Ink bearing paper for thermal dye sublimation record and preparation method of ink bearing paper

A technology of dye sublimation and thermal transfer printing, applied in the field of ink printing paper, to achieve timely thermal insulation, increase chromaticity, and improve the effect of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

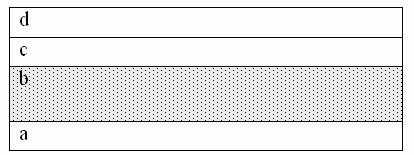

[0023] On the substrate prepared by combining synthetic paper (thickness 80 μm, manufactured by Korea Hwaseung Industrial Co., Ltd.) and white photo paper (95g, Korea Hansol Paper Manufacturing) according to conventional methods in this field, each layer is coated according to the following steps, and finally An ink base paper for dye sublimation thermal transfer recording was prepared.

[0024] 1) middle layer

[0025] After mixing the raw materials in the following weight ratios, use a flexible rod coater (#5) to coat one side of the above-mentioned substrate film at room temperature, and the coating amount is 0.5g / m 2 After coating, dry (dry at 100°C for 30 seconds) to form an intermediate layer and enter the next process;

[0026] Intermediate layer composition: 10.0 parts by weight of polyurethane resin (UB705 manufactured by SKC Corporation in Korea);

[0027] EVA resin (VA-600 produced by Hunan Petrochemical Co., Ltd., South Korea) 5.0 parts by weight;

[0028] Harde...

Embodiment 2

[0049] The raw material composition and proportion of the middle layer are as follows, and the others are the same as in Example 1.

[0050] Polyurethane resin (UB705 manufactured by SKC Corporation in Korea) 10.0 parts by weight

[0051] EVA resin (VA-600 produced by Hunan Petrochemical Co., Ltd., Korea) 5.0 parts by weight

[0052] Hardener (U9081 manufactured by SKC Corporation in Korea) 0.4 parts by weight

[0053] Talc powder (manufactured by Korea Western Industrial Co., Ltd.) 3.0 parts by weight

[0054] 40.8 parts by weight of methyl ethyl ketone

[0055] 40.8 parts by weight of toluene.

Embodiment 3

[0057] The raw material composition and proportion of the middle layer are as follows, and the others are the same as in Example 1.

[0058] Polyurethane resin (UB705 manufactured by SKC Corporation in Korea) 12.0 parts by weight

[0059] EVA resin (VA-600 produced by Hunan Petrochemical Co., Ltd., South Korea) 3.0 parts by weight

[0060] Hardener (U9081 manufactured by SKC Corporation in Korea) 0.4 parts by weight

[0061] Titanium oxide (KA-100 manufactured by Cosmo Chemical, Korea) 1.6 parts by weight

[0062] 41.5 parts by weight of methyl ethyl ketone

[0063] 41.5 parts by weight of toluene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com