Patents

Literature

260results about How to "Improve interface adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermally conductive thermoplastic

InactiveUS6162849AImprove thermal conductivityImprove mechanical propertiesPlastic/resin/waxes insulatorsMixingThermoplasticPolymer science

This invention relates to a thermally conductive moldable polymer blend comprising a thermoplastic polymer having a tensile at yield of at least 10,000 psi; at least 60% by weight of a mixture of boron nitride powders having an average particle size of at least 50 microns; and a coupling agent. The composition displays a thermal conductivity of at least about 15 W / m DEG K and it is capable of being molded using high speed molding techniques such as injection molding.

Owner:FERRO CORP

Benzoxazines, thermosetting resins comprised thereof, and methods for use thereof

InactiveUS7517925B2Improve adhesionSimple interfaceOrganic chemistrySemiconductor/solid-state device manufacturingInterfacial adhesionThermal expansion

In accordance with the present invention, there are provided novel benzoxazine compounds and thermosetting resin compositions prepared therefrom. Invention compositions are particularly useful for increasing adhesion at interfaces within microelectronic packages. Invention benzoxazines are useful for the preparation of invention compositions with properties which are associated with increased adhesion at interfaces, such as, for example, low shrinkage on cure and low coefficient of thermal expansion (CTE). In another aspect of the invention, there are provided die-attach pastes having increased interfacial adhesion. Invention die-attach pastes include benzoxazine-containing thermosetting resin compositions. In further aspects of the invention, there are provided methods for enhancing adhesive strength of thermosetting resin compositions and methods for enhancing adhesion of a substrate bound to a metallic surface by a thermosetting resin composition.

Owner:HENKEL IP & HOLDING GMBH

Coupling agents for orthopedic biomaterials

ActiveUS7270813B2Improve lubrication and flow propertyEasy injectionBiocideTissue regenerationPolymer compositesBiocompatible polymers

The invention provides a method for the preparation of bone-polymer composites wherein the mineral portion of the bone is treated with a coupling agent before being incorporated into a biocompatible polymeric matrix. The resulting composites may be used as such or be further processed to form an osteoimplant.

Owner:WARSAW ORTHOPEDIC INC

Adhesive composition comprising a particulate thermoplastic component

InactiveUS6548579B2Improve interface adhesionInhibition formationMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesWater basedParticulates

The invention is directed to an adhesive composition comprising a water based component including a film-forming polymer and a particulate thermoplastic component selected from the group consisting of thermoplastic polymers, thermoplastic resins, hot melt adhesive compositions, and mixtures thereof. The thermoplastic component has a mean particle size of from about 10 microns to about 1,500 microns. The adhesive composition is useful as a one-shot bookbinding adhesive, a primer composition as well as a second-shot adhesive for two-shot bookbinding method. The invention is also directed to the bookbinding methods using the adhesive composition.

Owner:HB FULLER CO

Partially vulcanized shaped rubber composition and preparation of an article, including tires, having a component thereof

InactiveUS6426378B1Improve responseIncrease stiffnessOther chemical processesSpecial tyresElastomerPolymer science

The invention relates to the preparation of a partially vulcanized, pre-shaped rubber composition and use thereof as a component of an article of manufacture. In practice, the partially vulcanized rubber composition is adhered to an unvulcanized rubber substrate to form a composite thereof and the resulting composite vulcanized to create an article of manufacture. Such pre-vulcanized rubber composition is a composite comprised of at least one diene-based elastomer, amorphous silica, coupling agent and liquid diene-based polymer. Such partially vulcanized, pre-shaped rubber composition may be a component of a tire such as, for example, an apex, sidewall insert or tread. It may also be a component of an industrial rubber product such as, for example, a component of a conveyor belt, power transmission belt or a hose.

Owner:THE GOODYEAR TIRE & RUBBER CO

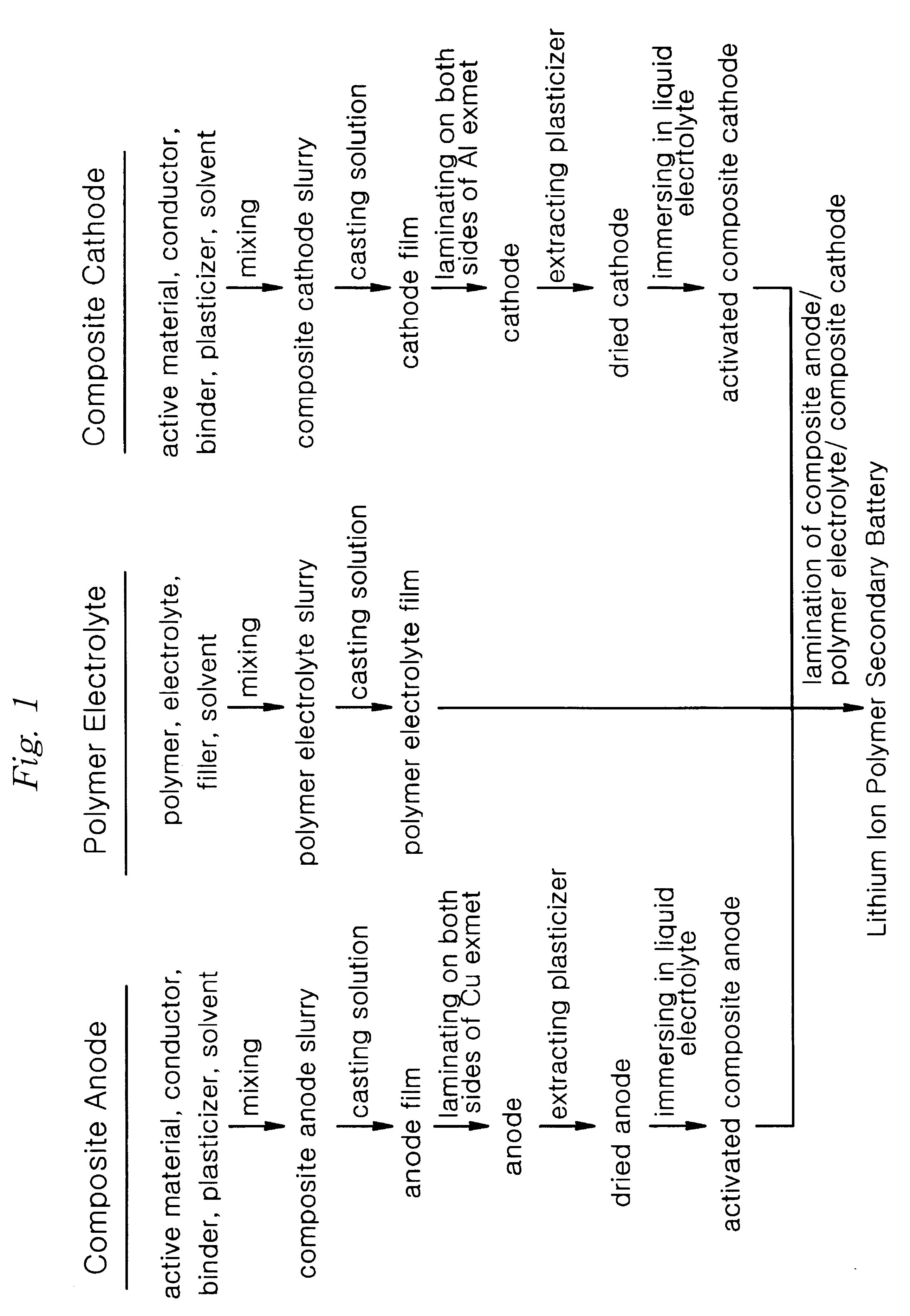

Method of preparing lithium ion polymer battery

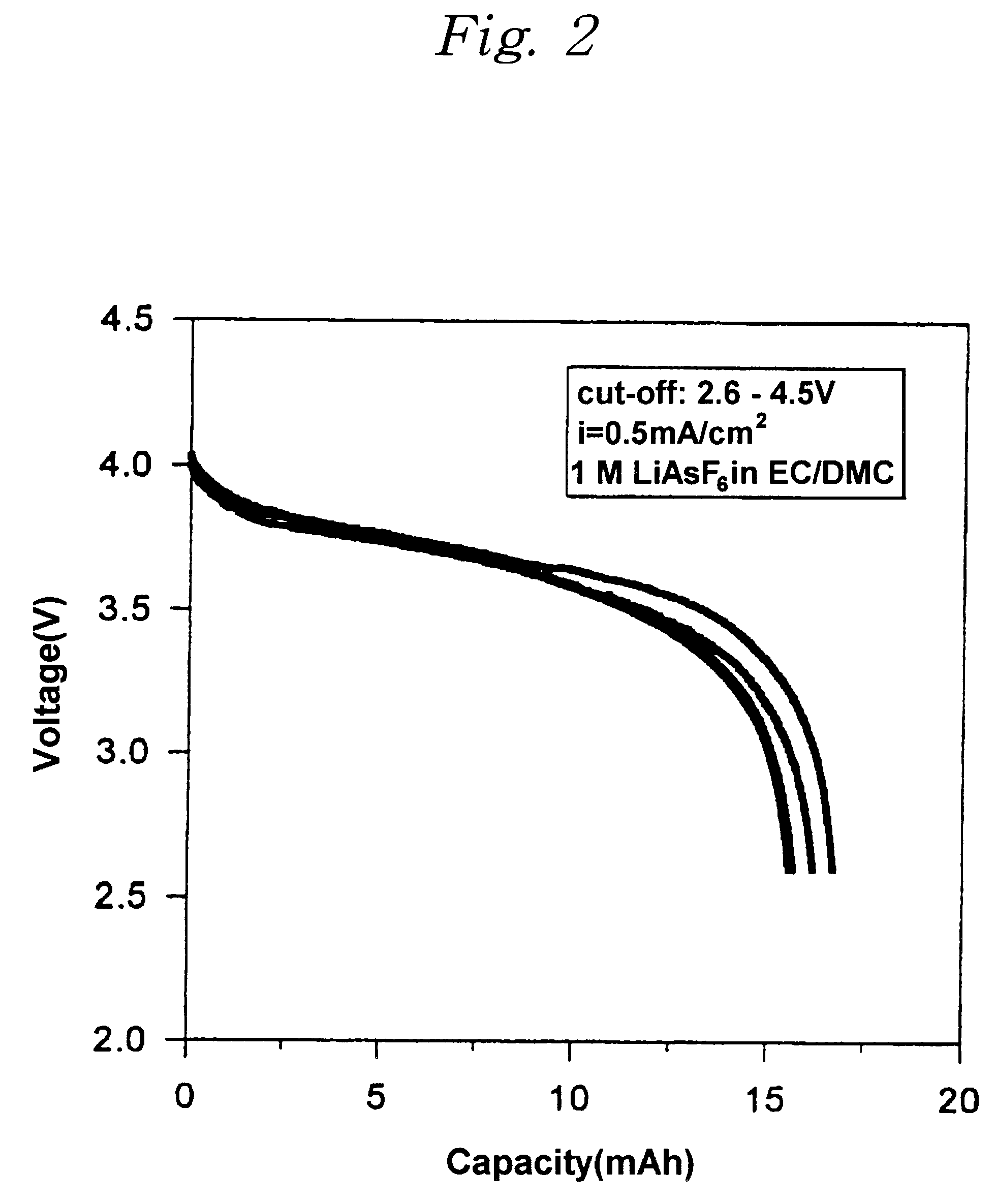

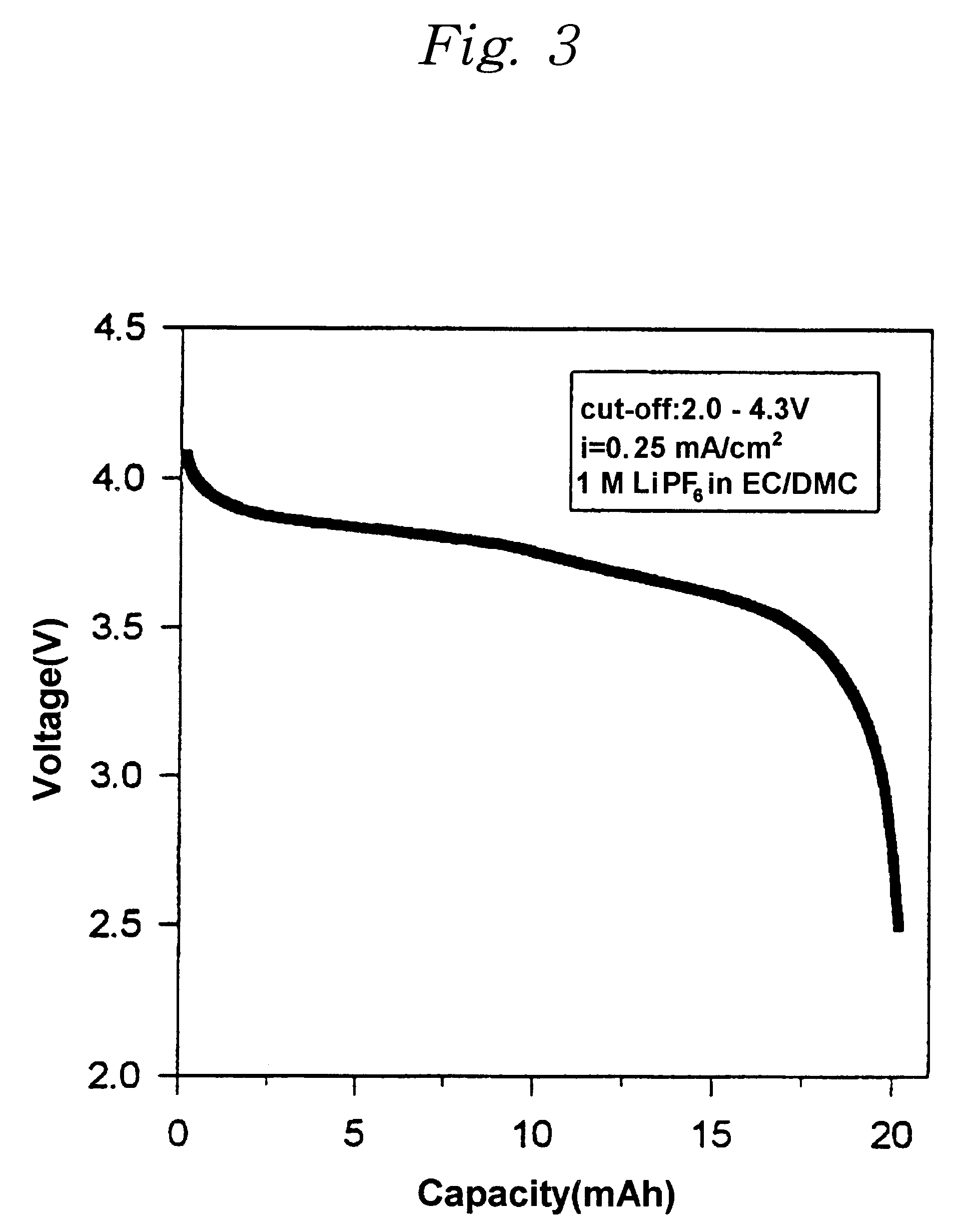

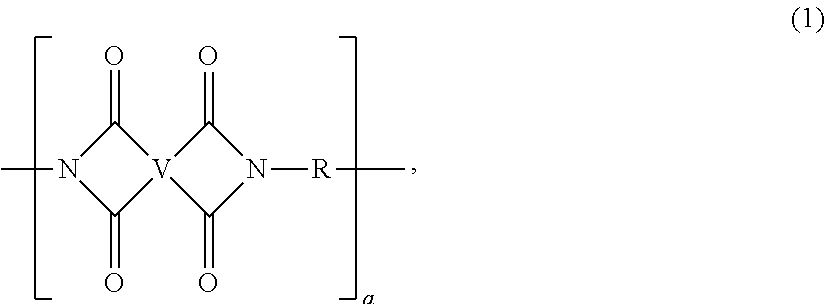

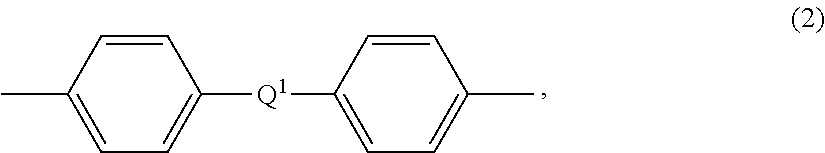

InactiveUS6268087B1Prevent exudationInhibition of exudationElectrode rolling/calenderingFinal product manufactureComposite cathodePolymer chemistry

The present invention relates to a method of preparing a lithium ion polymer battery which has a high capacity and a good cyclability as well as no exudation of liquid electrolyte. The lithium ion polymer battery according to the present invention is prepared by the steps of forming electrode films, laminating the electrode films on both surfaces of a grid or extended metal so as to improve the interfacial adhesion between the electrode films, forming a polymer electrolyte film composed of a polymer, an electrolyte solution, and a filler, and laminating the composite anode, the polymer electrolyte and the composite cathode. The activated composite anode / polymer electrolyte film / activated composite cathode is laminated to obtain a lithium ion polymer battery structure. The lithium ion polymer battery is vacuum-packaged using a vacuum packaging apparatus.

Owner:SAMSUNG DISPLAY DEVICES CO LTD

Polypropylene-based resin composition and injection molded article thereof

InactiveUS6011102AReduced impact strengthInferior appearanceFilm/foil adhesivesMixingPolymer scienceOctene

A polypropylene-based resin composition comprising: (1) 55 to 75% by weight of a polypropylene-based resin (A) selected from the following (i) and (ii); (i) a crystalline propylene-ethylene block copolymer composed of a propylene homopolymer portion as a first segment and a propylene-ethylene random copolymer as a second segment, and (ii) a mixture of the crystalline propylene-ethylene block copolymer (i) and a crystalline propylene homopolymer; (2) 10 to 15% by weight of an ethylene-octene copolymer rubber (B) having a melt flow rate (measured according to JIS-K-6758, 190 DEG C.) of 0.5 to 10 g / min., an octene content of 20 to 25% by weight and a density of 0.860 to 0.875; and (3) 15 to 30% by weight of talc (C) having an average particle diameter of not more than 3 mu m, the total amount of (A), (B) and (C) being 100% by weight, wherein said polypropylene-based resin composition satisfies the following expression:0.25< / =(A)' / [(A)'+(B')]< / =0.40in which (A)' represents an amount by weight of the second segment of the crystalline propylene-ethylene block copolymer (i) in the polypropylene-based resin composition and (B') represents an amount by weight of the ethylene-octene copolymer rubber (B) in the polypropylene-based resin composition, and further has a specific flexural modulus, Izod impact strength, elongation, melt flow rate and density.

Owner:TOYOTA JIDOSHA KK +1

Process of making dispersed polyetherimide micronized particles and process of coating and further forming of these particles products made therefrom

InactiveUS20140272430A1Improve interface adhesionImprove performanceSynthetic resin layered productsPretreated surfacesFiberPolymer science

Processes involving wetting fibers with an aqueous dispersion of micronized thermoplastic powders; processes for producing an aqueous dispersion of micronized thermoplastic powders; processes of chemically surface cross-linking micronized particles; and articles of produced therefrom.

