Patents

Literature

244results about "Chromatisation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating including inorganic fullerene-like particles and inorganic tubular-like particles

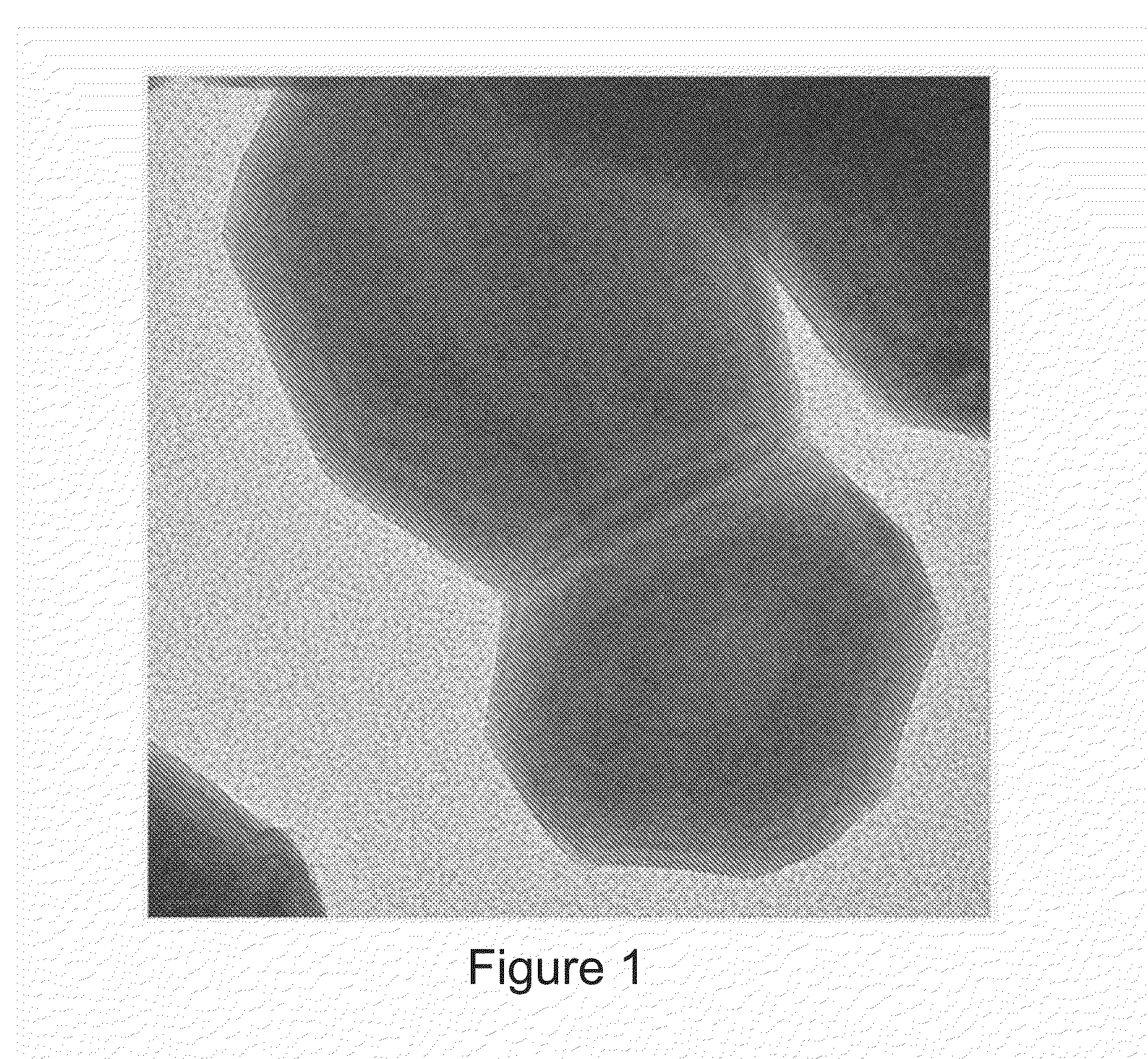

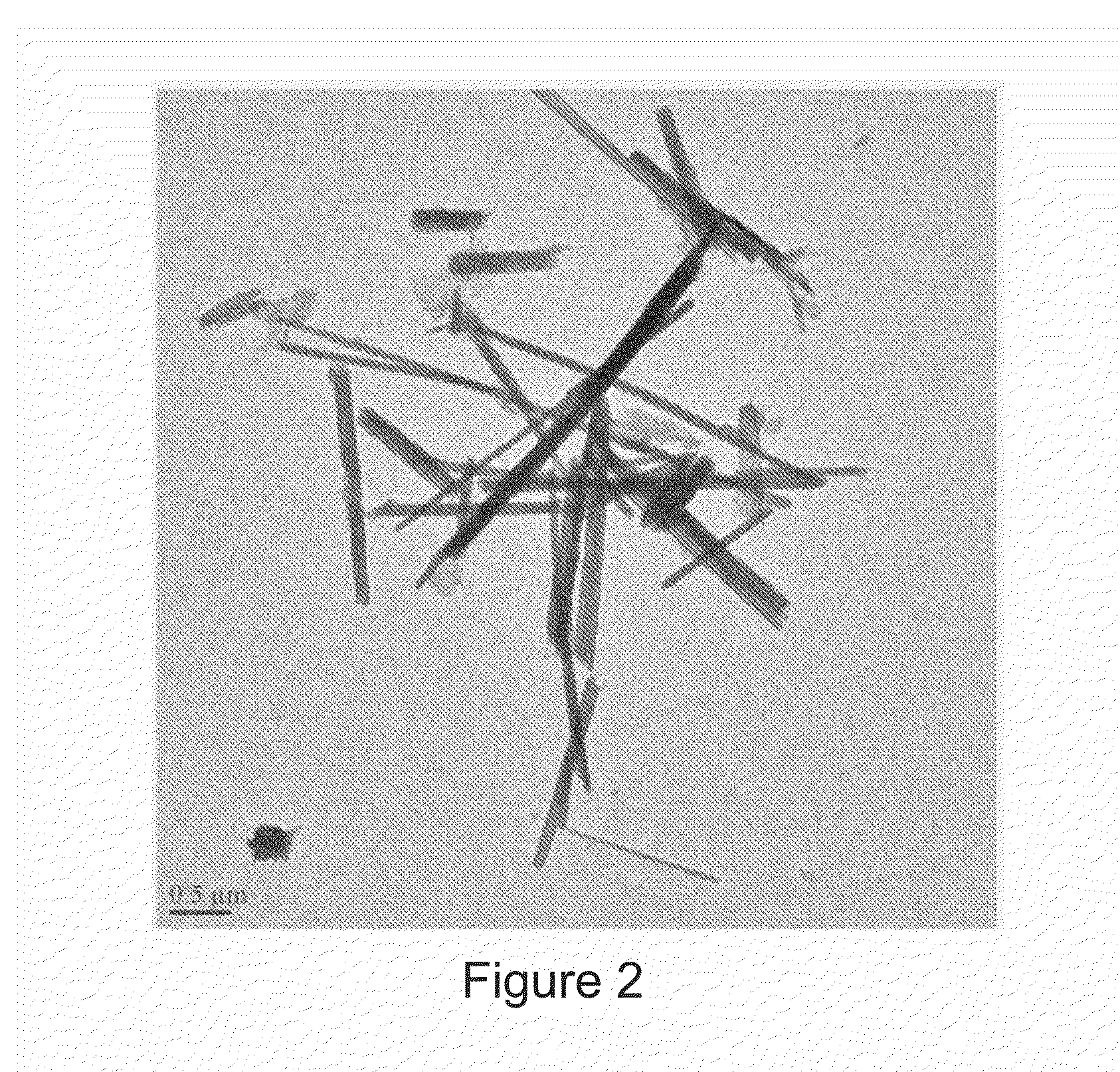

In one embodiment, a coating is provided that includes a deposition surface, and a coating on the deposition surface. The coating may include particles of a metal chalcogenide comprising a fullerene-like geometry, a tubular-like geometry or a combination of fullerene-like geometries and tubular-like geometries. The metal chalcogenide composition has a molecular formula of MX2.

