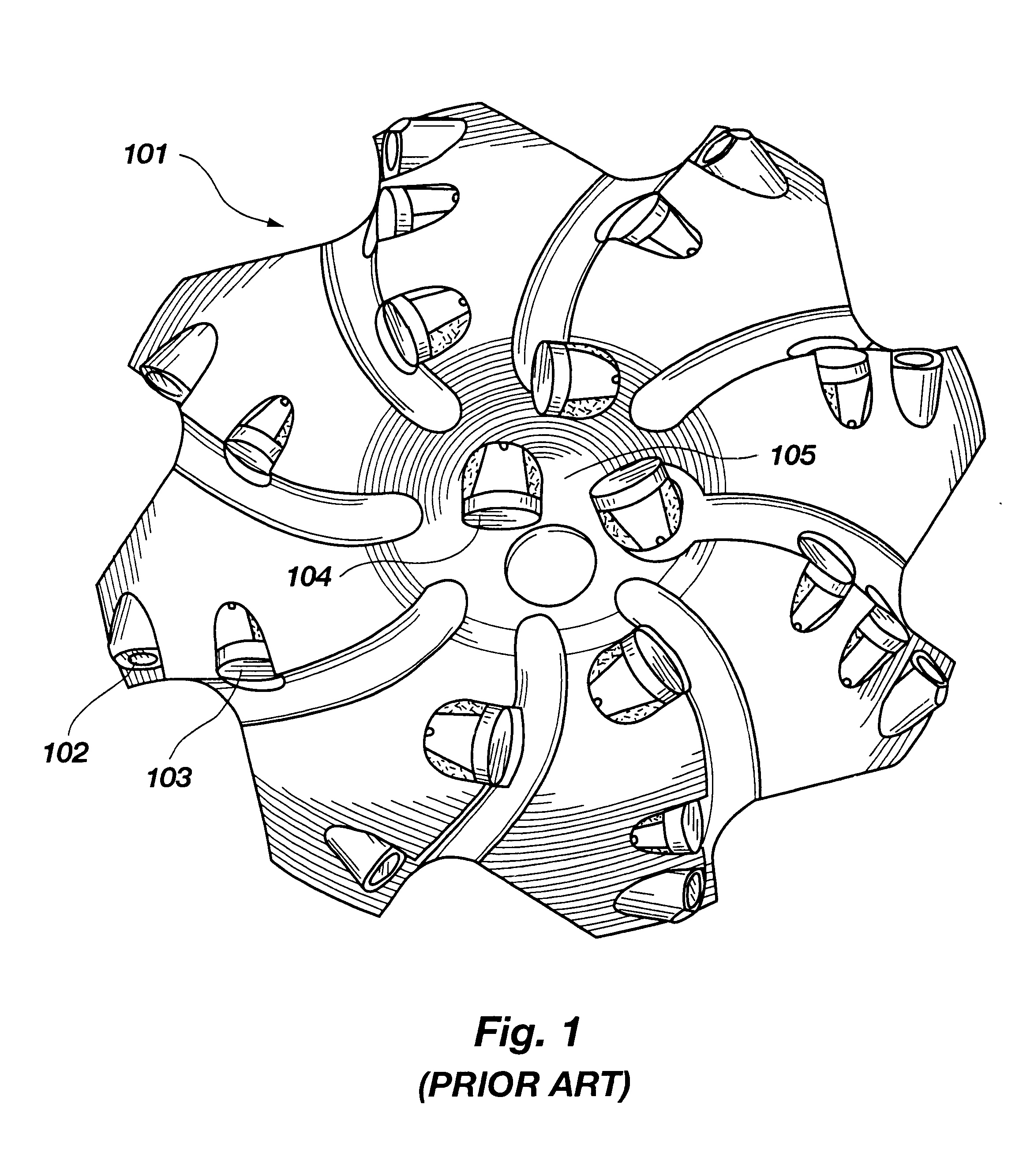

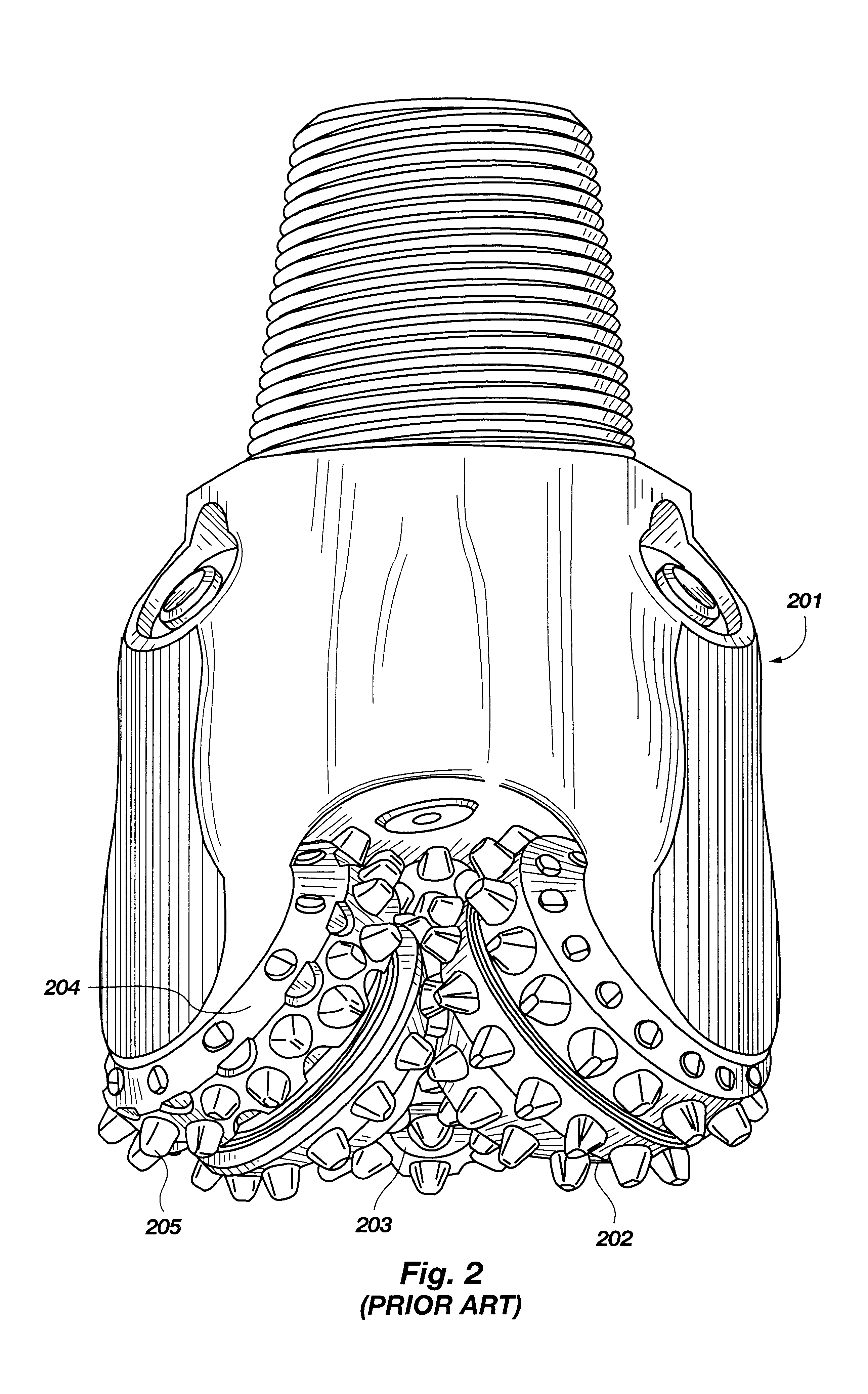

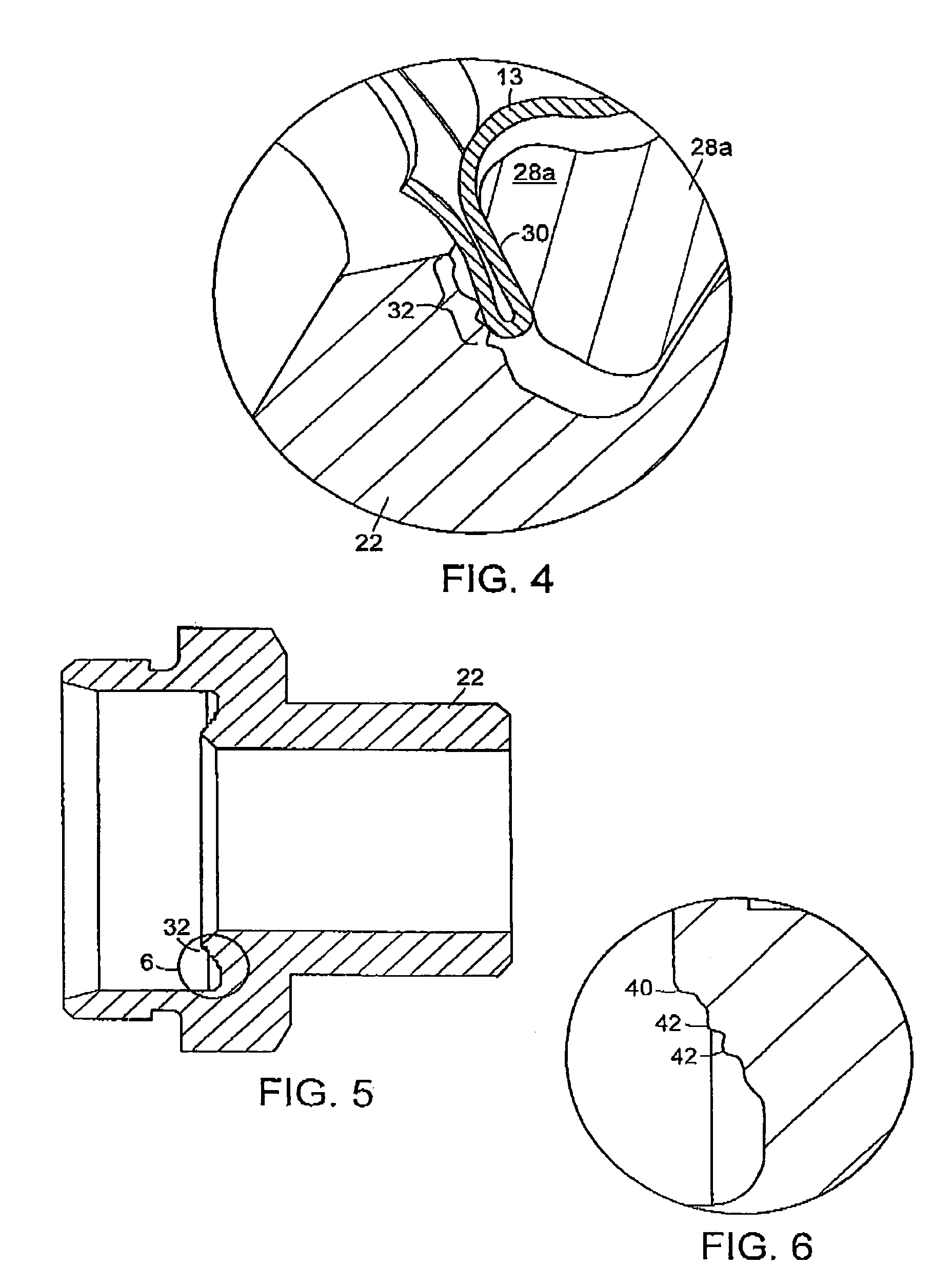

Superabrasive cutting element with enhanced durability and increased wear life and apparatus so equipped

InactiveUS6202770B1Extended service lifeReduced tendency to catastrophically spallDrill bitsConstructionsEngineeringMechanical engineering

A cutting element for use in drilling subterranean formations. The cutting element includes a superabrasive table mounted to a supporting substrate. The superabrasive table includes a two-dimensional cutting face having a cutting edge along at least a portion of its periphery, and a first surface extending forwardly and inwardly from a location radially interior of the cutting edge at a first angle of orientation with respect to the longitudinal axis of the cutting element. The cutting face also includes at least a second surface located between the first surface and the cutting edge and oriented at a different, greater angle to the longitudinal axis than the angle of orientation of the first surface.

Owner:BAKER HUGHES INC

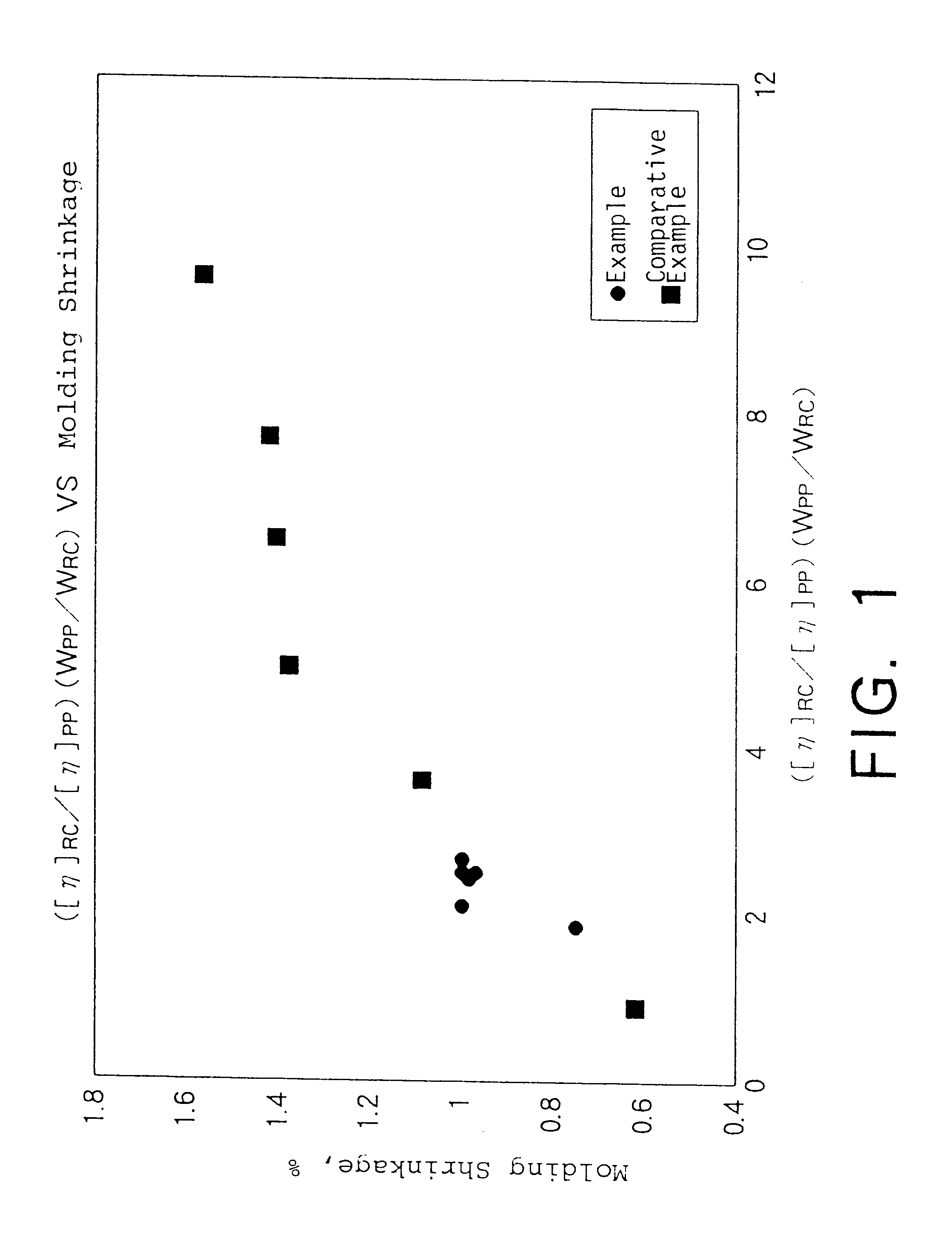

Propylene composition, process for preparing the same, polypropylene composition, and molded articles

InactiveUS6300415B1Excellent propertyImpact resistanceSynthetic resin layered productsWood working apparatusPolypropylenePolyresin

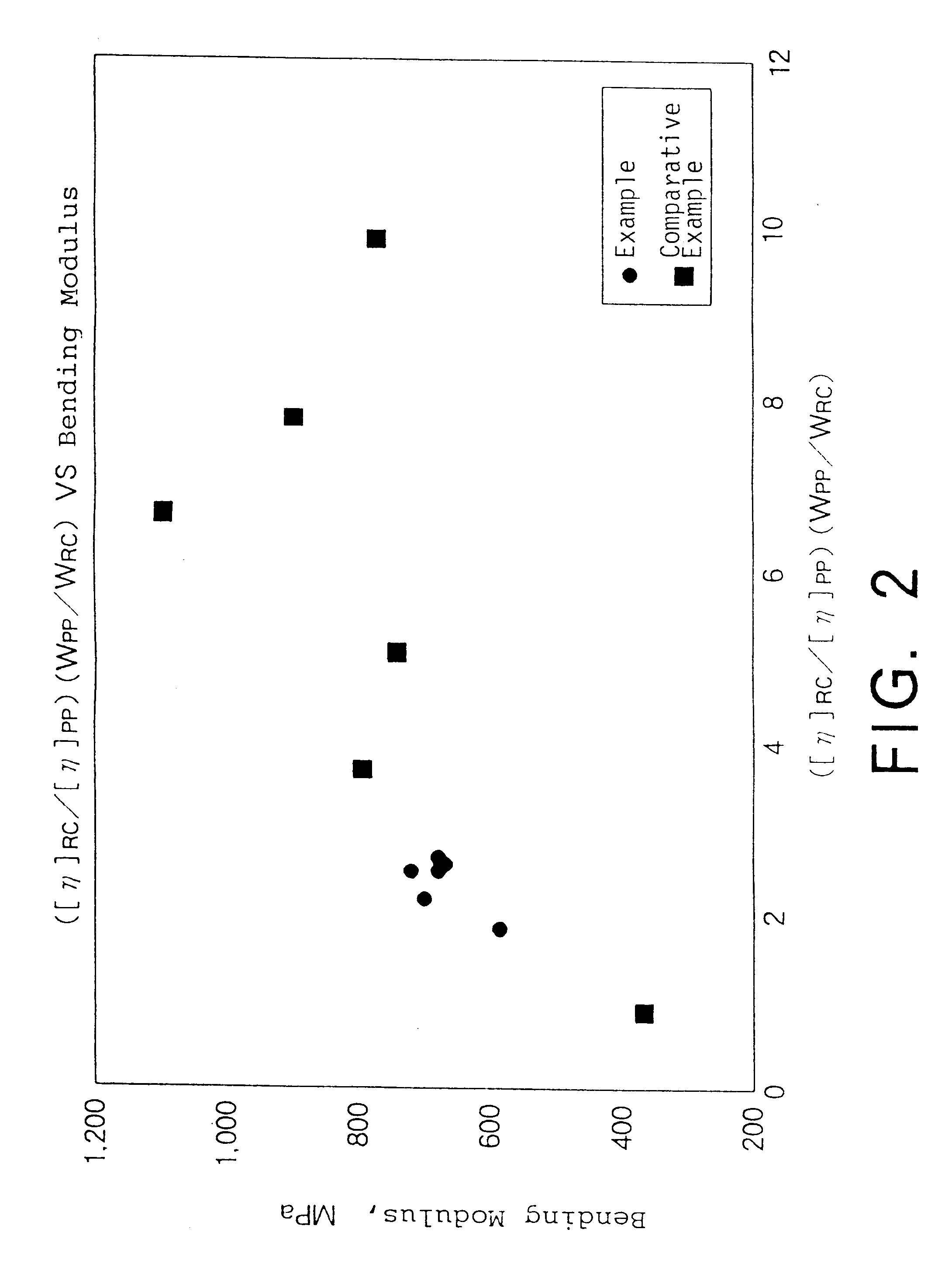

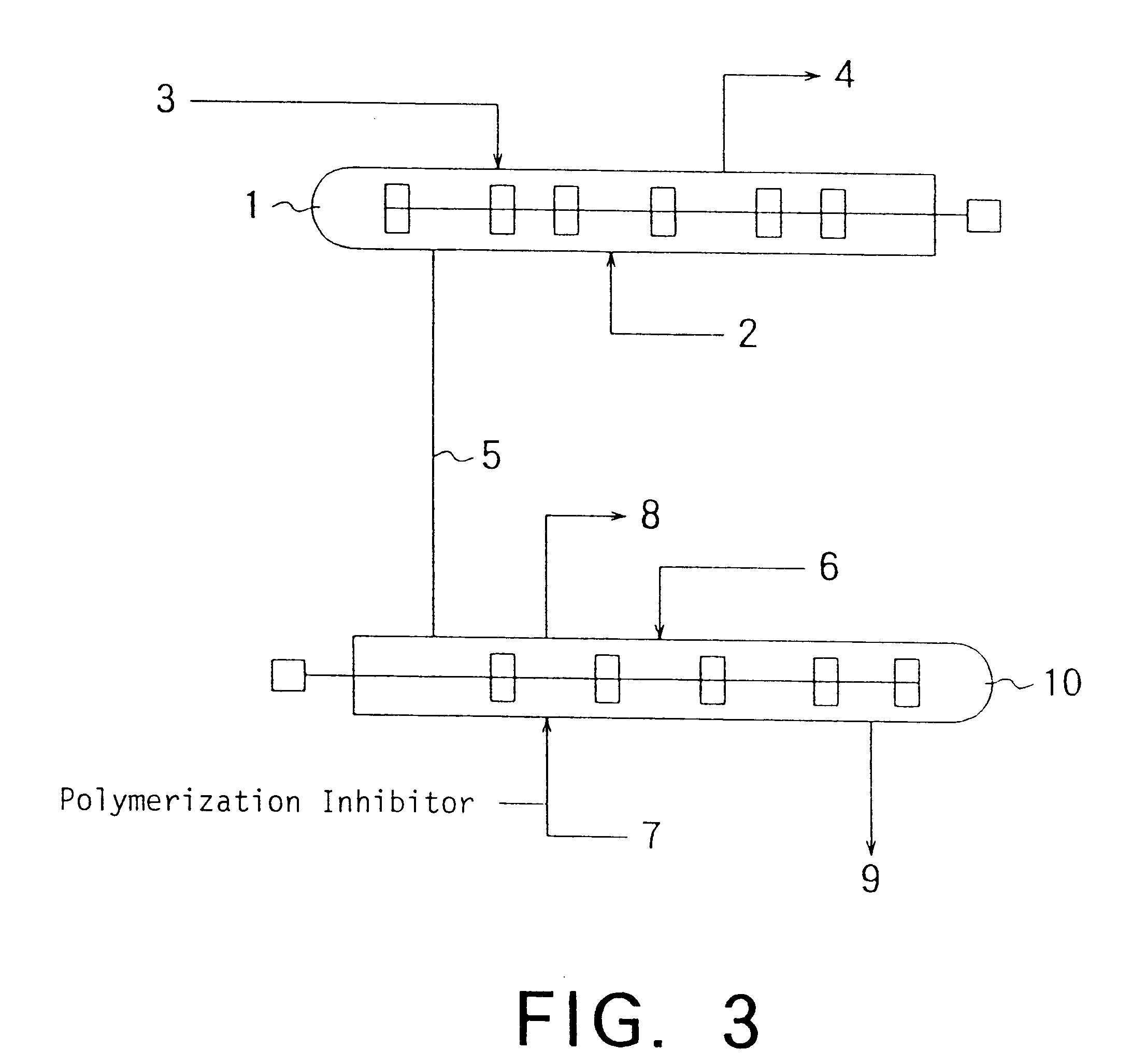

A polypropylene composition for the production of various molded articles which are excellent in moldability, mold shrinkage factor on molding, rigidity, flexibility, impact resistance, in particular low-temperature impact resistance, transparency, gloss, stress-whitening resistance, and the balance thereof; various molded articles having the above properties; a propylene composition which is suitable for a base resin for the polypropylene composition; and a process for the production thereof. The propylene composition comprises a propylene homopolymer and a propylene-ethylene copolymer, the intrinsic viscosity of the copolymer ([eta]RC) is in the range of 1.7 to 2.8 dl / g, the intrinsic viscosity ratio of the homopolymer to the copolymer ([eta]RC / [eta]pp) is in the range of 0.7 to 1.2 and a product [(WPP / WRC)x([eta]RC / [eta]pp)] of the weight ratio (WPP / WRC) of the homopolymer to the copolymer and the intrinsic viscosity ratio thereof is in the range of 1.0 to 3.0.