Owner:SABIC GLOBAL TECH BV

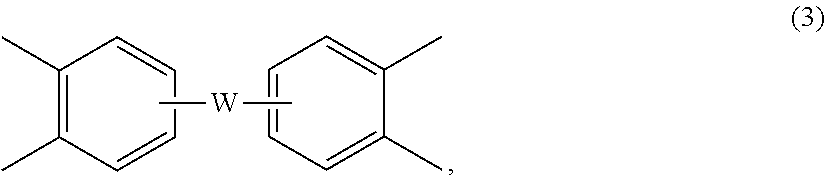

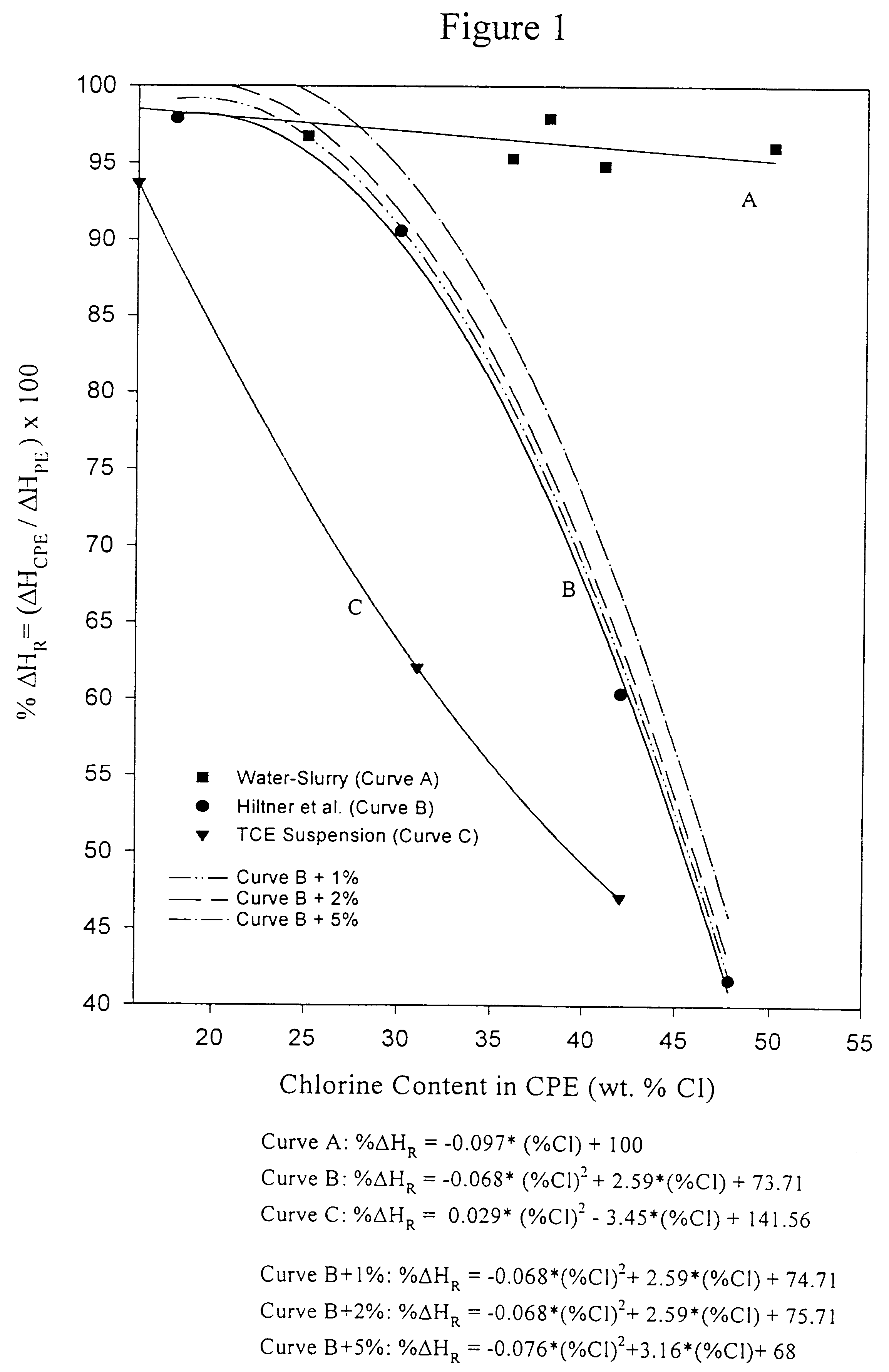

Blocky chlorinated polyolefins, process for making and use as impact modifier compatibilizer for PVC or CPVC

Blocky chlorinated polyolefins are disclosed as compatibilizers of PVC and / or CPVC resins with polyolefin elastomers. The blocky chlorinated polyolefins facilitate the dispersion of the elastomers as a dispersed phase with the proper size for impact modification of the PVC and / or CPVC. The blocky chlorinated polyolefin provides better adhesion between the elastomer and the PVC and / or CPVC providing better physical properties such as impact strength as measured by Notched Izod and variable height impact testing (VHIT) than did the randomly chlorinated polyolefins, often used as processing aids and as impact modifiers in PVC or CPVC. The differences in properties achieved with blocky chlorinated polyolefins versus randomly chlorinated polyolefins are attributed to the individual blocks of the blocky polyolefin being compatible (and / or co-crystalizable) with either the polyolefin elastomer or the PVC / CPVC resulting in better adhesion between phases. Also disclosed is a process for making optimal blocky chlorinated polyolefins.

Owner:NOVEON INC

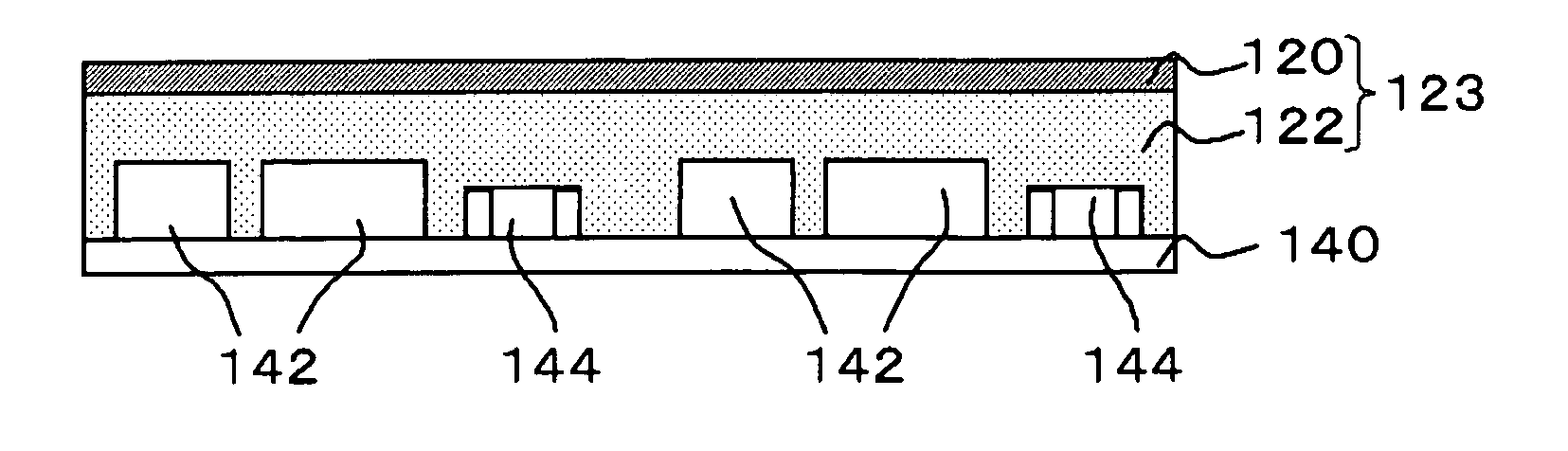

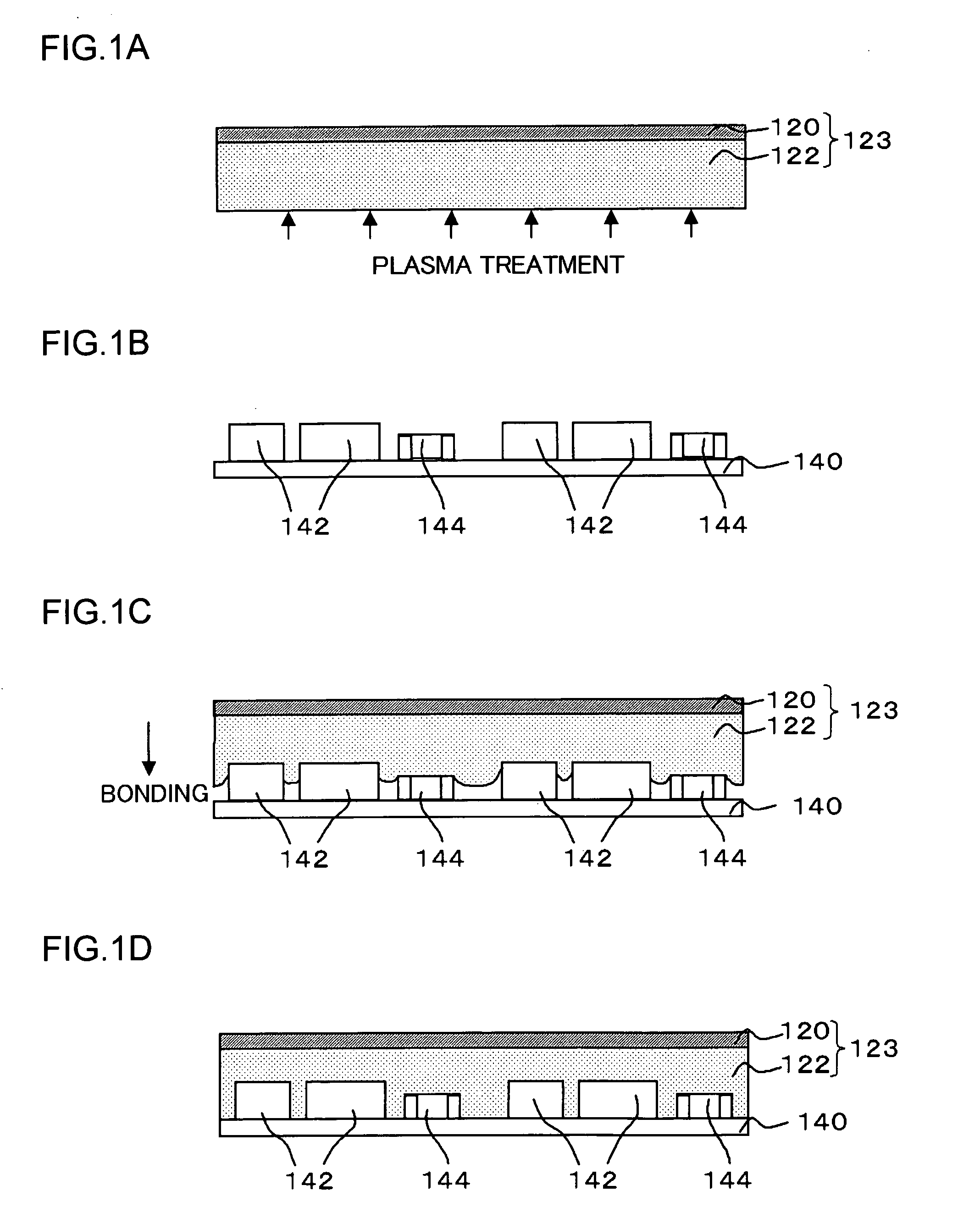

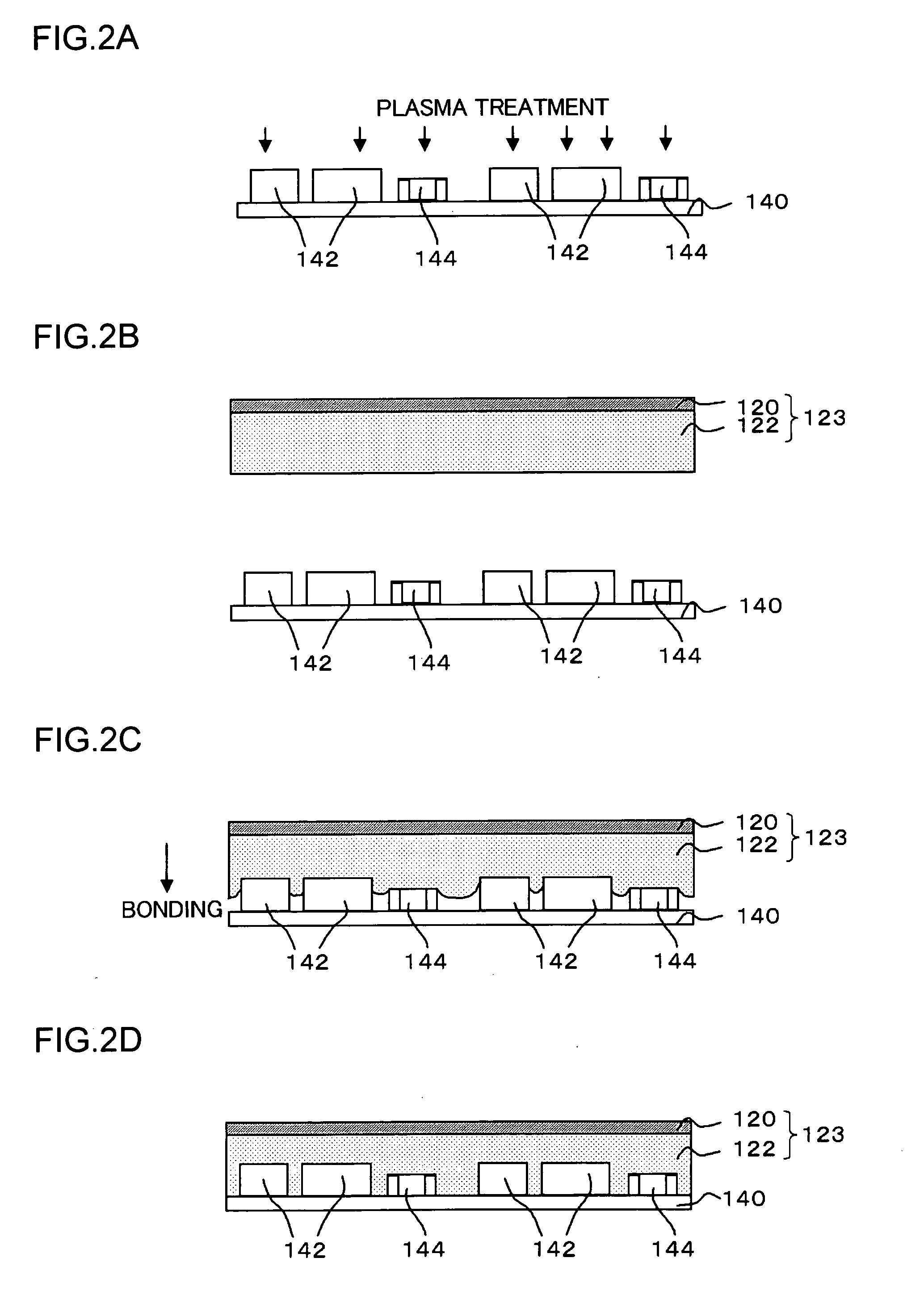

Semiconductor apparatus

InactiveUS20050205996A1Improve interface adhesionLower performance requirementsInsulating substrate metal adhesion improvementCross-talk/noise/interference reductionSemiconductor chipCompound (substance)

A semiconductor apparatus includes a substrate and elements or semiconductor chips provided on the substrate. The elements are sealed by being brought into contact with a sealing compound. The surface of contact on the elements or the sealing compound is plasma treated. The semiconductor chip is adhesively attached to another semiconductor chip via an adhesive compound. The surface of the semiconductor chip in contact with the adhesive compound is plasma treated.