Owner:NANOTECH IND SOLUTIONS

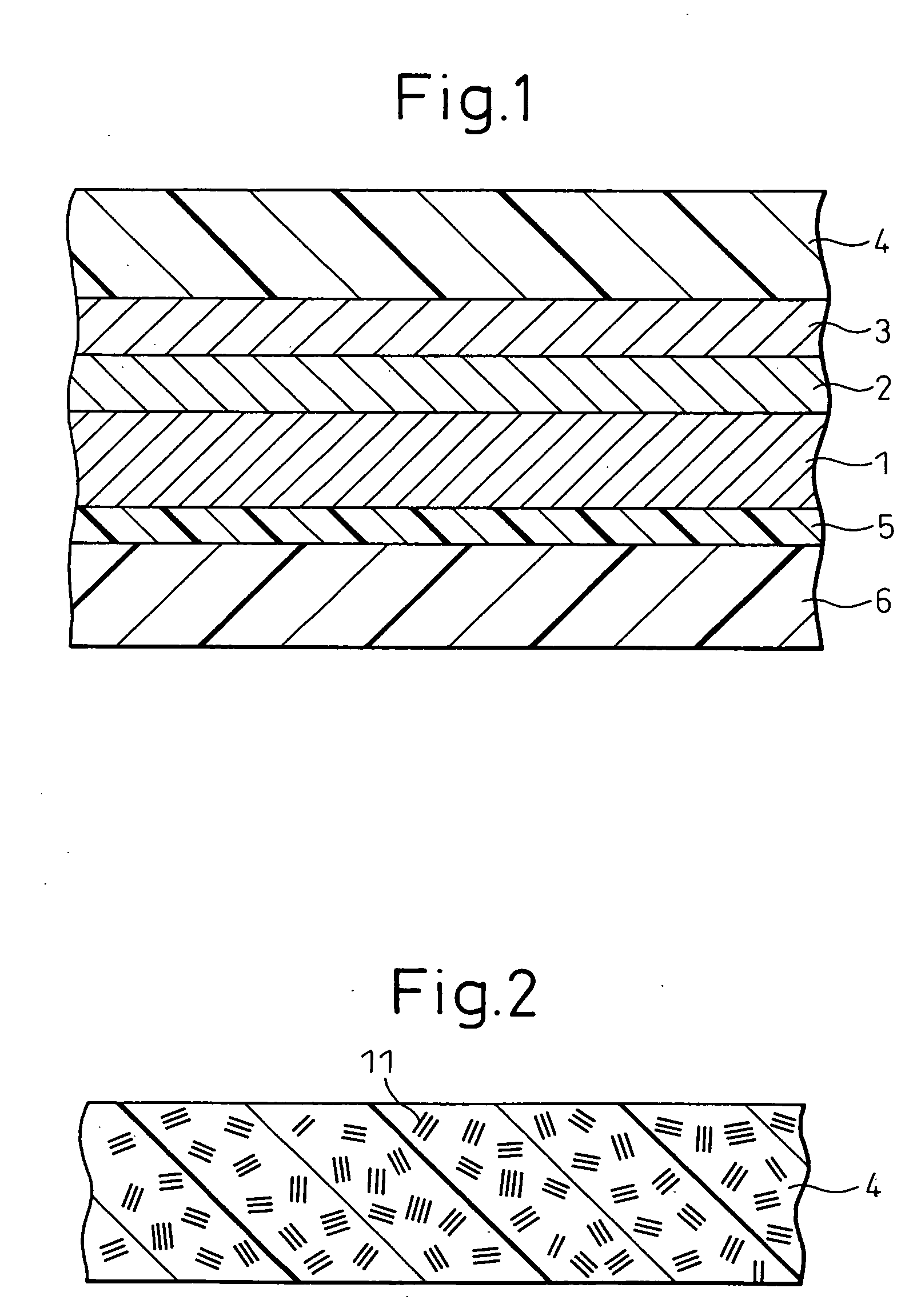

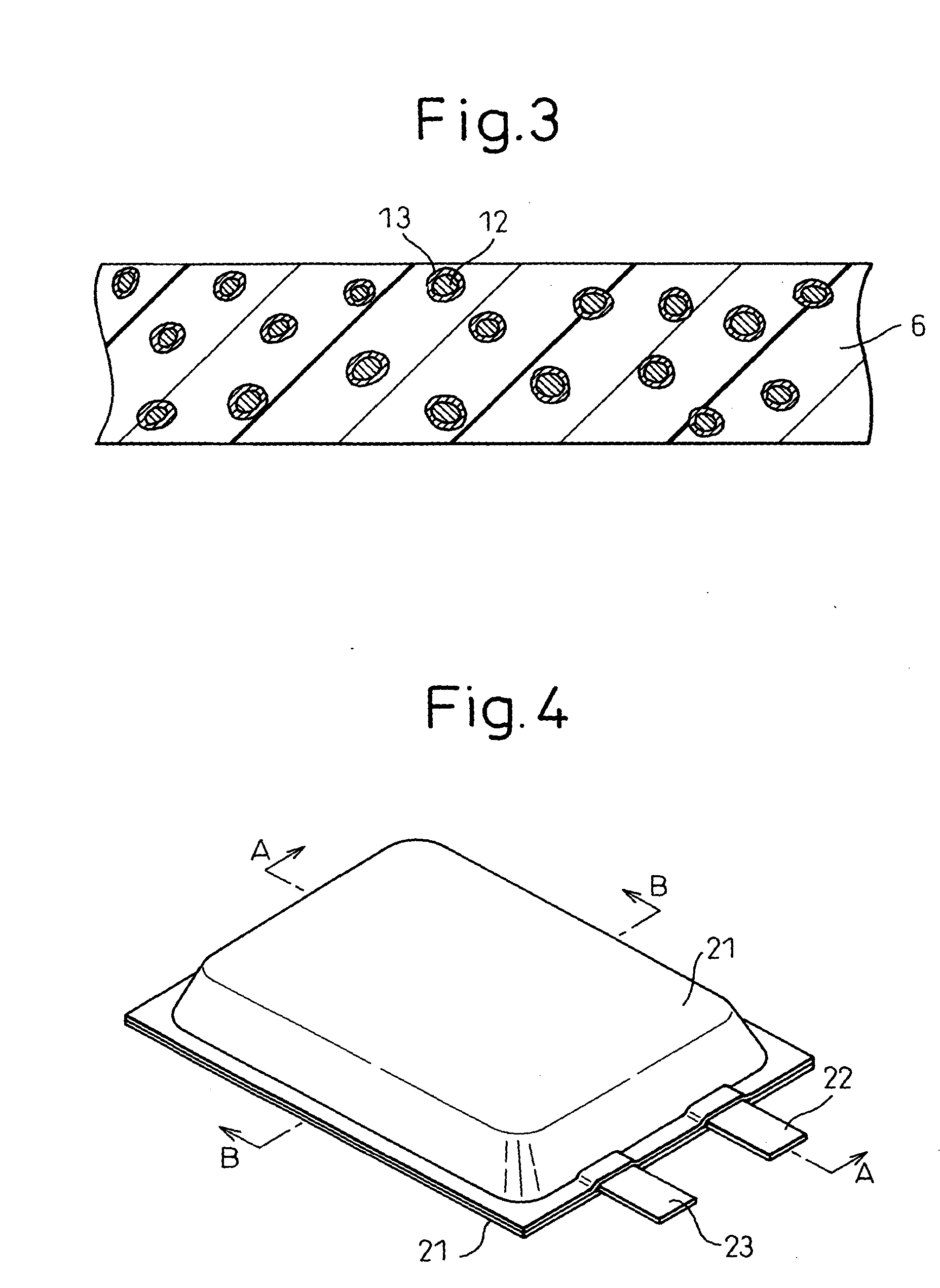

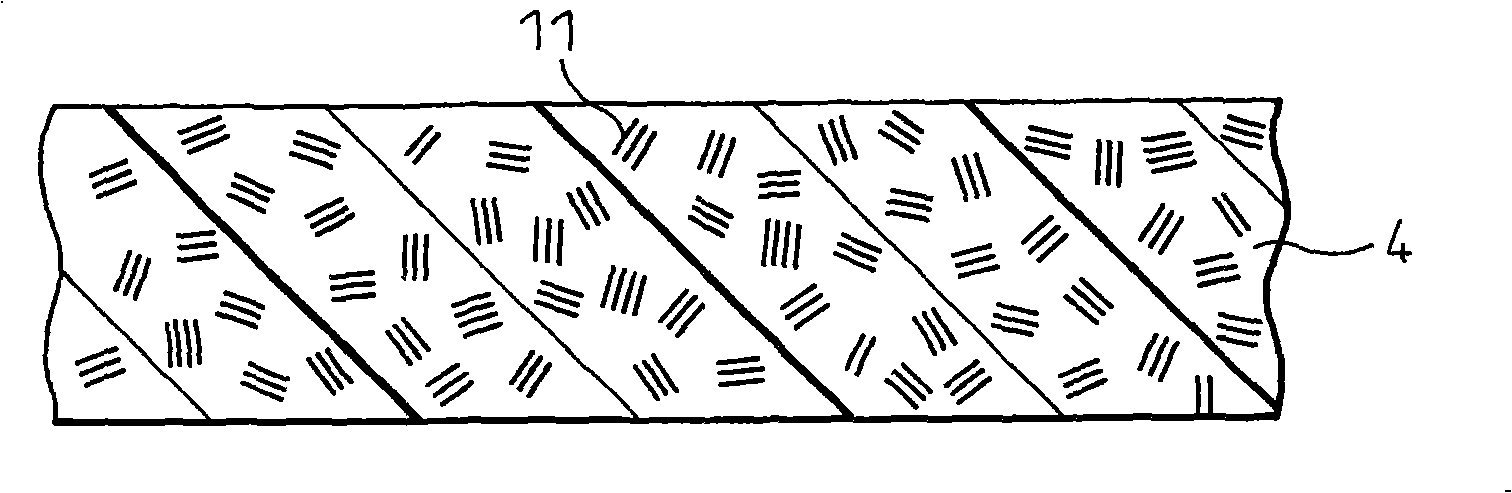