Owner:JNC CORP

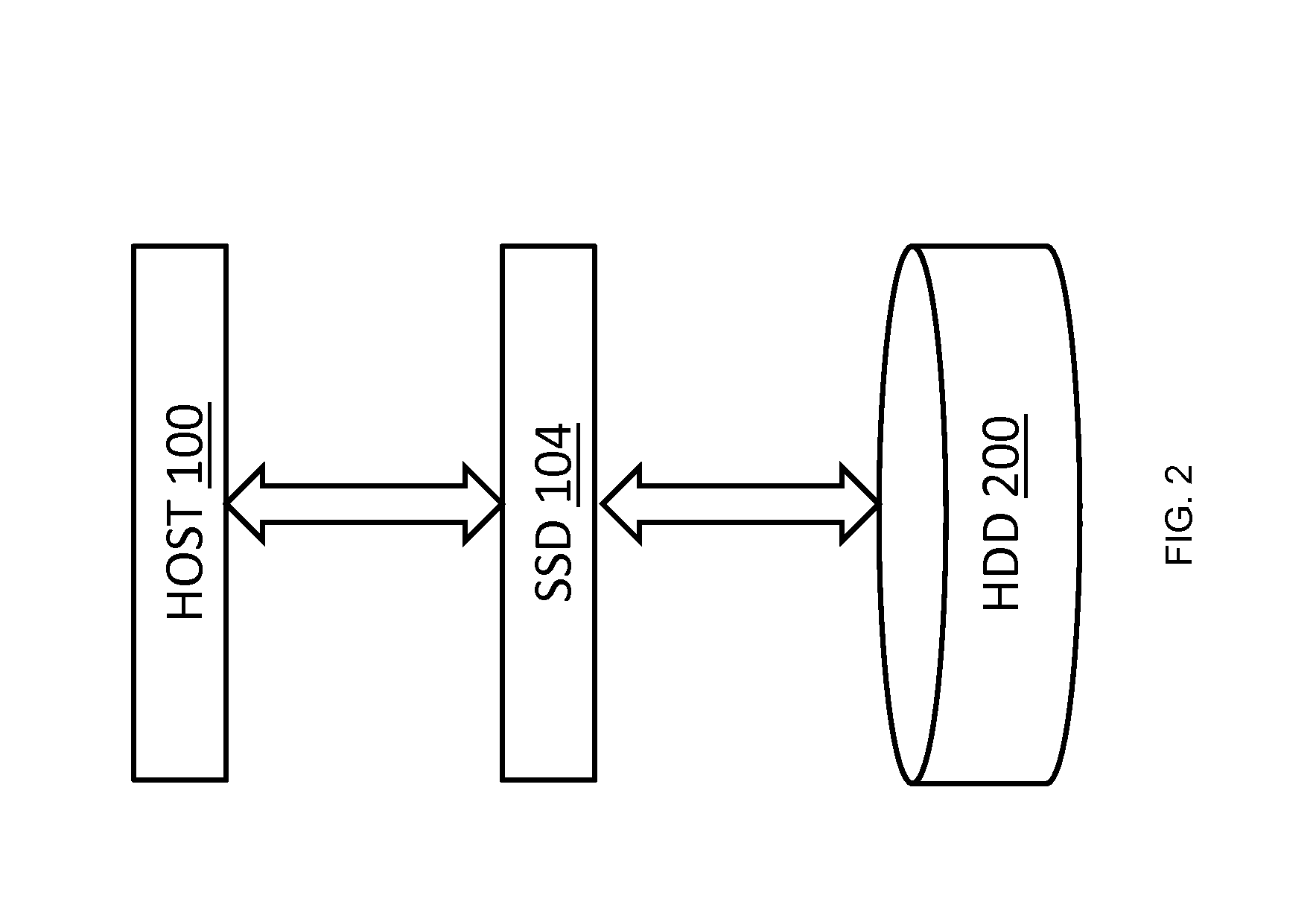

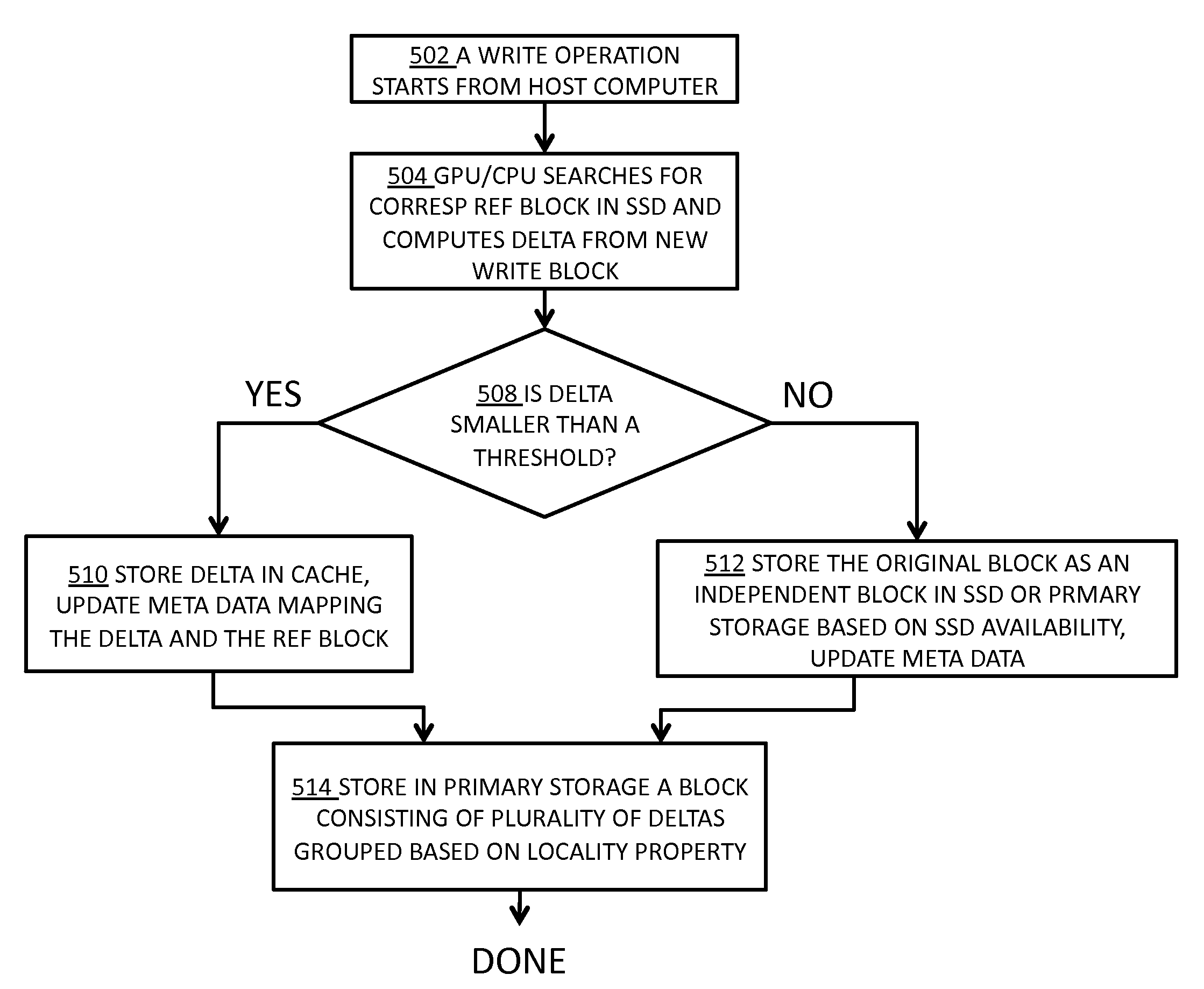

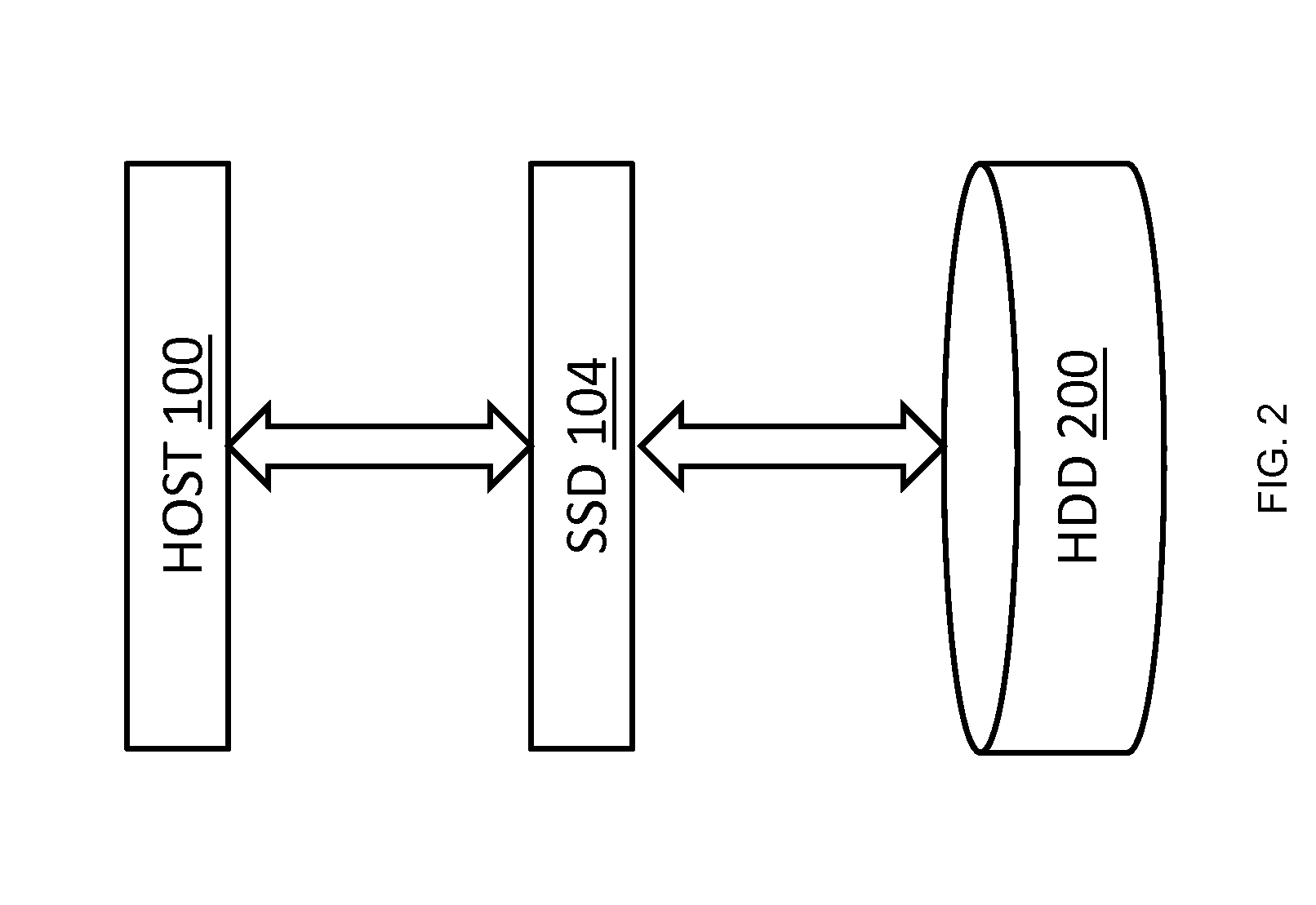

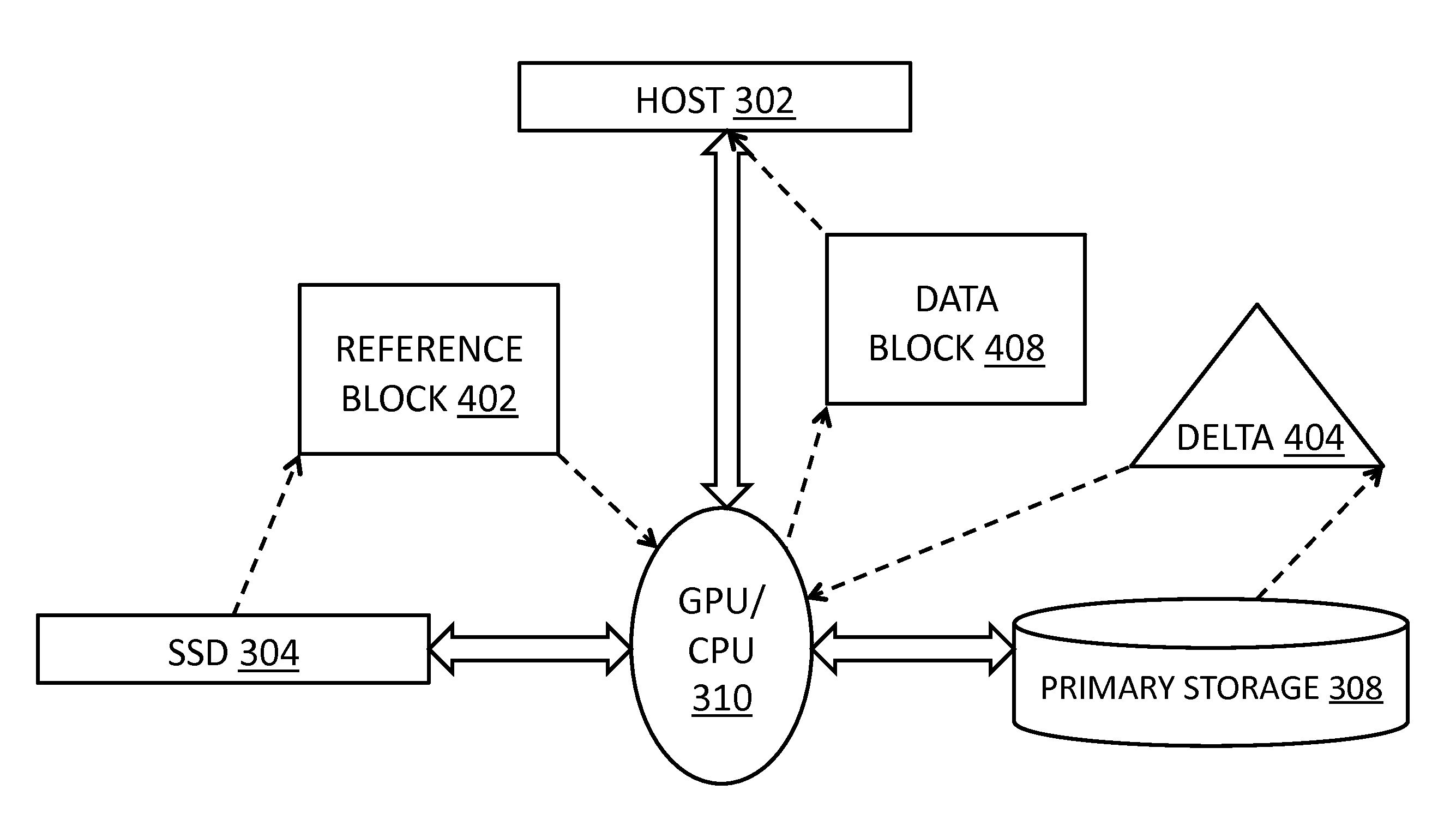

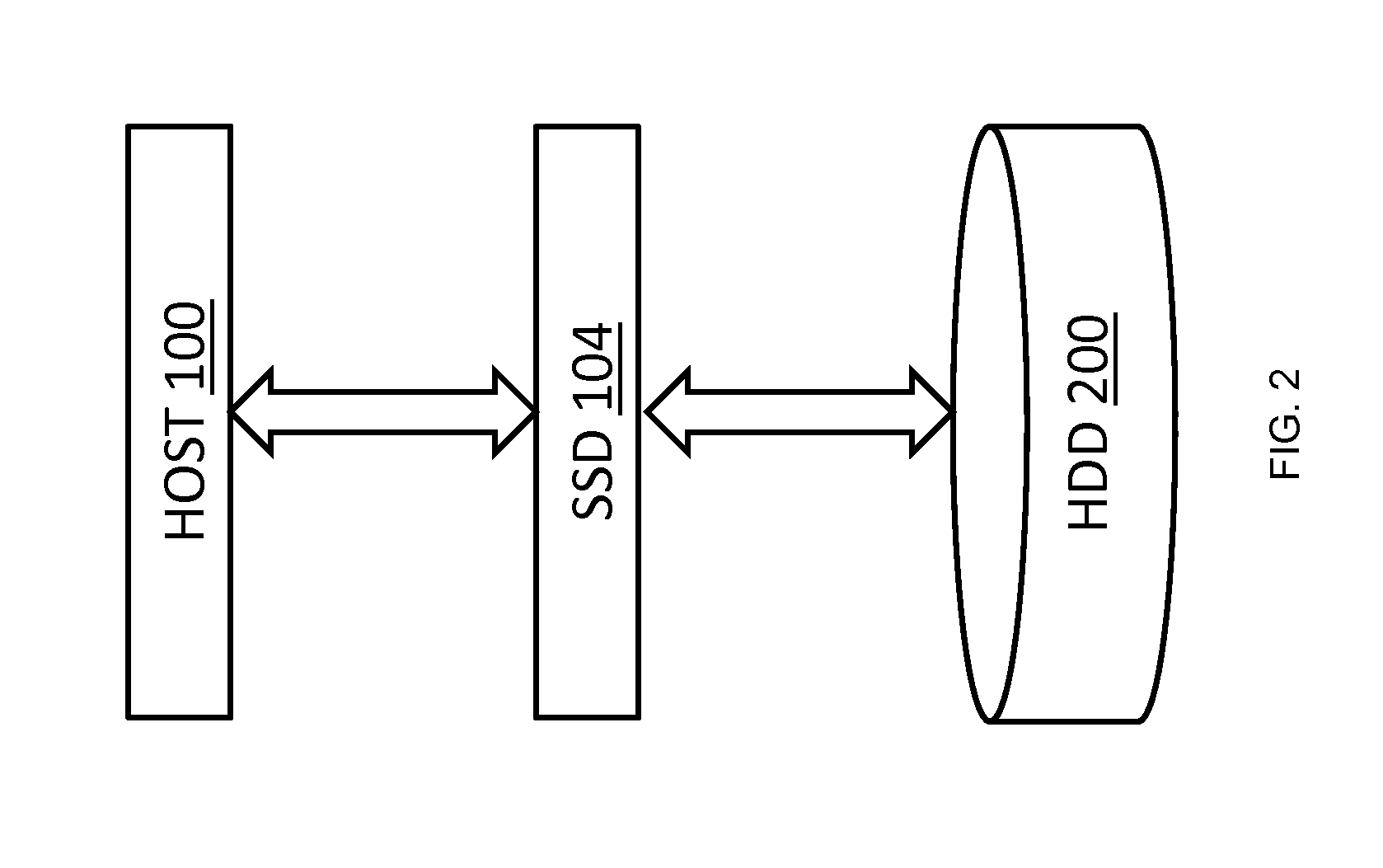

Content locality-based caching in a data storage system

InactiveUS20120137059A1Quick upgradeLow costMemory architecture accessing/allocationEnergy efficient ICTData accessLeast frequently used

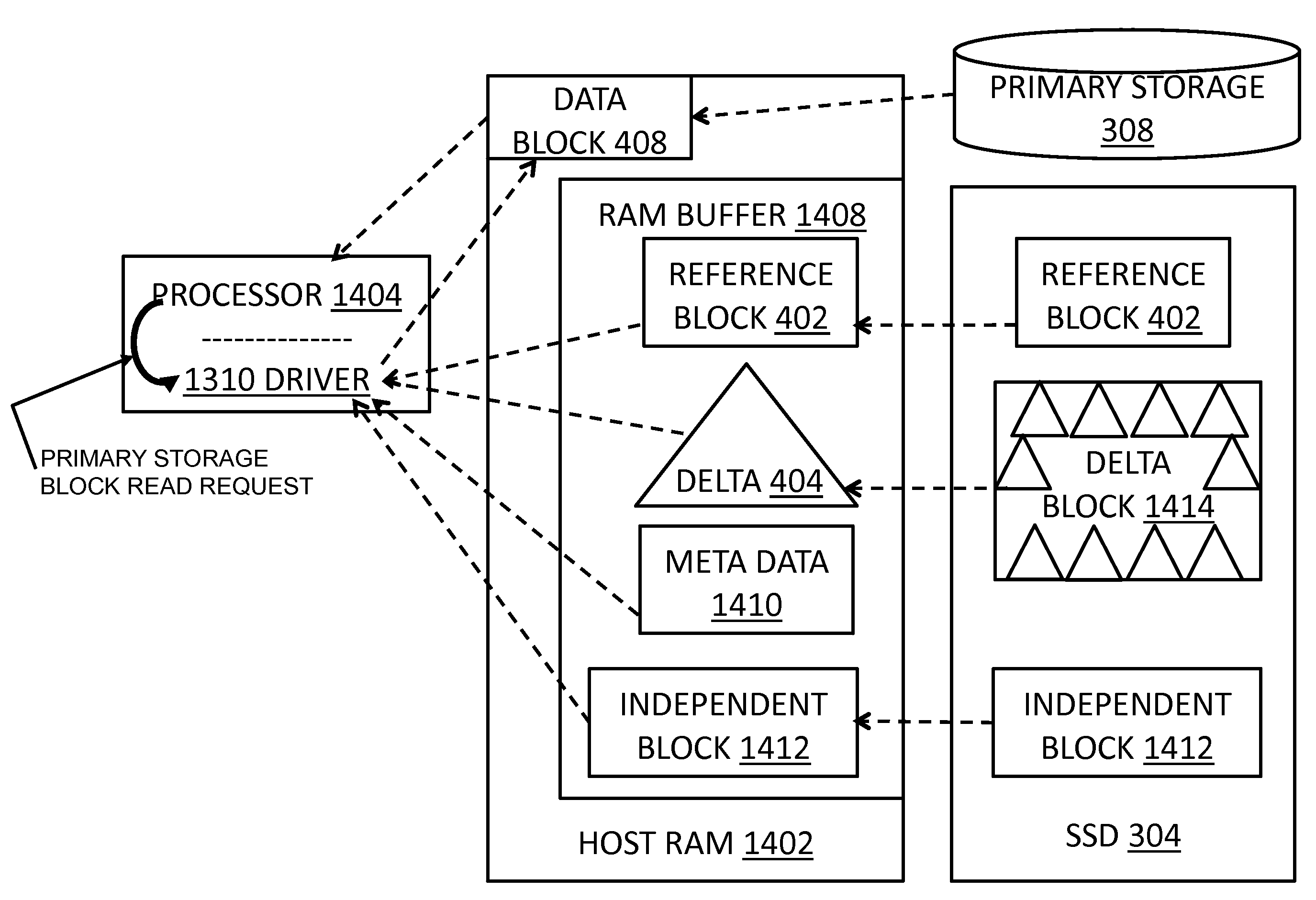

A data storage caching architecture supports using native local memory such as host-based RAM, and if available, Solid State Disk (SSD) memory for storing pre-cache delta-compression based delta, reference, and independent data by exploiting content locality, temporal locality, and spatial locality of data accesses to primary (e.g. disk-based) storage. The architecture makes excellent use of the physical properties of the different types of memory available (fast r / w RAM, low cost fast read SSD, etc) by applying algorithms to determine what types of data to store in each type of memory. Algorithms include similarity detection, delta compression, least popularly used cache management, conservative insertion and promotion cache replacement, and the like.

Owner:VELOBIT

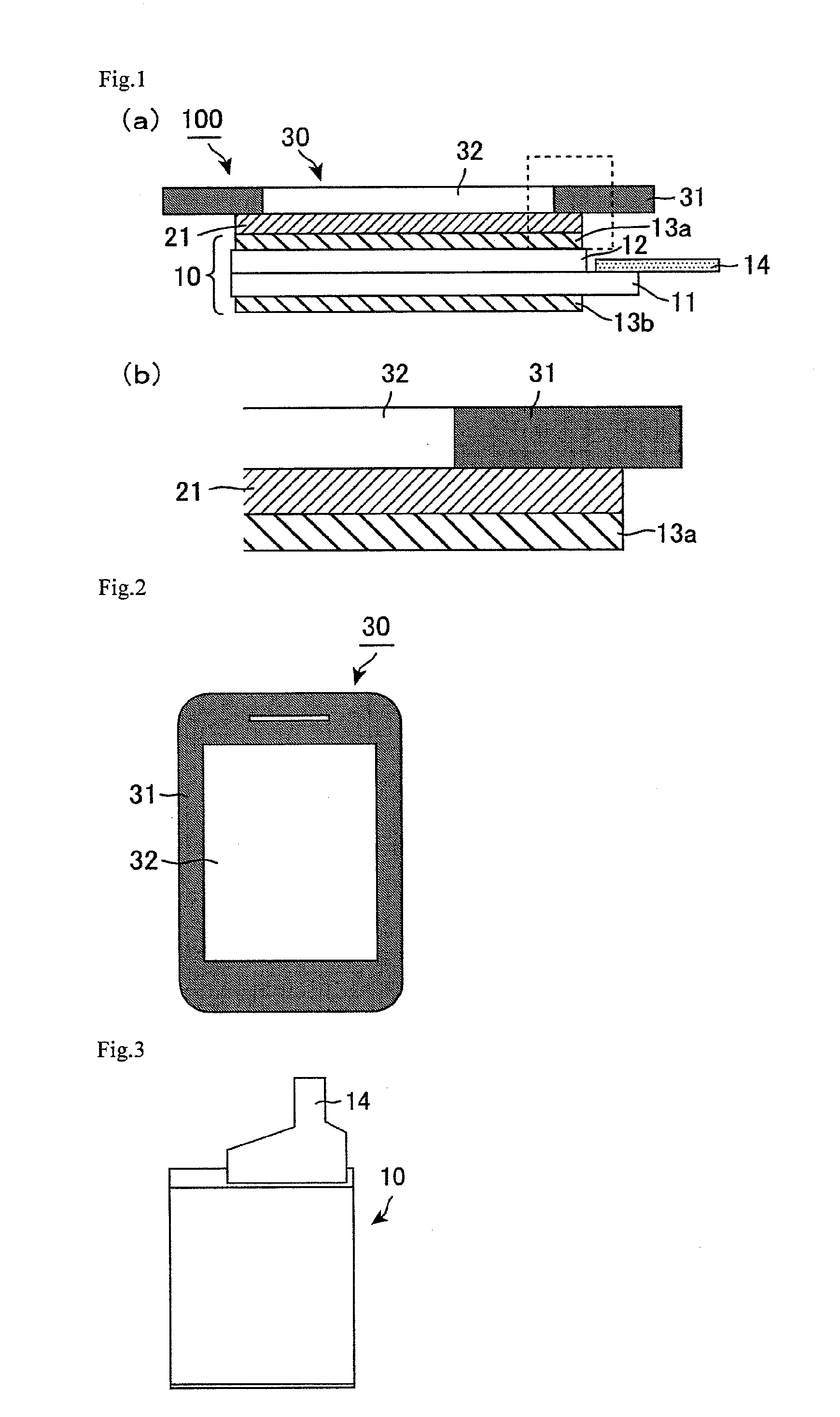

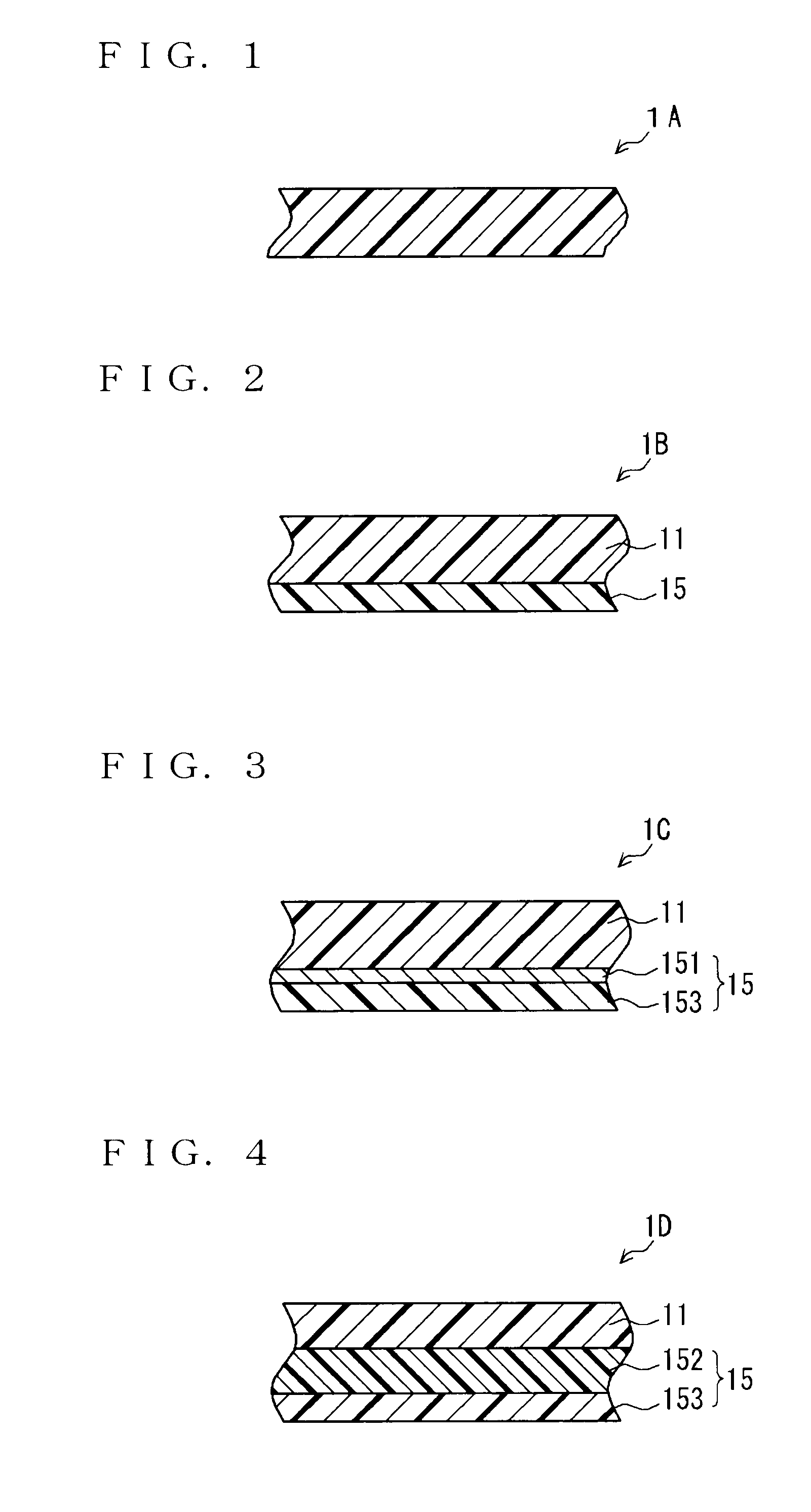

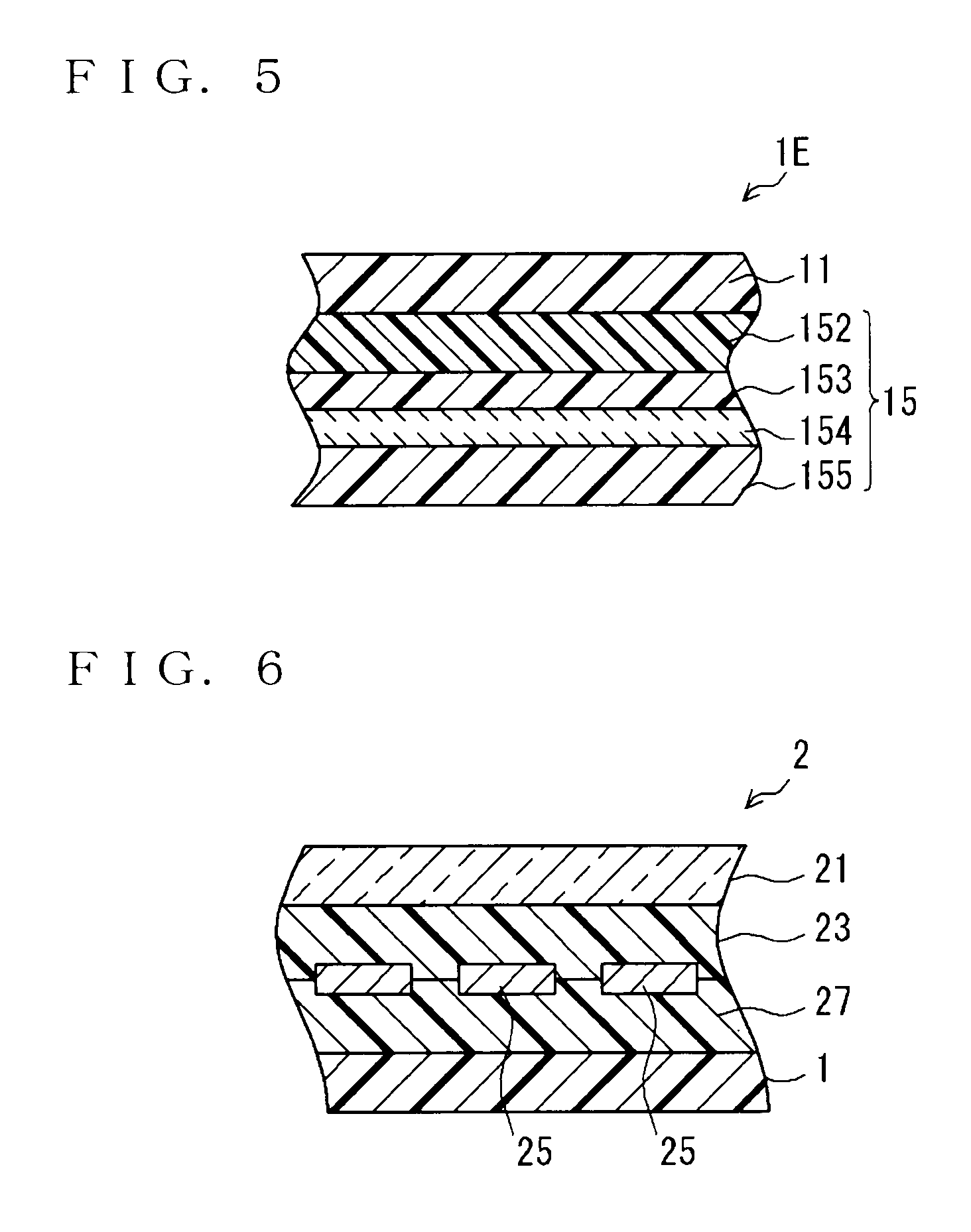

Display device and method for production thereof

InactiveUS20100277684A1Reduce displayImpact resistanceLamination ancillary operationsElectroluminescent light sourcesAdhesiveRefractive index

The present invention provides a display device in which the adhesive for bonding the display panel and the substrate to each other is prevented from remaining as an uncured portion, and a method for production thereof. The present invention provides: a display device comprising a display panel, a substrate disposed on a display side, and an adhesive layer via which the display panel and the substrate are bonded to each other, wherein the adhesive layer contains a cationically polymerized resin; and the method for production thereof. The adhesive layer more preferably has a refractive index corresponding to that of a member adjacent to the adhesive layer.