Owner:SANYO ELECTRIC CO LTD

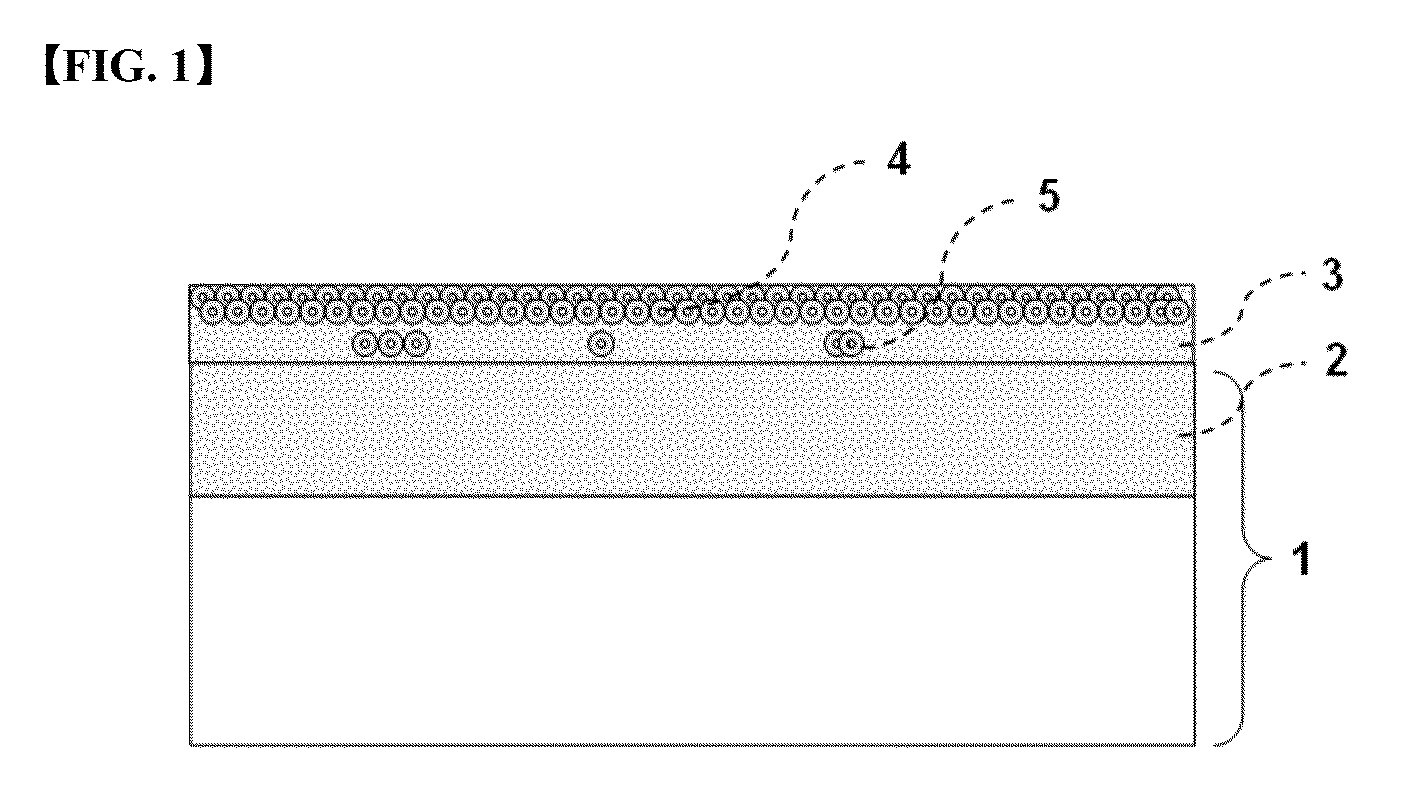

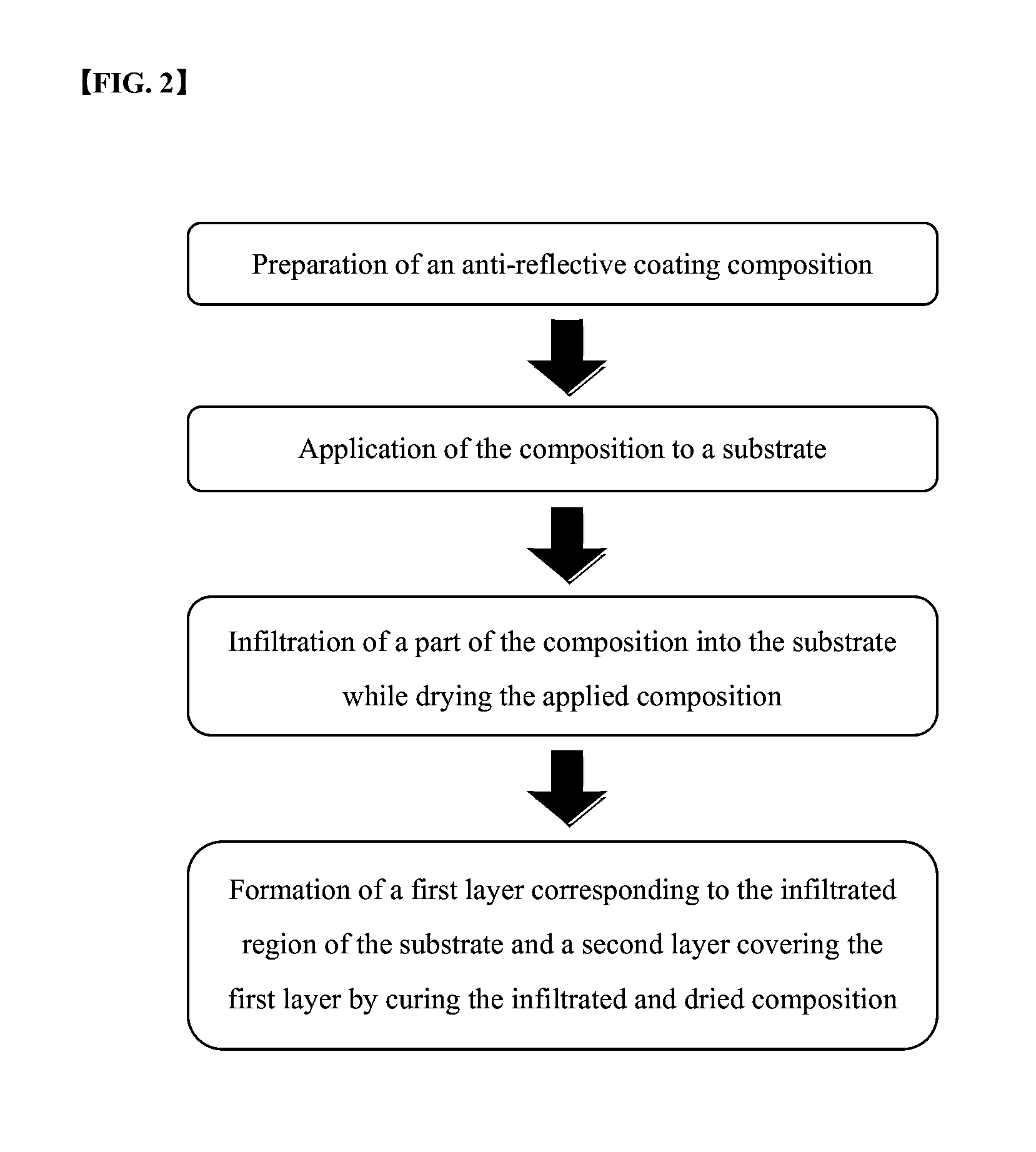

Anti-reflective coating film

ActiveUS20130215514A1Improve interface adhesionImprove scratch resistanceSynthetic resin layered productsPretreated surfacesAnti-reflective coatingMaterials science

Owner:LG CHEM LTD

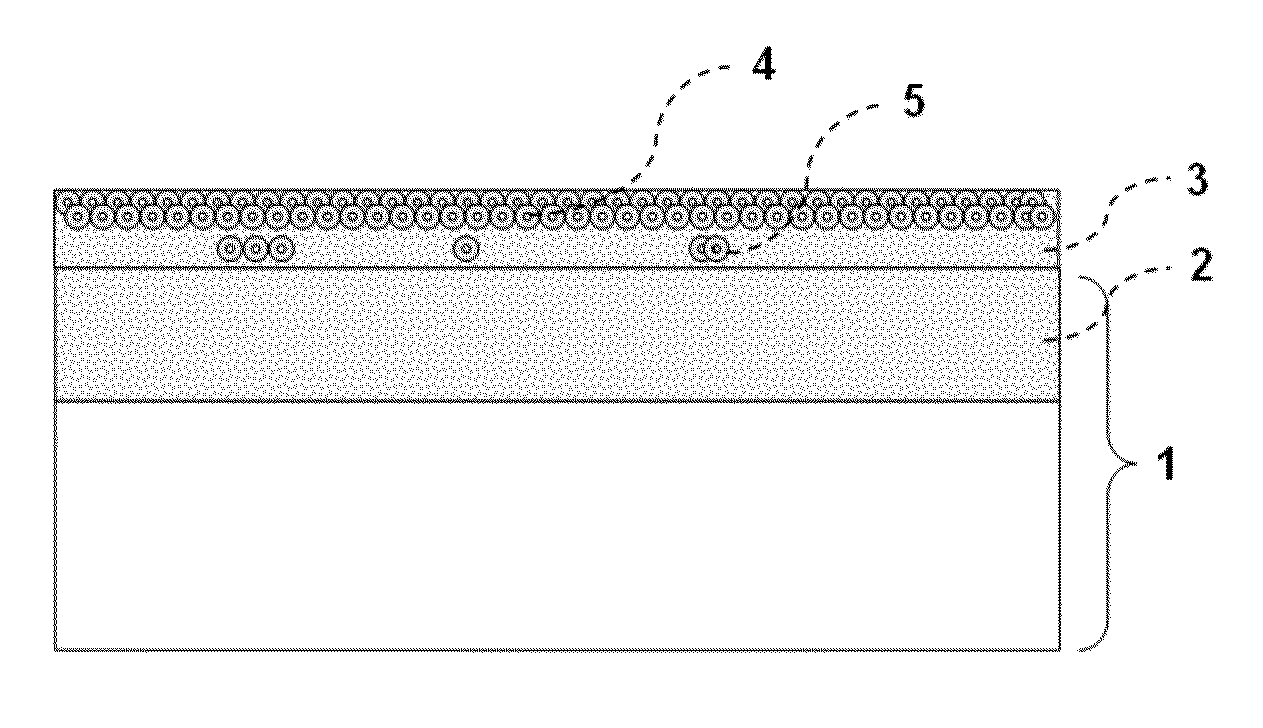

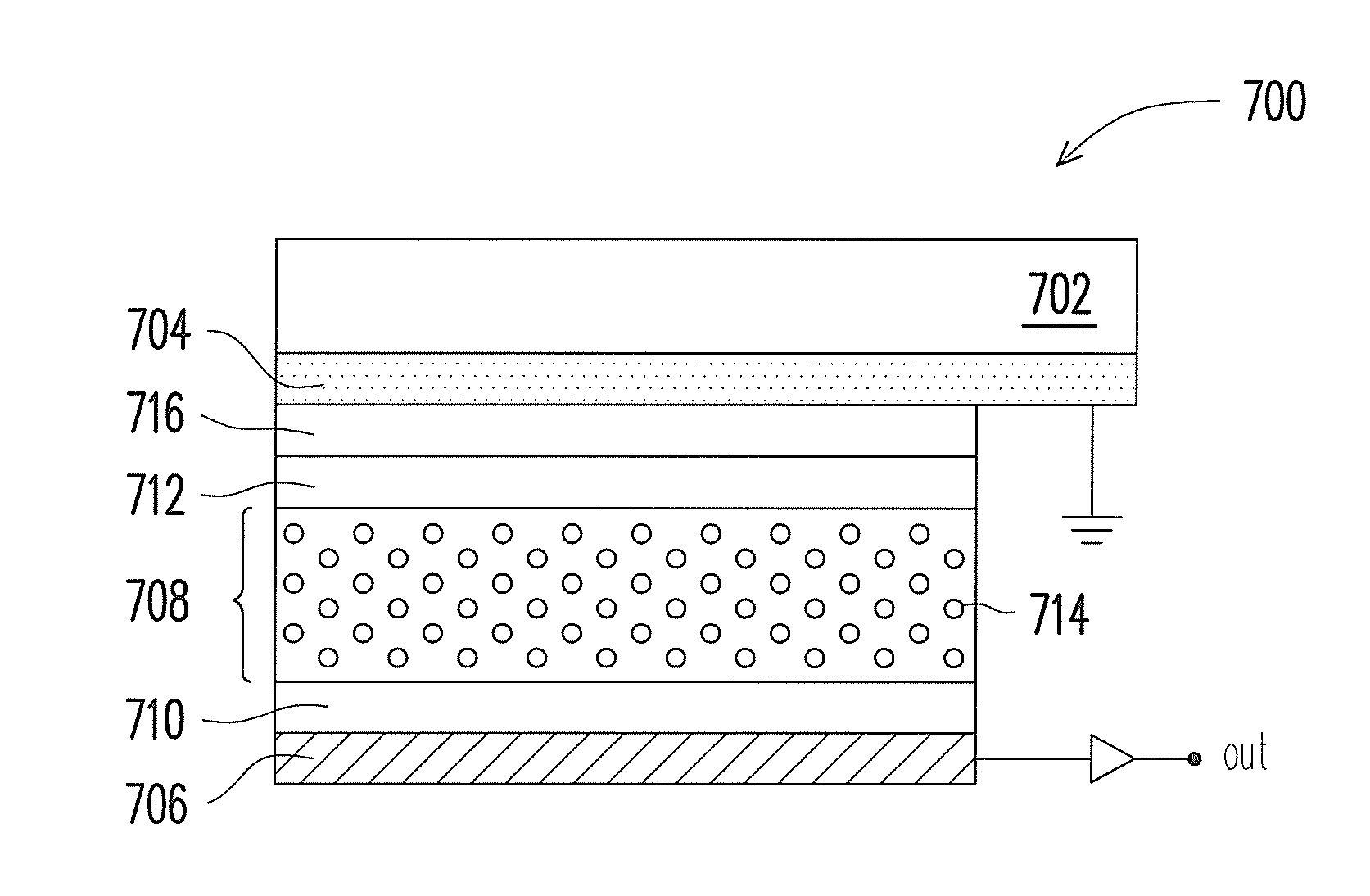

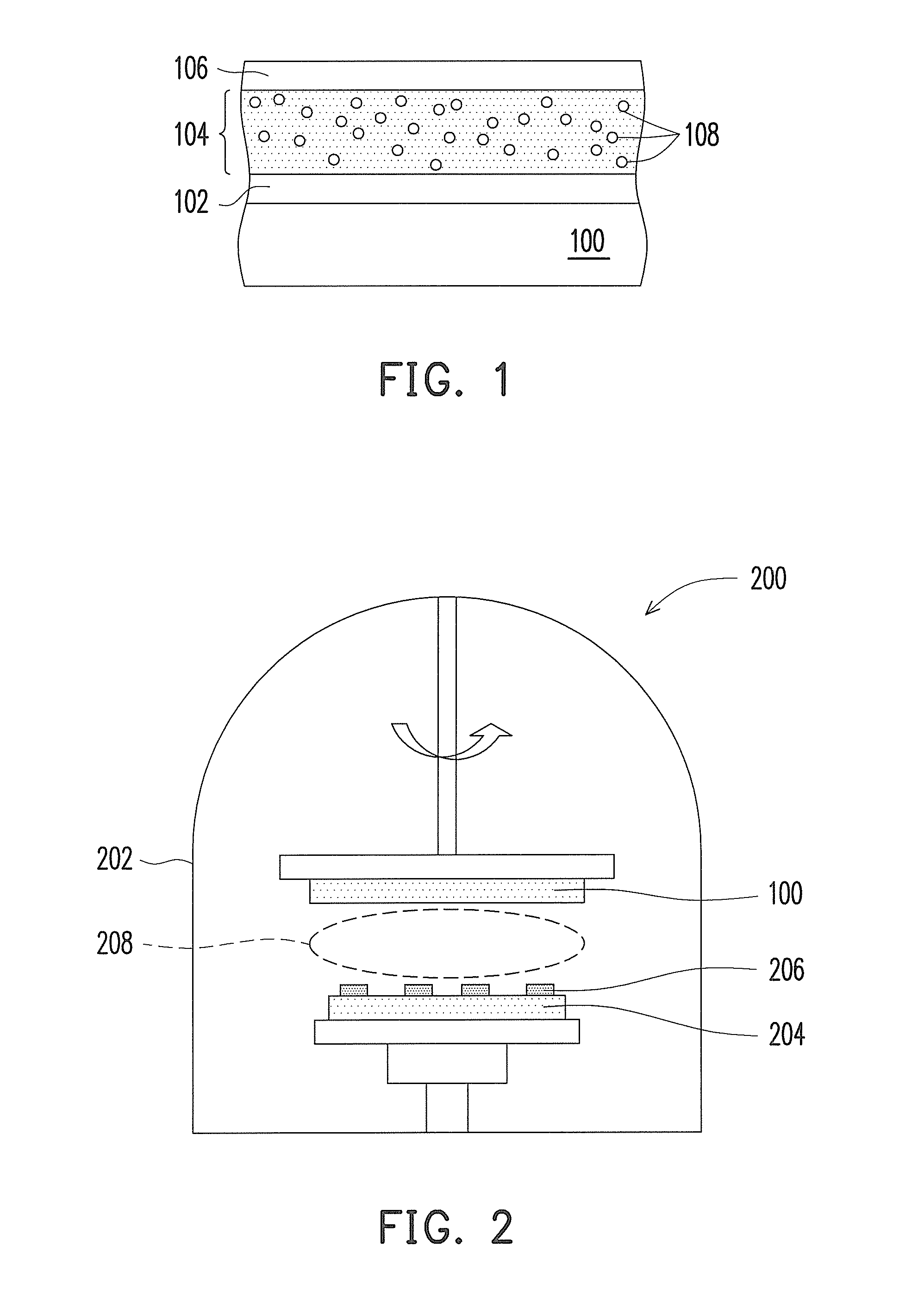

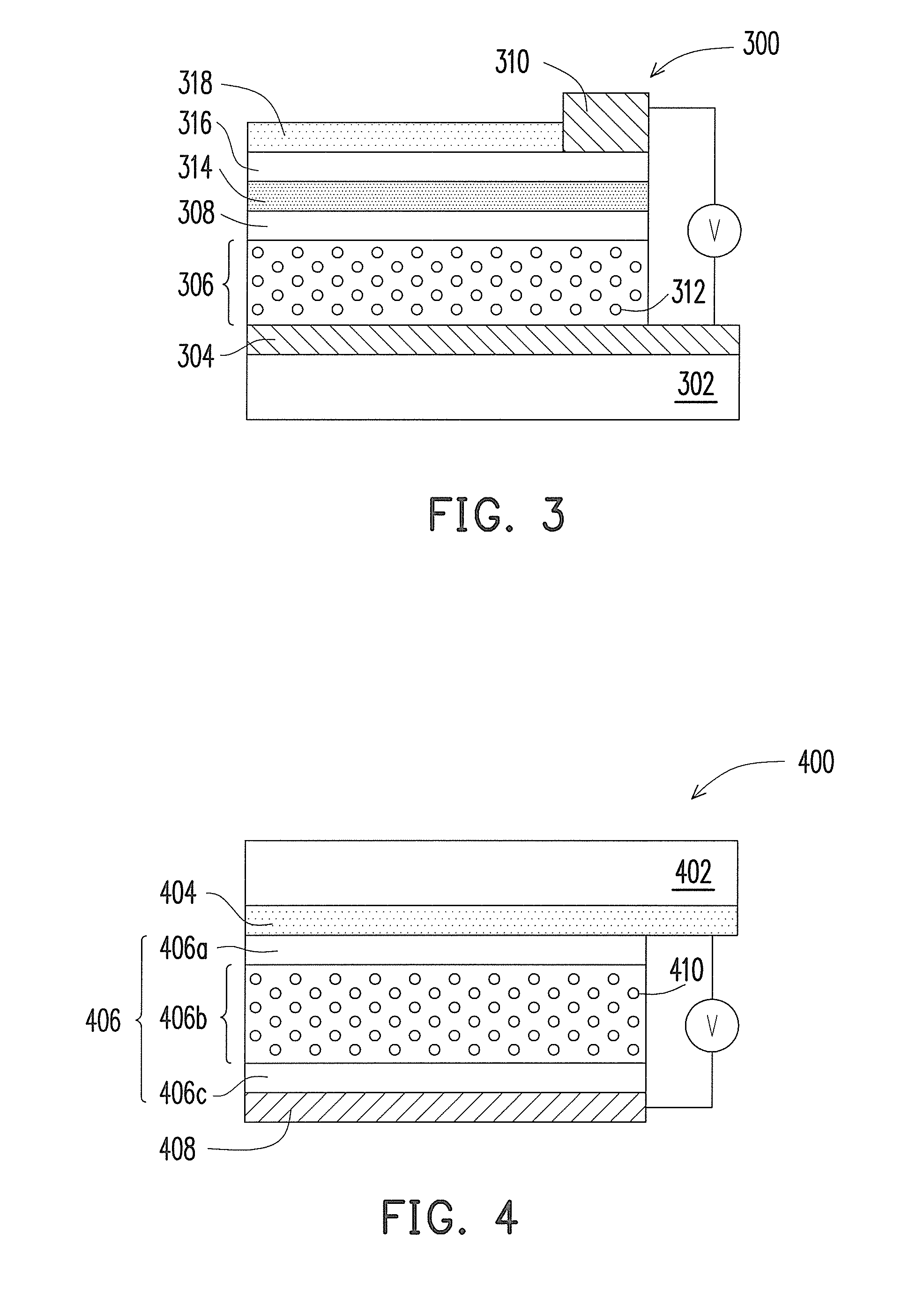

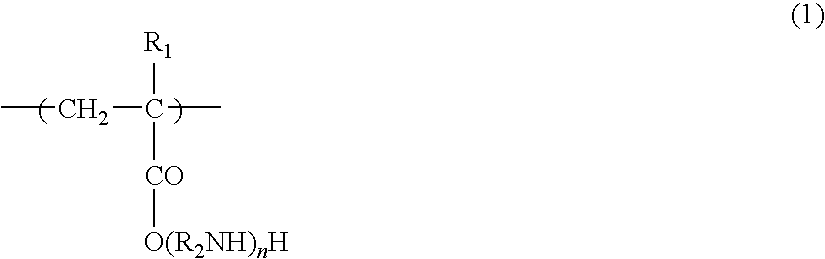

Quantum dot thin film solar cell

InactiveUS20100288345A1Improve interface adhesionElectrolytic capacitorsPhotovoltaic energy generationSputteringQuantum dot

A quantum dot thin film solar cell is provided, which at least includes a first electrode layer, an optical active layer, and a second electrode layer sequentially deposited on a substrate. A plurality of quantum dots is formed in the optical active layer. Since the plurality of quantum dots and the optical active layer are formed through co-sputtering, an interface adhesion between the plurality of quantum dots and the optical active layer is good in this quantum dot thin film solar cell.