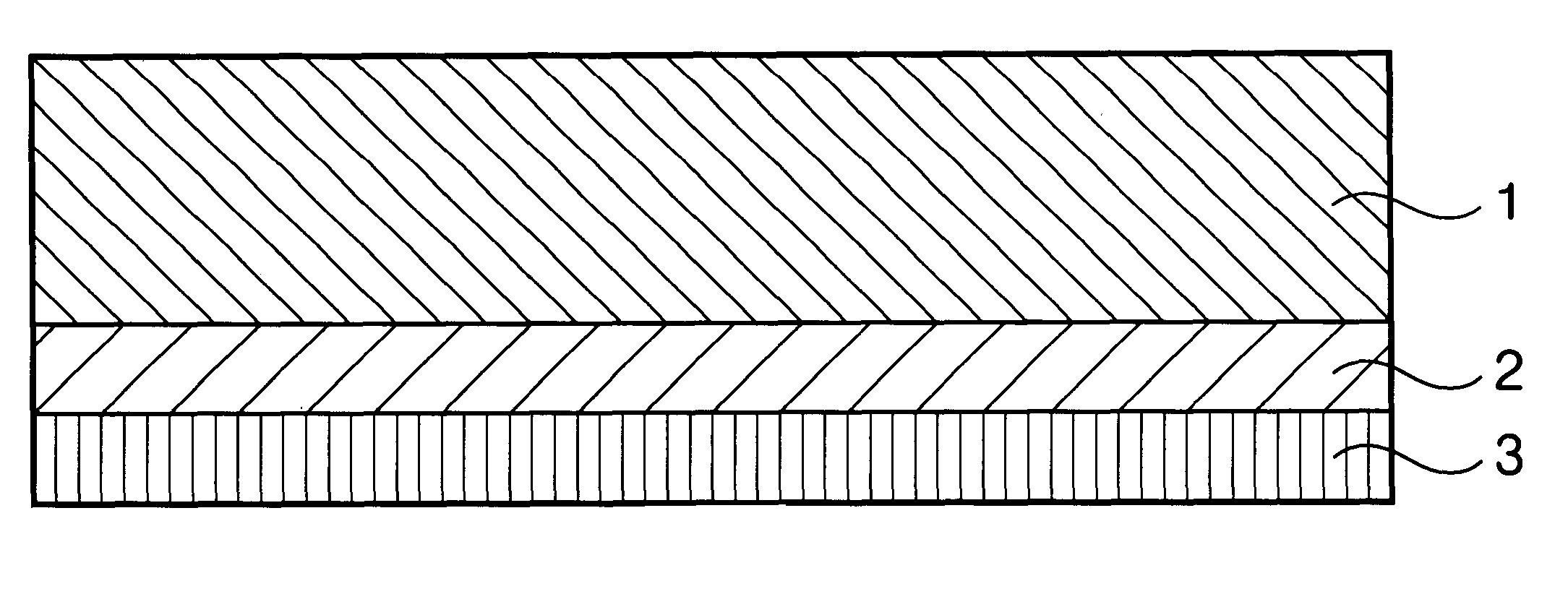

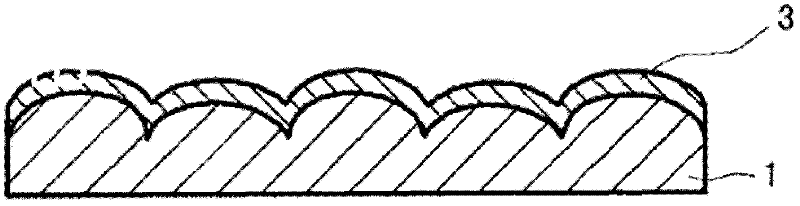

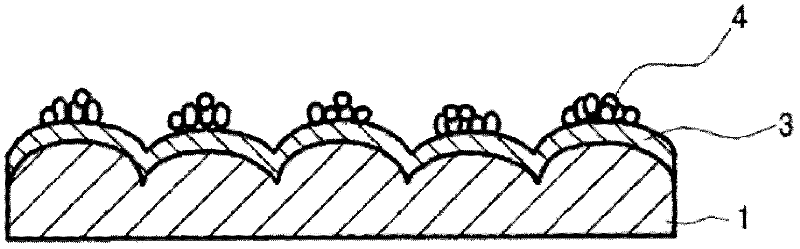

Resin-Coated Stainless Steel Foil, Container and Secondary Battery

ActiveUS20090029245A1Strong adhesionImprove corrosion resistanceEnvelopes/bags making machineryChromatisationPolyolefinMachinability