Owner:SHARP KK

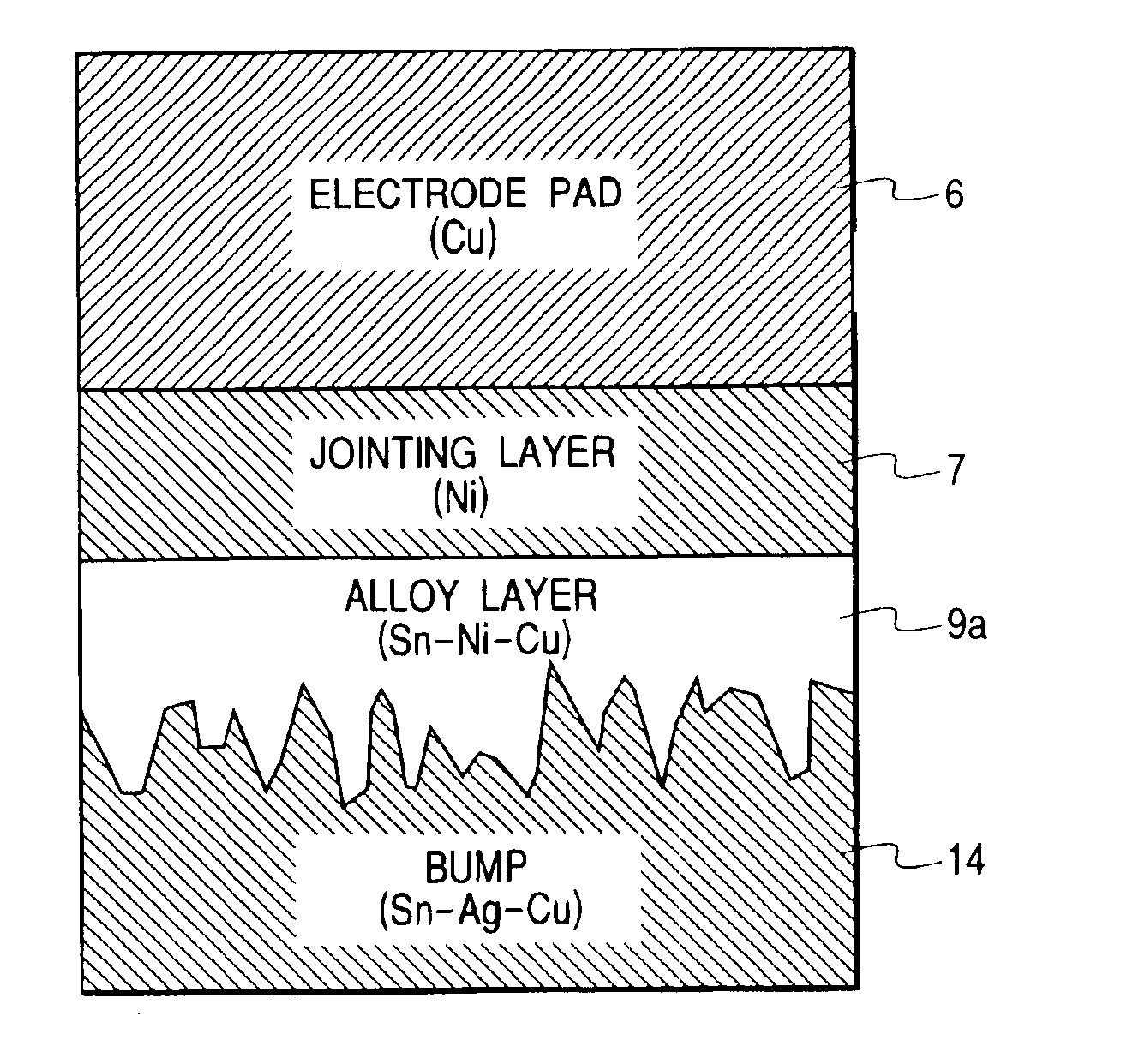

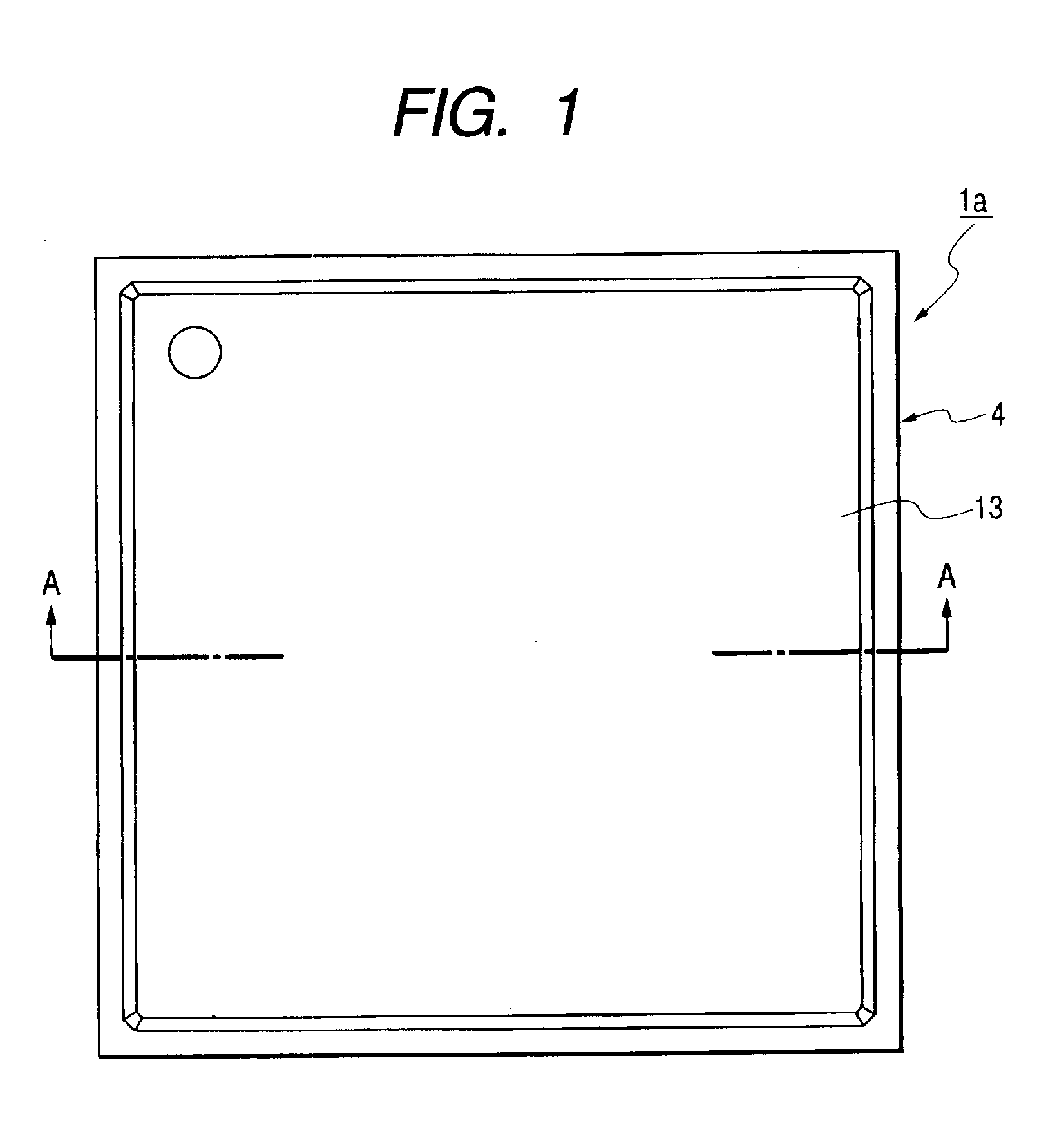

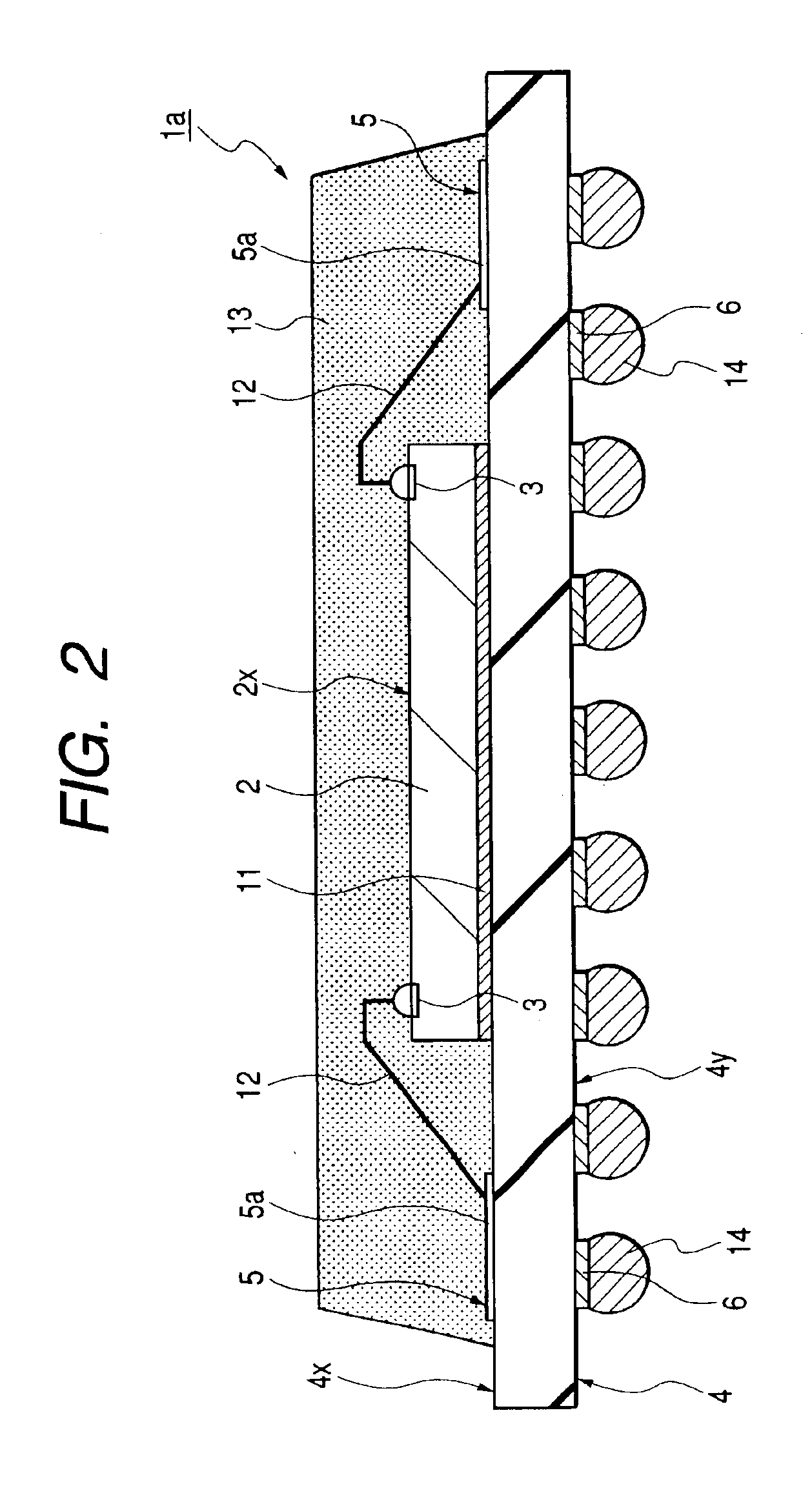

Semiconductor device with joint structure having lead-free solder layer over nickel layer

InactiveUS6879041B2Low melting pointImpact resistancePrinted circuit assemblingSemiconductor/solid-state device detailsDevice materialSulfur

The impact strength resistance of a solder joint portion of a semiconductor device is improved. The semiconductor device has a joint structure wherein a jointing layer which does not contain sulfur substantially is arranged between an underlying conductive layer and a lead-free solder layer and further between the jointing layer and the lead-free solder layer is formed an alloy layer comprising elements of these layers.

Owner:RENESAS ELECTRONICS CORP

Device driver deployment of similarity-based delta compression for use in a data storage system

InactiveUS20120144099A1Quick upgradeLow costMemory architecture accessing/allocationEnergy efficient ICTLeast frequently usedCache management

A data storage caching architecture supports using native local memory such as host-based RAM, and if available, Solid State Disk (SSD) memory for storing pre-cache delta-compression based delta, reference, and independent data by exploiting content locality, temporal locality, and spatial locality of data accesses to primary (e.g. disk-based) storage. The architecture makes excellent use of the physical properties of the different types of memory available (fast r / w RAM, low cost fast read SSD, etc) by applying algorithms to determine what types of data to store in each type of memory. Algorithms include similarity detection, delta compression, least popularly used cache management, conservative insertion and promotion cache replacement, and the like.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Multiple locality-based caching in a data storage system

InactiveUS20120144098A1Quick upgradeLow costMemory architecture accessing/allocationEnergy efficient ICTLeast frequently usedCache management

A data storage caching architecture supports using native local memory such as host-based RAM, and if available, Solid State Disk (SSD) memory for storing pre-cache delta-compression based delta, reference, and independent data by exploiting content locality, temporal locality, and spatial locality of data accesses to primary (e.g. disk-based) storage. The architecture makes excellent use of the physical properties of the different types of memory available (fast r / w RAM, low cost fast read SSD, etc) by applying algorithms to determine what types of data to store in each type of memory. Algorithms include similarity detection, delta compression, least popularly used cache management, conservative insertion and promotion cache replacement, and the like.