Owner:IND TECH RES INST

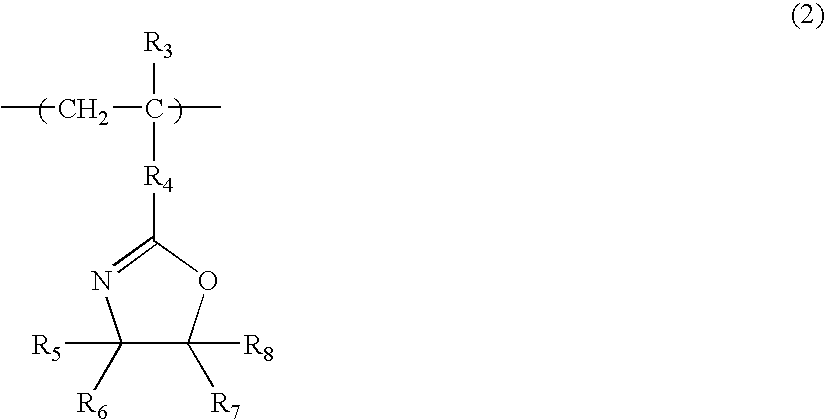

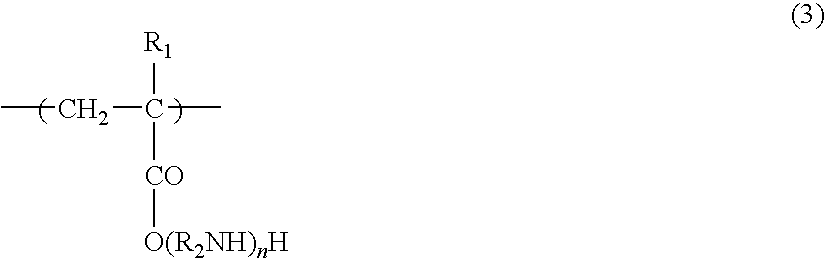

Fiber-Reinforced Thermoplastic Resin Composition, Method for Producing the Same, and Carbon Fiber for Thermoplastic Resin

InactiveUS20090143524A1Improve interface adhesionImprove mechanical propertiesPretreated surfacesLaminationMeth-Carbon fibers

According to the present invention, a fiber-reinforced thermoplastic resin composition that is superior in adhesivity between reinforcing fiber and thermoplastic resin is provided. It is possible to sufficiently improve mechanical properties of a molded product with such composition. Such fiber-reinforced thermoplastic resin composition comprises a (meth)acrylic polymer (A1) having an aminoalkylene group in a side chain or a polymer having an oxazoline group (A2) (0.1% to 10% by weight), reinforcing fibers (B) (1% to 70% by weight), and a thermoplastic resin (C) (20% to 98.9% by weight).

Owner:TORAY IND INC

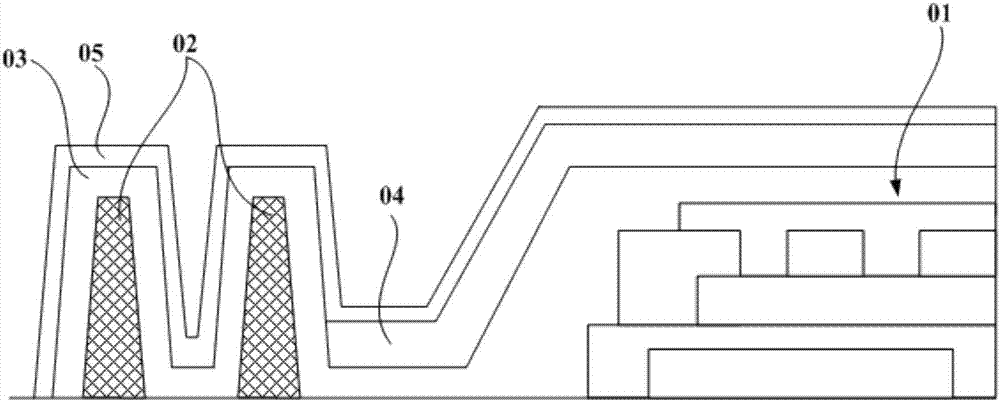

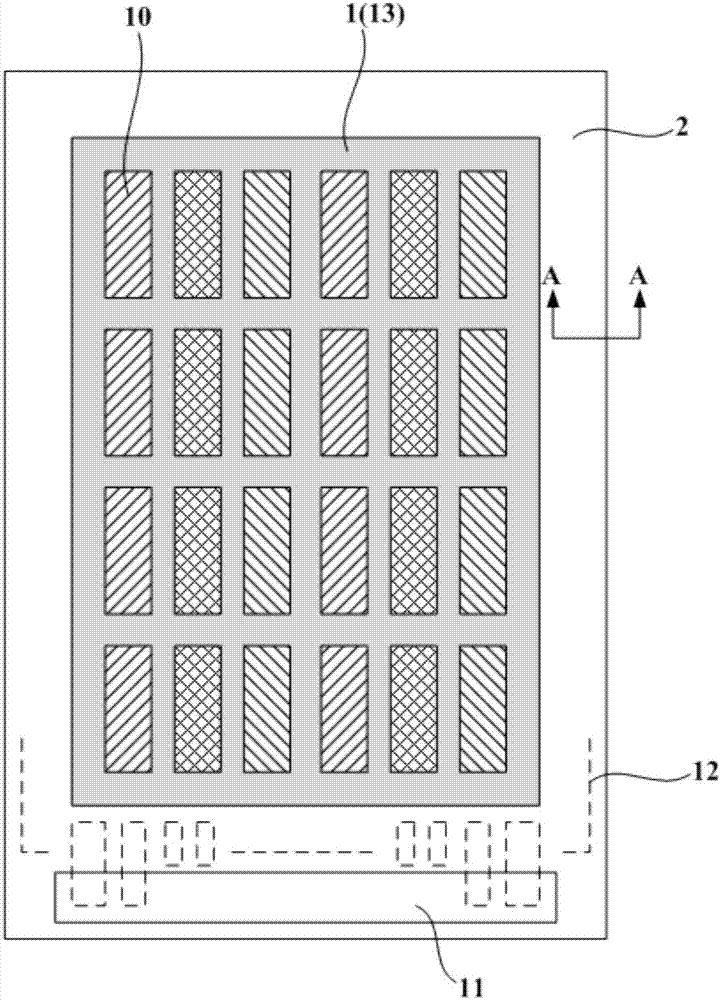

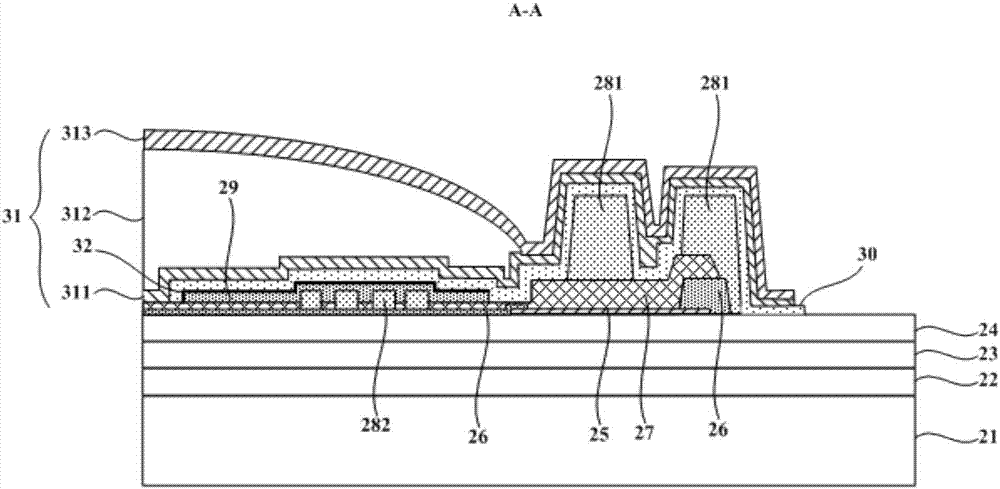

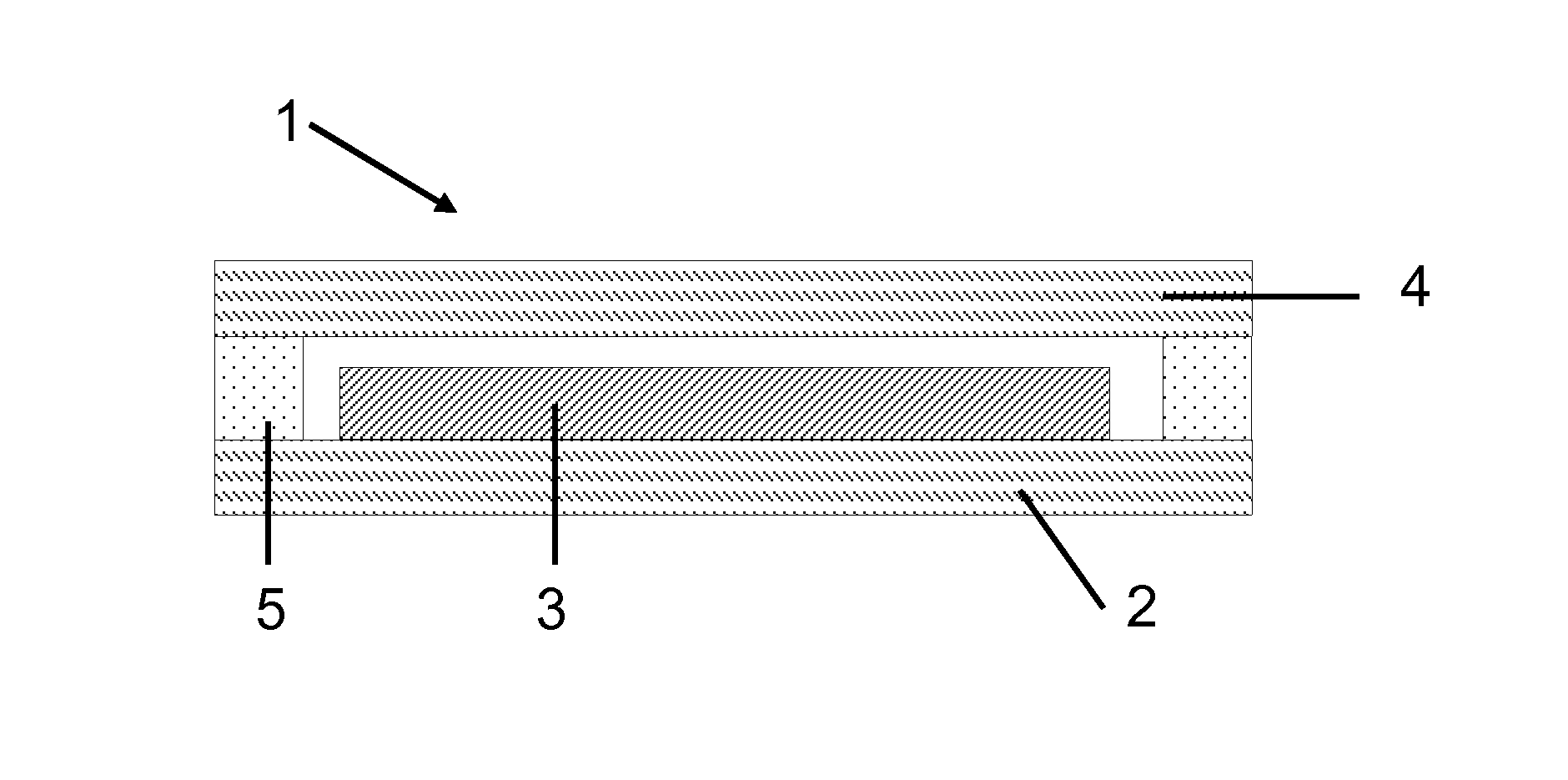

OLED display substrate and manufacturing method thereof, and OLED display device

ActiveCN107482042AReduce breakageAvoid erosionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The present invention discloses an OLED (Organic Light-Emitting Diode) display substrate and a manufacturing method thereof, and an OLED display device. The objective of the invention is to improve the bending reliability and prolong the service life of an OLED display device. The OLED display substrate comprises: a display area, a non-display area arranged around the display area, a retaining wall arranged at the non-display area, a packaging structure layer configured to cover the display area and extending to cover the retaining wall, and a metal halide layer located between the retaining wall and the packaging structure layer and configured to at least cover the retaining wall. The metal halide layer is increased between the retaining wall and the packaging structure layer, and the interface bonding force between the metal halide layer and the retaining wall and between the metal halide layer and the packaging structure layer is good to reduce the fracture or delamination of the edges of the OLED display substrate so as to effectively prevent steam and oxygen from entering the internal portion of the OLED display substrate for erosion of an OLED device and prolong the service life of the OLED display device.

Owner:BOE TECH GRP CO LTD

Modified graphene and paint containing modified graphene

InactiveCN106519901AGood dispersionImprove bindingAnti-corrosive paintsPigment treatment with macromolecular organic compoundsOrganic solventCoating system

The invention discloses modified graphene. A preparation method of the modified graphene comprises (1) adding graphene oxide into an organic solvent, carrying out ultrasonic dispersion treatment, adding glucose, polyvinylpyrrolidone and a silane coupling agent into the dispersion liquid, and stirring the mixture for 10 to 20 minutes to obtain an initial mixed solution, and (2) carrying out centrifuging washing on the initial mixed solution through an organic solvent to obtain residual solids which are modified graphene. Through modification of the graphene oxide, the hydrophilic groups such as a carboxyl group and a hydroxyl group react to be removed so that lipophilic properties are enhanced. Through use of a non-aqueous solvent in the reaction, interface bonding strength of the modified graphene and organic solvent is improved. The modified graphene can be easily dispersed in an oily coating system and the improvement of the dispersibility is conducive to improvement of the anticorrosive performances of the paint.

Owner:ANHUI YINENG NEW MATERIAL TECH CO LTD

Carbon fiber reinforced composite materials

InactiveUS20120295504A1Improve interface adhesionImprove mechanical propertiesSynthetic resin layered productsLaminationMolten statePolymer science

The invention provides a carbon fiber-reinforced composite material including reinforcing fibers which are continuous carbon fibers in the form of a unidirectional (UD) material, a woven fabric, or a knitted fabric, and a matrix resin including a modified polyolefin resin, thereby achieving better adhesion and mechanical strength. The matrix resin forms a polyphase structure having a sea-island structure which has an average island (independent phase) diameter of not greater than 0.5 μm. The composite material includes as a matrix resin a modified polyolefin resin obtained by, for example, graft-modifying a polyolefin resin with a monomer that contains an ethylenic double bond and a polar group in the same molecule; and includes as reinforcing fibers continuous carbon fibers. For example, the fiber-reinforced composite material is obtained by stacking the modified polyolefin resin and carbon fibers in a mold with a predetermined shape, and impregnating the carbon fibers with the modified polyolefin resin in a molten state under pressure, followed by cooling and curing.

Owner:KANEKA CORP

Prepn process of nanometer tin oxide material with surface decorating silver

The present invention relates to the preparation process of nanometer tin oxide material with surface decorating silver, and belongs to the field of electric contact material preparing technology. The preparation process includes the following steps: adding tin oxide powder of 20-30 nm size into anhydrous ethanol and adding polyglycol as dispersant; ultrasonic stirring at room temperature and stoving; adding the treated nanometer tin oxide powder into 10-30 % concentration silver nitrate solution via electromagnetic and ultrasonic stirring for homogeneous dispersion; adding reductant hydrazine hydrate to reduce silver ion and obtain silver coated nanometer tin oxide powder and stoving at 80-120 deg.c. The present invention has the advantages of simple technological process and being suitable for industrial production, and the surface decorated nanometer tin oxide may be used in producing electric contact with excellent mechanical performance and high conductivity.