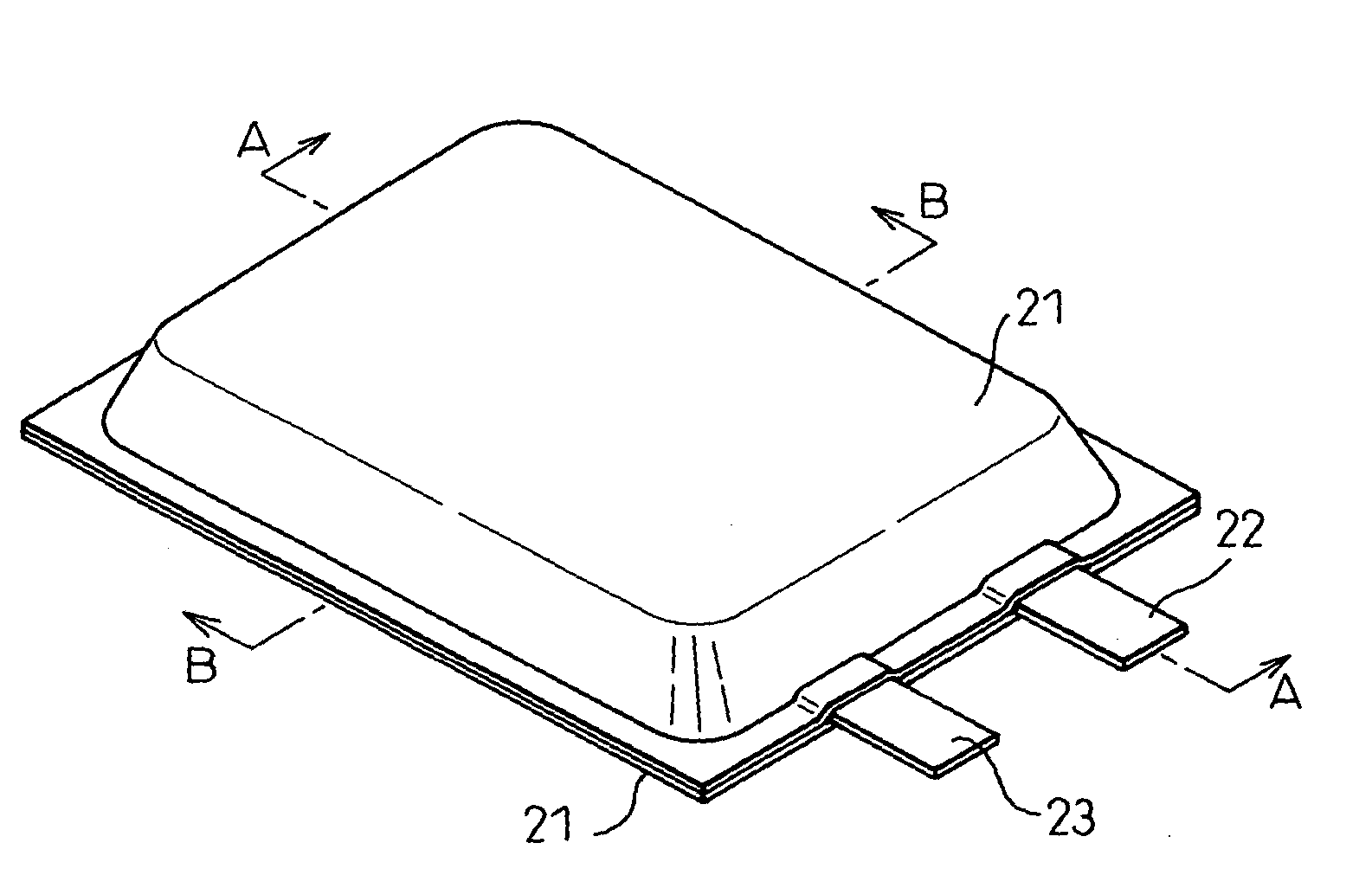

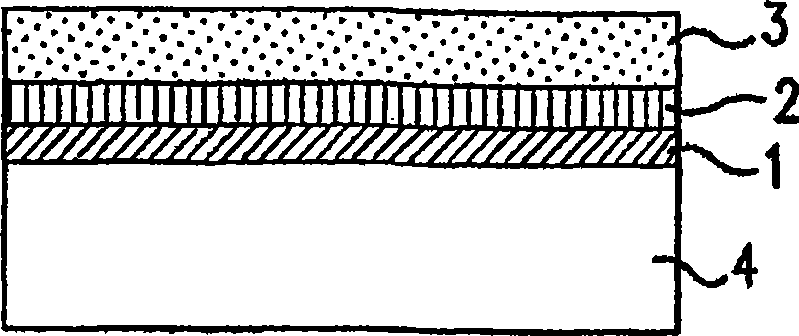

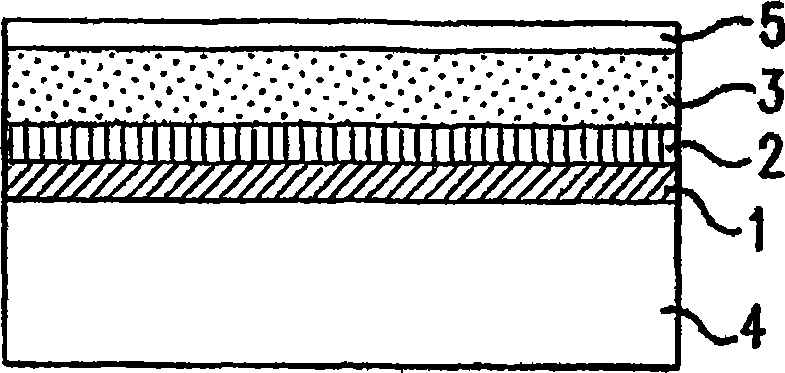

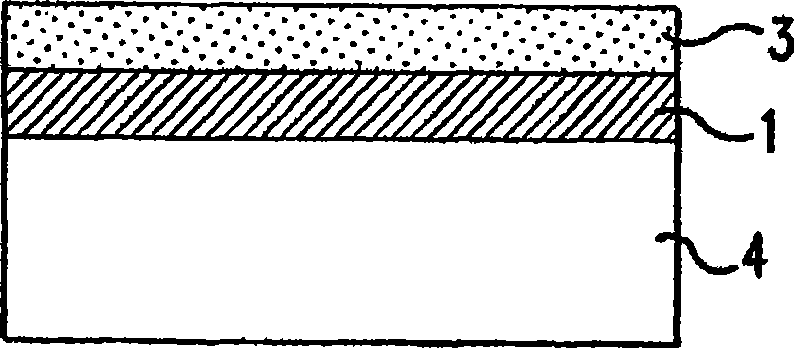

The present invention provides a resin-coated stainless steel foil capable of maintaining a strong adherence force to the film even in an electrolytic solution to exhibit good corrosion resistance and excellent in the workability, design property and piecing resistance, and a container and a secondary battery each using the resin-coated stainless steel foil. According to the present invention, a resin-coated stainless steel foil having a chromate treatment layer of 2 to 200 nm in thickness on at least one surface of a stainless steel foil and having at least a polyolefin-based resin (A) layer containing a functional group having polarity on the chromate treatment layer; and a container and a secondary battery each using the resin-coated stainless steel foil are provided.