Owner:VELOBIT

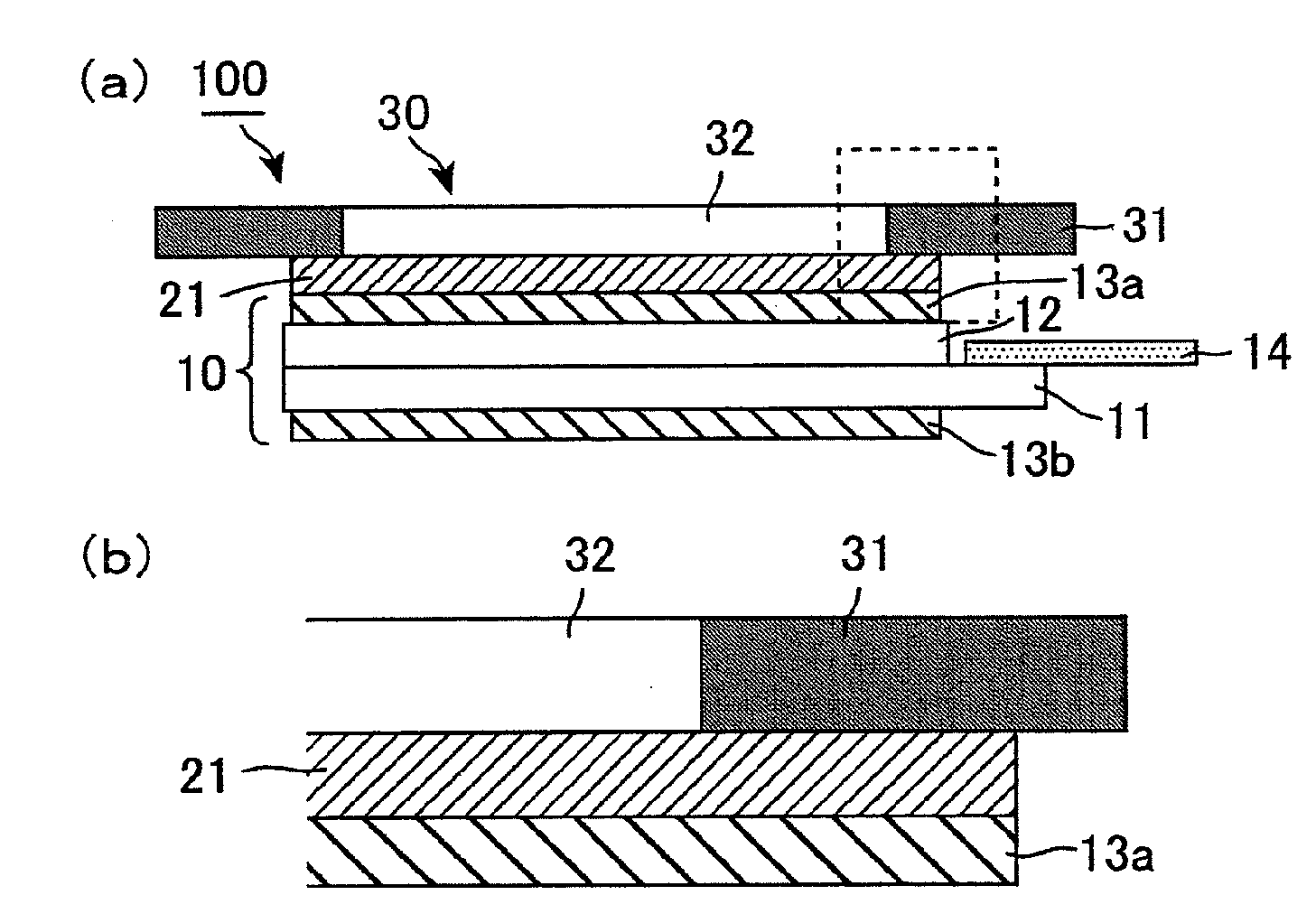

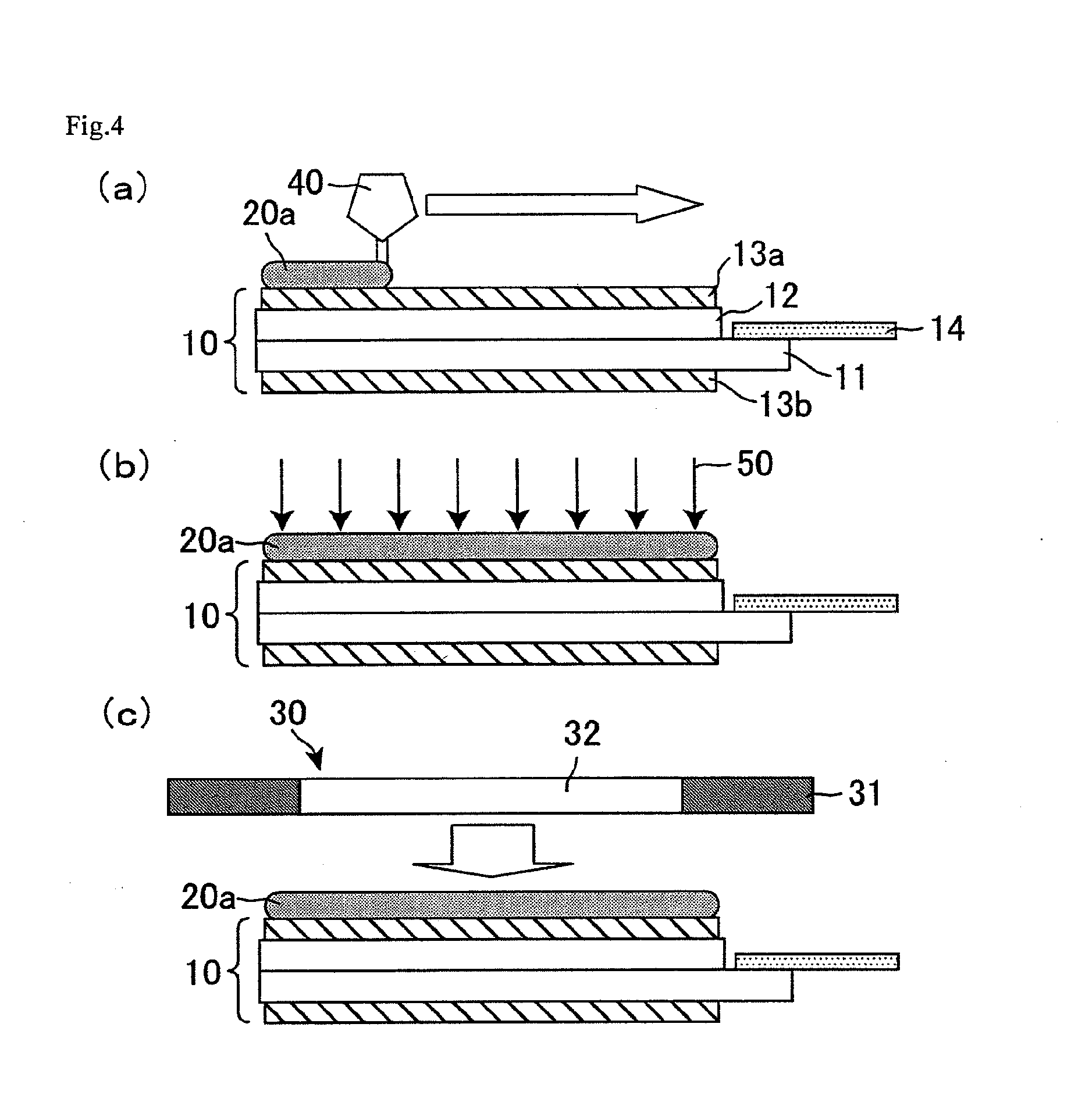

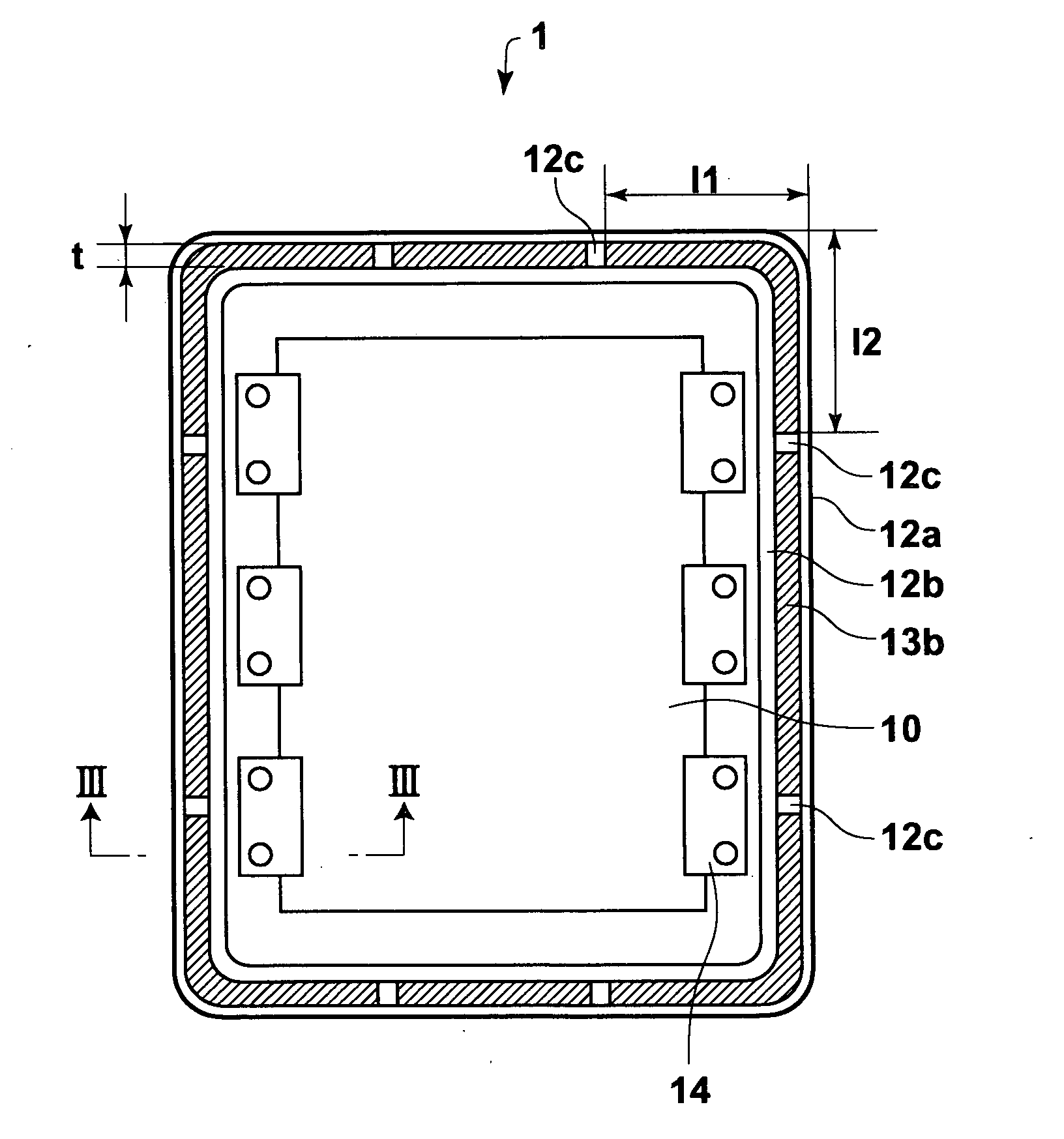

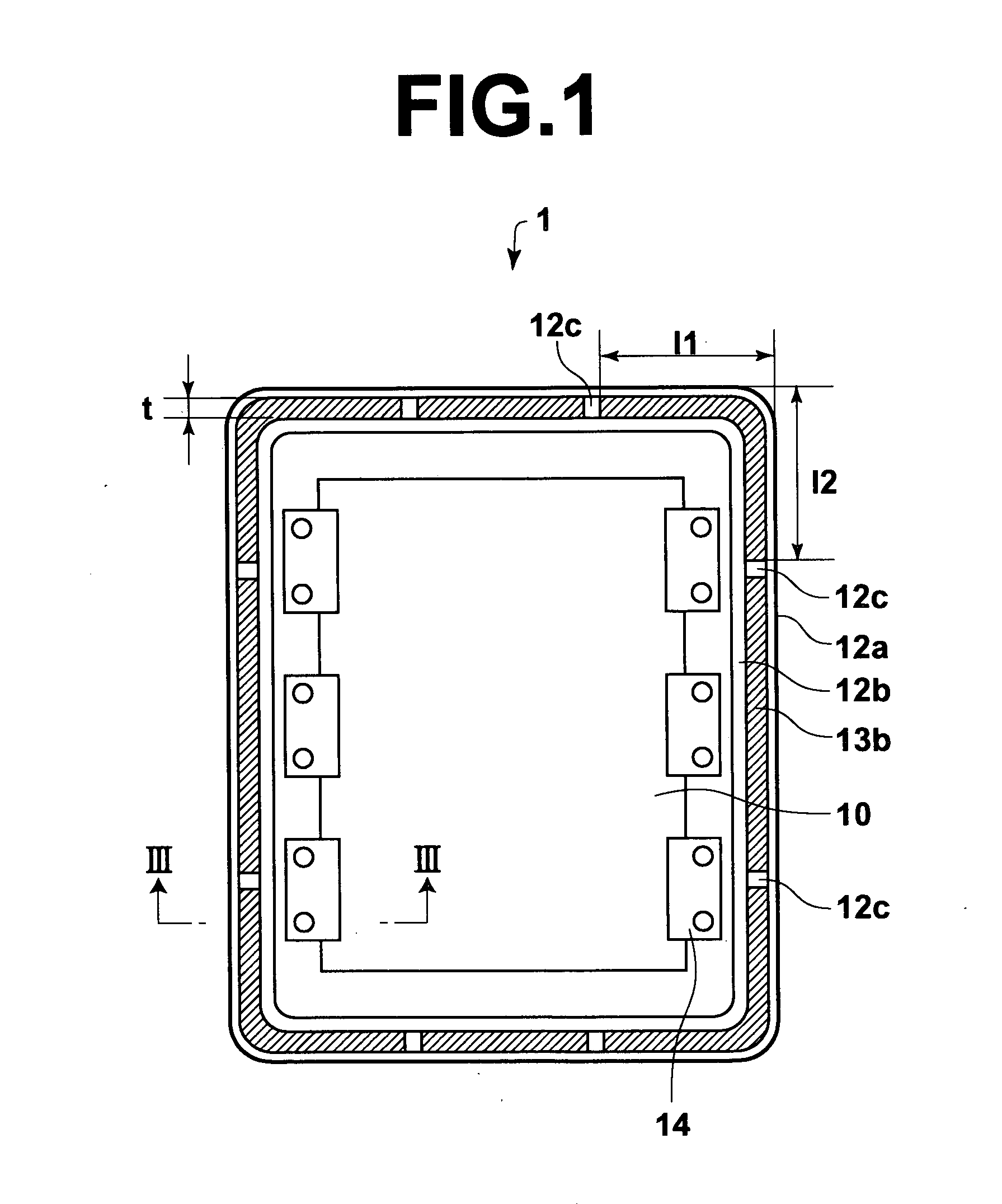

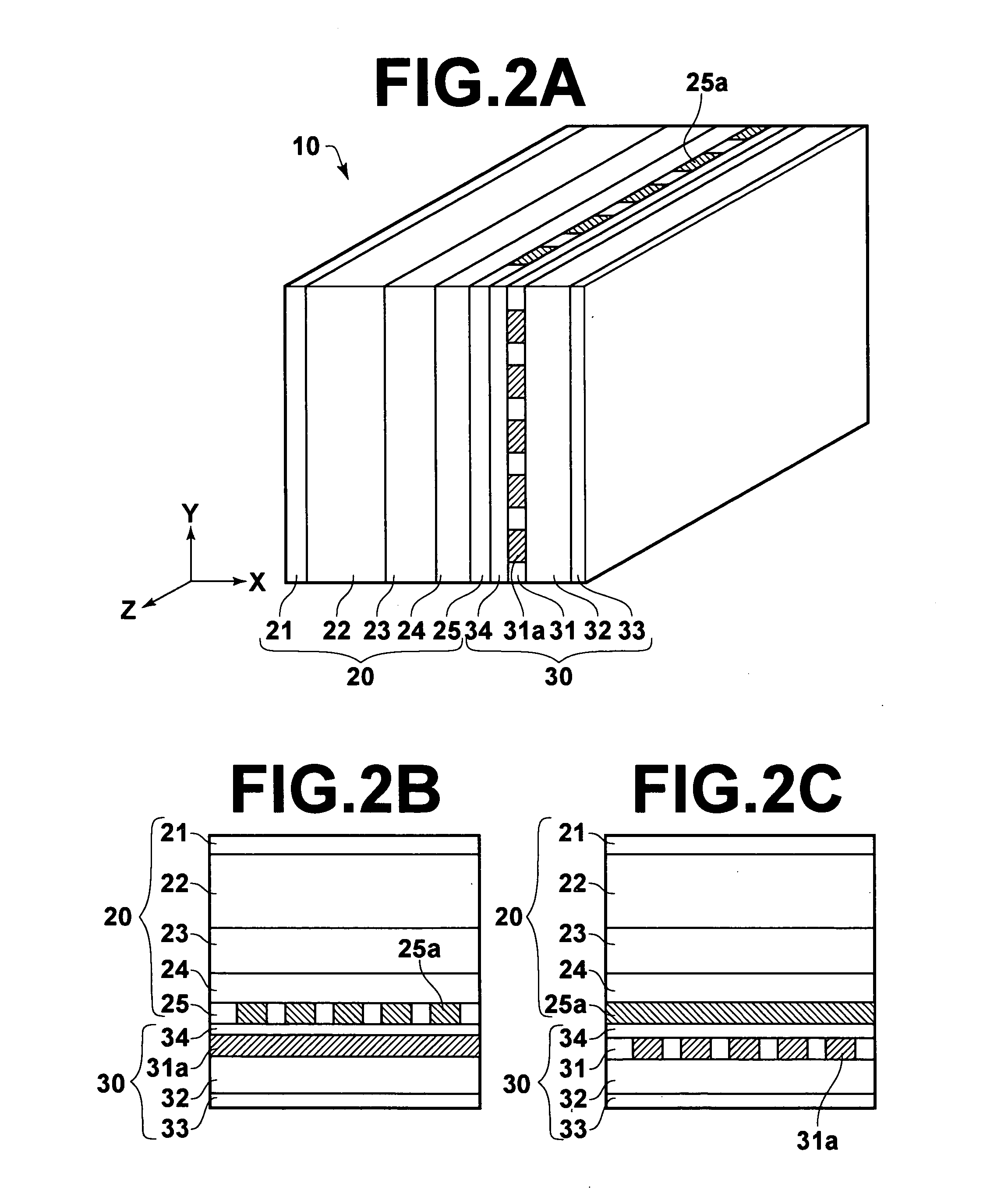

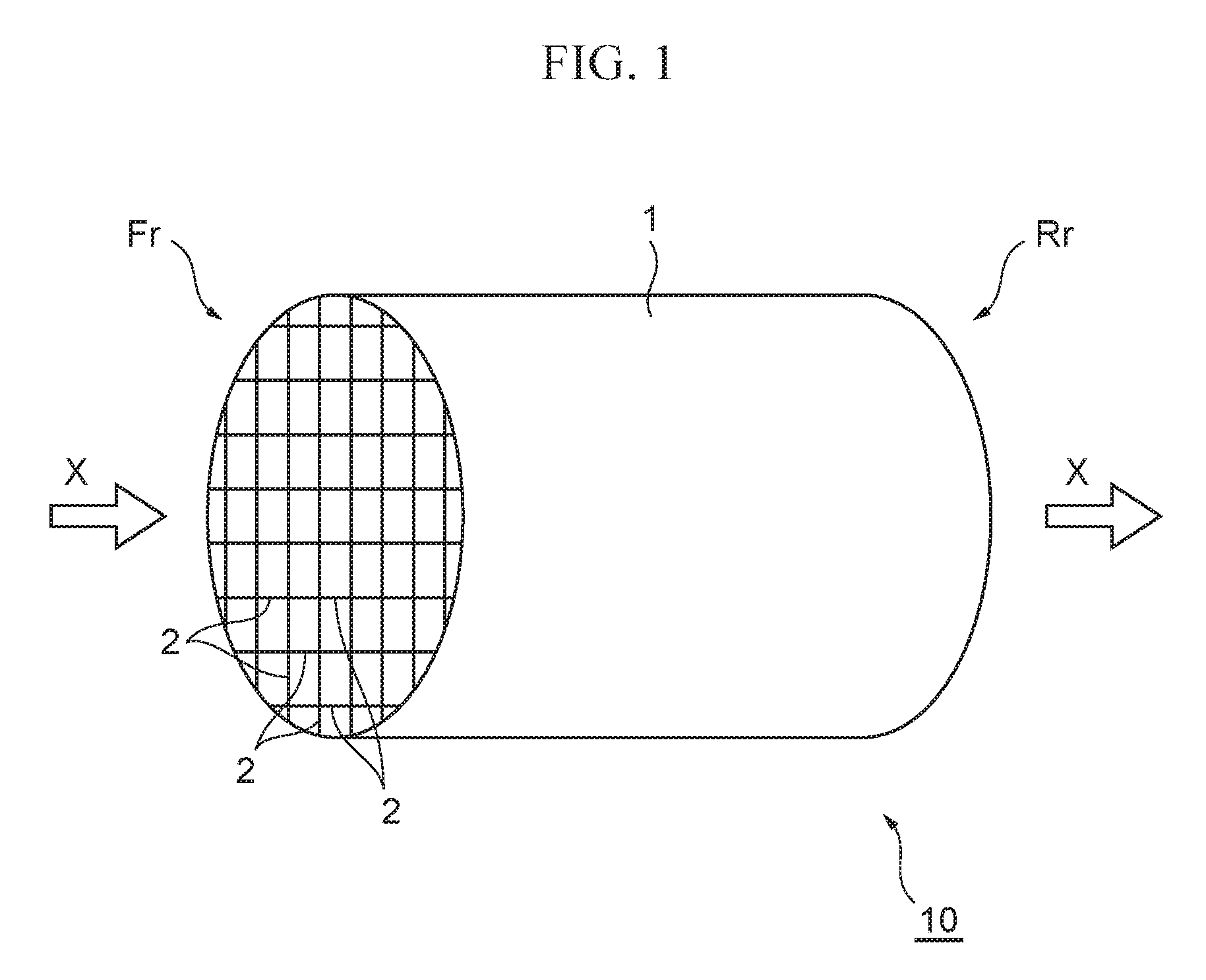

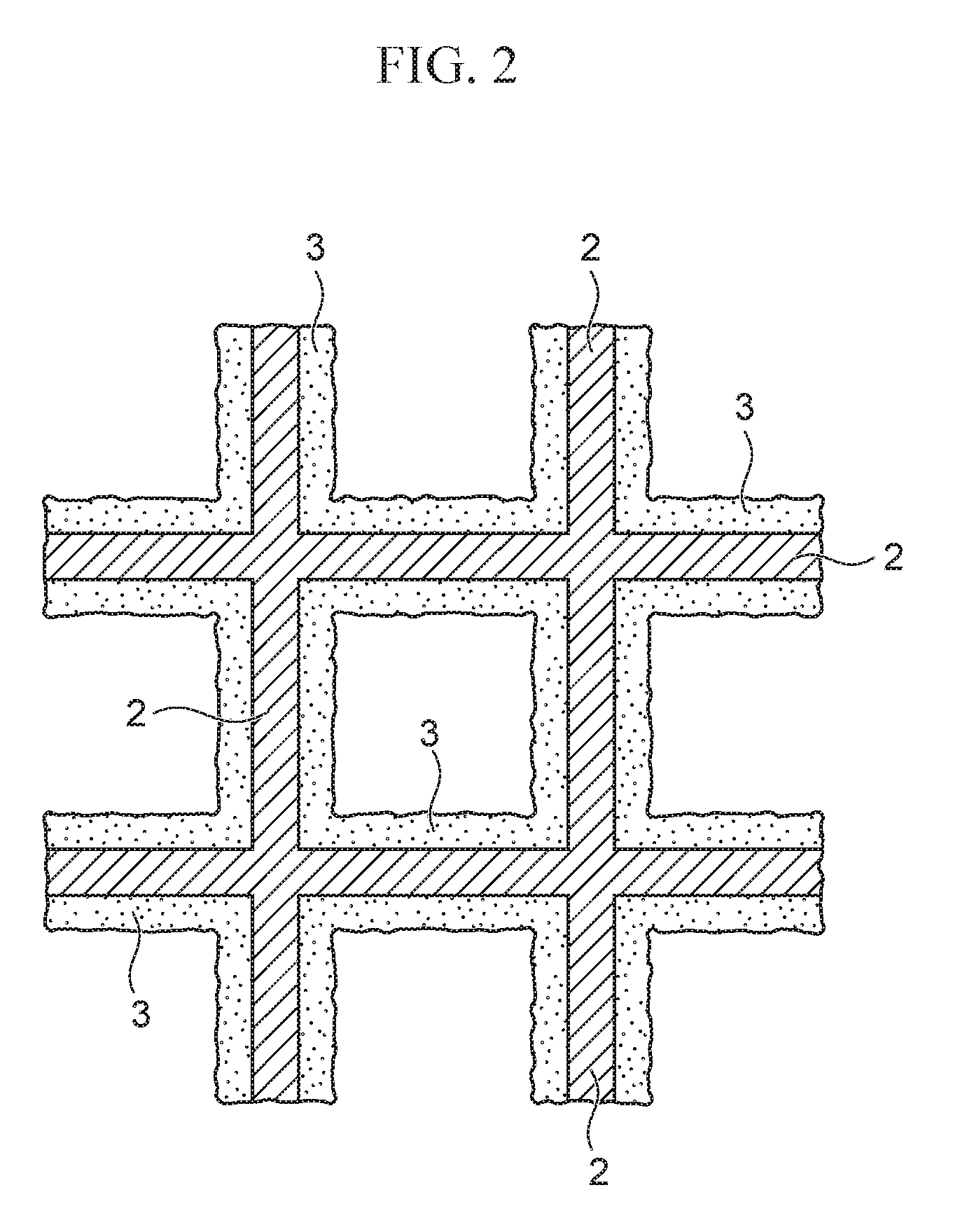

Radiation detecting cassette

ActiveUS20050017188A1Position precision be improveSufficient shock resistanceSolid-state devicesMaterial analysis by optical meansPhysicsSolid-state

A solid-state radiation detector is provided which has an improved positional precision within a casing thereof while ensuring the shock resistance properties. A radiation cassette 1 comprises: a solid-state radiation detector 10 which is an image pickup device, a casing constituted by upper and lower shell halves 11 and 12 and accommodates therein the solid-state radiation detector and the like. Each of the upper and lower shell halves comprises: an outer frame 11a, 12a; an inner frame 11b, 12b, and a coupling member 11c, 12c for coupling the outer and inner frames. A space between the outer frame 11a, 12a and the inner frame 11b, 12b is filled with a shock absorbing material 13a, 13b, thereby imparting shock absorbency to the casing itself. The solid-state radiation detector 10 is rigidly secured to the inner frame 12b of the lower shell half 12.

Owner:FUJIFILM HLDG CORP +1

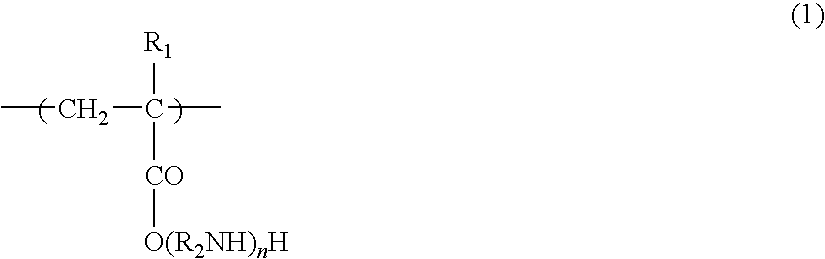

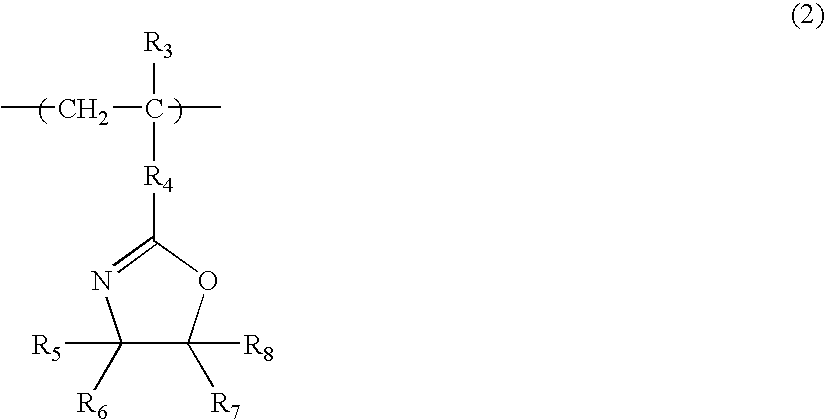

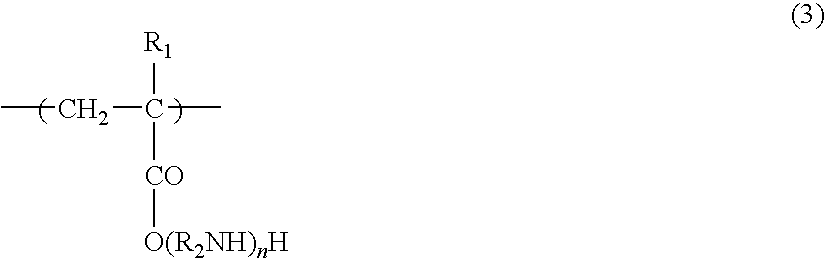

Fiber-Reinforced Thermoplastic Resin Composition, Method for Producing the Same, and Carbon Fiber for Thermoplastic Resin

InactiveUS20090143524A1Improve interface adhesionImprove mechanical propertiesPretreated surfacesLaminationMeth-Carbon fibers

According to the present invention, a fiber-reinforced thermoplastic resin composition that is superior in adhesivity between reinforcing fiber and thermoplastic resin is provided. It is possible to sufficiently improve mechanical properties of a molded product with such composition. Such fiber-reinforced thermoplastic resin composition comprises a (meth)acrylic polymer (A1) having an aminoalkylene group in a side chain or a polymer having an oxazoline group (A2) (0.1% to 10% by weight), reinforcing fibers (B) (1% to 70% by weight), and a thermoplastic resin (C) (20% to 98.9% by weight).

Owner:TORAY IND INC

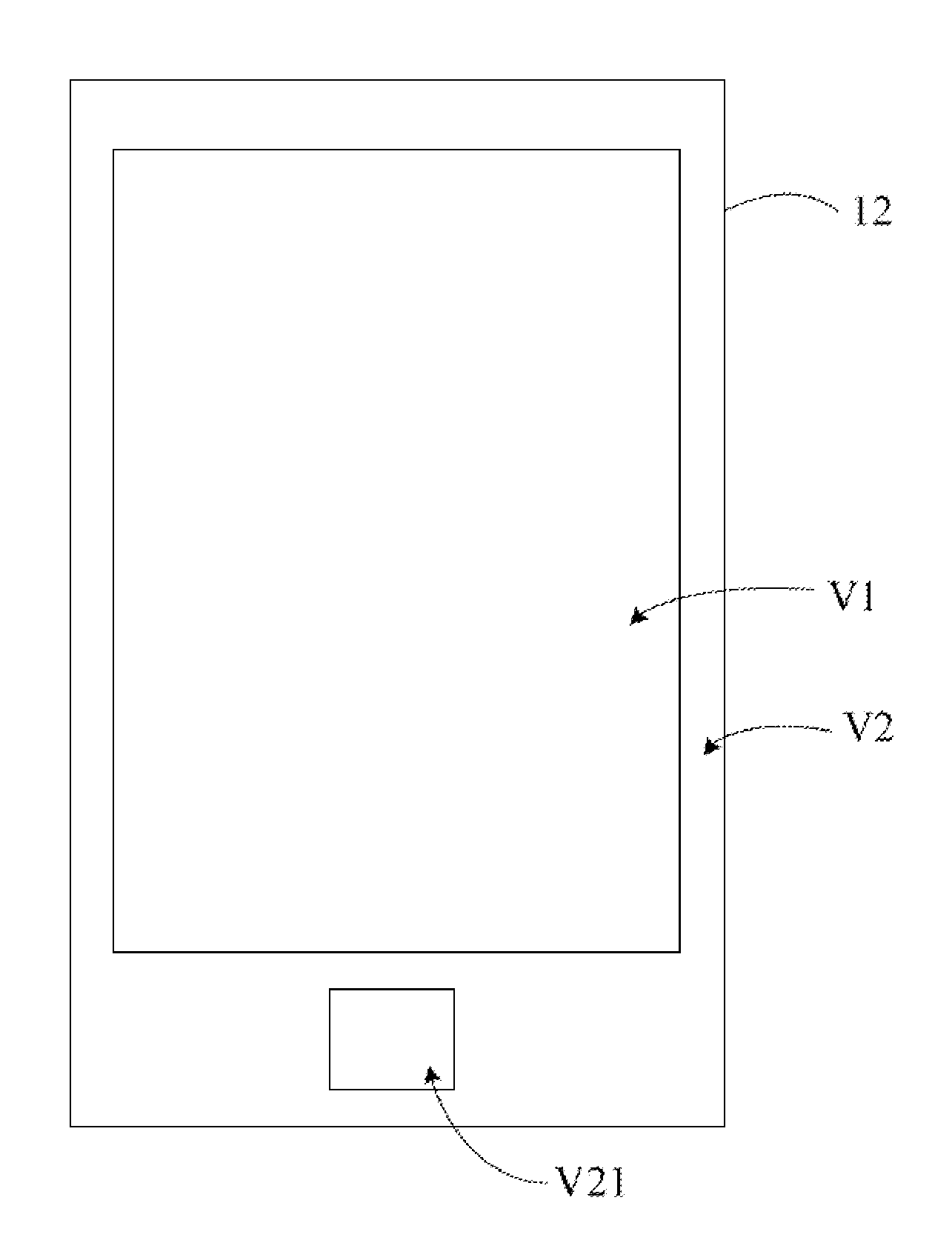

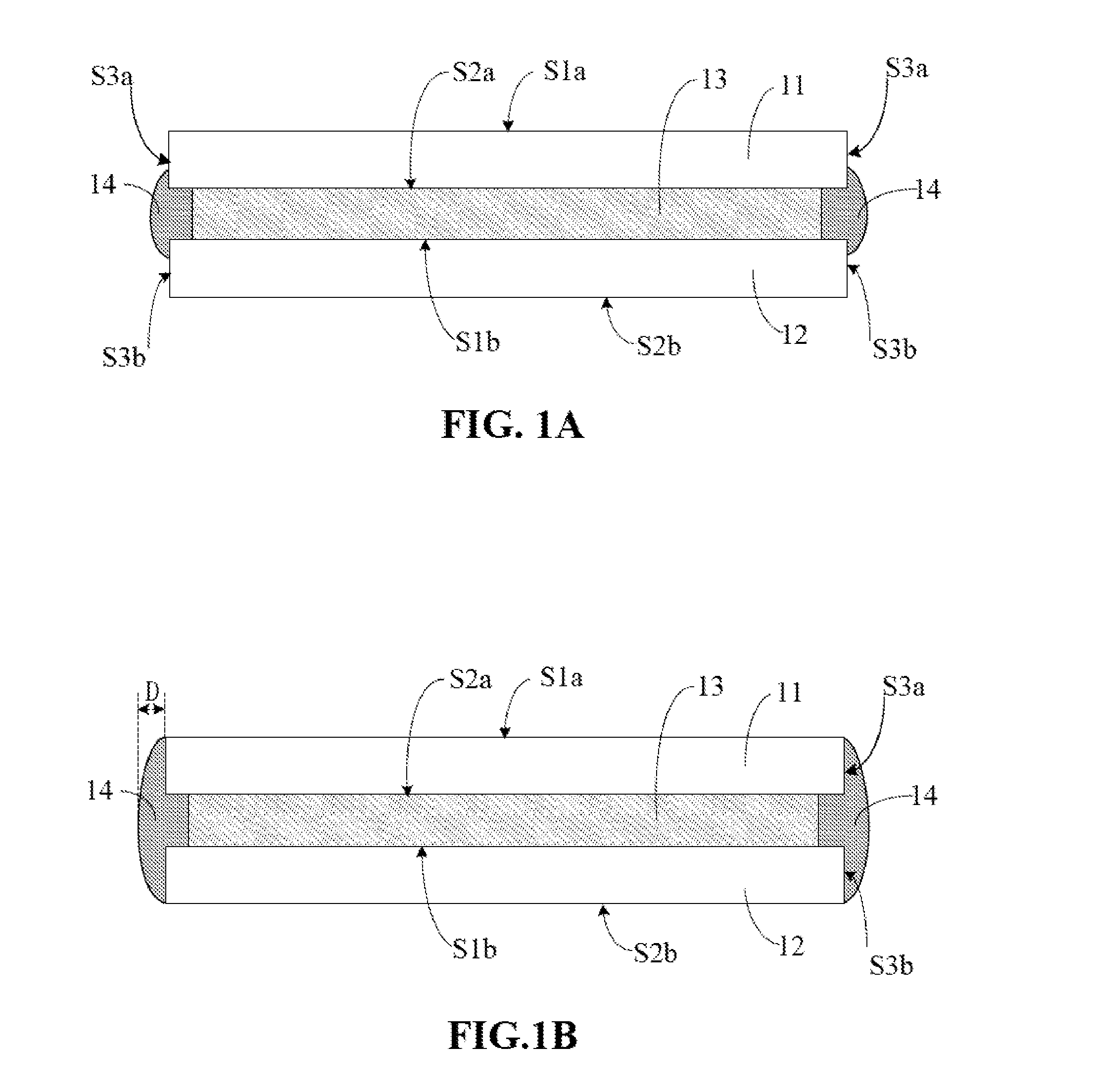

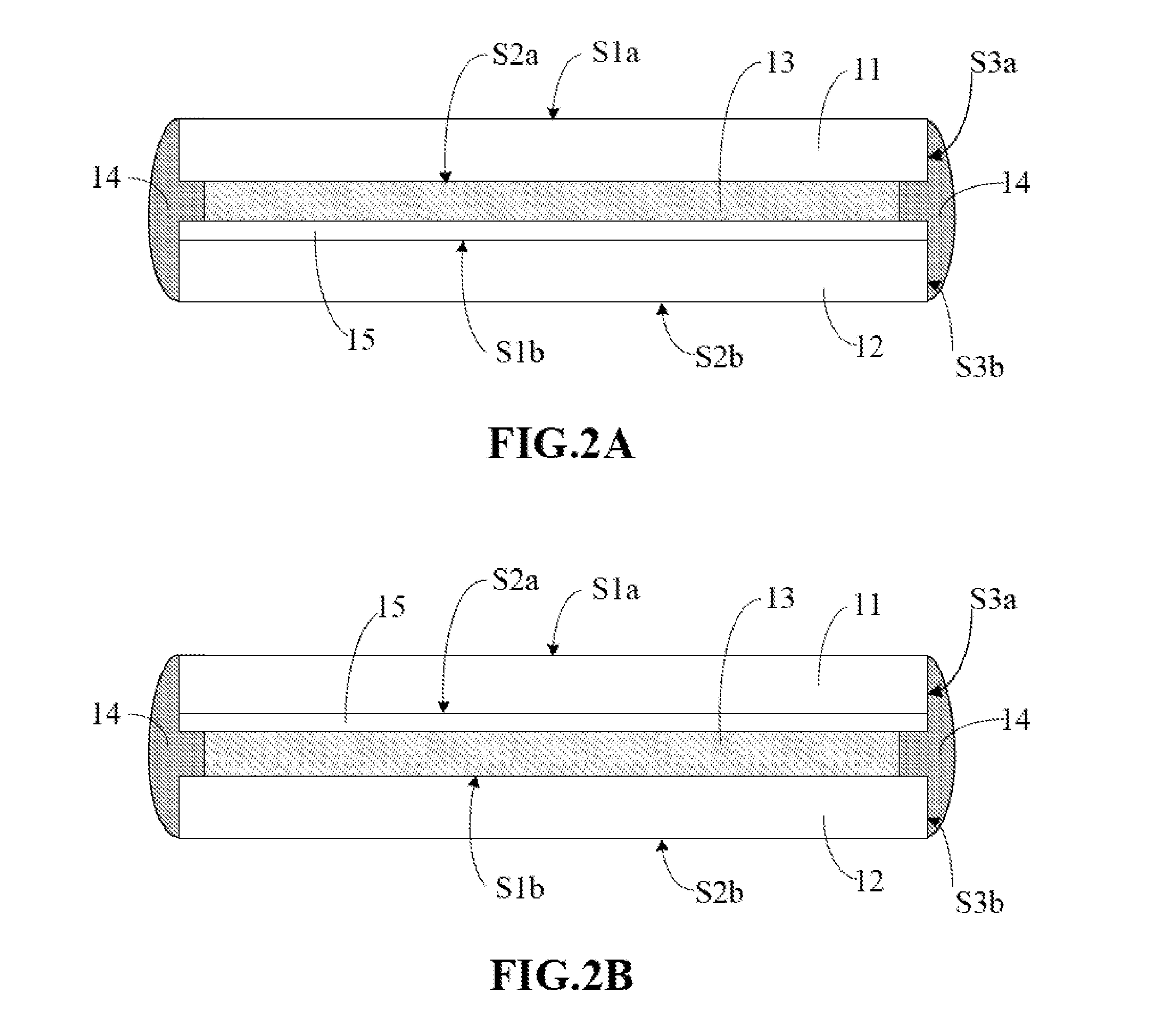

Touch device

InactiveUS20160077622A1High strengthImprove impact resistanceDigital data processing detailsSubstation equipmentEngineeringUltimate tensile strength

A touch device includes a cover plate, a substrate, a first adhesive layer and a strengthening glue. The cover plate and the substrate each has first and second opposite surfaces and a side surface between the first surface and the second surface. The first adhesive layer is located between the second surface of the cover plate and the first surface of the substrate. A space is formed between the side surface of the first adhesive layer, the second surface of the cover plate and the first surface the substrate a space. The space is filled with the strengthening glue. The cover plate and the substrate are fully bonded to enhance the strength, the compression resistance and the impact resistance of the touch device. Further the accuracy requirement for the first adhesive layer is lowered and the material of the first adhesive layer is saved.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