Owner:TIANJIN UNIV

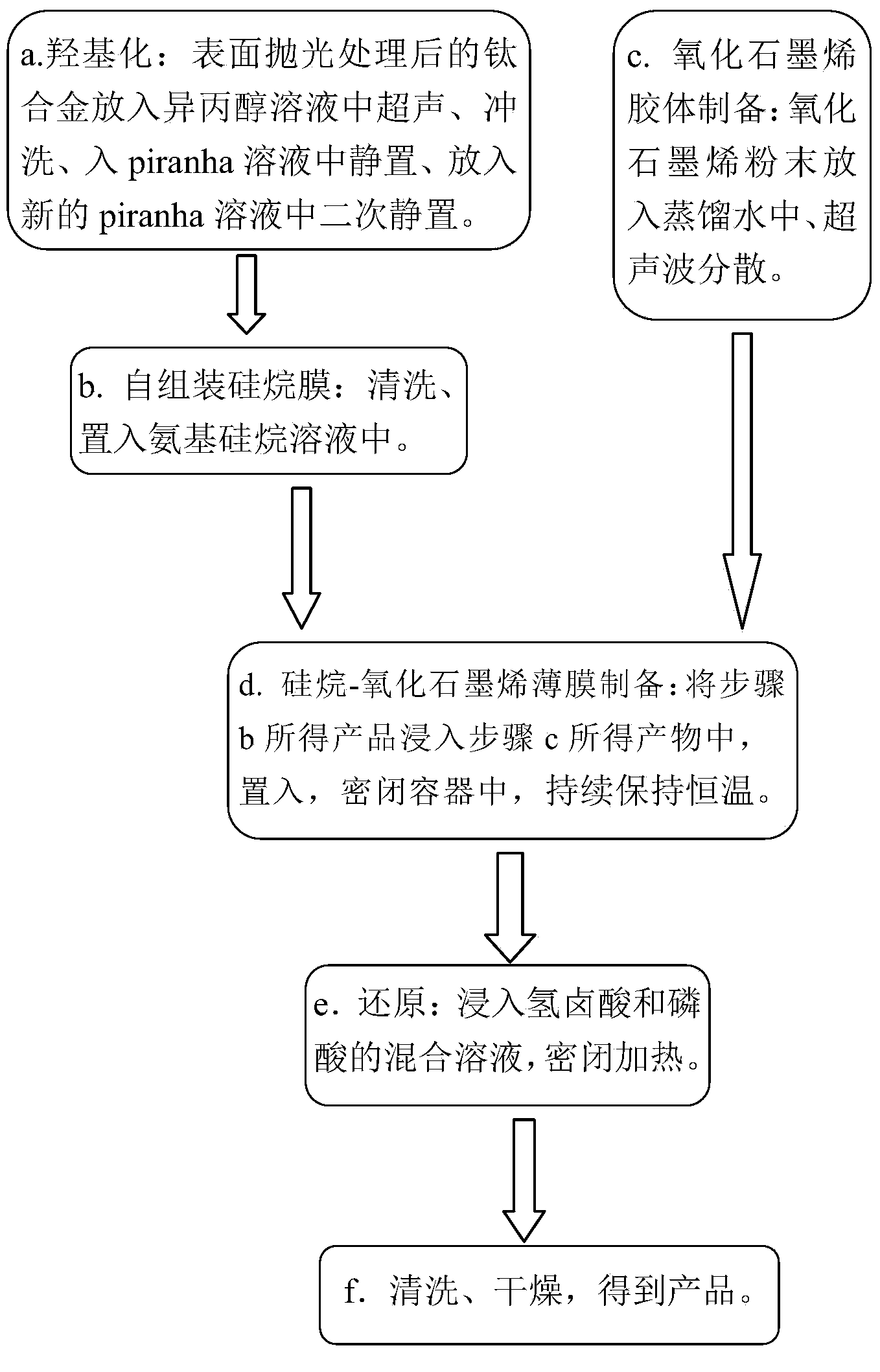

Method for preparing graphene film on surface of titanium alloy

InactiveCN104018145AReduce coefficient of frictionHigh strengthSolid/suspension decomposition chemical coatingHydrogen halideSilanes

The invention discloses a method for preparing a graphene film on the surface of titanium alloy. The method specifically comprises the following steps of putting a medical titanium alloy into a piranha solution and carrying out hydroxylation treatment, and then putting into an amino silane solution, and self-assembling a silane film; carrying out ultrasonic treatment on graphene oxide powder to obtain a stable graphene oxide colloid; immersing the titanium alloy of which the surface is attached with the silane film in the graphene oxide colloid to prepare a silane-graphene oxide film; and finally, reducing the graphene oxide film with hydrogen halide acid, and drying to obtain the reduced graphene oxide composite film. The method disclosed by the invention is simple and causes no harm to experiment operators, and the obtained film has the advantages of good integrity, high strength, low coefficient of friction and excellent wear resistance and is expected to become a medical joint material.

Owner:SHANGHAI JIAO TONG UNIV

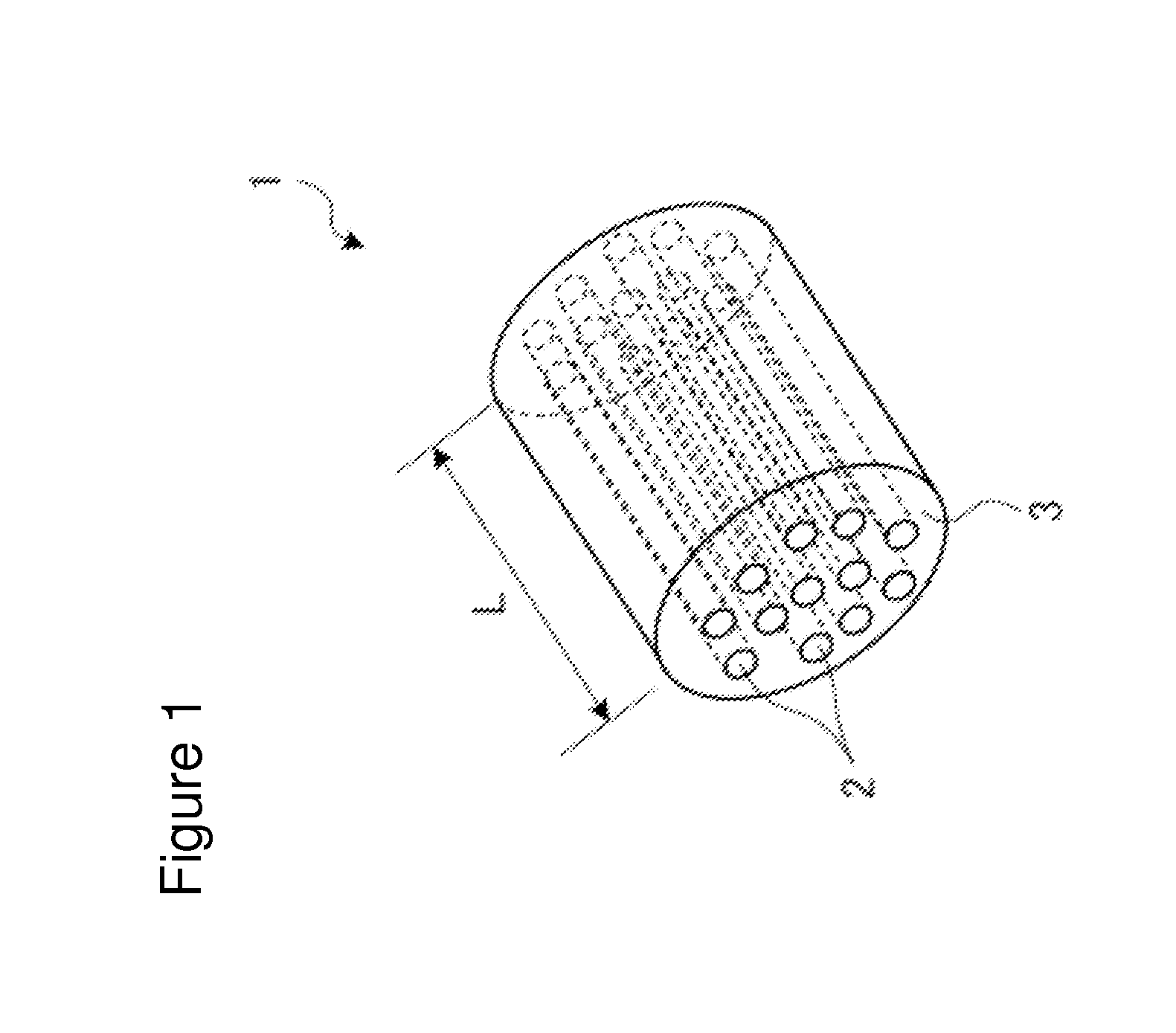

Carbon fiber-reinforced thermoplastic resin composition, molding material, prepreg, and methods for producing same

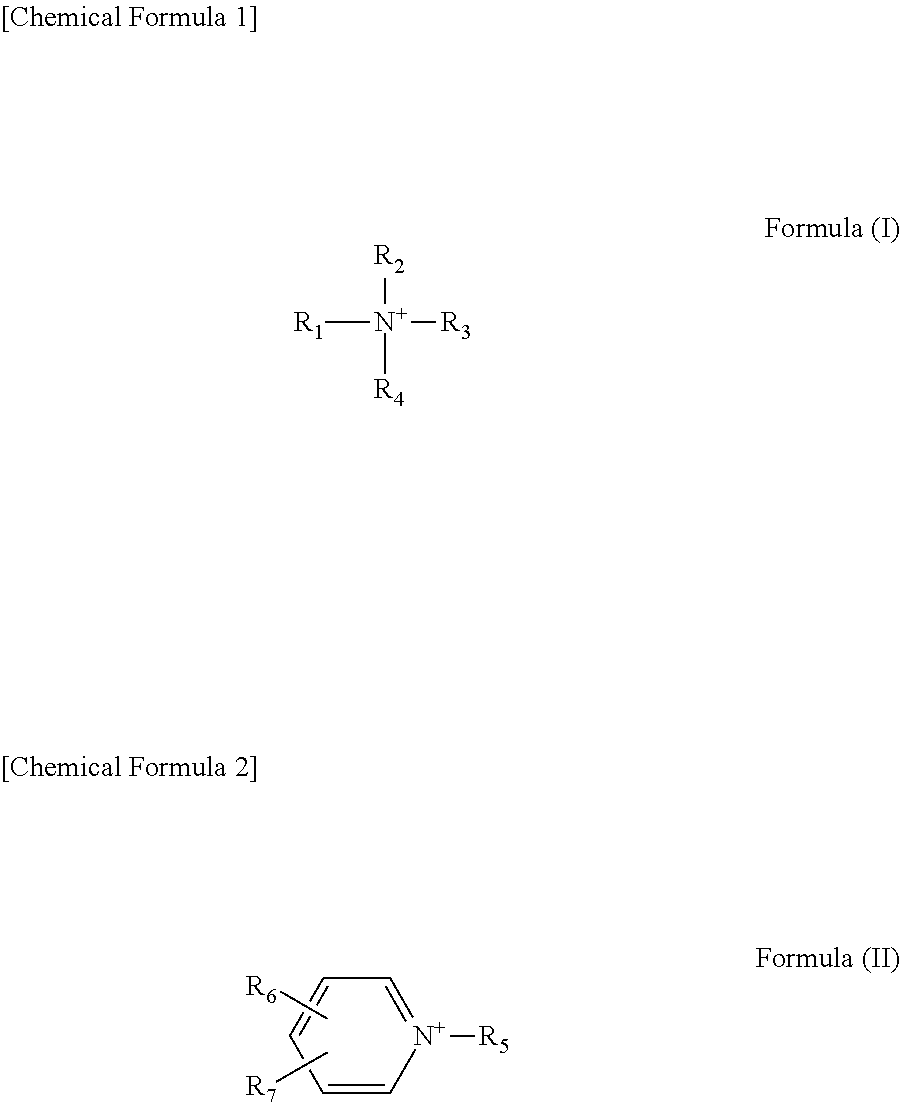

ActiveUS20140228519A1Improve dynamic characteristicsInterfacial adhesionFibre treatmentWood working apparatusEpoxyFiber

Provided are a carbon fiber-reinforced thermoplastic resin composition excellent in interfacial adhesion between carbon fiber and a thermoplastic resin and excellent in dynamic characteristics, and a molding material, a prepreg, and a method for producing the same. The carbon fiber-reinforced thermoplastic resin composition includes the following components (A) and (B), carbon fiber and a thermoplastic resin; component (A): (A1) a bifunctional or higher functional epoxy compound and / or (A2) an epoxy compound which has a monofunctional or higher epoxy group and has one or more taypes of functional groups selected from a hydroxyl group, an amide group, an imide group, a urethane group, a urea group, a sulfonyl group and a sulfo group; and component (B): 0.1 to 25 parts by mass, based on 100 parts by mass of the component (A), of at least one reaction accelerator selected from the group consisting of [a] a specific tertiary amine compound (salt) (B1), [b] a specific quaternary ammonium salt (B2) and [c] a quaternary phosphonium salt and / or phosphine compound (B3).

Owner:TORAY IND INC

Coupling Agents for Orthopedic Biomaterials

ActiveUS20080009955A1Improve mechanical propertiesImprove stabilityBone implantTissue regenerationBone implantPolymer composites

The invention provides a method for the preparation of bone-polymer composites wherein the mineral portion of the bone is treated with a coupling agent before being incorporated into a biocompatible polymeric matrix. The resulting composites may be used as such or be further processed to form an osteoimplant.

Owner:WARSAW ORTHOPEDIC INC

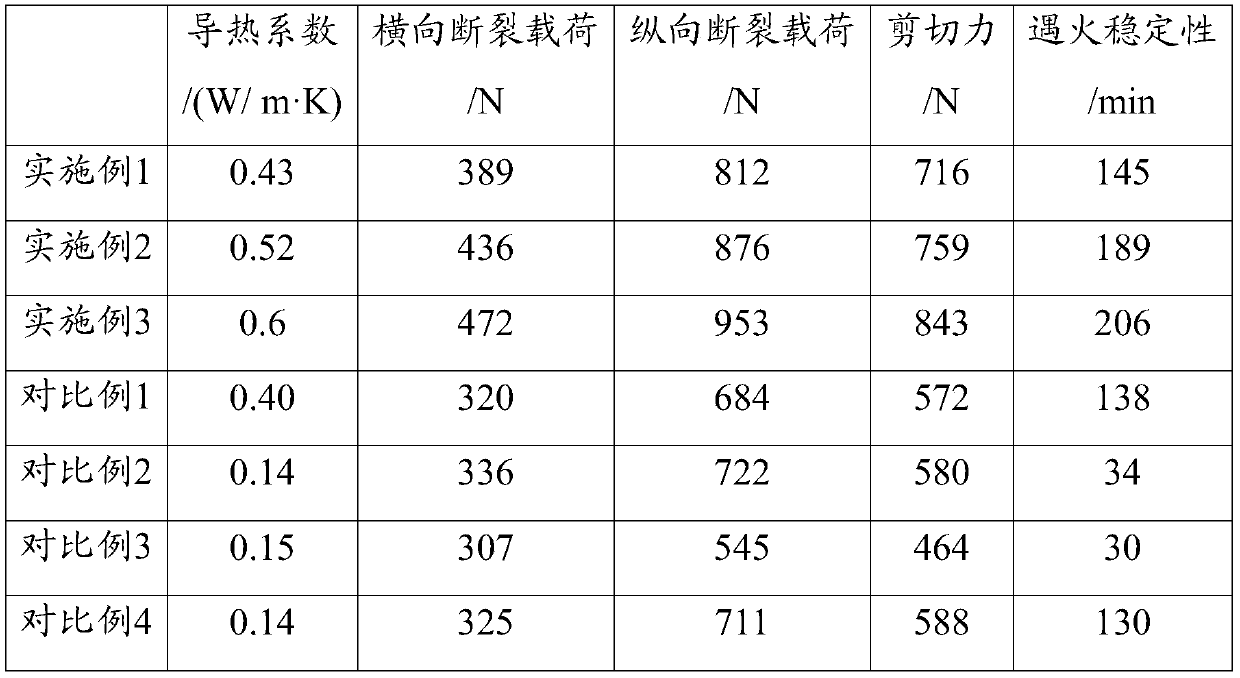

Gypsum plaster board and preparation and application thereof

ActiveCN111153669AImprove interface adhesionHigh strengthCovering/liningsSurface layering apparatusGlass fiberFoaming agent

A gypsum plaster board is characterized in that the core board of the gypsum plaster board comprises following raw materials: gypsum, emulsion and nano particle modified glass fibers, and preferably,the raw materials of the gypsum plaster board comprise gypsum, emulsion, nano particle modified glass fibers, a foaming agent, a water reducing agent, modified starch and water. The preparation methodof the gypsum plaster board comprises the following steps: firstly, uniformly stirring gypsum, the emulsion, the nano particle modified glass fibers, the foaming agent, the water reducing agent, themodified starch and water to prepare gypsum slurry; secondly, pouring the slurry on surface protection paper, performing lap joint, firm adhesion and forming to prepare a wet board; finally, after thewet board is solidified, delivering the wet board to a drying machine, and drying the wet board. The provided gypsum plaster board is excellent in heat-conducting property, mechanical property and fire resistance. The longitudinal strength and the transverse strength of the gypsum plaster board with the thickness of 12 mm are improved by 53% and 75% respectively compared with those of a common gypsum plaster board, the heat conductivity coefficient is improved by 300% compared with that of the common gypsum plaster board, and the gypsum plaster board has wide application prospects in heat conduction building materials.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