Owner:NIPPON STEEL & SUMIKIN MATERIALS CO LTD

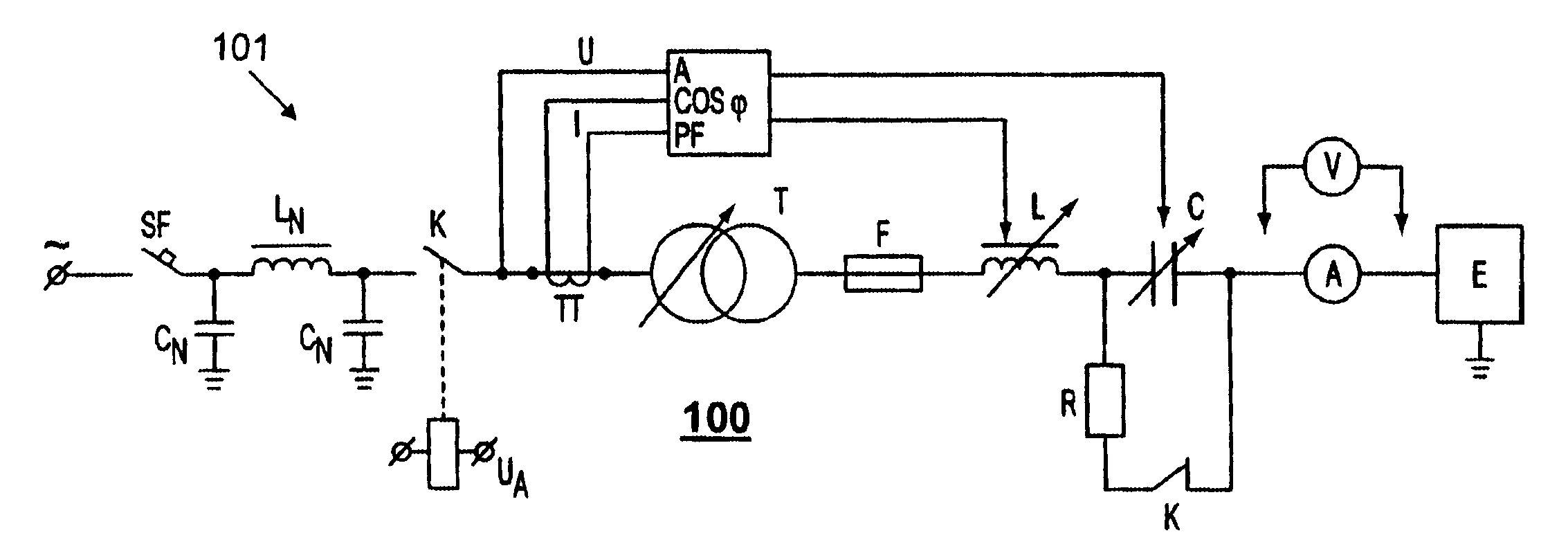

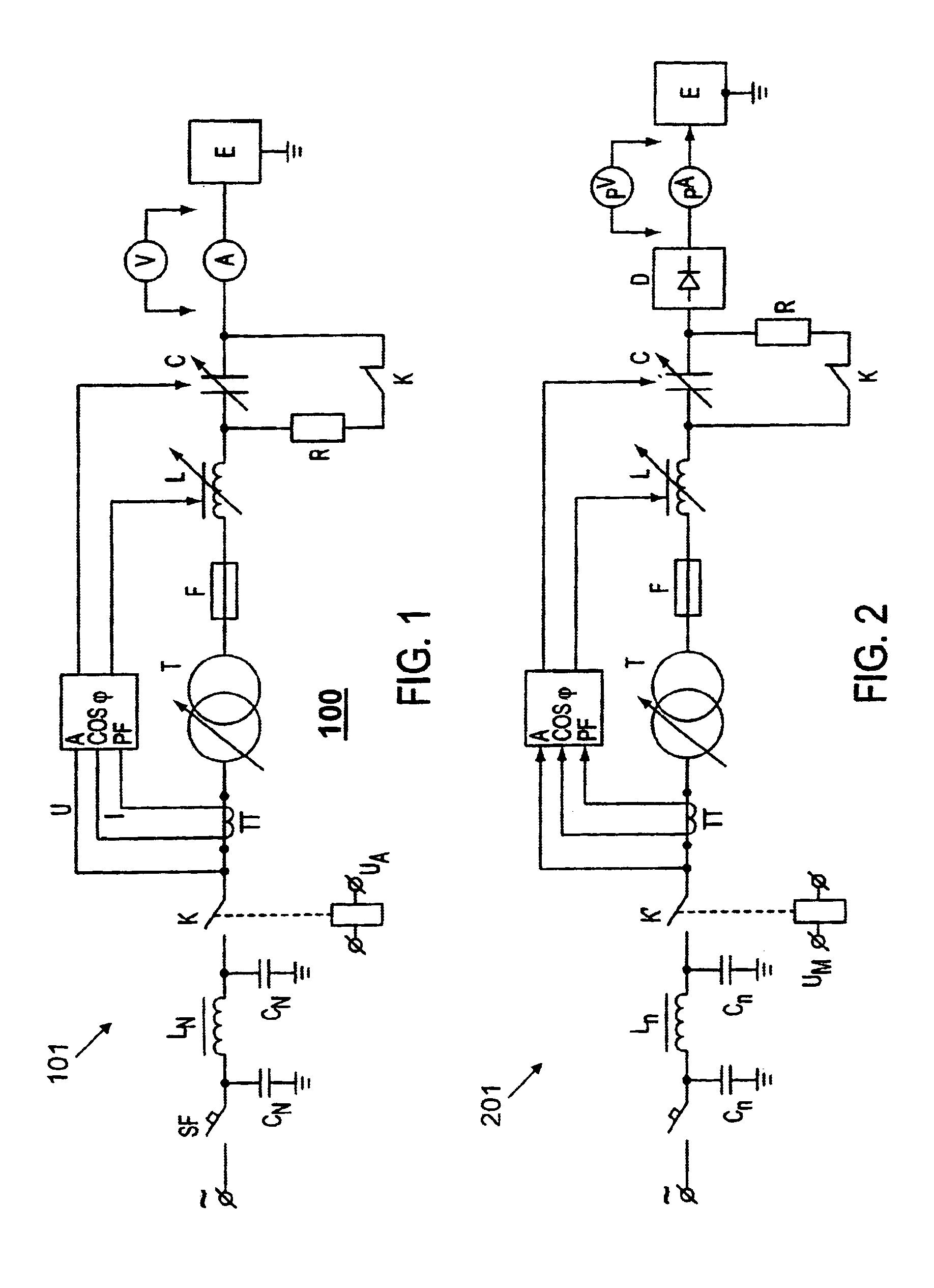