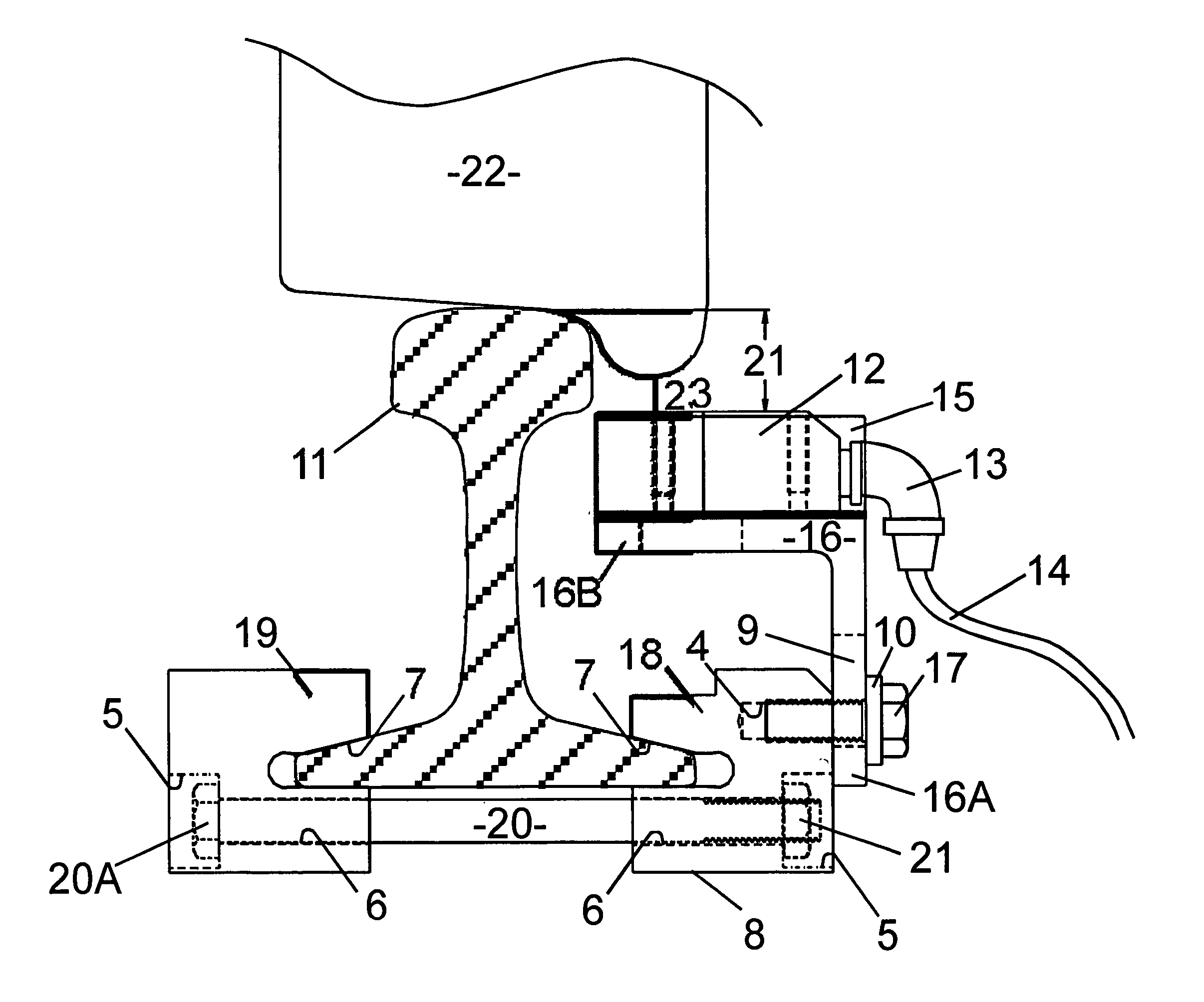

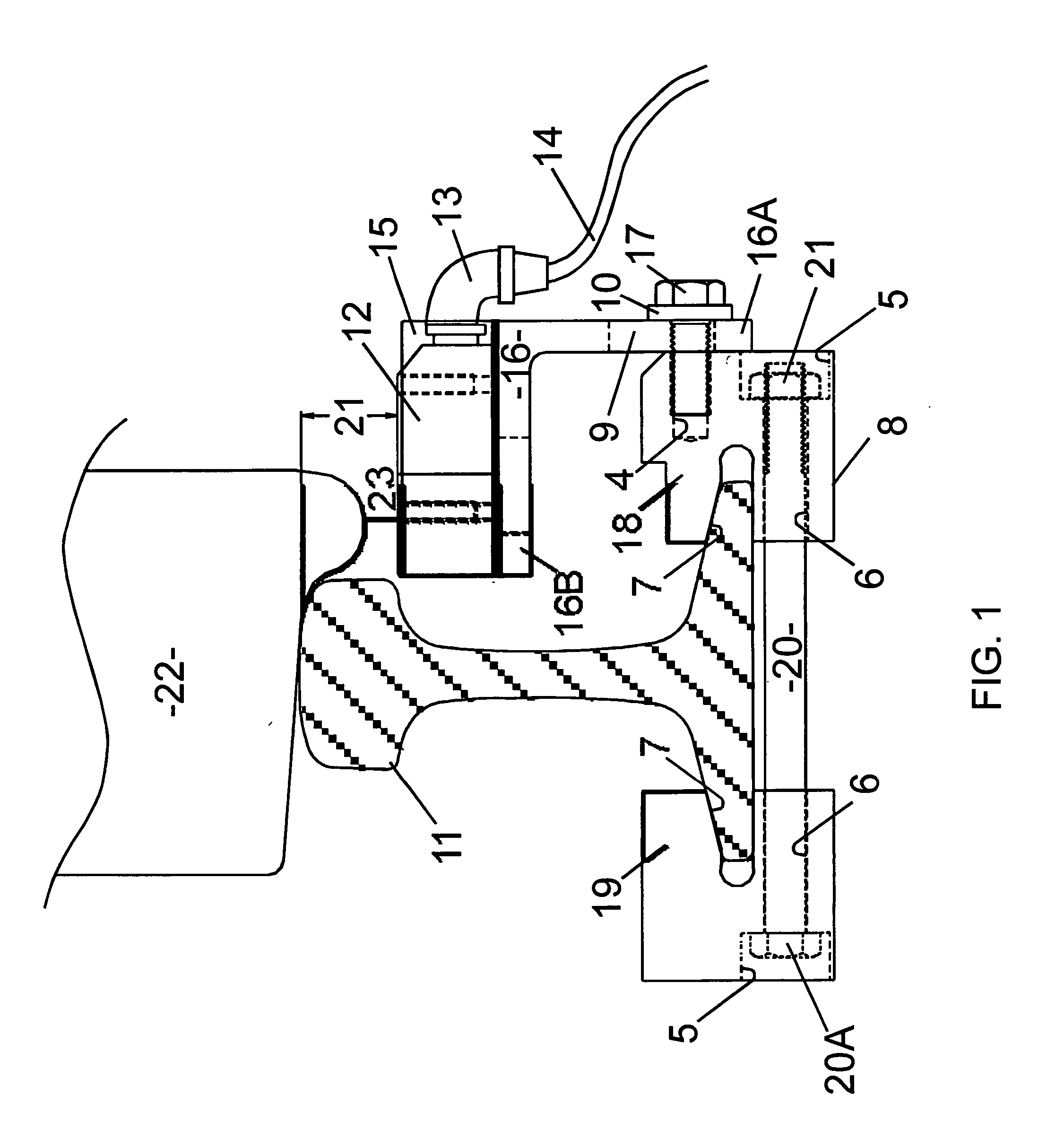

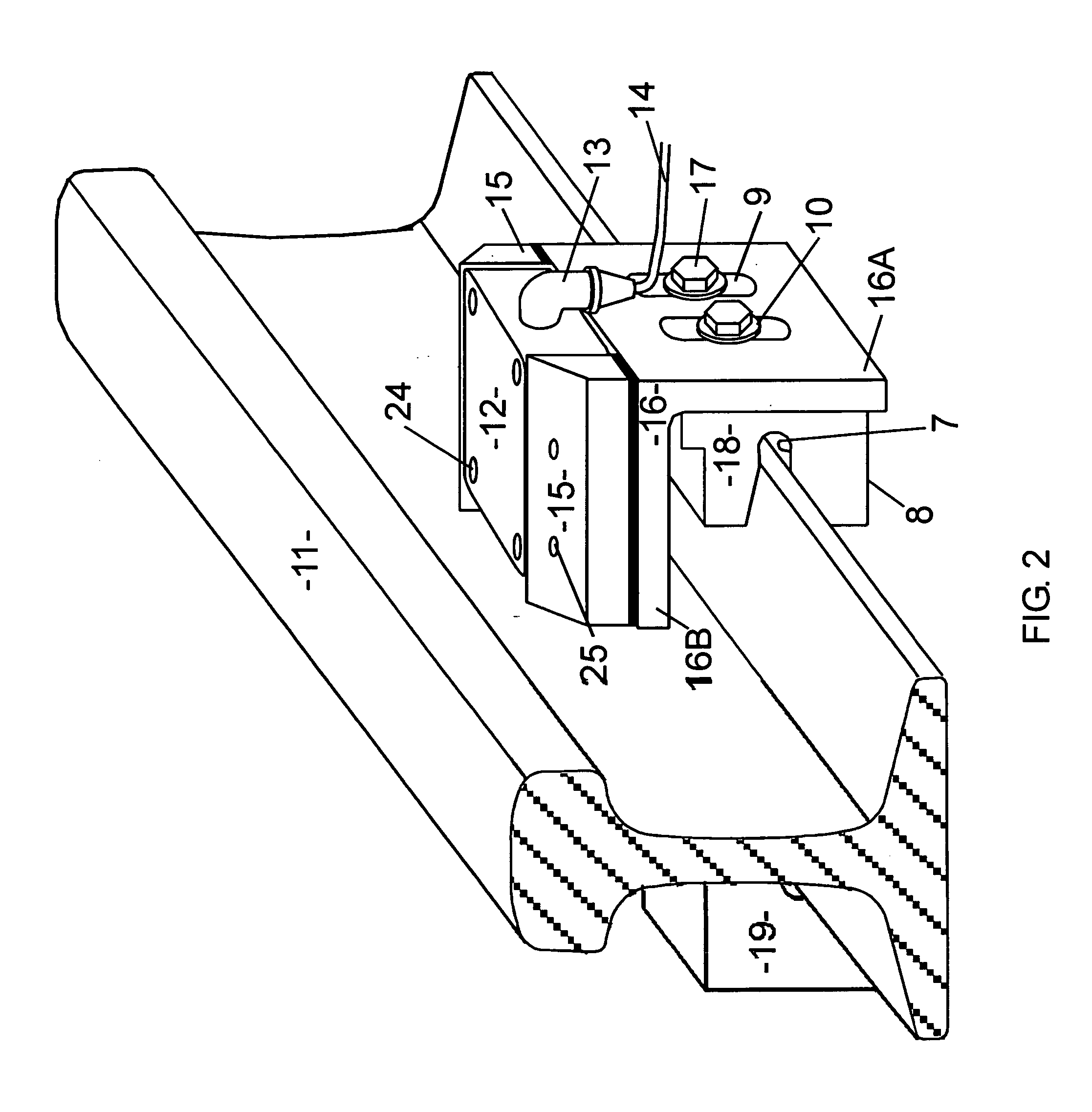

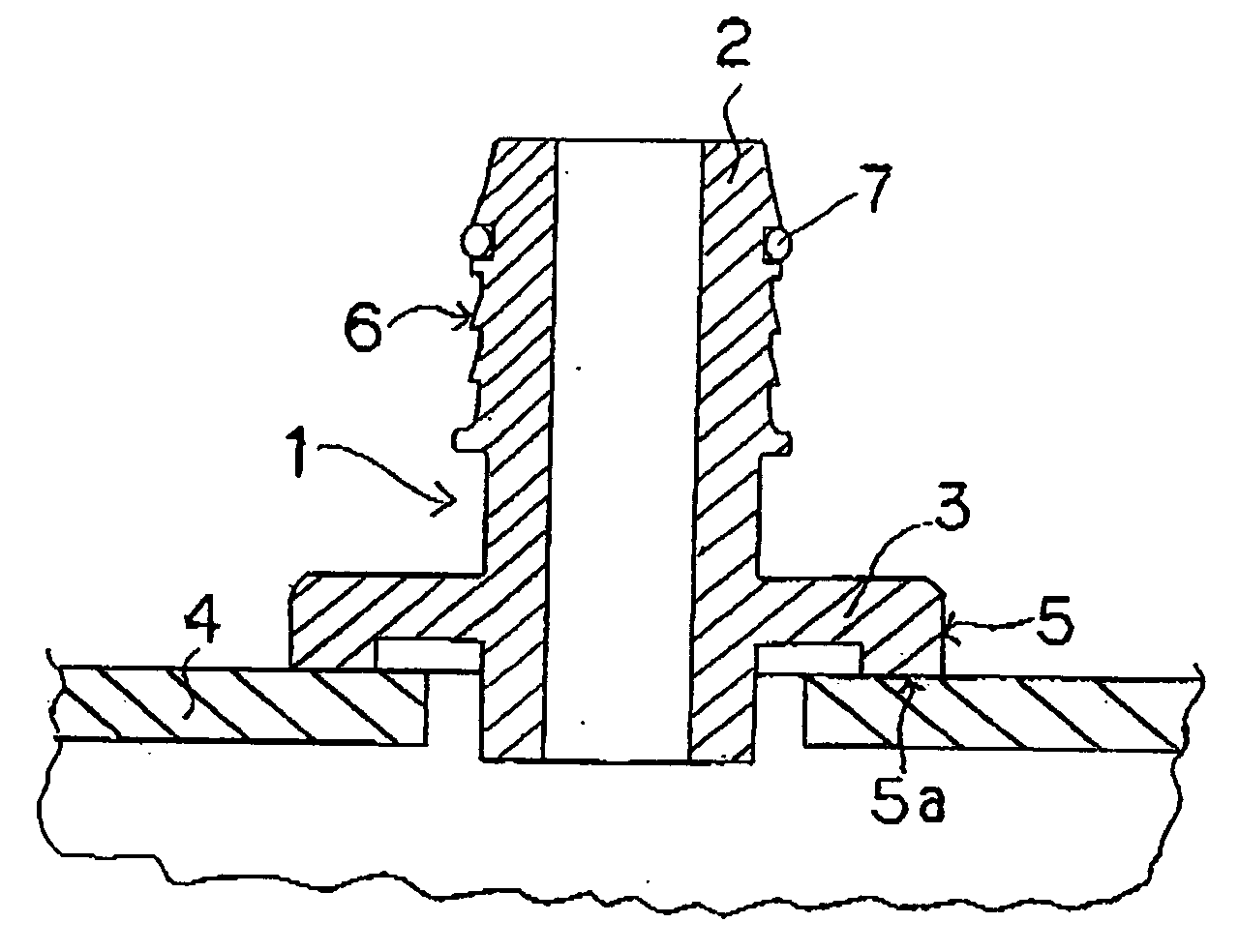

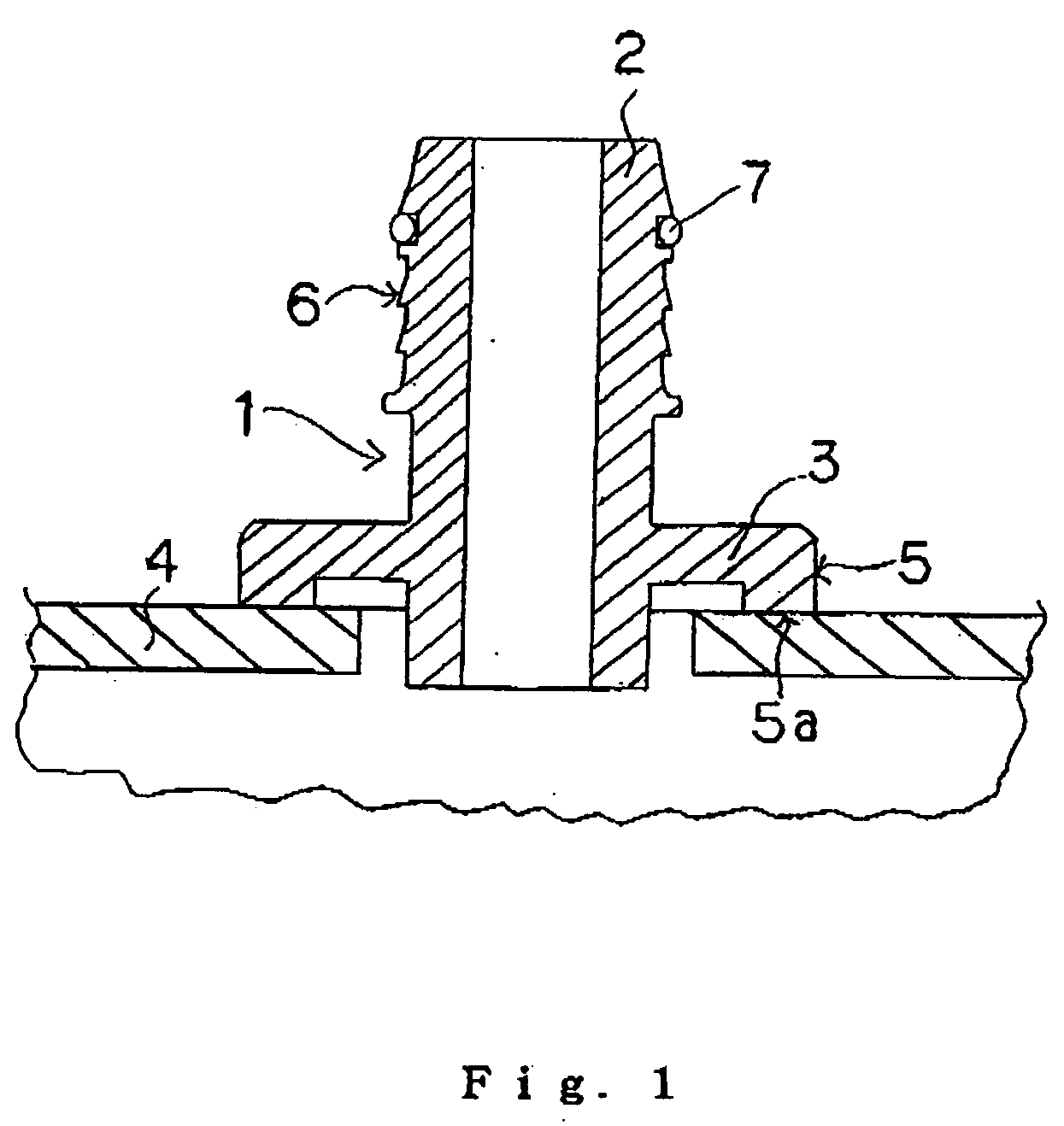

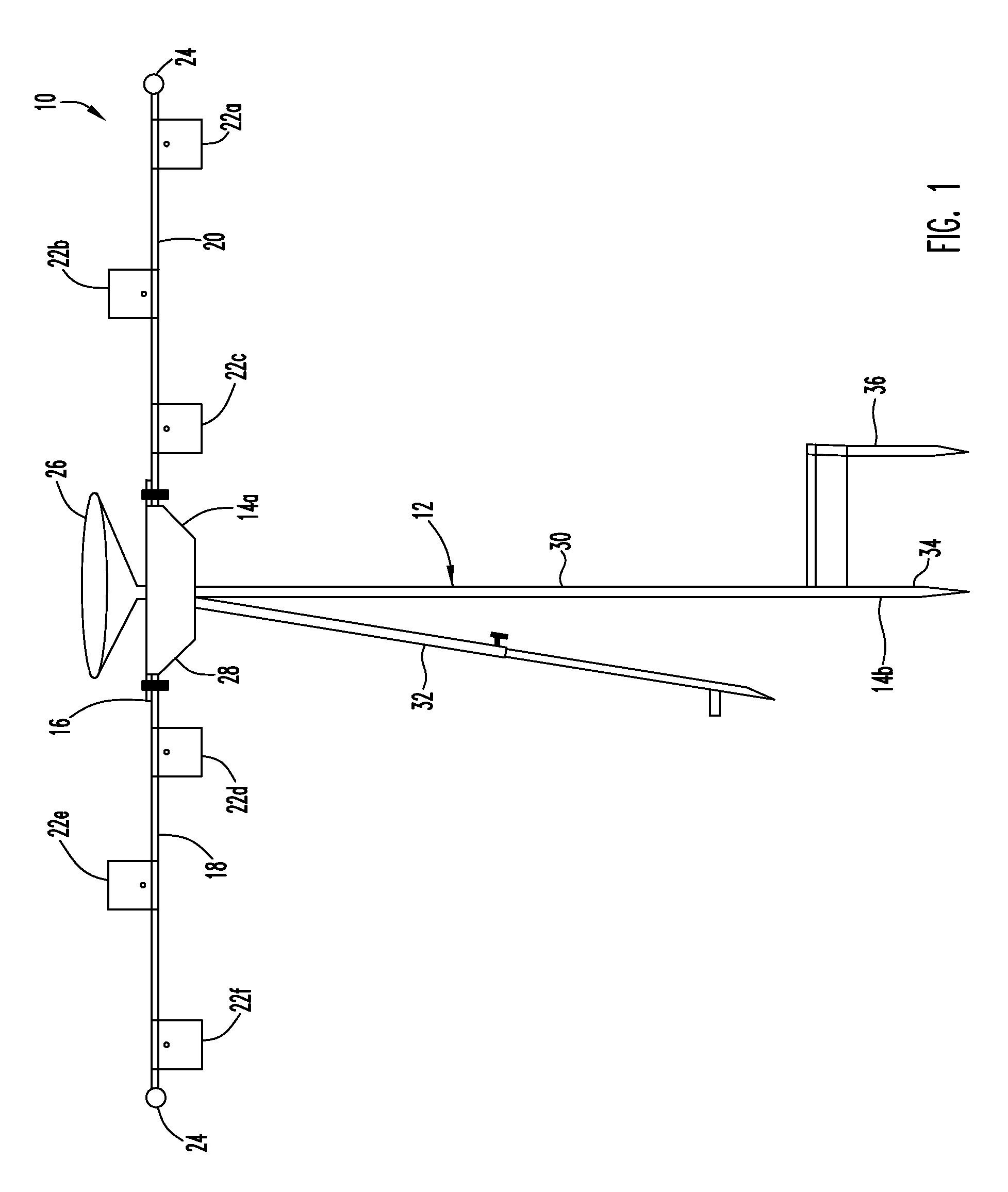

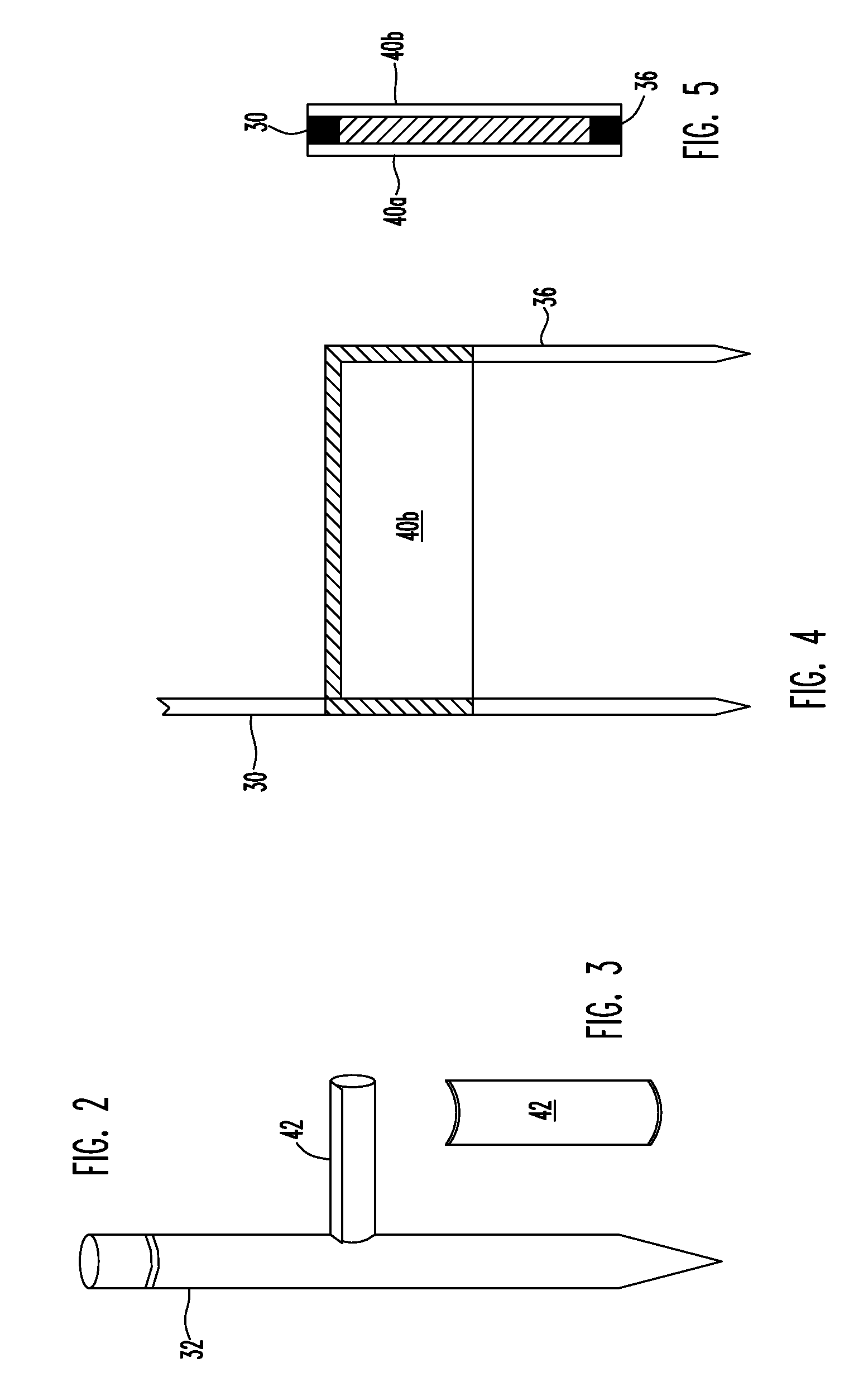

Wheel sensor assembly for rail base mounting

InactiveUS20050072252A1Easy to installLow priceVehicle route interaction devicesVehicle wheel testingMechanical engineeringSensing system

A rail-mounted, wheel-sensing system is shown having a wheel sensor and a rail mounting platform. The system includes a rugged steel rail clamp including two blocks mounted on the base of the rail by a pair of bolt extending under the rail. One block is connected to a vertically adjustable mounting bracket for carrying a sensor or other device. The mounting bracket includes a platform for the sensor. Two shields on the platform protecting a sensor mounted between them. An adapter plate may be added between the mounting bracket and the clamp for installation on lighter or heavier rails.