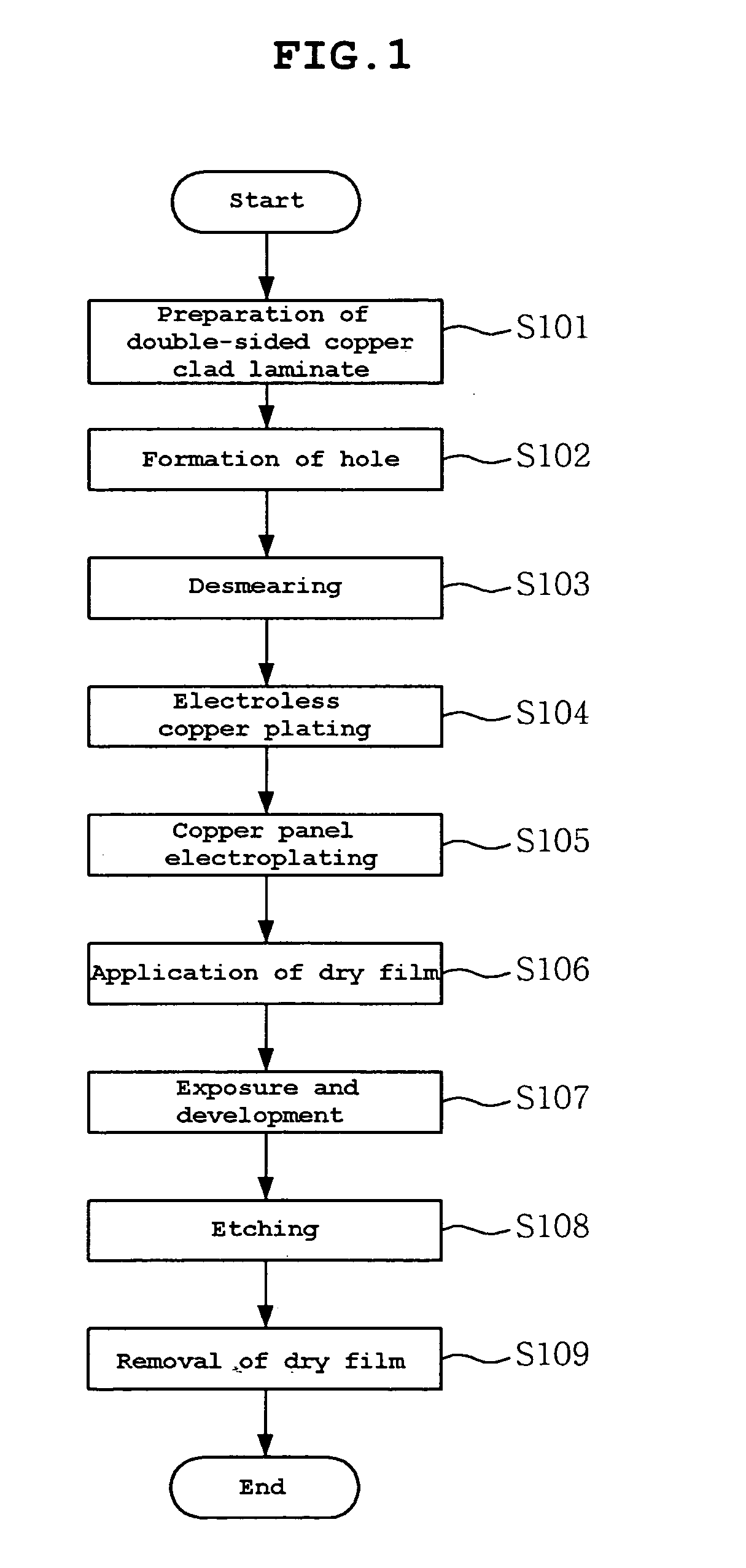

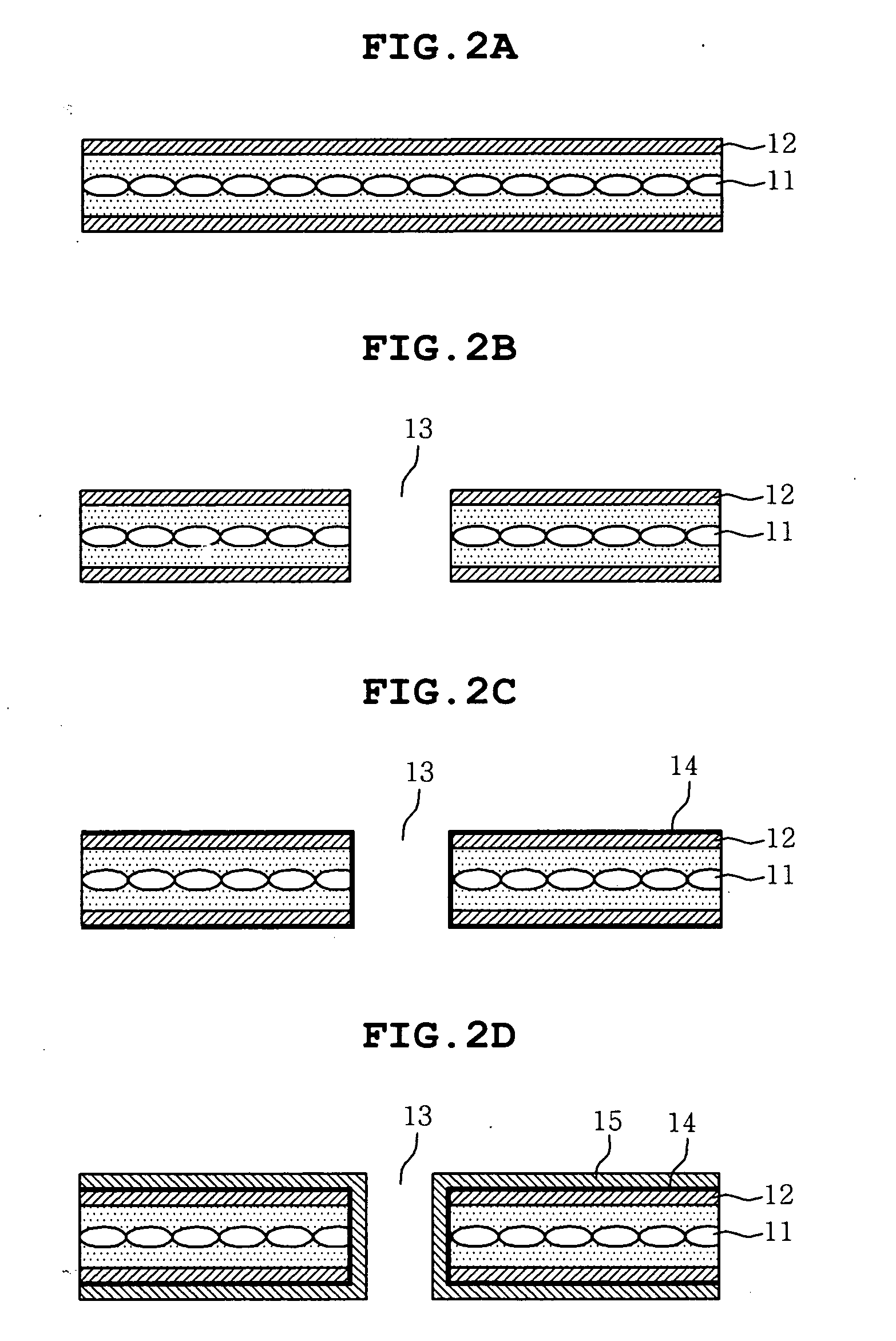

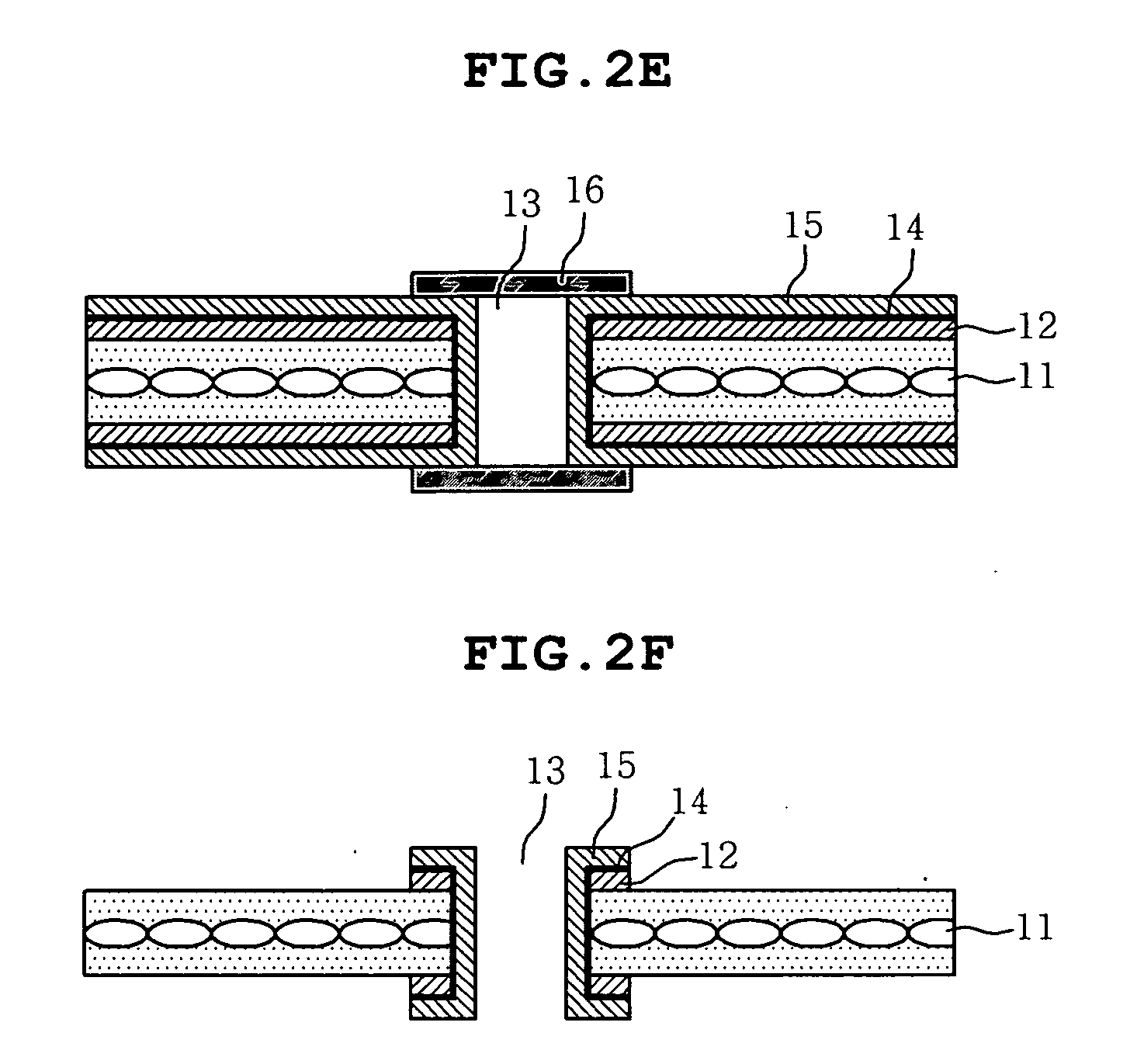

Printed circuit board and method of manufacturing the same

InactiveUS20070141310A1Highly reliable fine circuitImprove interface adhesionDielectric materialsSynthetic resin layered productsCopper platingInterfacial adhesion

Disclosed are a printed circuit board and a method of manufacturing the same, in which a fluorine resin coating layer is formed on a resin substrate, and then a copper layer is formed using a dry process including ion beam surface treatment and vacuum deposition instead of a conventional wet process including surface roughening and electroless copper plating. According to this invention, the interfacial adhesion of the substrate material may be increased without changing the surface roughness thereof, thus realizing a highly reliable fine circuit. As well, a low dielectric constant and a low loss coefficient may be obtained thanks to the formation of the fluorine resin layer. Further, a wet process is replaced with a dry process, whereby the copper plating layer may be formed in an environmentally friendly manner.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Composite coatings for oxidation protection

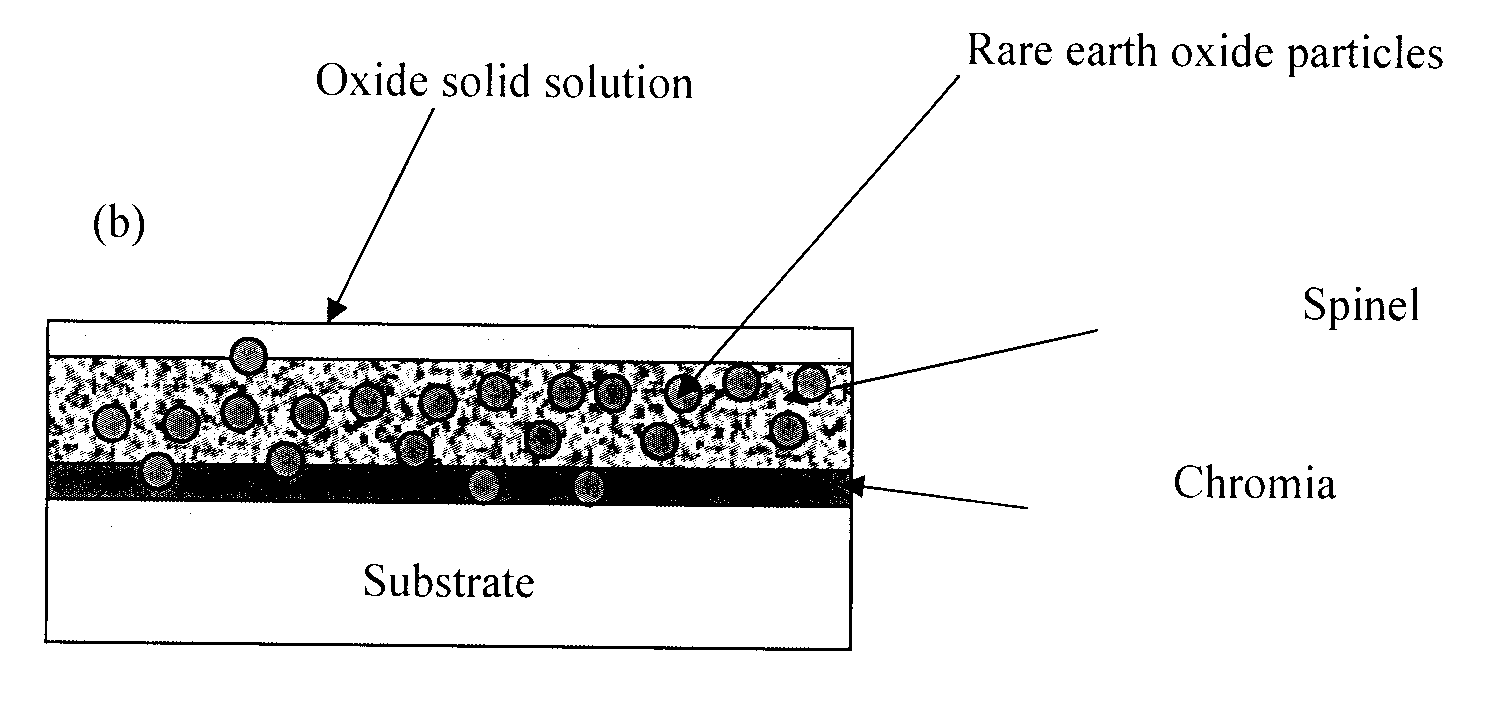

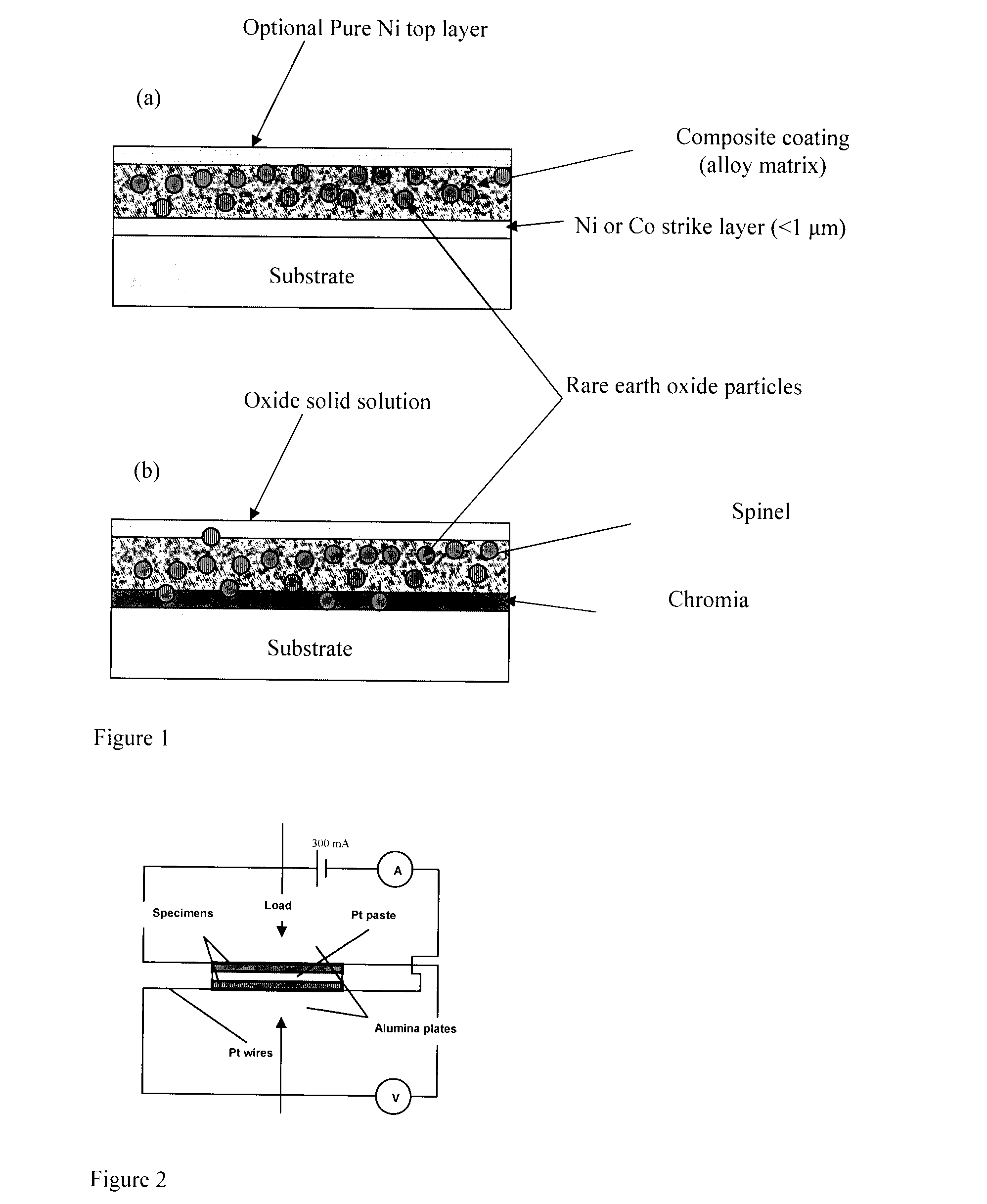

InactiveUS20130004881A1Reduce contact resistanceImprove the immunityChromatisationFuel cells groupingMischmetalRare earth

The invention disclosed relates to an oxidized metal matrix composite coated substrate, comprising a substrate made of a material selected from the group consisting of a chromia-forming Fe, Ni and / or Co based alloy containing an amount of Cr ranging from 16 to 30 wt %, and an oxide-dispersion strengthened Cr-based alloy and a plain Cr-based alloy, and an oxidized metal matrix composite coating comprising at least two metals and reactive element oxide particles in the form of a tri-layer scale on the substrate surface comprising an inner chromia layer, an intermediate layer of a spinel solid solution formed by Cr and one or more of the deposited metals selected from the group consisting of Ni, Co, Cu, Mn, Fe and Zn and a mixture thereof, and an electrically conductive top layer comprising oxides of one or more deposited metals selected from the group consisting of Ni, Co, Cu, Fe, Mn, Zn and a mixture thereof, which is substantially free from Cr ions, and wherein one or more of such layers contain particles of doped or undoped oxides of a rare earth metal selected from the group consisting of Ce, Y, La, Hf, Zr, Gd and a mixture thereof.

