Anodic sacrifice protection method of steel reinforced concrete bridge pier

A sacrificial anode protection and reinforced concrete technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of limited application, low price, unfavorable use of large-scale reinforced concrete structures, etc., to achieve low price, enhanced protection, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

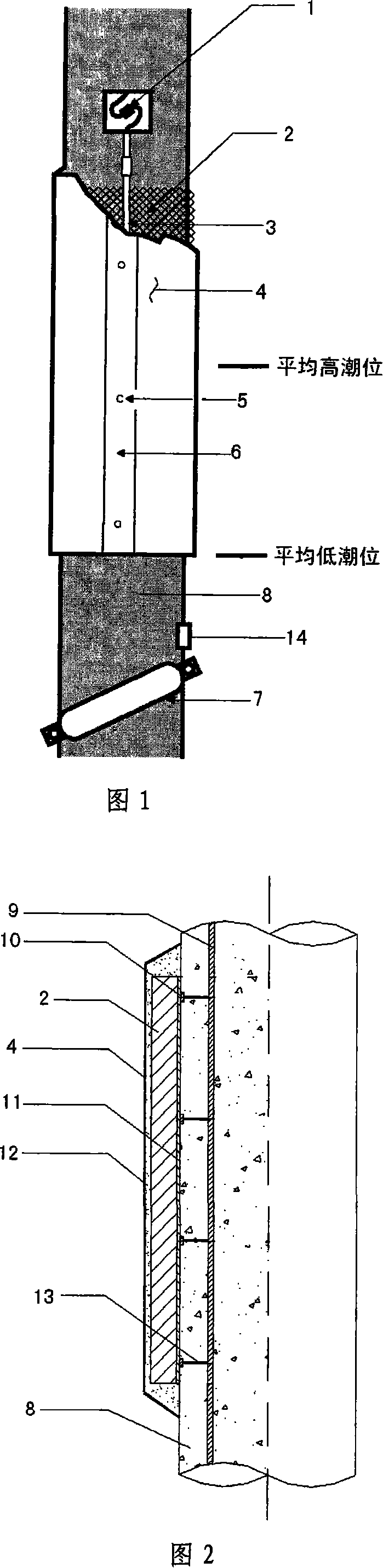

[0021] First determine the protected area of the expanded anode, the area is above the average low tide level and the splash area, fix the expanded anode 2 on the surface of the inner reinforced concrete pier 8, and then wrap the expanded anode 2 with a composite sheath 4, and fill it with conductive cement mortar The material 12 is poured between the composite sheath 4 and the reinforced concrete pier 8, so that the conductive cement mortar filler 12 evenly wraps the extended anode 2; during the fixing of the composite sheath 4 and the curing of the conductive cement mortar filler 12, non The metal fastener 5 assists in fixing the composite material sheath 4, and finally promotes the combination of the composite material sheath 4 and the conductive cement mortar filler 12; one end; the extended anode 2 is integrated through the extended anode connector 11 to generate a protective current; the underwater sacrificial anode 7 is fixed with an underwater fixture 14, and the fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com