Owner:TRANERGY CORP

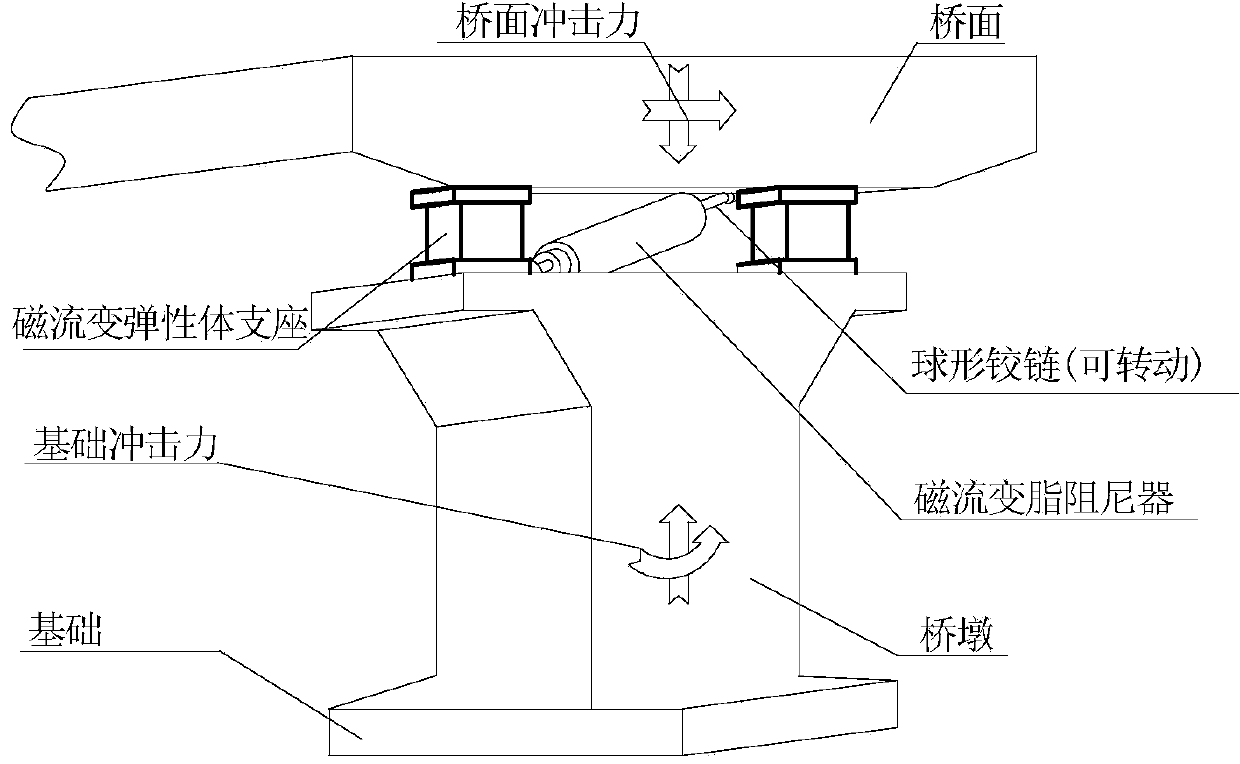

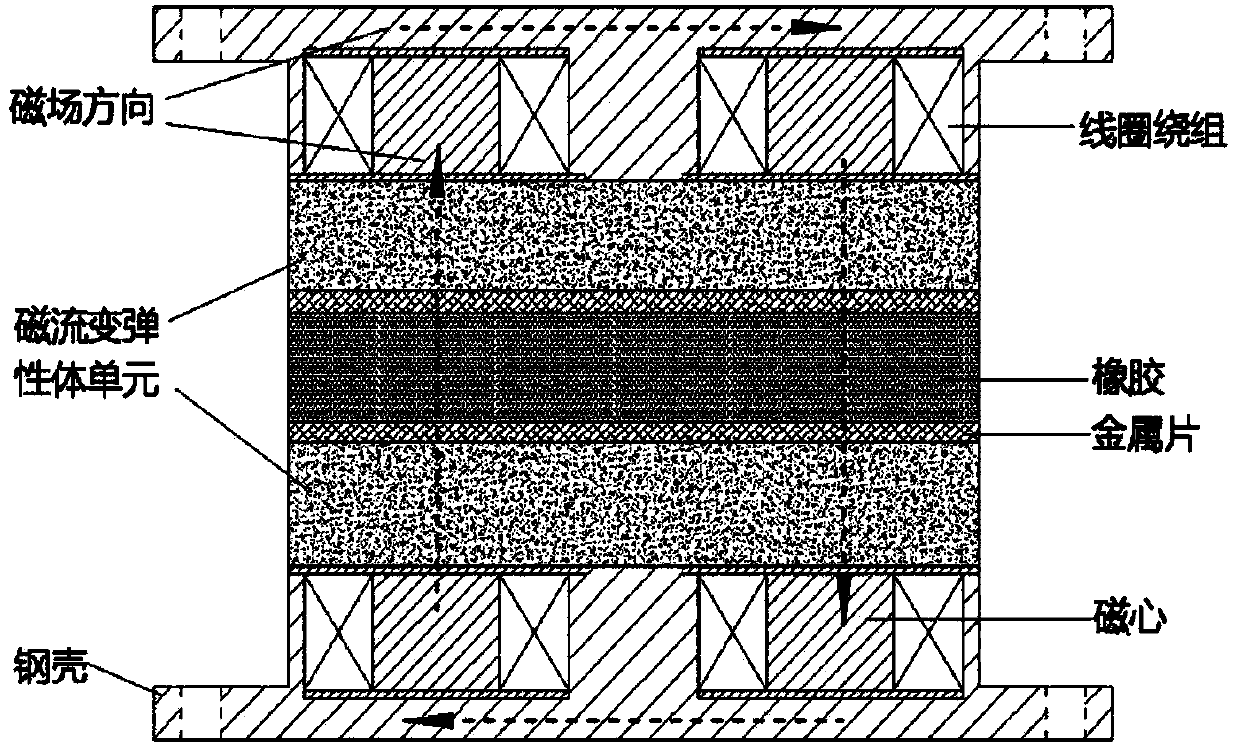

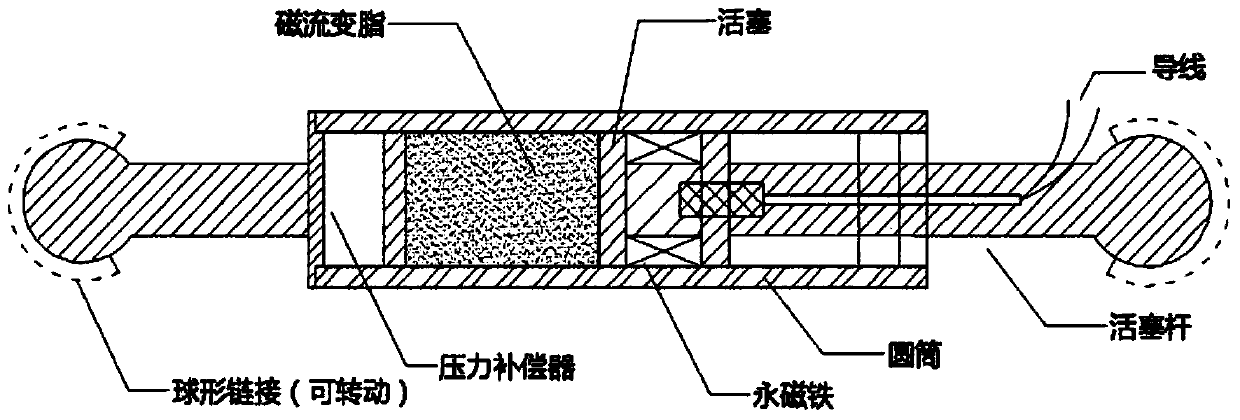

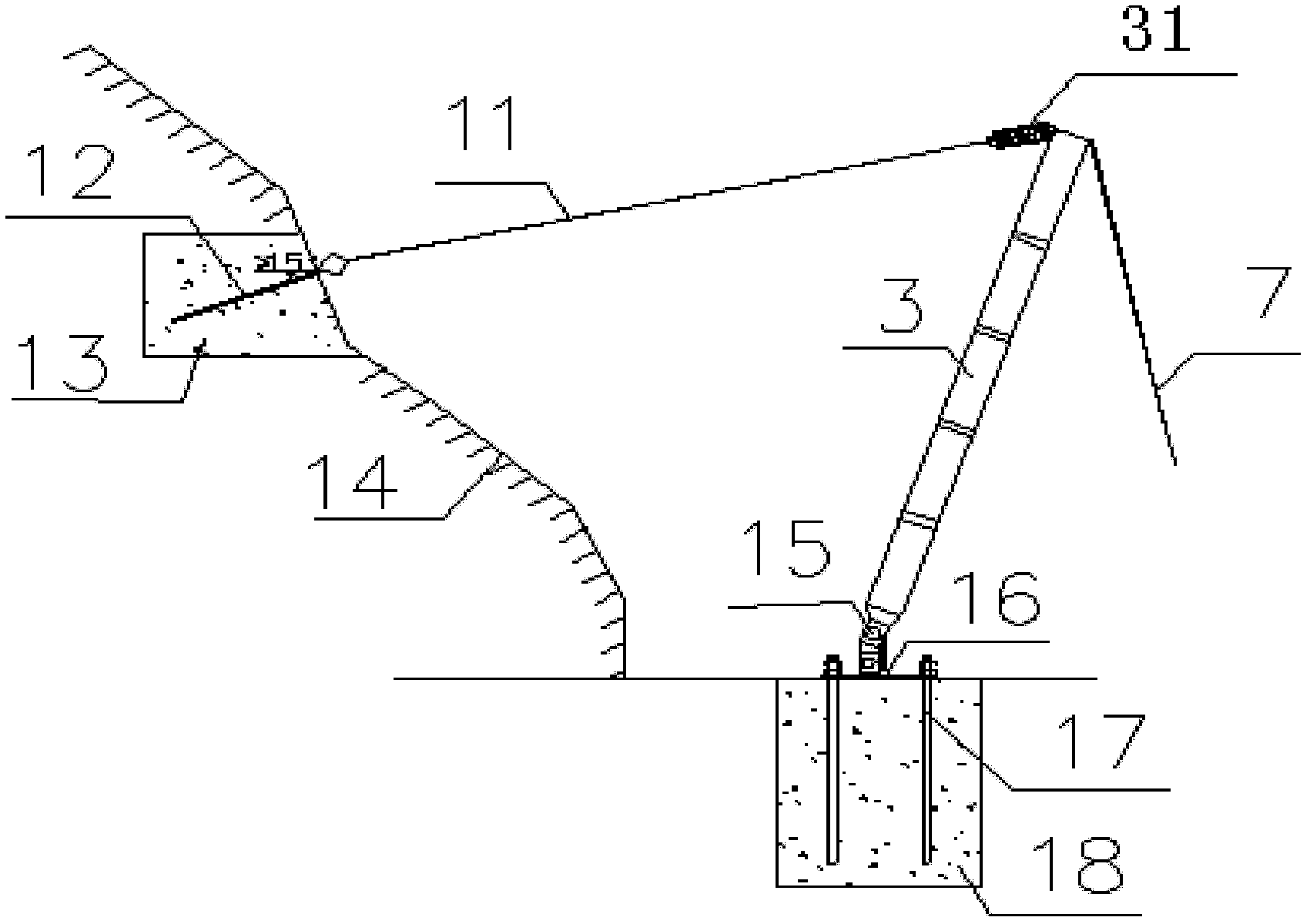

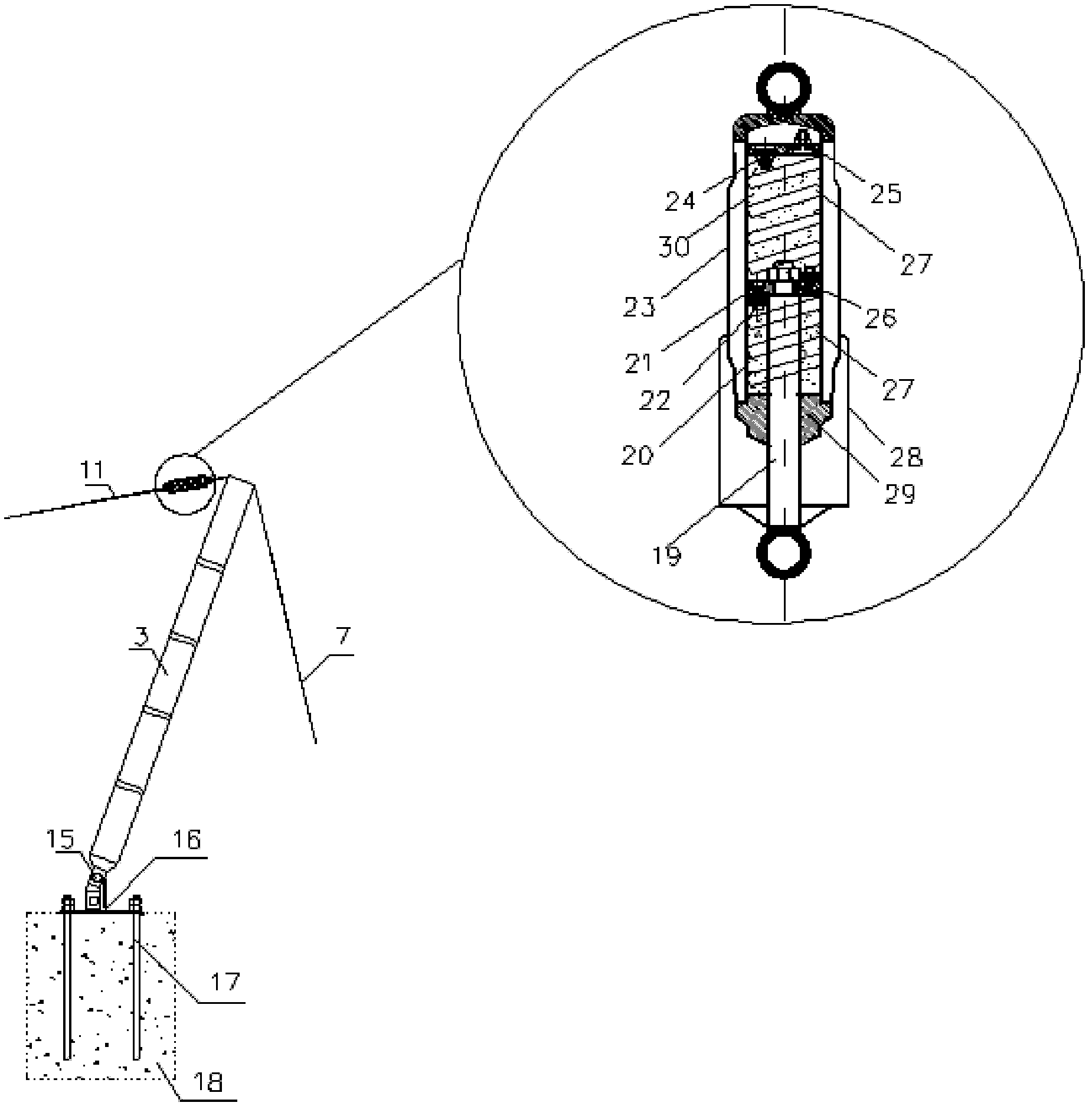

Design method and device of anti-impact vibration isolation type magnetorheological pier bearing-damper system

ActiveCN104179118AInhibition shiftEnhanced vertical strengthBridge structural detailsElastomerDamping ratio

The invention relates to a design method and a device of an anti-impact vibration isolation type magnetorheological pier bearing-damper system. According to the method, magnetorheological elastomers which are large in vertical stiffness, high in structural strength and adjustable in elasticity modulus are used as bearing bodies, and impact resistance and vibration isolation of a pier-beam structure under the action of large load are realized by adjustment of pier stiffness; a magnetorheological damper capable of providing large damping without medium settlement is used as a damping device, three-dimensional rotation capacity of the damper is improved by using a ball-and-socket joint mode at two ends thereof, and pier-beam displacement is restrained by damping adjustment for further vibration reduction and energy dissipation; magnetorheological elastomer bearings, the magnetorheological damper and a controller jointly form an anti-impact vibration-isolation pier bearing device, the controller intelligently adjusts stiffness and damping of the bearing-damper system by detecting the impact vibration of a bridge, structural strength of the pier-beam structure is improved while damping ratio thereof is increased, and when the bridge is under large-load impact vibration, impact transmission is slowed down or isolated and pier-bean displacement is restrained so as to guarantee structural safety of the bridge.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

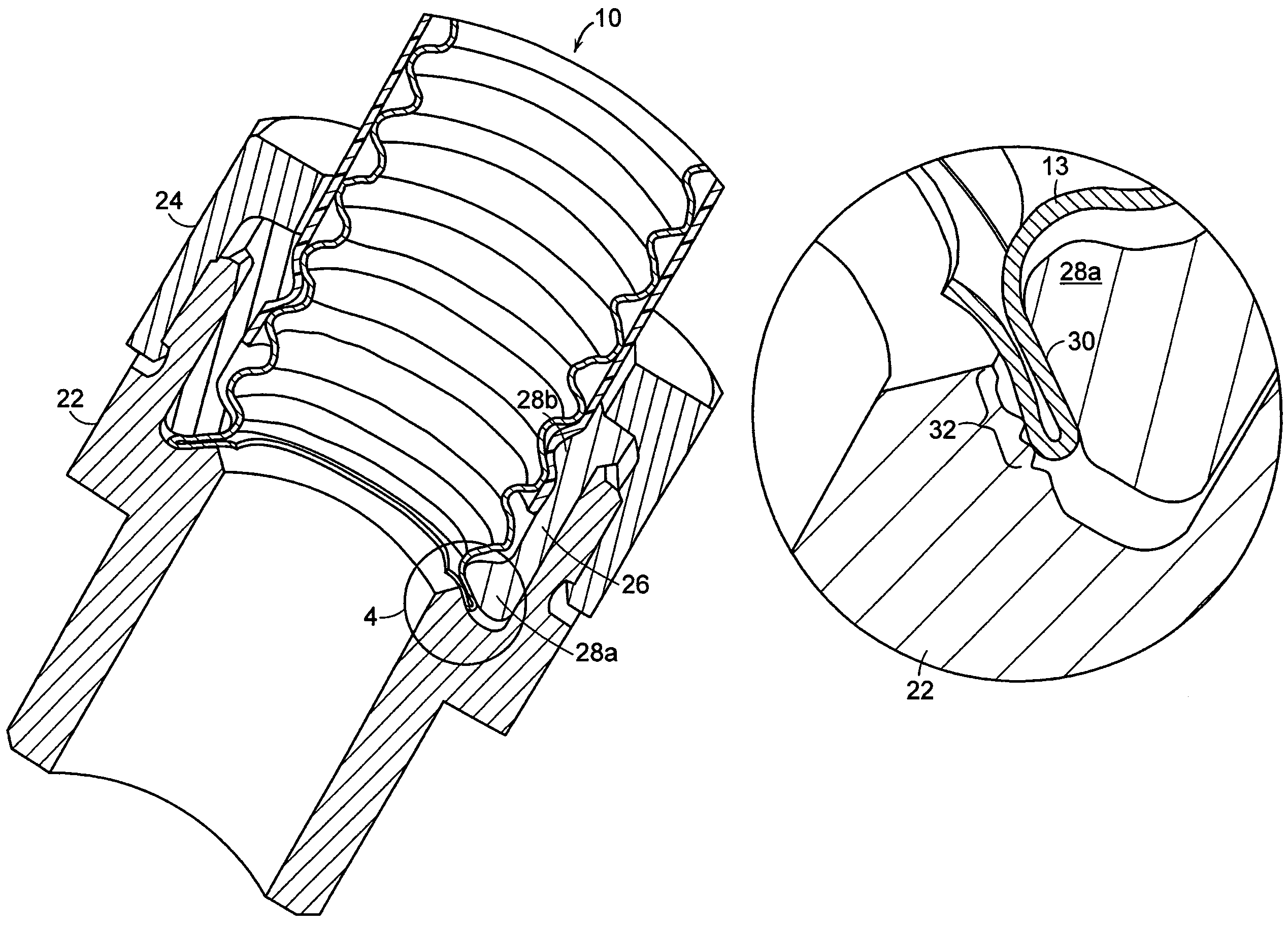

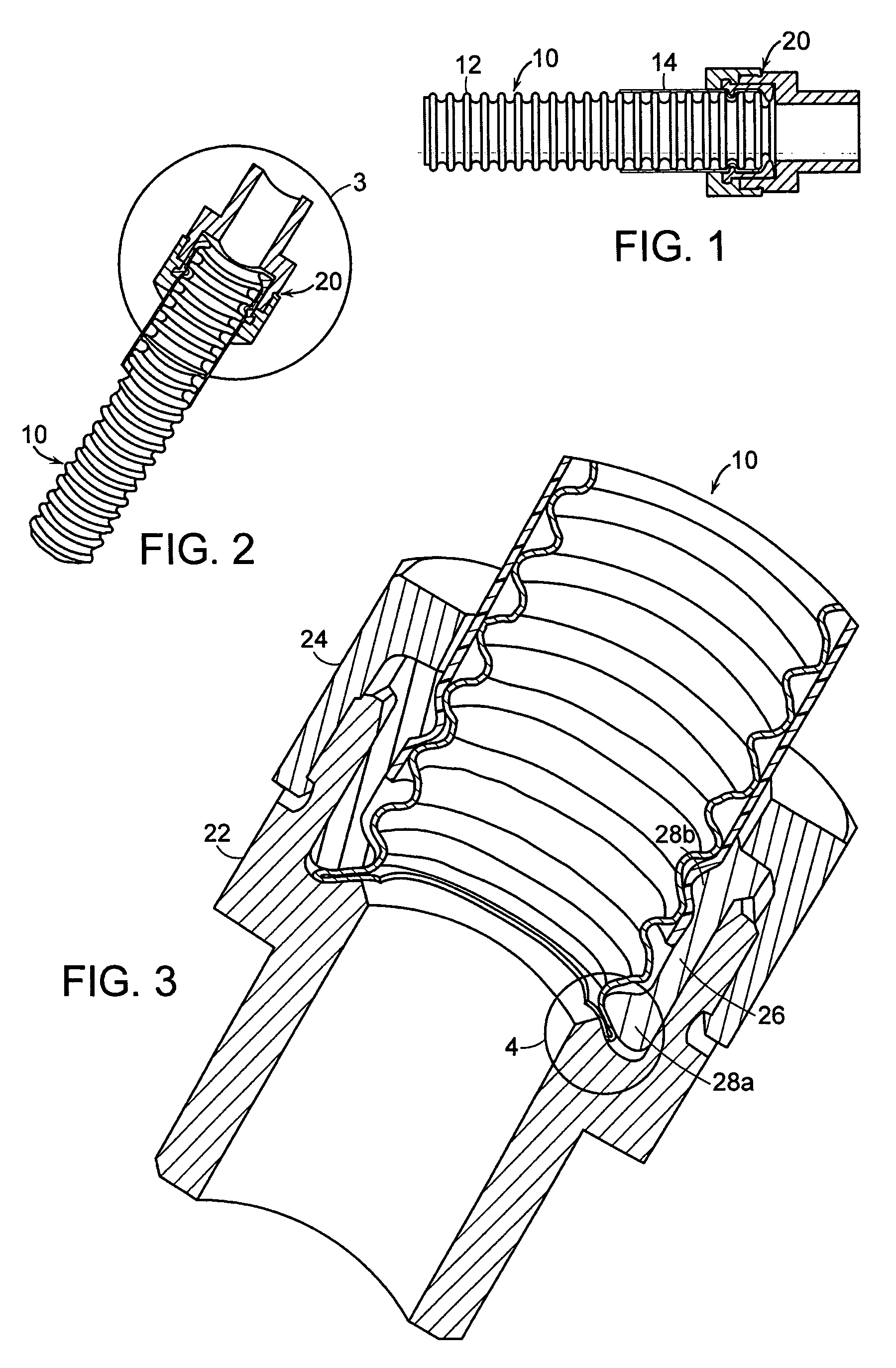

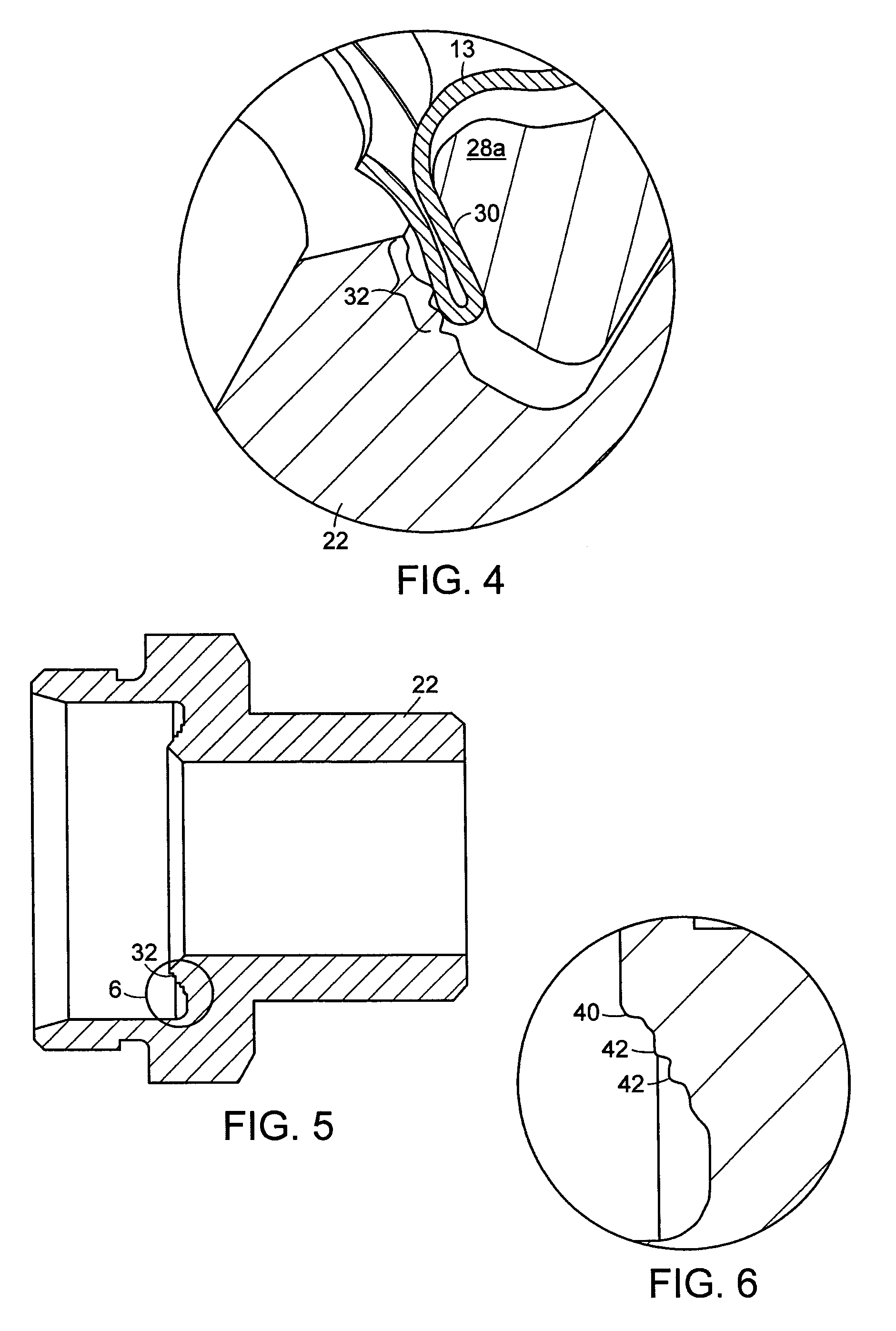

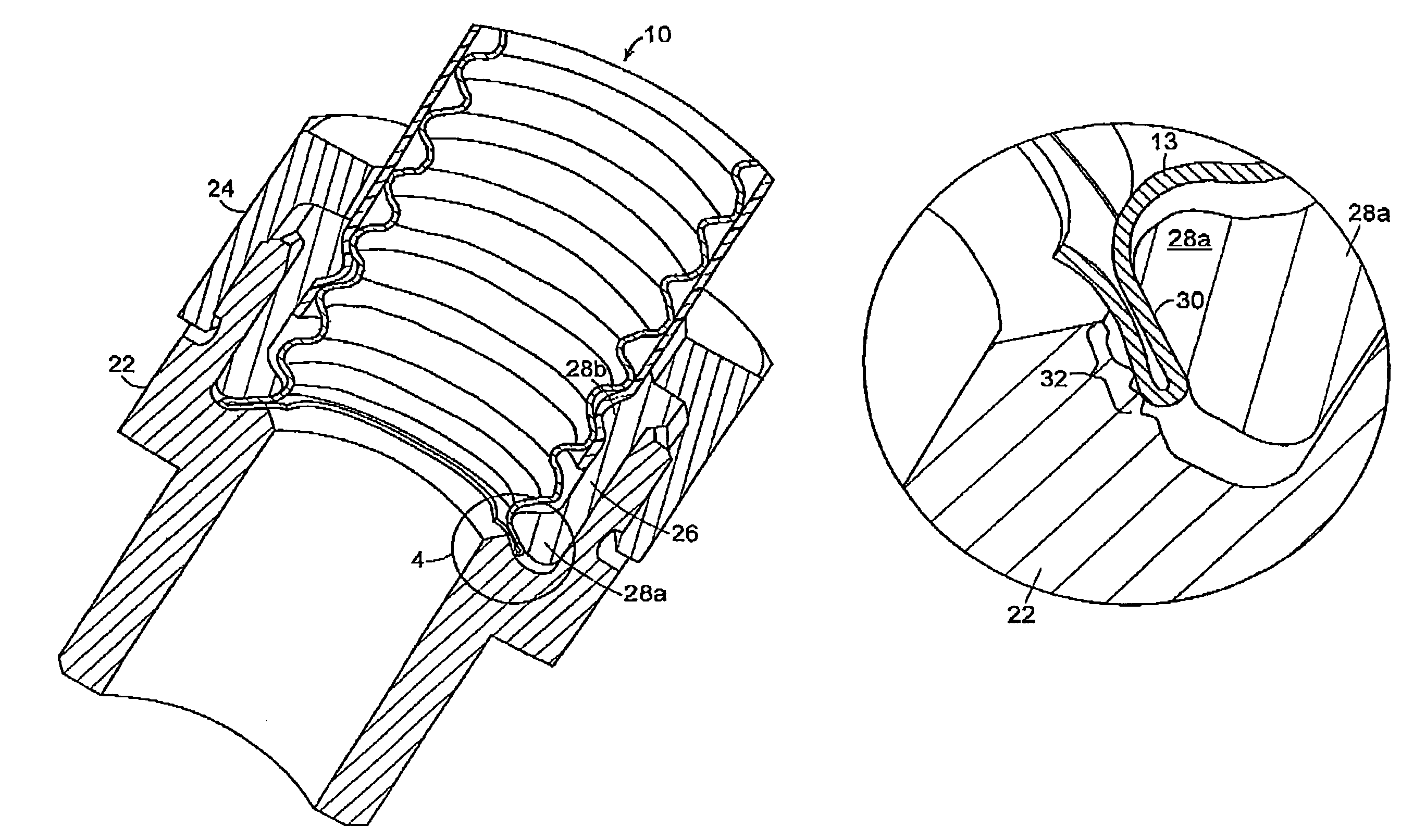

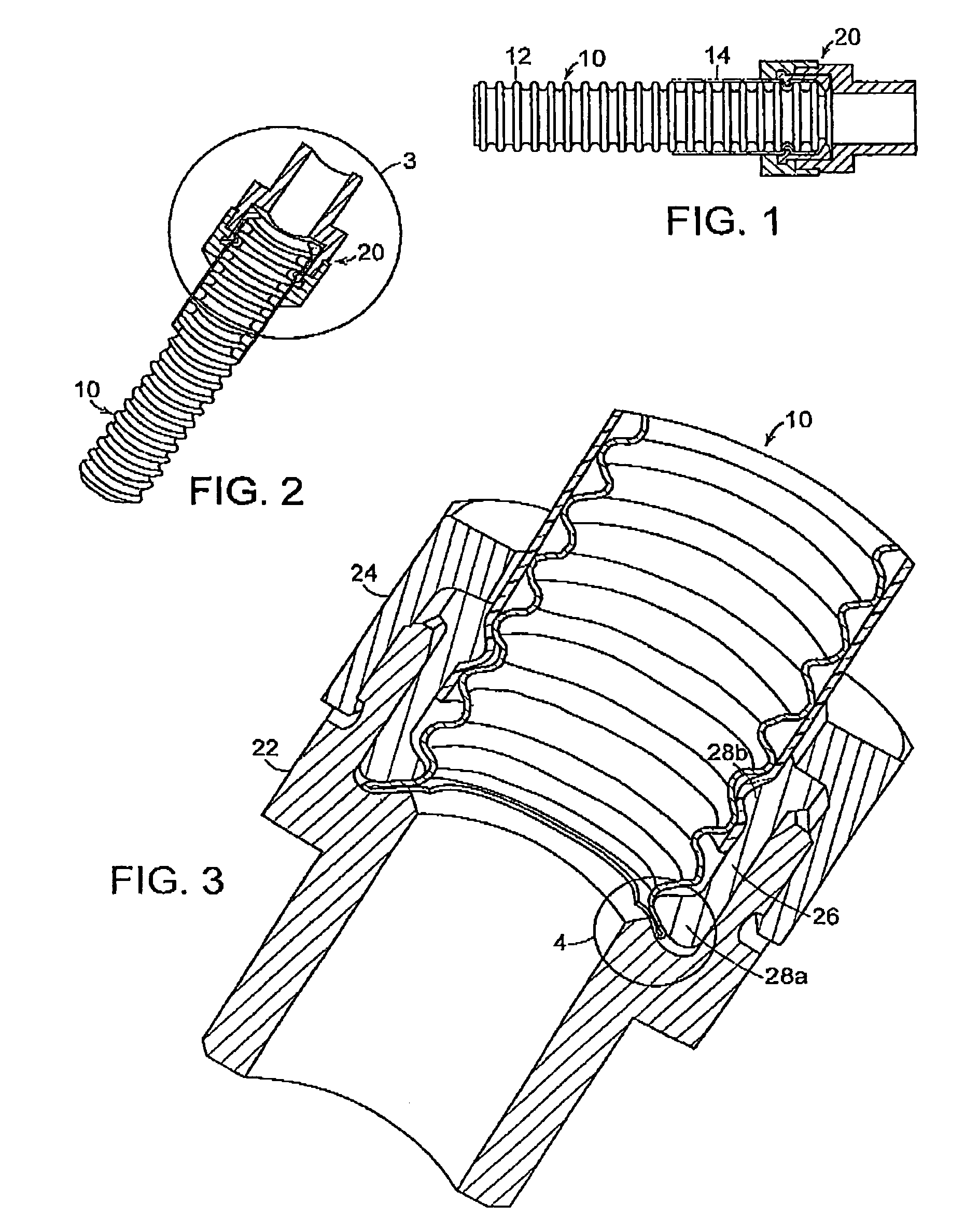

Sealing device with ridges for corrugated stainless steel tubing

ActiveUS7607700B2Avoiding durability and reliability problemImpact resistanceJoints with sealing surfacesPipe elementsEngineeringRidge

A sealing device and method for sealing a length of tubing with a fitting, where the sealing device includes at least one sealing surface formed with a plurality of ridges. The sealing device is particularly useful for sealing at least an end corrugation of tubing in a fitting used in gas and liquid piping systems. The fitting is sized to maintain a generally circular shape of the end corrugation after the corrugation is collapsed between the ridged sealing surface and another sealing surface. In particular, an inner diameter of one or more components of the fitting can be sized such that the corrugated tubing will have a circular profile to provide an optimal seal.