Owner:NAT RES COUNCIL OF CANADA

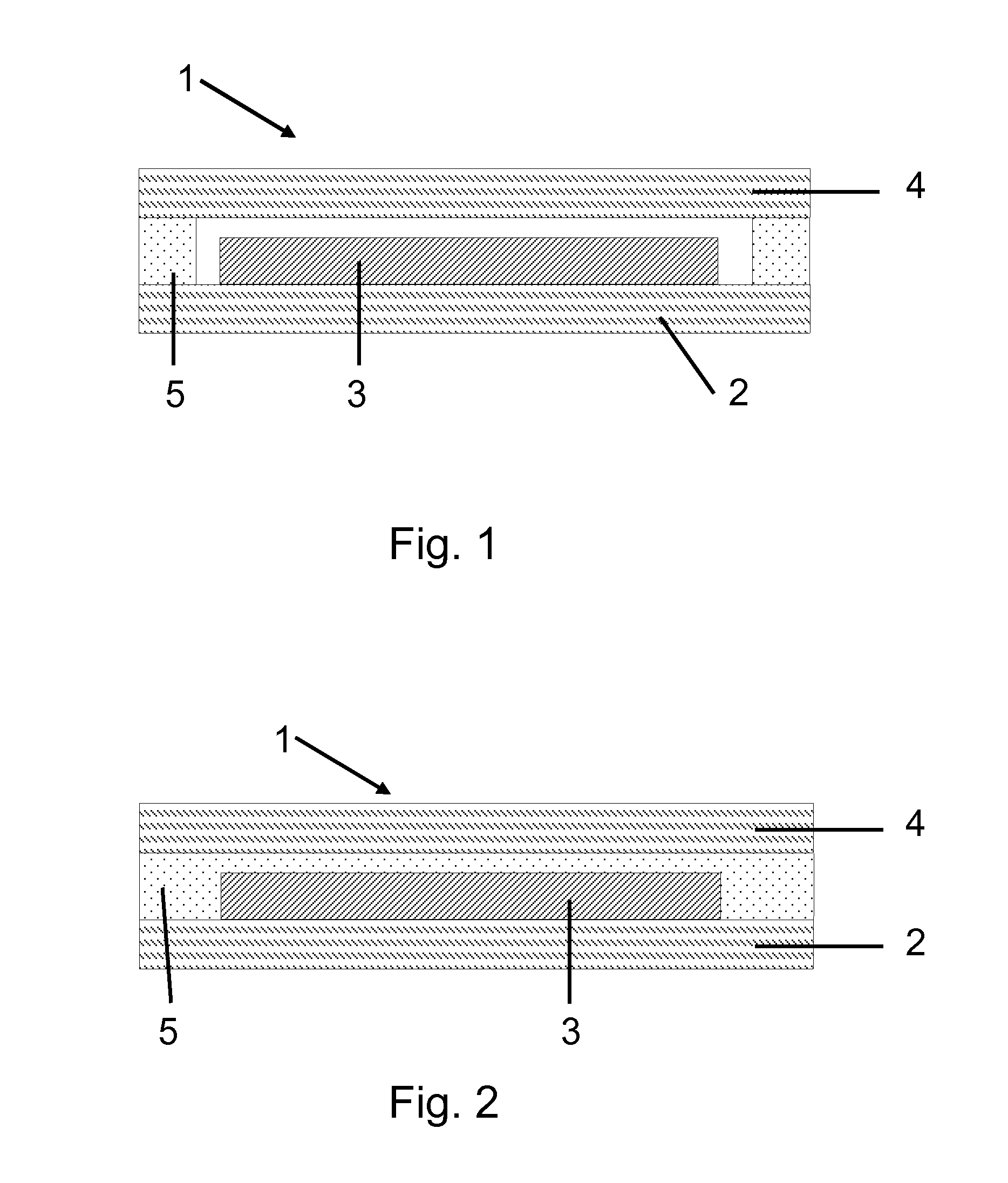

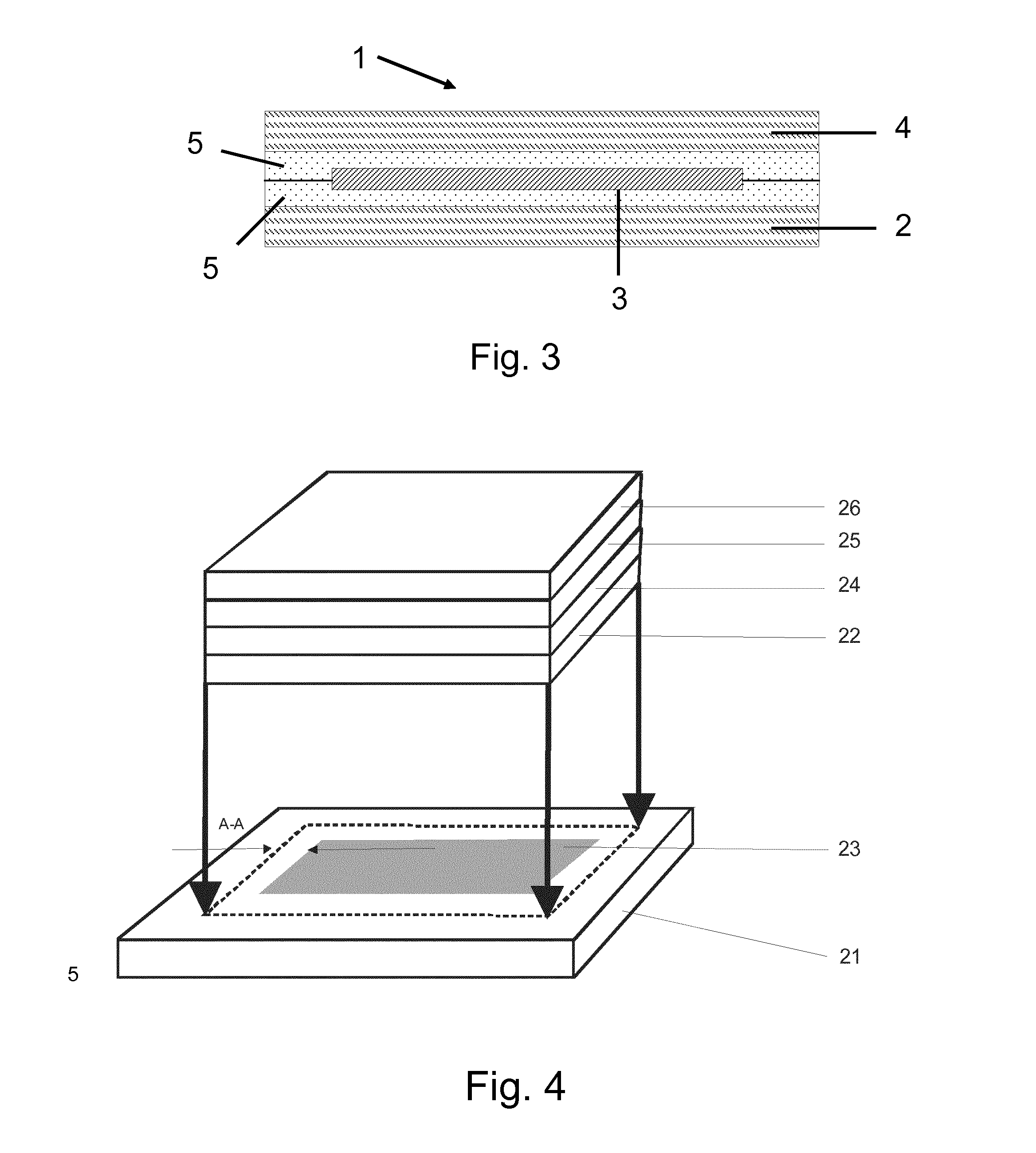

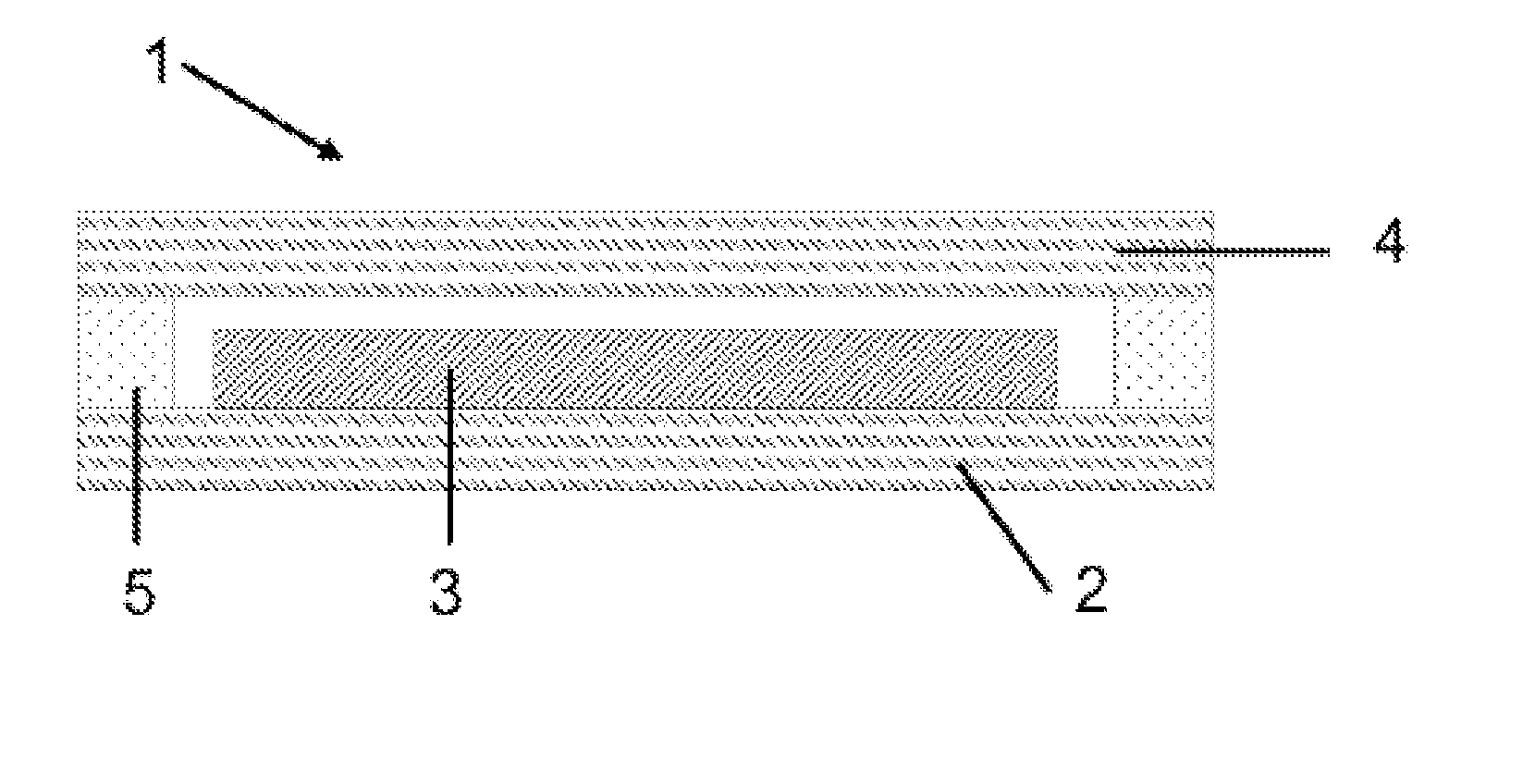

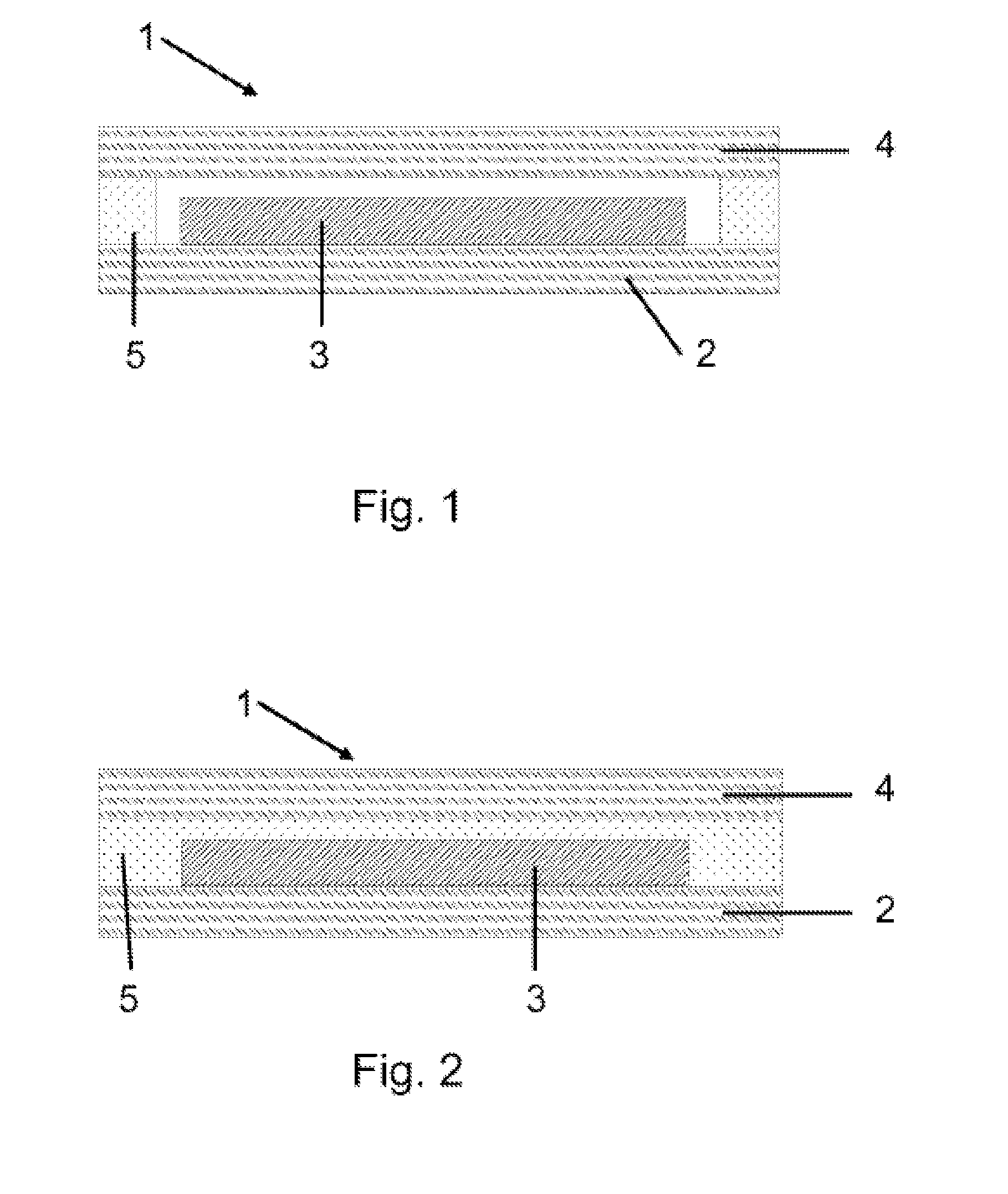

Pressure-sensitive adhesive material particularly for encasing an electronic arrangement

ActiveUS20150240134A1Good barrier propertyGood interfacial adhesionAdhesive processesSynthetic resin layered productsPressure sensitiveChemistry

Pressure-sensitive adhesive material for encasing an electronic arrangement to prevent permeate, which material comprises at least 70 percent by weight of a mixture of at least one fluorine-containing thermoplastic elastomer and at least one fluorine-containing liquid elastomer, wherein the mass ratio of the fluorine-containing liquid elastomer to the fluorine-containing thermoplastic elastomer is between 5:95 to 55:45

Owner:TESA SE

Adhesive composition comprising a particulate thermoplastic component

InactiveUS20020010256A1Improve interface adhesionInhibition formationMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesWater basedParticulates

The invention is directed to an adhesive composition comprising a water based component including a film-forming polymer and a particulate thermoplastic component selected from the group consisting of thermoplastic polymers, thermoplastic resins, hot melt adhesive compositions, and mixtures thereof. The thermoplastic component has a mean particle size of from about 10 microns to about 1,500 microns. The adhesive composition is useful as a one-shot bookbinding adhesive, a primer composition as well as a second-shot adhesive for two-shot bookbinding method. The invention is also directed to the bookbinding methods using the adhesive composition.

Owner:HB FULLER CO

Cross-linkable adhesive compound with hard and soft blocks as a permeant barrier

ActiveUS20150079389A1Improve barrier propertiesImprove interface adhesionNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentPolymer scienceAlkene

Adhesive compound as a permeant barrier, comprising (i) block copolymers having a construction A-B-A, (A-B)n, (A-B)nX, or (A-B-A)nX, where X is the radical of the coupling reagent, n is a whole number between 2 and 10, A is a polymer made of a vinyl aromatic compound and B is a polymer block made of an alkene or diene, wherein this polymer block can also be hydrated, with the condition that at least part of the A blocks is sulfonated, optionally with two-block copolymers in the form of A-B as an admixture component, and (ii) at least one tackifier resin.

