Gypsum plaster board and preparation and application thereof

A paper-faced gypsum board and gypsum technology, applied in the field of building materials, can solve the problems of difficulty in meeting new application scenarios, poor strength and toughness, damage to the overall coordination and aesthetics of the house, etc., to improve adhesion and strength. and toughness, the effect of improving fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

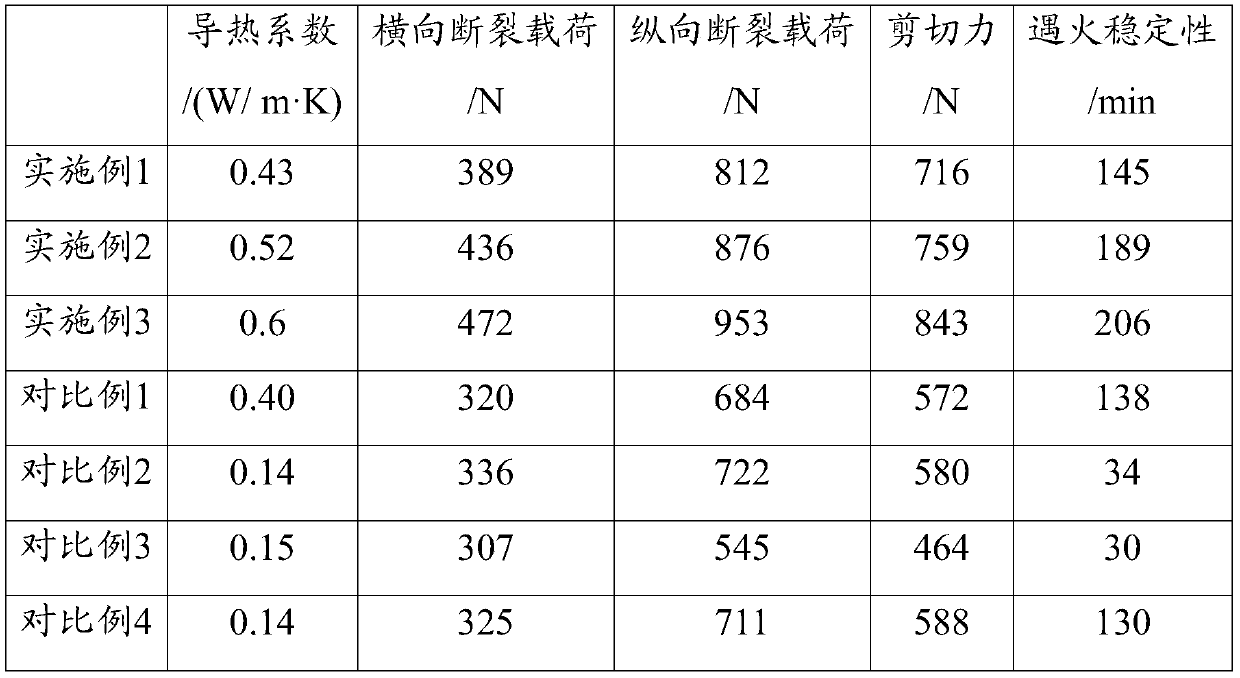

Examples

Embodiment 1

[0068] This embodiment provides a high-strength, high-toughness, high-thermal-conductivity gypsum board, said gypsum board consists of 100 parts by weight of desulfurized gypsum clinker, 0.5 parts by weight of styrene-butadiene emulsion, and 0.4 parts by weight of carbon nano Tube modified glass fiber, 0.02 parts by weight of sodium lauryl sulfate foaming agent, 0.5 parts by weight of water reducing agent, 0.4 parts by weight of modified cornstarch and 67 parts by weight of water. The high-strength, high-toughness, and high-thermal-conductivity gypsum board of this embodiment is prepared by the following method:

[0069] (1) Stir gypsum clinker, emulsion, nano-particle modified glass fiber, foaming agent, water reducer, modified starch and water evenly to prepare gypsum slurry;

[0070] (2) Pour the gypsum slurry on the face-protecting paper, overlap and stick it firmly to form a wet board;

[0071] (3) After the wet board is solidified, enter the dryer, and pass through the ...

Embodiment 2

[0073] This embodiment provides a high-strength, high-toughness, high-thermal-conductivity gypsum board, said gypsum board consists of 100 parts by weight of natural gypsum clinker, 2 parts by weight of polyvinyl acetate emulsion, 0.7 parts by weight of Nano boron nitride modified glass fiber, 0.04 parts by weight of sodium dodecylbenzenesulfonate foaming agent, 0.7 parts by weight of water reducer, 0.8 parts by weight of modified potato starch and 72 parts by weight of water.

[0074] The preparation method of the high-strength, high-toughness, and high-thermal-conductivity gypsum board of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0076] This embodiment provides a high-strength, high-toughness, high-thermal conductivity gypsum board, said gypsum board consists of 100 parts by weight of desulfurized gypsum clinker, 4 parts by weight of vinyl acetate-ethylene copolymer emulsion, 1 part by weight Parts of graphene nanosheet modified glass fibers, 0.03 parts by weight of sodium dodecylbenzenesulfonate blowing agent, 0.8 parts by weight of water reducing agent, 1 part by weight of modified cornstarch and 76 parts by weight of water.

[0077] The preparation method of the high-strength, high-toughness, and high-thermal-conductivity gypsum board of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com