Owner:TITEFLEX

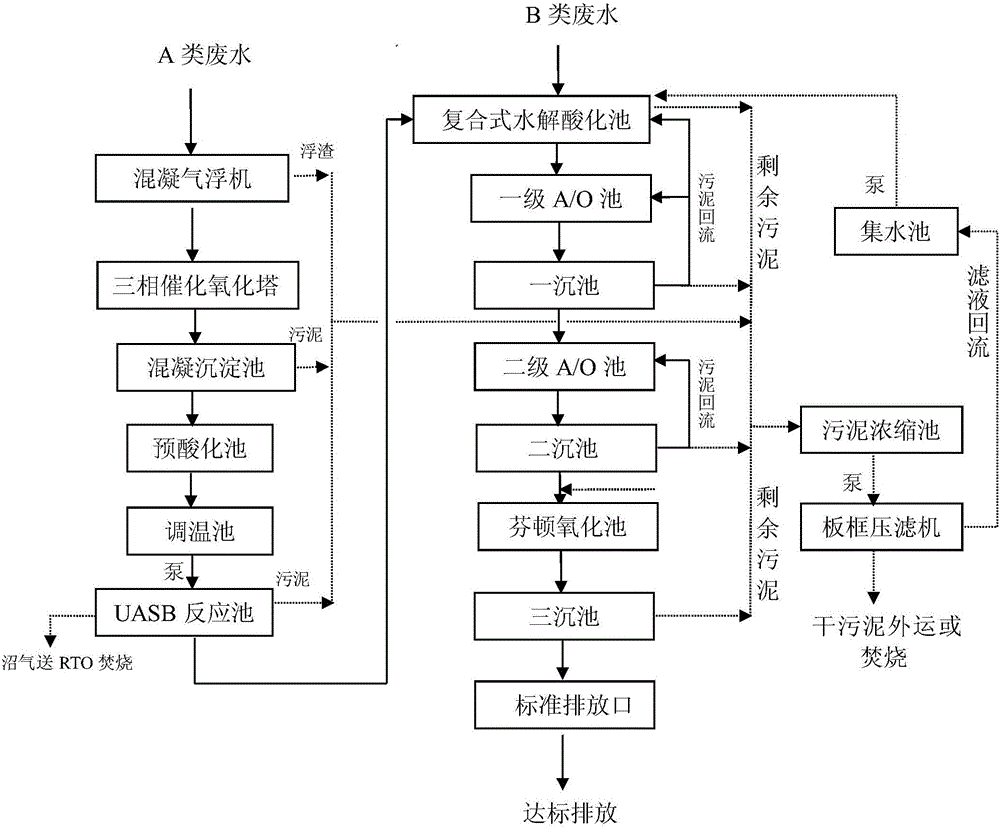

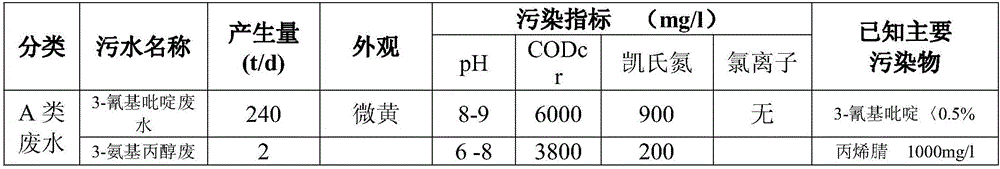

Pharmaceutical wastewater treatment process

ActiveCN106007221AHigh activityHigh removal rateSludge treatment by de-watering/drying/thickeningWater treatment parameter controlCatalytic oxidationHydrolysis

The invention relates to the technical field of wastewater treatment, and discloses a pharmaceutical wastewater treatment process which comprises steps: preforming wastewater pre-treatment and comprehensive treatment, pumping wastewater into a coagulation gas floatation clarifier, adding polyaluminum chloride and polyacrylamide in a water input pipeline through a coagulation medicine adding system, then enabling mixed wastewater to enter a three-phase catalytic oxidation tower, a coagulative precipitation tank, a pre-acidification pool, a thermoregulation pool, a UASB reaction pool and a combined type hydrolysis acidification pool sequentially, subjecting the mixed wastewater to hydrolysis acidification, enabling the wastewater to enter a primary A / O pool, a primary precipitation pool, a secondary A / O pool, a secondary precipitation pool, a Fenton oxidation pool and a tertiary precipitation pool sequentially, and discharging standard outlet water from a standard discharging opening. The process has the advantages of stable running effect, high ammonium-nitrogen removal rate, and low running cost, thereby being suitable for treatment of wastewater, which is refractory to degrade, in the pharmaceutical industry.

Owner:ZHEJIANG HUANYAO ENVIRONMENTAL CONSTR

Joint part for resin fuel tank and manufacturing method thereof

InactiveUS20060099365A1Low fuel permeabilityImprove weld strengthSynthetic resin layered productsBranching pipesMaleic anhydrideHigh-density polyethylene

Owner:TOKAI RUBBER IND LTD

Corrugated tube fitting with a ridge sealing device and method

ActiveUS7621567B2Avoiding durability and reliability problemImpact resistanceJoints with sealing surfacesHose connectionsStress concentrationEngineering

Owner:TITEFLEX

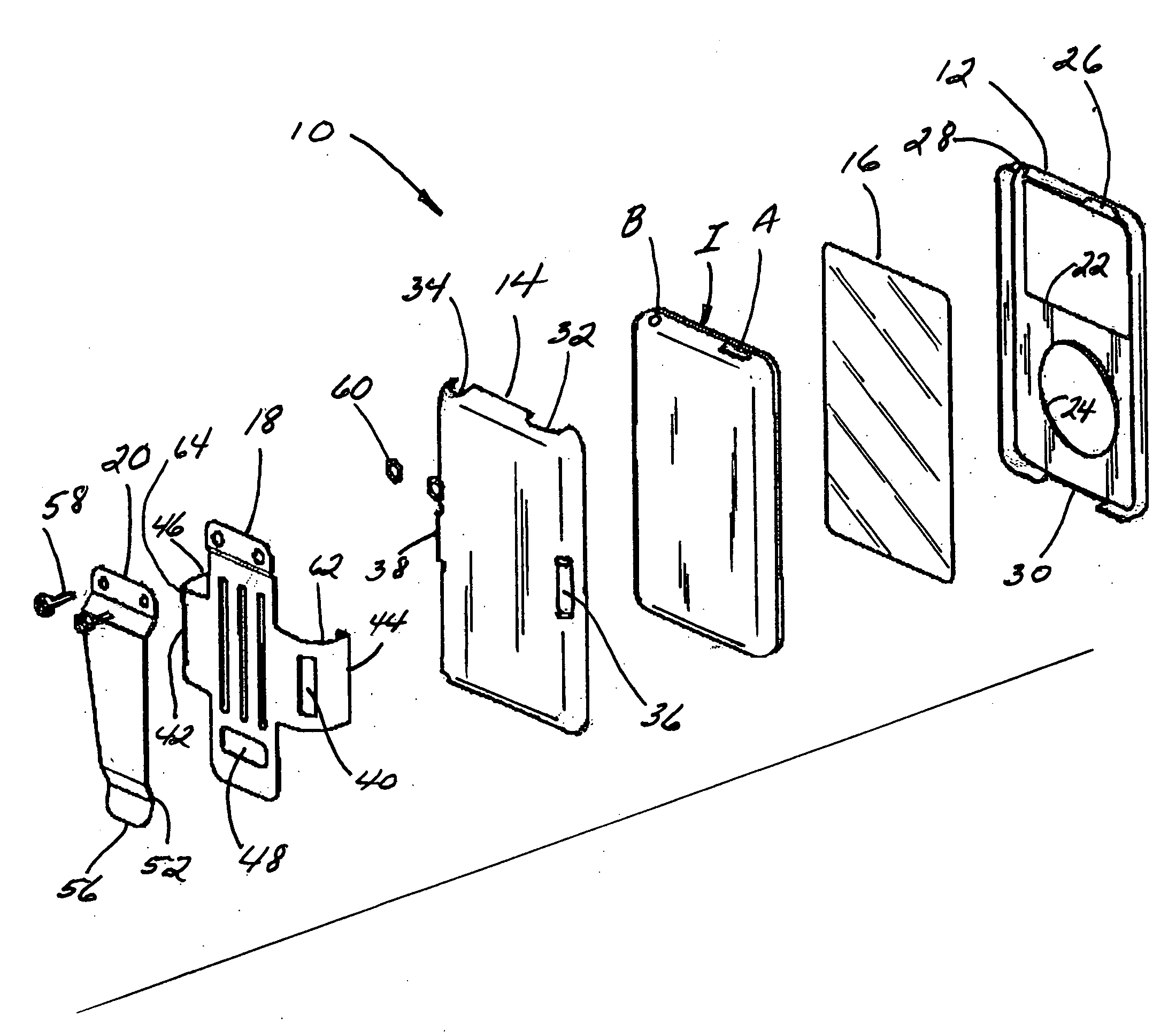

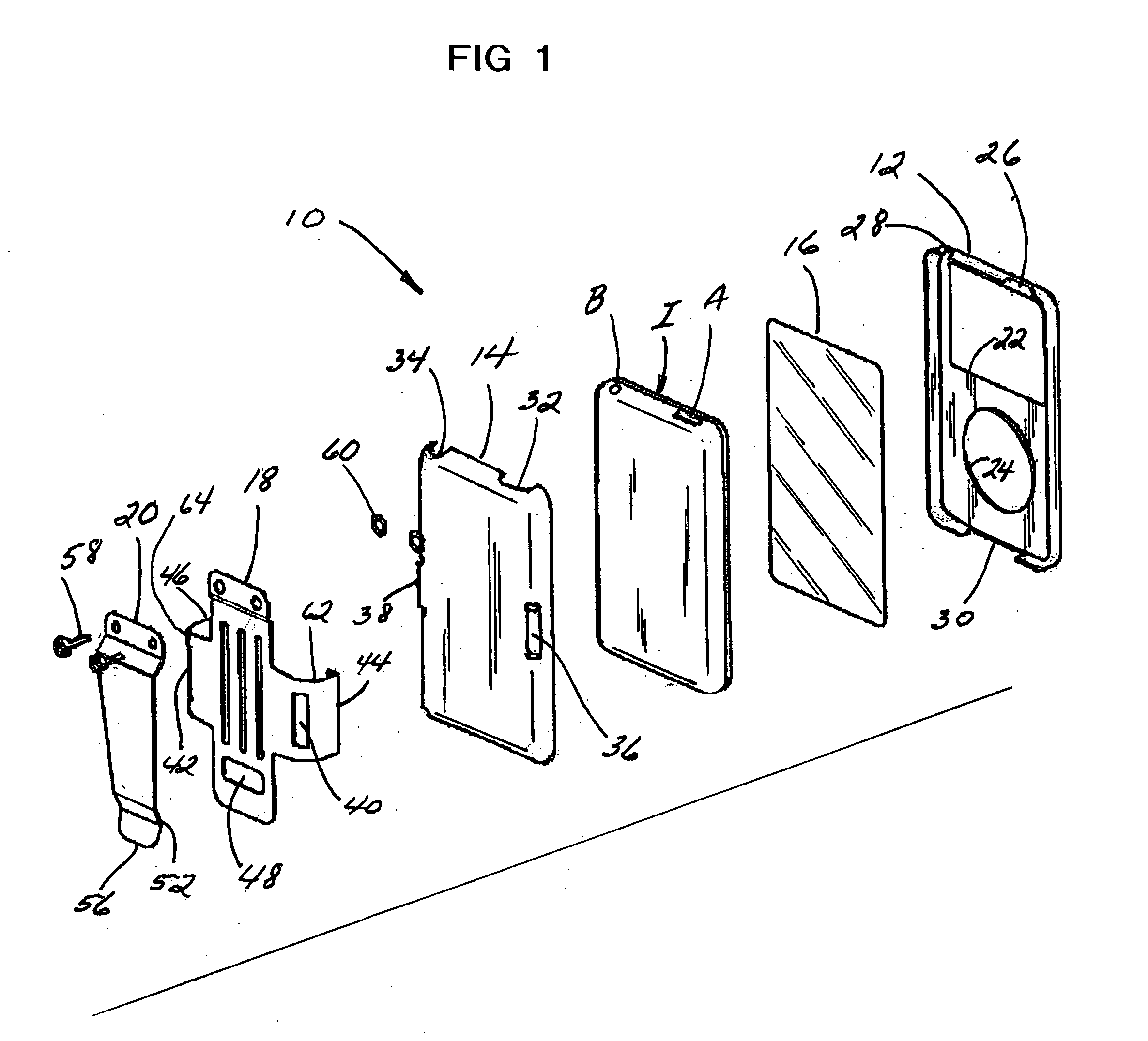

Protective enclosure for personal electronic devices

InactiveUS20090059481A1Easily interchangeable protectiveGood adhesionDigital data processing detailsSupport structure mountingThin metalSmall hand

A protective enclosure for a small hand or body carryable personal electronic devices such as a well-known IPOD or IPHONE. A two-part generally rectangular housing includes front and back covers formed of high-impact thin-wall molded material and sized to protectively fit together along mating edges around the electronic device. Access openings are preferably provided for the viewing screen, control wheel, touch screen, battery charger, car phone plug-in, and docking port of the electronic device. A device clip formed of thin metal material having laterally extending retaining arms biasingly engage around opposing edges of front and back covers to hold them together against the front and back of the device. A belt clip may be connected to one end of the device clip adapted for releasable attachment to a clothing article.

Owner:TAYLOR ALAN R

Adhesion promotion in printed circuit boards

InactiveUS7232478B2Increase capacityHigh peel strengthInsulating substrate metal adhesion improvementSolid state diffusion coatingAlcoholCopper

An adhesion promotion process and composition for enhancing adhesion between a copper conducting layer and a dielectric material during manufacture of a printed circuit board. The composition contains a corrosion inhibitor, an inorganic acid, and an alcohol which is effective to increase copper-loading in the composition.

Owner:MACDERMID ENTHONE INC

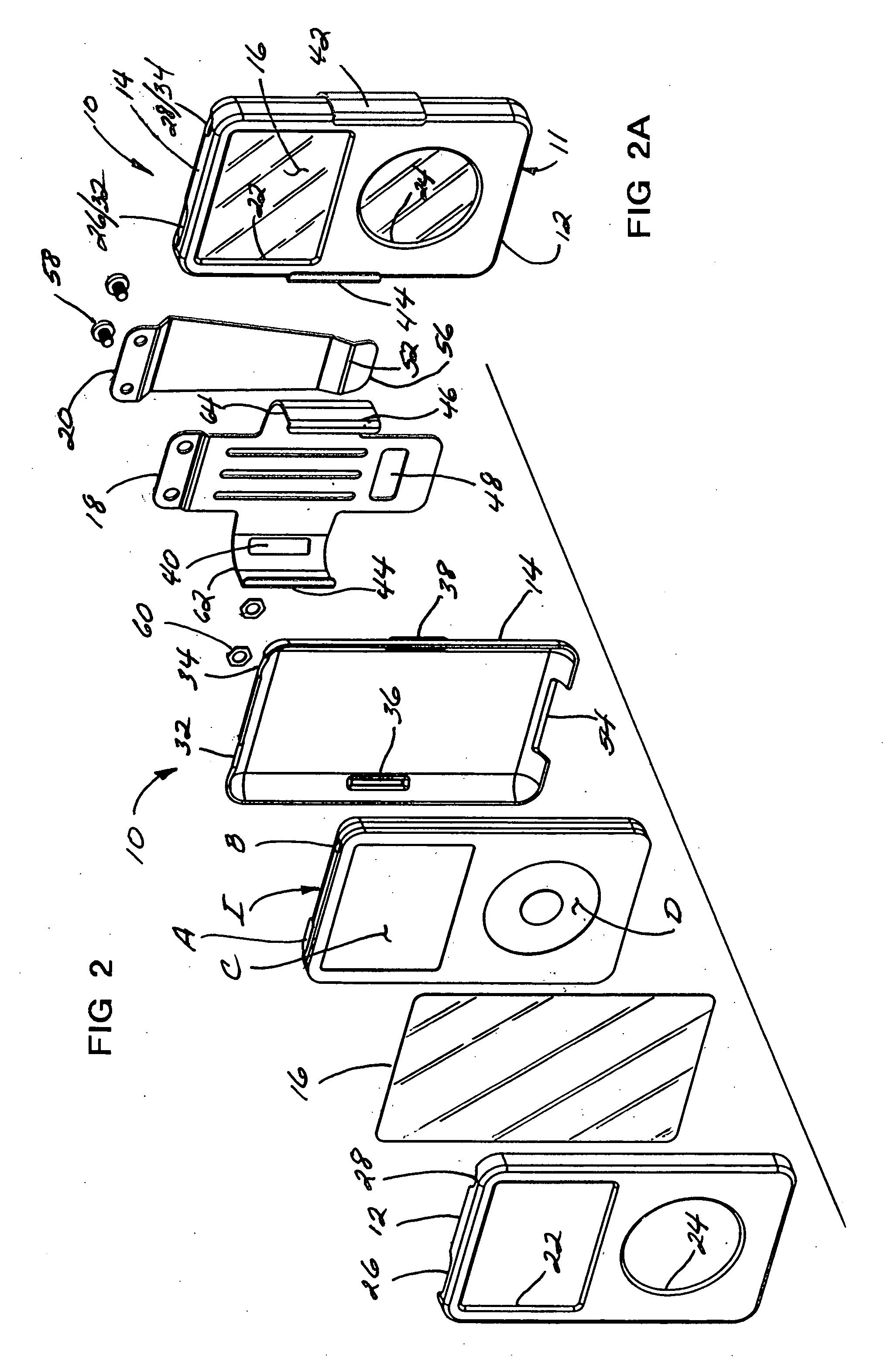

Anodic sacrifice protection method of steel reinforced concrete bridge pier

InactiveCN101109087AEasy to installImprove protectionBridge structural detailsRebarElectrically conductive

The utility model relates to an abandon-anode-protection method in the technical field of anti-corrosion for metals in reinforced concrete structures in marine environment, in particular to an abandon-anode-protection method for reinforced concrete in an area with tide difference and wave splashing. The main structure includes a terminal box, an extended anode, an electric connecting wire, a composite sheath, a metallic fastener, a sheath-connecting slot, an under-water abandon anode, a reinforced concrete bridge pier, rebars, fixing parts, extended-anode connector, electrically conductive cement mortar filler, conductive connectors and under-water fixers. The rebars in the concrete are fixedly connected with the conductive connectors at one end of the abandon anode; the electrically conductive cement mortar filler fixes the extended anode on the surface to be protected; the under-water abandon anode is fixed by steel strip or angle steel, and is electrically connected with the rebars in the concrete. The abandon-anode-protection method for reinforced concrete in an area with tide difference and wave splashing is characterized by no maintenance, easy installation, is helpful for after-stage replacing and re-protection, and will not influence the service life or operation of the reinforced concrete structures.

Owner:SUNRUI MARINE ENVIRONMENT ENG

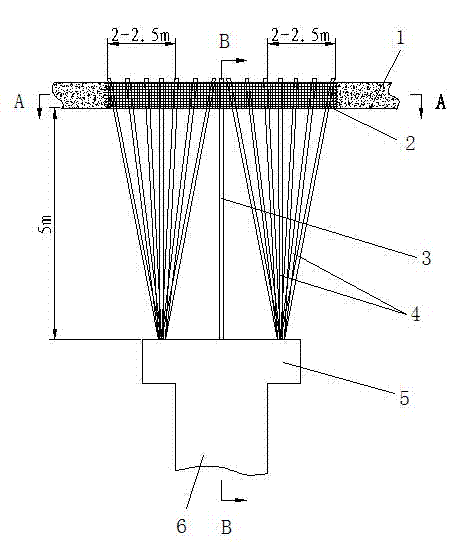

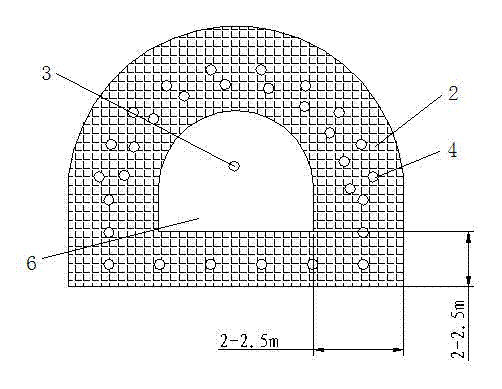

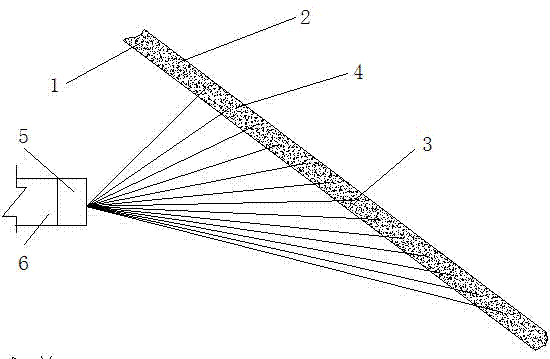

Hydraulic fracturing and grouting solidification combined rock cross-cut coal uncovering method

The invention discloses a hydraulic fracturing and grouting solidification combined rock cross-cut coal uncovering method which includes that when roadway drivage reaches a 10m coal layer vertical distance, fracturing holes of a coal layer are drilled, the coal layer is subjected to hydraulic fracturing, and the water injection amount reaches the preset value after above 3MPa pressure drop appears in fracturing; a plurality of grouting holes are drilled when the roadway drivage reaches a 5m coal layer vertical distance; coal layer methane gases are extracted through the fracturing holes and the grouting holes; the coal layer is subjected to quantitative grouting through the grouting holes with grouting pressure to be above 15MPa; and roadway drivage is continued after grouting solidification, and rock cross-cut coal uncovering is completed. Single hole grouting amount includes grouting hole grouting amount M1 and coal layer permeation grouting amount M2 and is calculated according to M=M1+M2=rho*eta / K *(pi*D<2> / 4 *L +pir<2>*l*P)*10<-6>, wherein rho is a grouting density, eta is a storage coefficient, K is a grouting foaming expansion rate, D is a drilling diameter, L is grouting hole length, r is a penetration radius of slurry in the coal layer, l is length of the grouting holes in the coal layer and p is a coal layer porosity. The hydraulic fracturing and grouting solidification combined rock cross-cut coal uncovering method has the advantages of being capable of fast and safely performing rock cross-cut coal uncovering, avoiding re-handling, and improving social benefit.

Owner:重庆市能源投资集团科技有限责任公司 +1

Portable target rack

InactiveUS7338048B1Impact resistanceEasy to disassembleTarget rangesMovable targetsEngineeringMechanical engineering

Owner:HULSTINE DAVID W

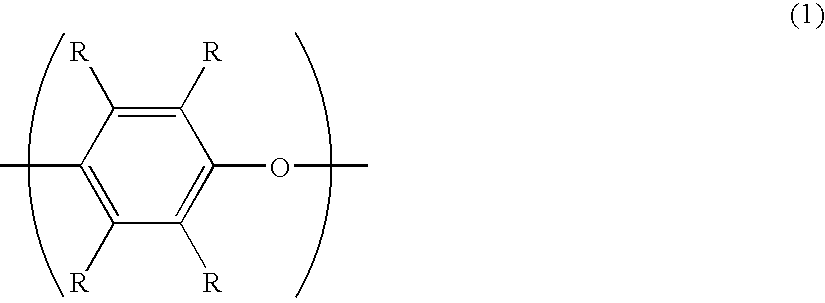

Resin Composition Having Excellent Heat Resistance

InactiveUS20090029138A1Impact resistance can be maintained without a deterioration in fluidityImprove heat resistanceSynthetic resin layered productsConductive materialPolymer sciencePolyamide

Disclosed is a resin composition comprising 10 to 90 parts by weight of a mixture of two or more aromatic polyamides having different intrinsic viscosities [η] and 90 to 10 parts by weight of a polyphenylene ether, both relative to 100 parts by weight of the sum total of the aromatic polyamides and the polyphenylene ether. The resin composition is extremely useful for an automotive exterior panel (e.g., a car fender), an SMT-compatible part, a lamp-related part, and the like.

Owner:ASAHI KASEI CHEM CORP

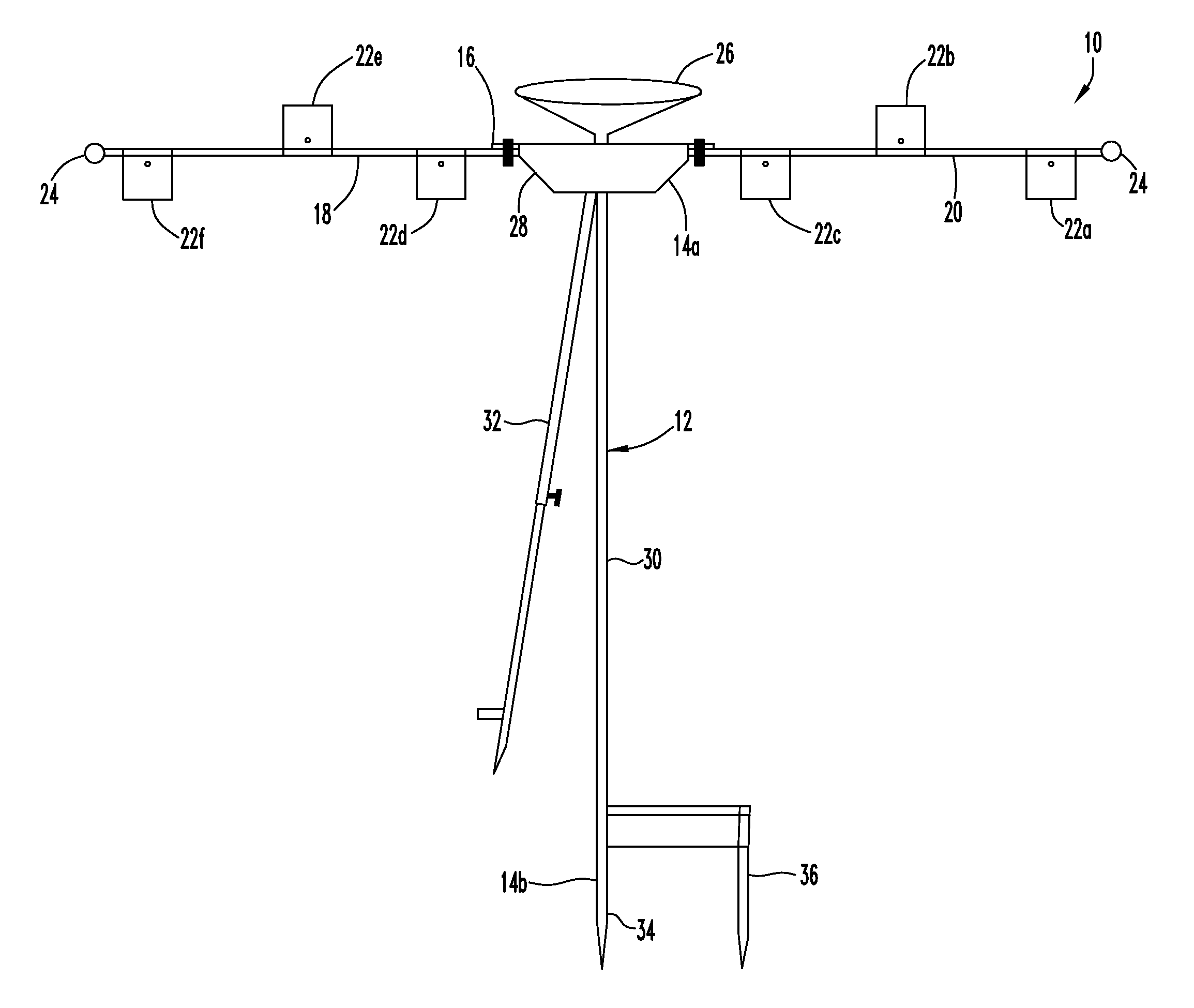

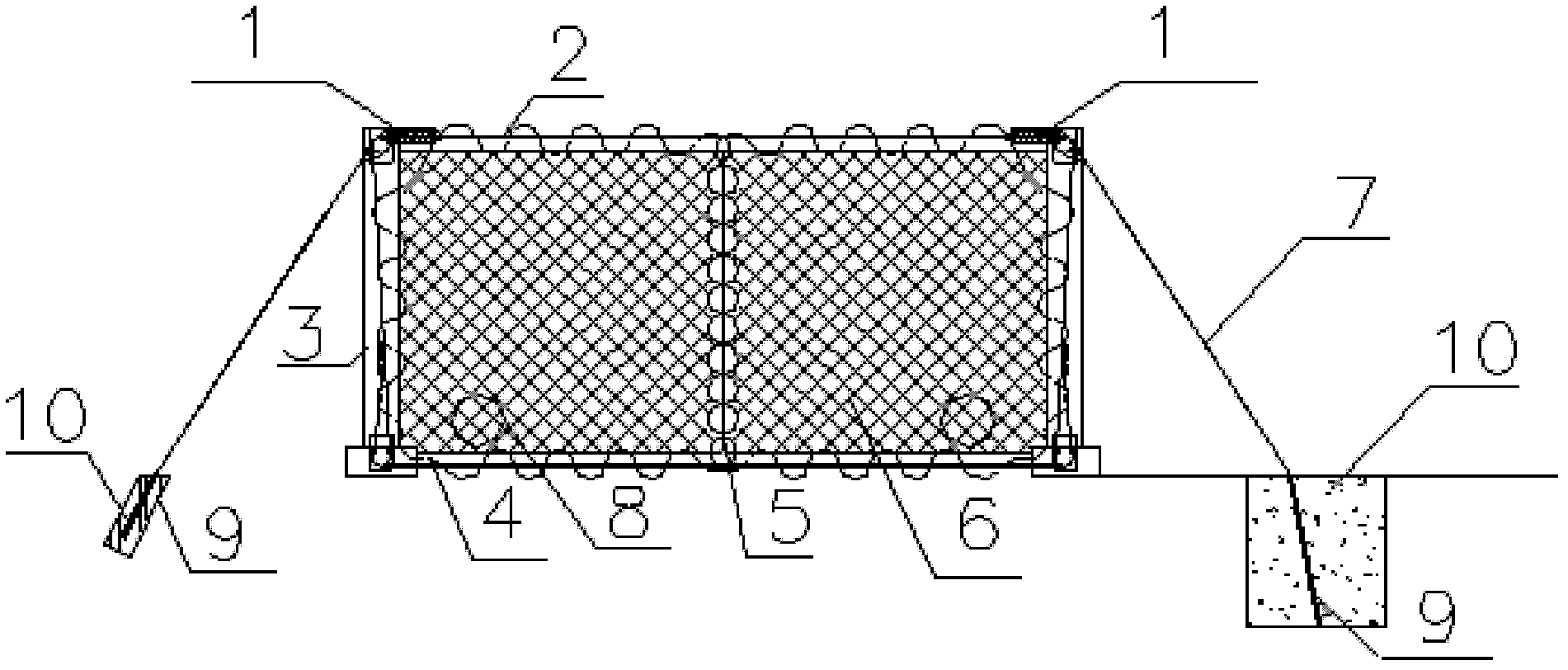

Anti-seismic flexible passive protecting screen system for side slope

InactiveCN102587396AImpact resistanceSimple structureClimate change adaptationExcavationsEngineeringSteel columns

The invention discloses an anti-seismic flexible passive protecting screen system for a side slope, which comprises a passive protecting screen, a steel column (3), an upper supporting rope (2), a lower supporting rope (4) and an upper anchor pulling rope (11). The anti-seismic flexible passive protecting screen system for the side slope is characterized in that at least one end of the upper supporting rope (2) is connected with the top end of the steel column (3) via an anti-seismic damping component, and the upper anchor pulling rope (11) is connected with the top end of the steel column (3) via another anti-seismic damping component. When the side slope is in earthquake, stones and rocks rolling along the surface of the side slope can generate large impact force to the passive protecting screen, and impact energy can be converted into damping liquid heat energy via the anti-seismic damping components. Impact caused by falling rocks, rolling stones, shallow collapse and the like on the rock side slope when in earthquake to the passive protecting screen can be effectively reduced, and the problem that buildings below the side slope are damaged due to the fact that the passive protecting screen is broken by the falling rocks and the rolling stones is avoided. In addition, the protecting screen system is simple in structure, convenient in manufacture and reliable in performance.