Owner:TESA SE

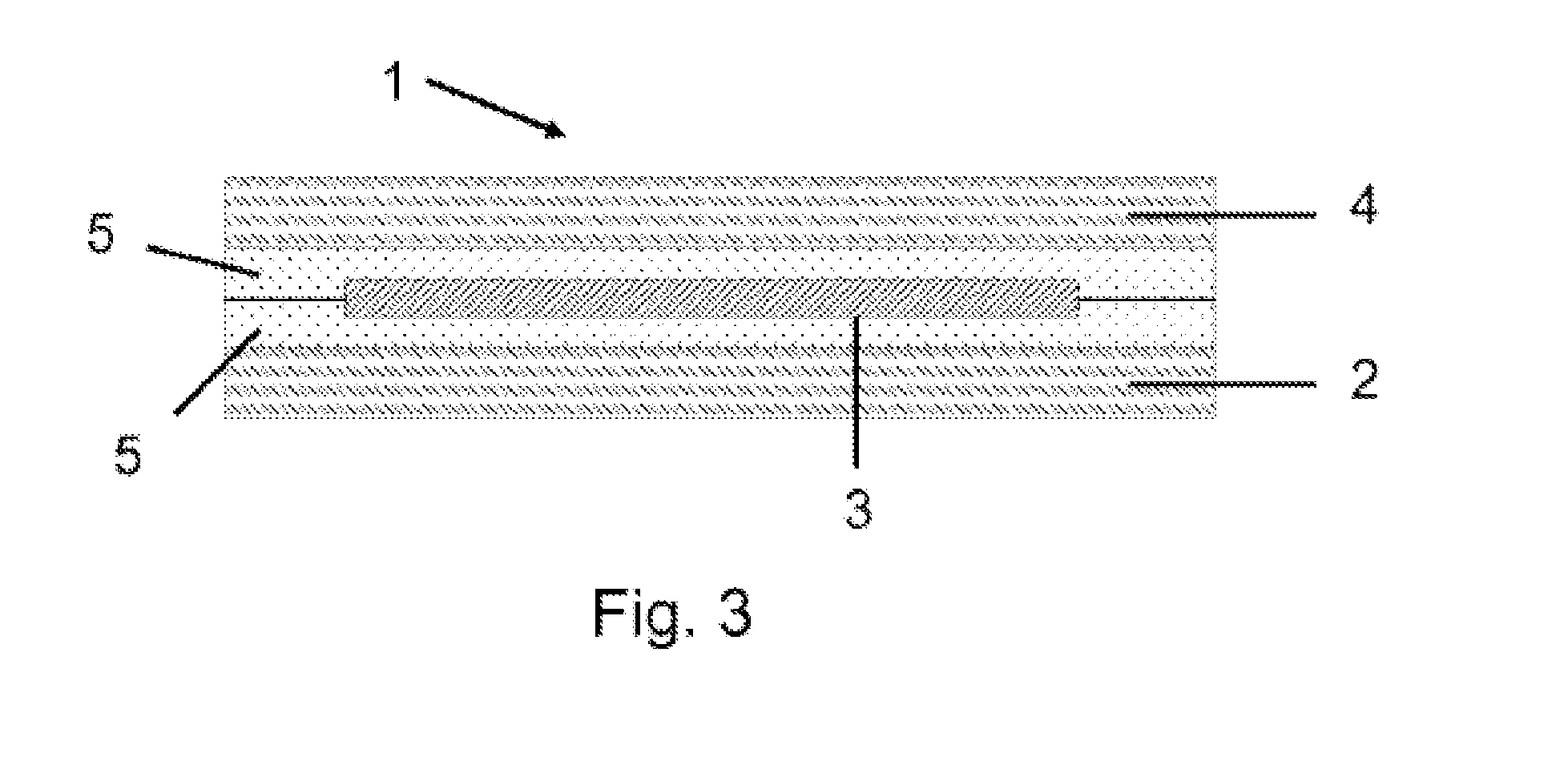

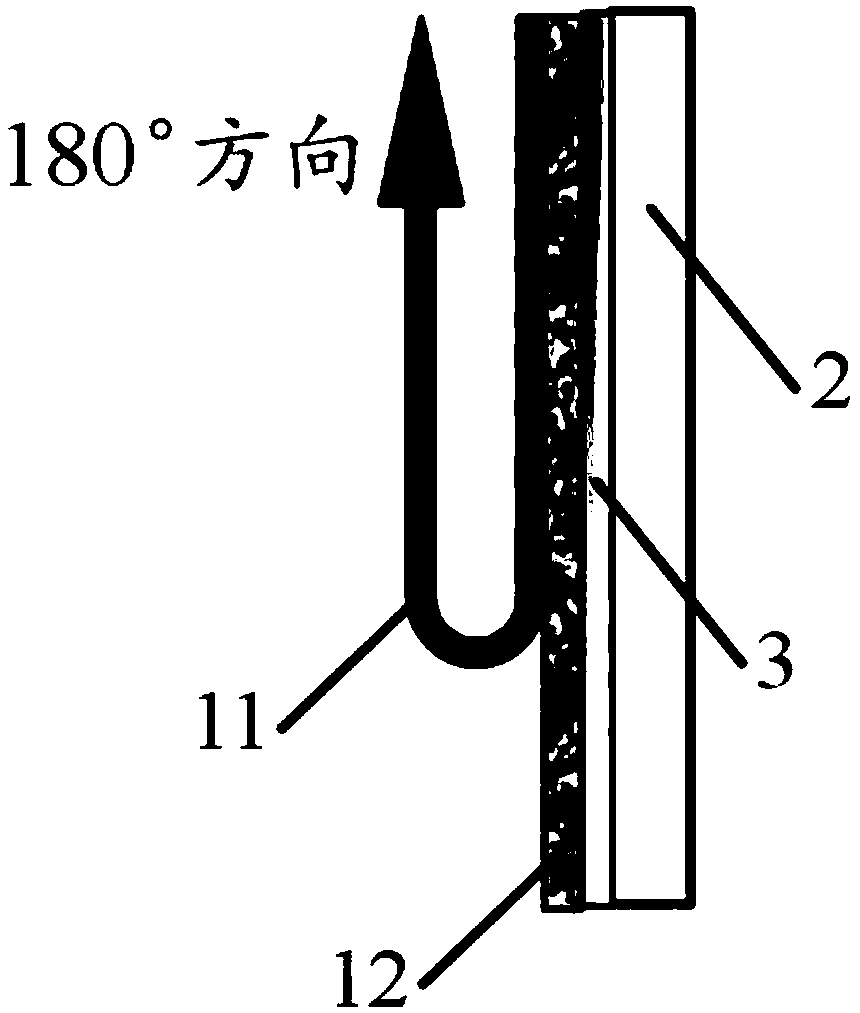

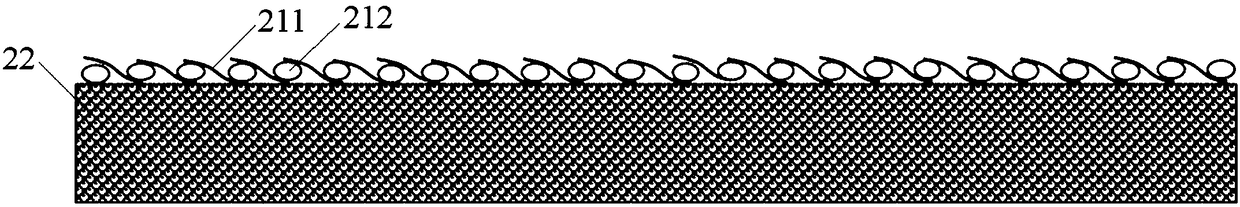

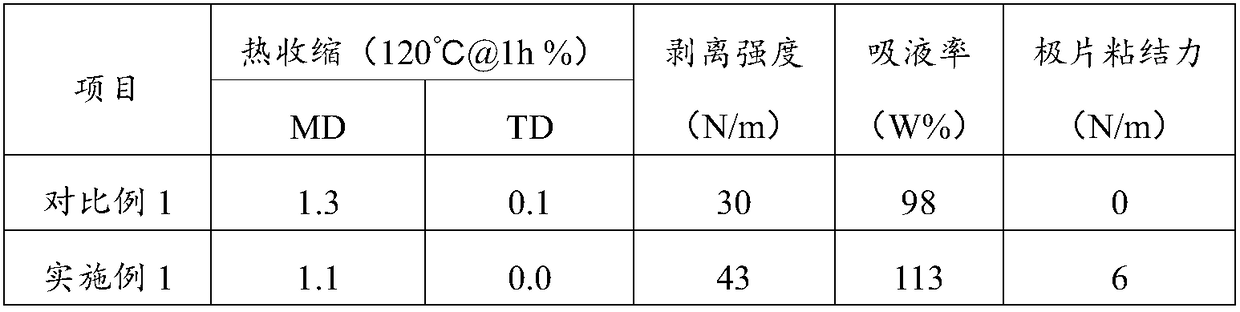

High-temperature resistant composite battery separator and preparation method thereof

ActiveCN108281592AGood thickening effectImprove hydrophilicityCell component detailsInorganic particleInorganic particles

The invention discloses a high-temperature resistant composite battery separator and a preparation method thereof. The high-temperature resistant composite battery separator comprises a base film anda high-temperature resistant coating layer, wherein the high-temperature resistant coating layer is coated on at least one surface of the base film and is formed by coating inorganic particles containing nanometer cellulose as a binding agent. In the composite battery separator, the nanometer cellulose is creatively used as the binding agent to prepare the high-temperature resistant coating layer,the interface bonding force of the coating layer and the base film is improved, the stripping strength of the composite battery separator is further improved, and the problems of falling and powder dropping of the coating layer are solved very well; with the addition of the nanometer cellulose, the inorganic particles are better in dispersion effect in water; moreover, the nanometer cellulose isused as the binding agent to form the coating layer, the high-temperature resistant composite battery separator is rapid in liquid conductivity and high in liquid absorption capability, gel is easilyformed after the electrolyte is absorbed, so that the composite battery separator can be attached onto a surface of an electrode very well, and the integral performance of the lithium ion battery is improved.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

Low density lightning strike protection for use in airplanes

Surface films, paints, or primers can be used in preparing aircraft structural composites that may be exposed to lightning strikes. Methods for making and using these films, paints or primers are also disclosed. The surface film can include a thermoset resin or polymer, e.g., an epoxy resin and / or a thermoplastic polymer, which can be cured, bonded, or painted on the composite structure. Low-density electrically conductive materials are disclosed, such as carbon nanofiber, copper powder, metal coated microspheres, metal-coated carbon nanotubes, single wall carbon nanotubes, graphite nanoplatelets and the like, that can be uniformly dispersed throughout or on the film. Low density conductive materials can include metal screens, optionally in combination with carbon nanofibers.

Owner:ROHR INC +1

Ink bearing paper for thermal dye sublimation record and preparation method of ink bearing paper

InactiveCN102635018AImprove sharpnessImprove diffusion abilityCoatings with pigmentsPaper/cardboardPolymer scienceAdhesive

The invention relates to ink bearing paper for thermal dye sublimation record, which comprises a base material, wherein a back coating is coated on one surface of the base material, the other surface of the base material is sequentially coated with an intermediate layer and an ink bearing layer from inside to outside, and the intermediate layer comprises the raw materials in parts by weight: 100 parts of polyurethane resin, 10-50 parts of EVA (Ethylene-Vinyl Acetate) resin, 0.1-10 parts of hardening agent, 1-60 parts of inorganic pigment and 700-900 parts of solvent. According to the ink bearing paper, the intermediate layer using the polyurethane resin and the EVA resin as main binding agents is additionally arranged between the base material and the ink bearing layer, thus the elasticity and adhering property of the ink bearing paper and the light fastness of a printed image during printing are improved.

Owner:JIAOZUO ZHUORIM DIGITAL MATERIAL

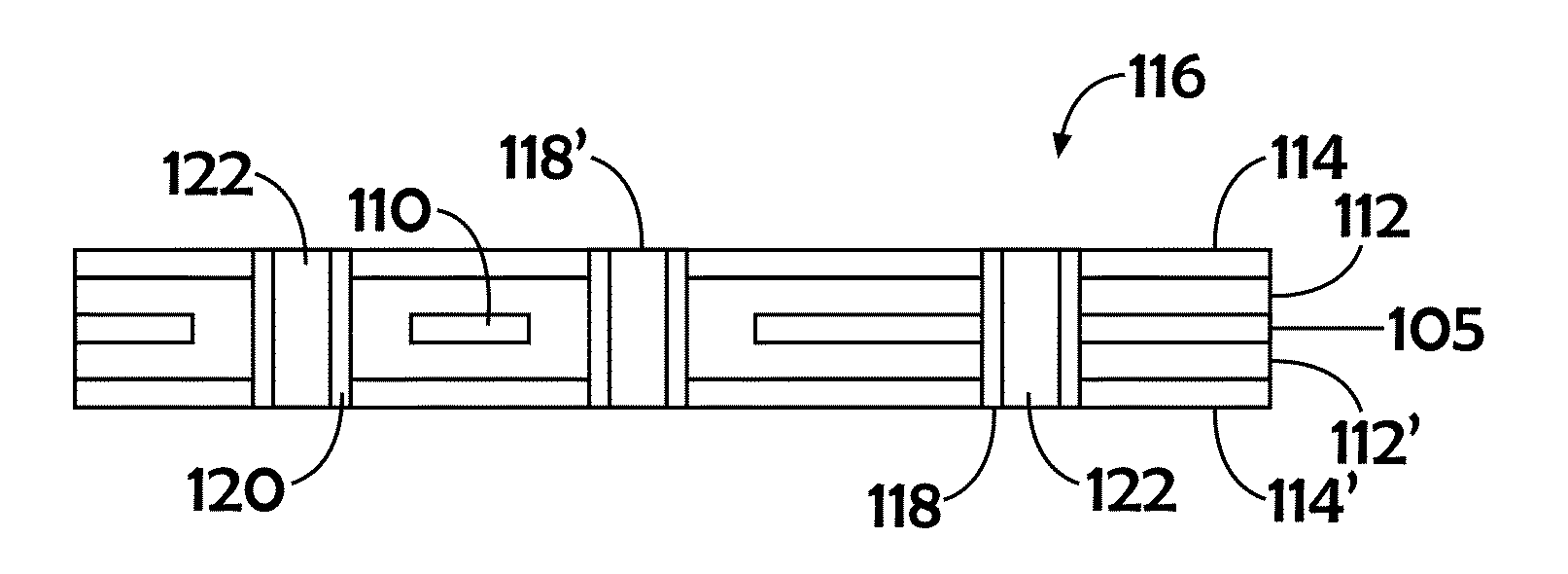

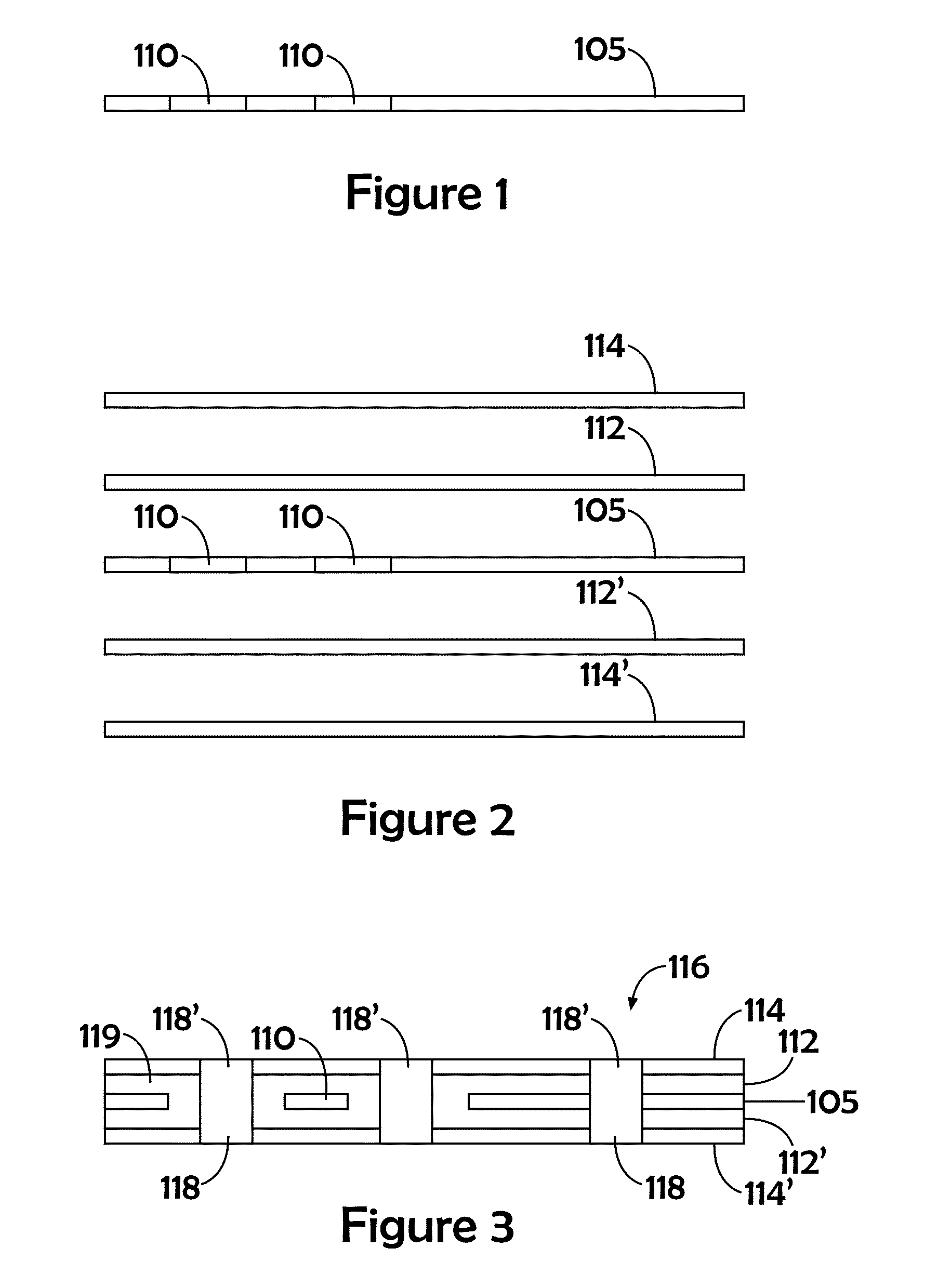

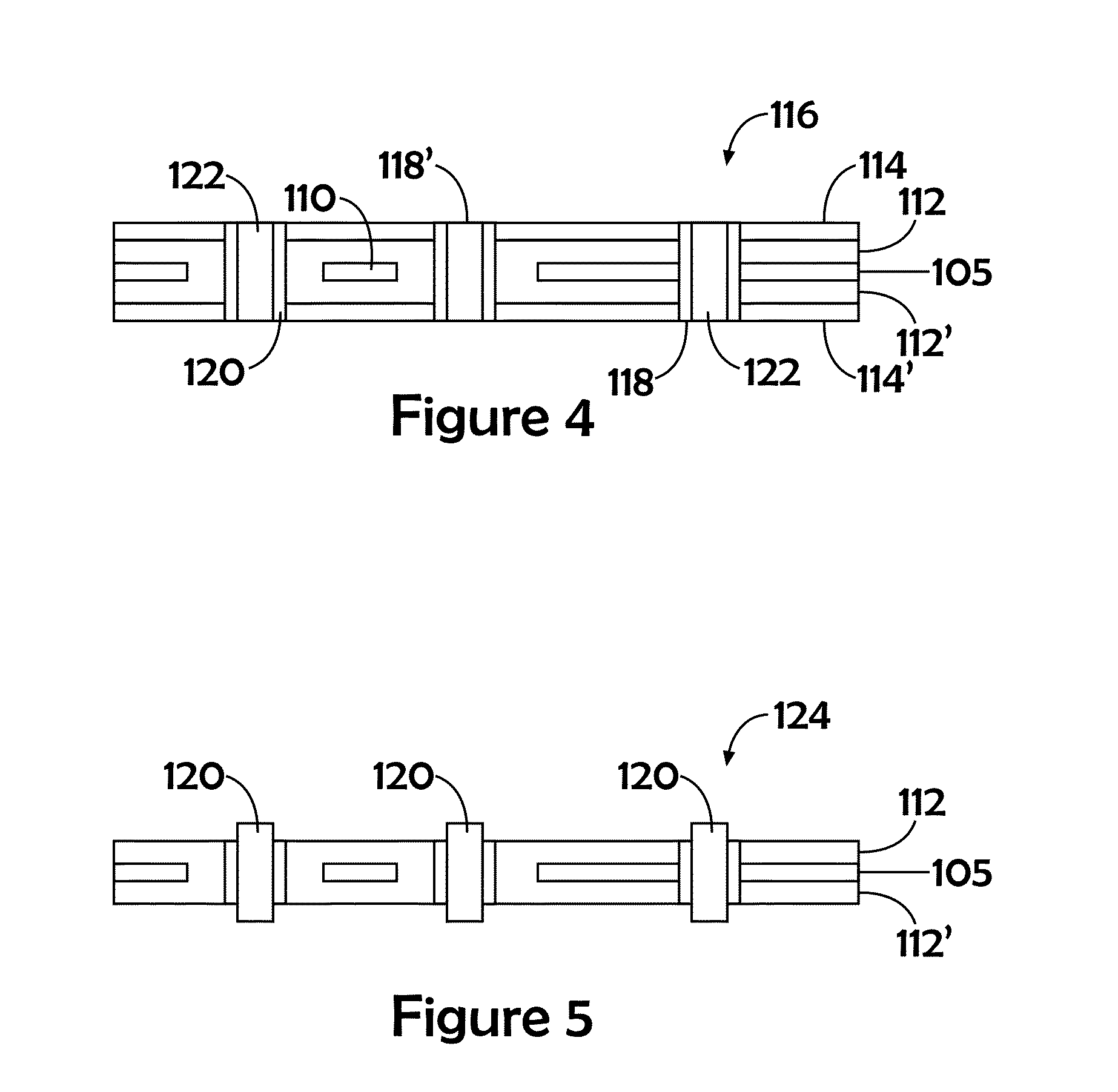

Electrically conductive adhesive (ECA) for multilayer device interconnects

InactiveUS20130033827A1Improve electricityImproved physical contactConductive materialSolid-state devicesDielectricConductive paste

A multilayer capable electrically conductive adhesive (ECA) mixture for connecting multilevel Z-axis interconnects and a method of forming the ECA for connecting multilevel Z-axis interconnects. The multilayer capable ECA contains a mixture of constituent components that allow the paste to be adapted to specific requirements wherein the method of making a circuitized substrate assembly in which two or more subassemblies having potentially disparate coefficients of thermal expansion (CTE) are aligned and Z-axis interconnection are created during bonding. The metallurgies of the conductors, and those of a multilayer capable conductive paste, are effectively mixed and the flowable interim dielectric used between the mating subassemblies flows to engage and surround the conductor coupling.

Owner:TTM TECH NORTH AMERICA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com