Owner:南京宏地工程咨询有限公司

Electrical distribution system components with fire resistant insulative coating

InactiveUS6960388B2Avoid large quantitiesImprove rigidityFireproof paintsElectrical apparatusMicrosphereDistribution system

Aqueous coating compositions containing a film-forming polymer, at least one flame retardant or smoke suppressant, glass or ceramic microballoons, and expandable flake graphite may be applied to building components pre- or post-installation, and provide a flexible and adherent coating. When exposed to heat, the coating expands to form an insulative yet cohesive layer which protects the component from fire-induced damage.

Owner:COMPOSITE TECH CO LLC

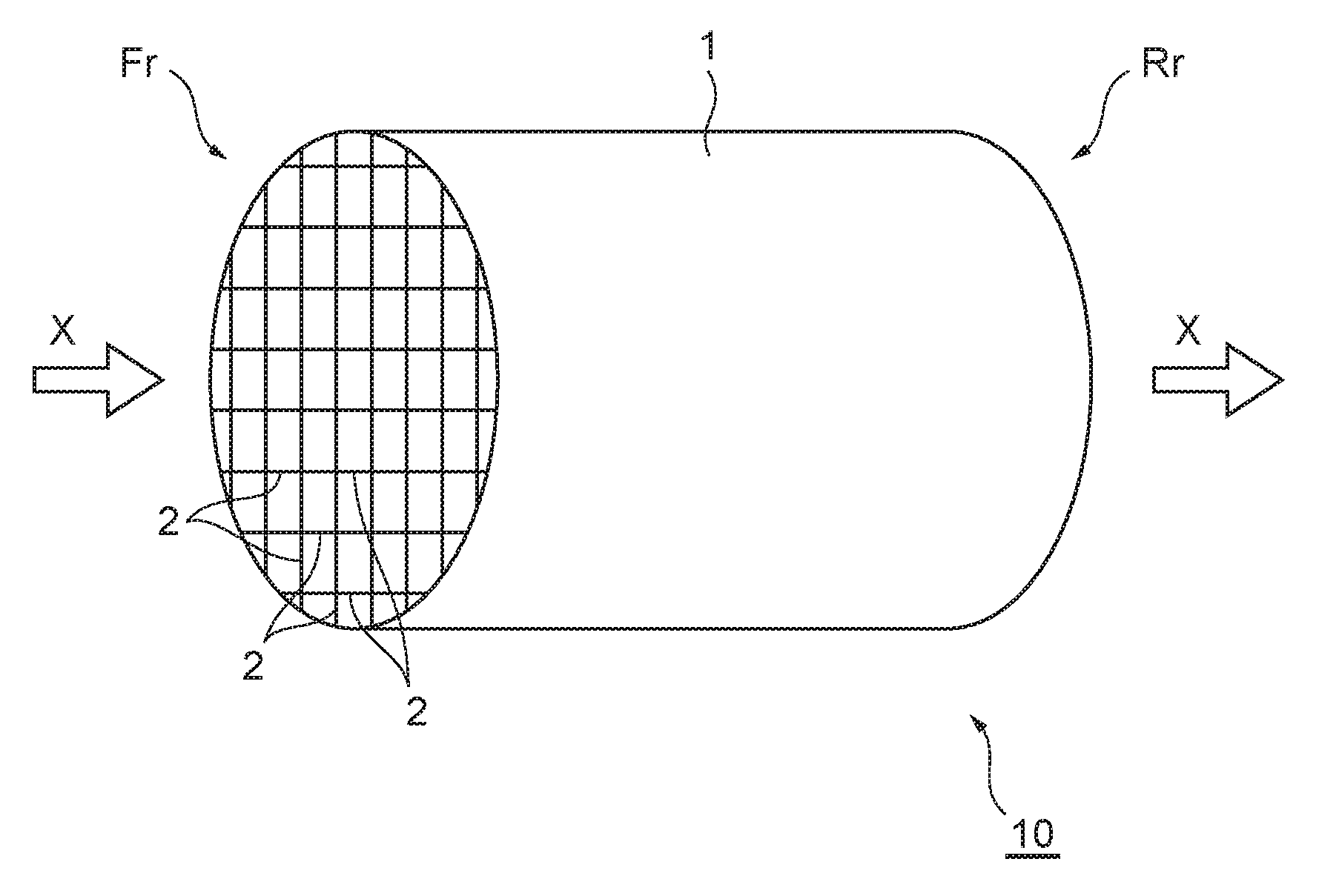

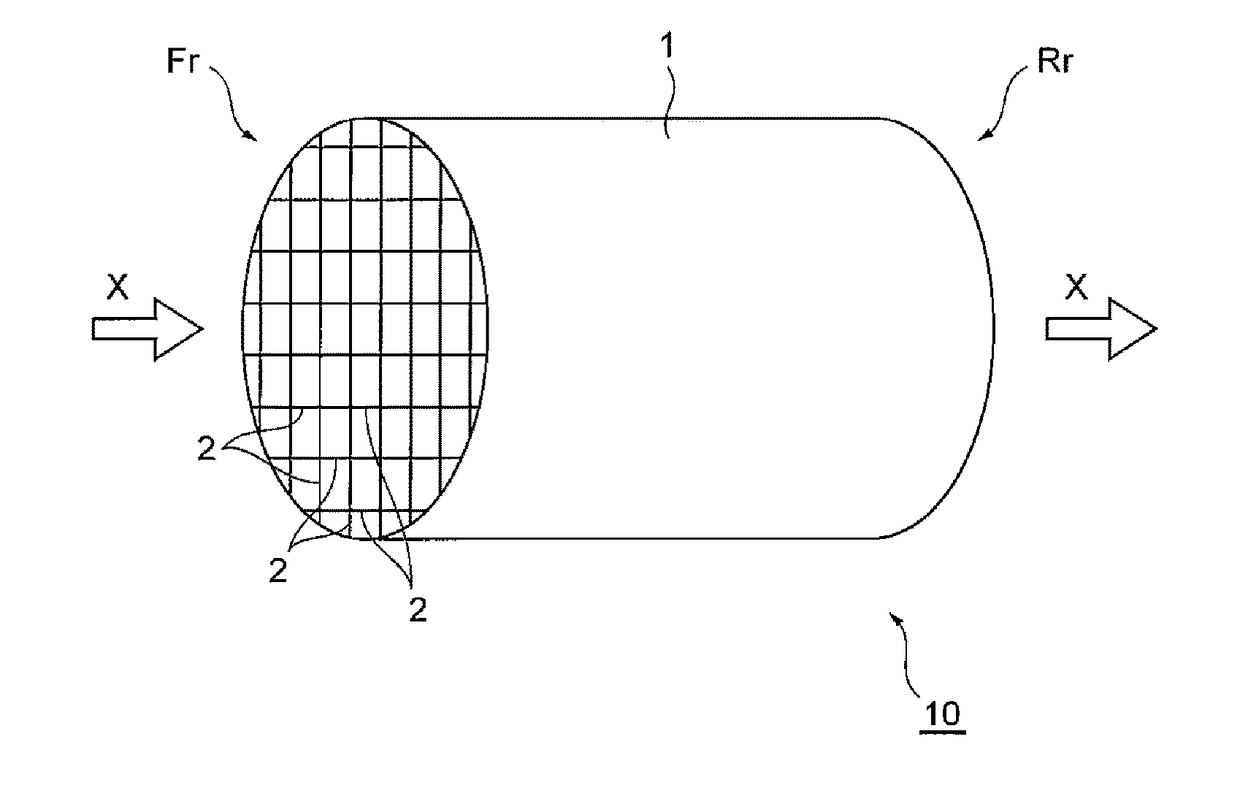

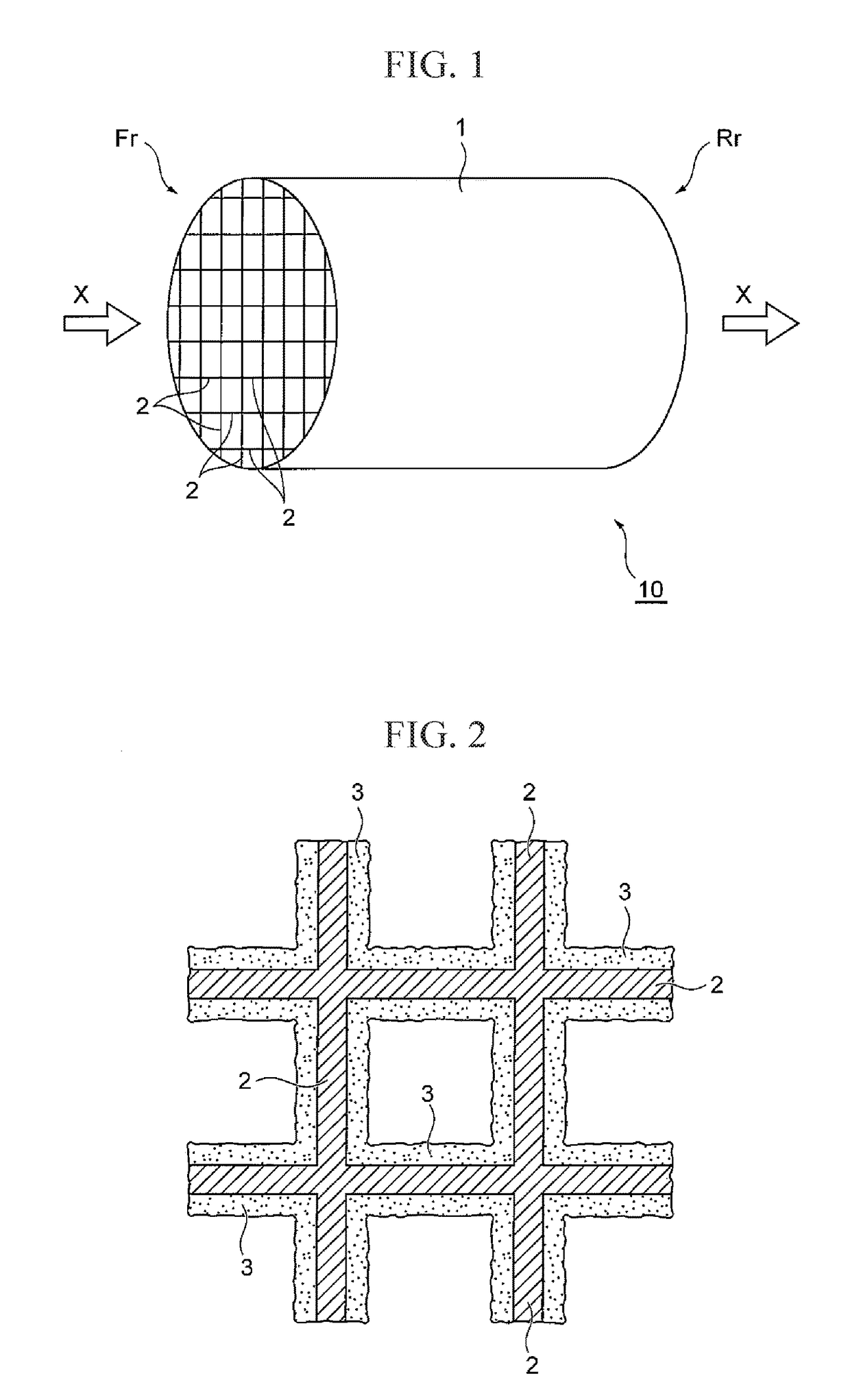

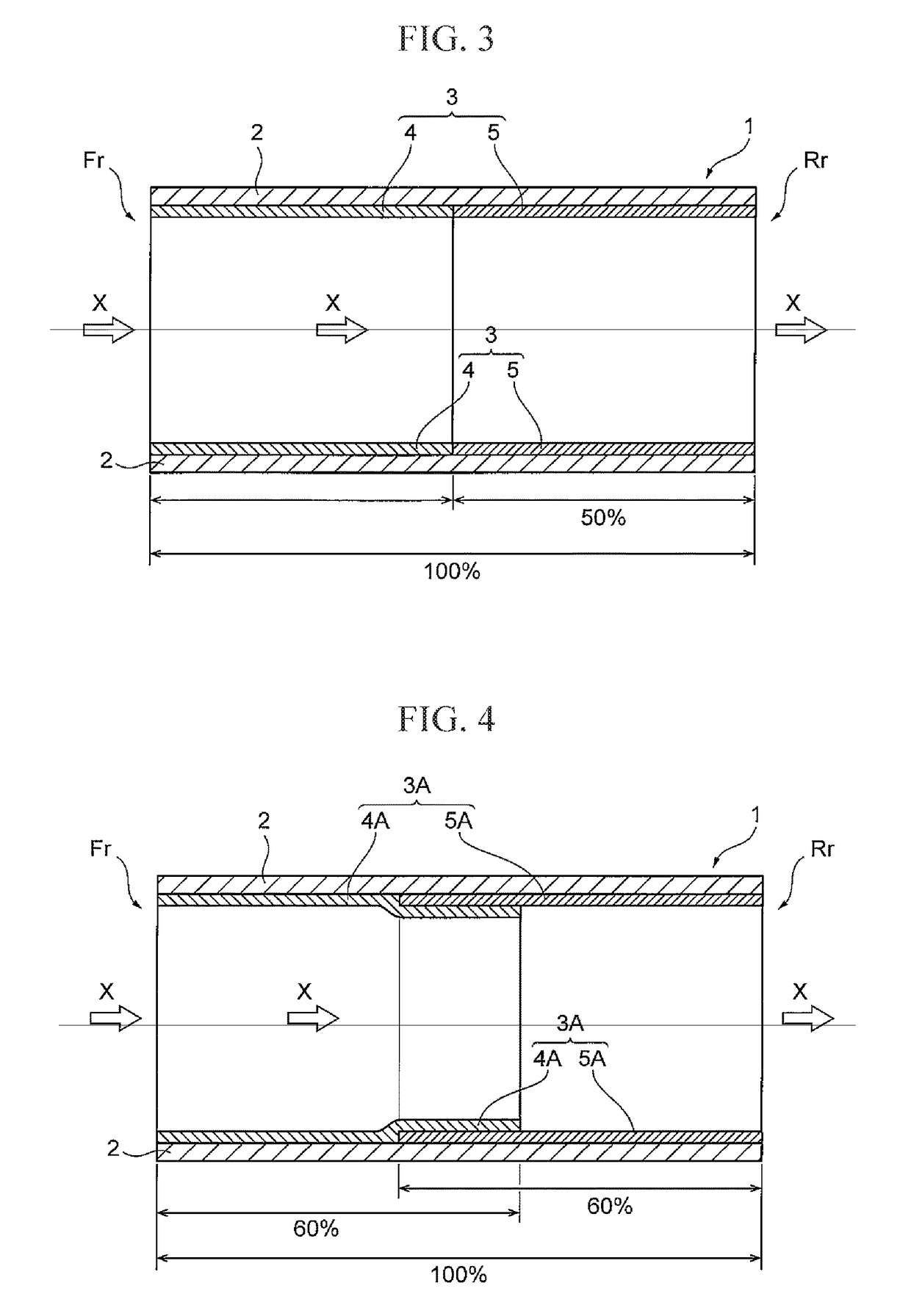

Catalytic converter

ActiveUS9579633B2Improve performanceNO purification performanceInternal combustion piston enginesExhaust apparatusCerium(IV) oxidePt element

A catalytic converter with excellent OSC performance and NOx purification performance. The catalytic converter includes a substrate with a cell structure and catalyst layer. The catalyst layer includes lower and upper catalyst layers. The upper catalyst layer includes a zirconia compound support with rhodium carried thereon that contains zirconia, lanthanum oxide, and yttrium oxide; an alumina compound without rhodium carried thereon that contains alumina and lanthanum oxide; and a ceria-zirconia-based composite oxide containing ceria, zirconia, lanthanum oxide, and neodymium oxide. The lower catalyst layer includes an alumina compound support with platinum carried thereon that contains alumina and lanthanum oxide that are the same materials as those of the alumina compound of the upper catalyst layer; and a ceria-zirconia-based composite oxide without platinum carried thereon that contains ceria, zirconia, lanthanum oxide, and neodymium oxide that are the same materials as those of the ceria-zirconia-based composite oxide of the upper catalyst layer.

Owner:TOYOTA JIDOSHA KK

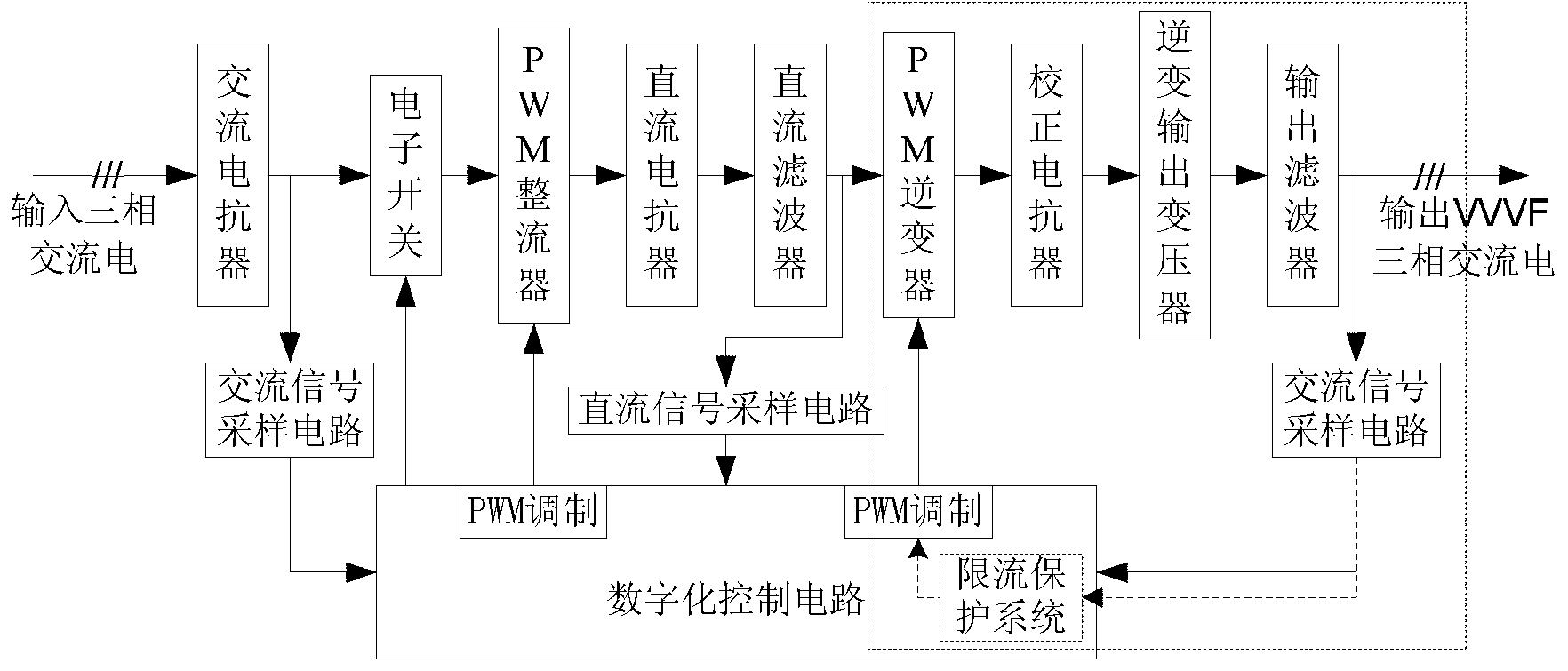

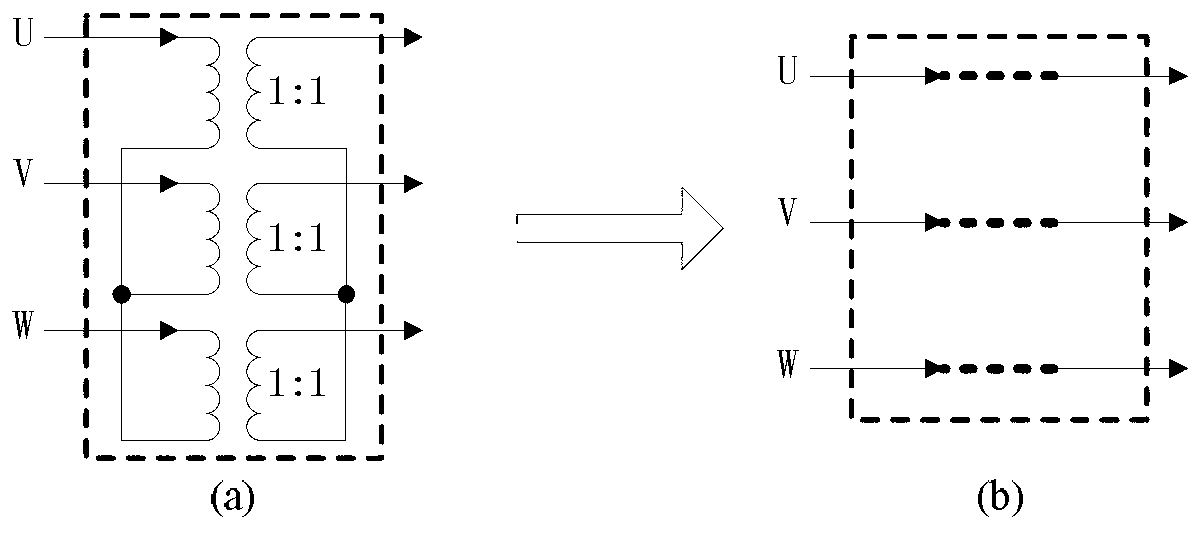

Current transformer current-limiting protection system control device and current-limiting control method thereof

ActiveCN103248013AGuaranteed continuityEffective protectionEmergency protective arrangements for limiting excess voltage/currentOutput transformerCurrent limiting

The invention discloses a control device of a current-limiting protection system for a current transformer, and the current-limiting control method thereof. The control device provided by the invention comprises a PWM (pulse-width modulation) inverter, a correction reactor, an inversion output transformer, an output filter, an AC signal sampling circuit, a DC signal sampling circuit and a processor. Compared with other operation protecting products for a current transformer, the device provided by the invention has the advantages that effective current-limiting protection can be achieved during the running process of the current transformer, the respond is fast, and high-current impact during the running process in case of instant and long-time short circuits and the like can be resisted; the method provided by the invention has high reliability, that the current transformer can maintain limited current output during failure period can be effectively ensured, the current transformer can be effectively protected, and meanwhile, better voltage current waveform output can be obtained, and the power supply sustainability can be maintained.

Owner:WENZHOU UNIVERSITY +1

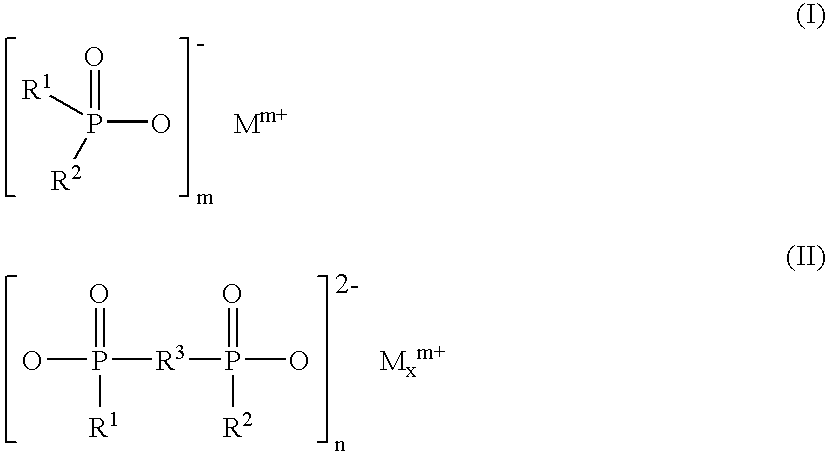

Reactive polyamide resins and polyamide resin compositions

Provided is a polyamide resin composition comprising an elastomer etc, and a reactive polyamide resin excellent in reactivity. The polyamide resin composition comprises 0.5 to 100 parts by mass of an elastomer per 100 parts by mass of a reactive polyamide resin, wherein the reactive polyamide resin obtained by polycondensing a diamine (A) containing 70 mol % or more of a diamine structural unit derived from xylylenediamine and a dicarboxylic acid (B) containing 50 mol % or more of a dicarboxylic acid structural unit derived from sebacic acid, and has a concentration of reactive functional groups of 100 μeq / g or more and a molar ratio of reacted diamine to reacted dicarboxylic acid (the number of moles of reacted diamine / the number of moles of reacted dicarboxylic acid) of 1.0 or more.

Owner:MITSUBISHI GAS CHEM CO INC

Solar cell back surface protective film, and solar cell module provided with same

InactiveUS20110174356A1Improve adhesionImprove heat resistancePV power plantsDiffusing elementsElectrical batterySolar cell

The back surface protective film for solar cell of the present invention is provided with a first resin layer obtained using a first thermoplastic resin composition which is prepared by melt-kneading a starting composition containing a first thermoplastic resin and a silane coupling agent. The back surface protective film may be provided with other resin layer bonding to the first resin layer. The thickness thereof is preferably in the range from 10 to 1,000 μm. The solar cell module of the present invention is provided with the back surface protective film for solar cell.

Owner:TECHNO POLYMER CO LTD

Catalytic converter

ActiveUS9873085B2Improve performanceImpact resistanceGas treatmentInternal combustion piston enginesCatalytic transformationEngineering

A catalytic converter with excellent OSC performance and Nox purification performance. The catalytic converter includes a substrate with a cell structure and a catalyst layer formed on a cell wall surface of the substrate. The catalyst layer has a catalyst layer arranged on the upstream side and a catalyst layer arranged on the downstream side in an exhaust gas flow direction on the substrate. The catalyst layer on the upstream side includes a support containing an Al2O3—CeO2—ZrO2 ternary composite oxide (ACZ material) and an Al2O3—ZrO2 binary composite oxide (AZ material), and at least Rh that is a noble metal catalyst carried on the support, and the catalyst layer on the downstream side includes a support and Pd or Pt that is a noble metal catalyst carried on the support. In the support in the catalyst layer on the upstream side, the mass proportion of ACZ material / (ACZ material+AZ material) is in the range of 0.33 to 0.5, and greater than or equal to 75% mass Rh is carried on the Al2O3—ZrO2 binary composite oxide of the support.

Owner:TOYOTA JIDOSHA KK

Composite polyamide article

ActiveUS20110241249A1Improve mechanical propertiesImpact fatigueFibre treatmentWood working apparatusPolymer sciencePolyamide

Uses of low molecular mass, non-evolutive polyamide resins for making composite articles are described. Articles obtained from such resins having good mechanical properties, such as rigidity, breaking load, impact resistance, and fatigue behaviour in particular, even when the articles are manufactured according to cycles shorter than those usually used, and without any processing before or after the manufacture of the composite articles, are also described.

Owner:RHODIA OPERATIONS SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com