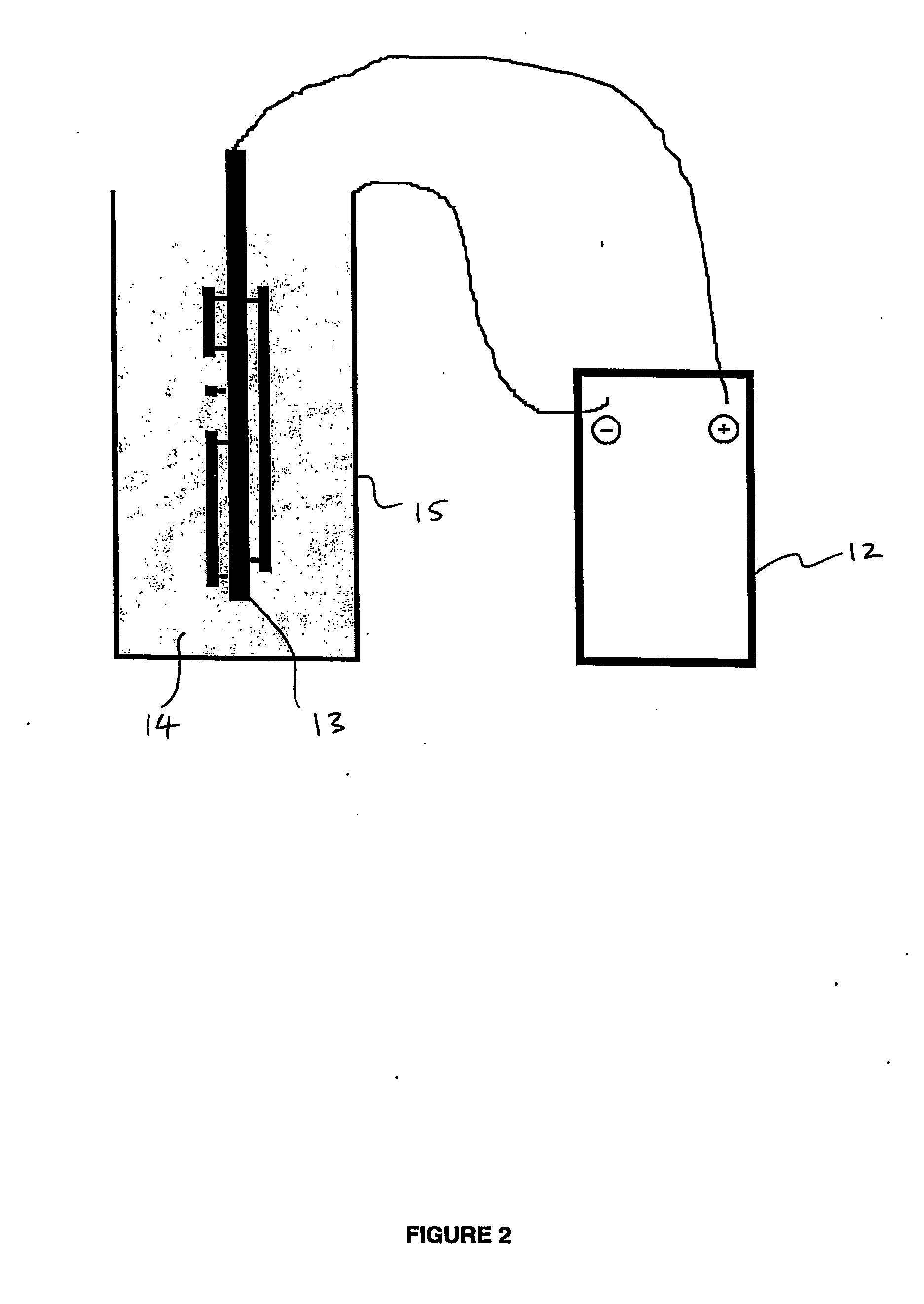

Method of making a composite article comprising a ceramic coating

InactiveUS6919012B1Improve propertiesSuperior physical/mechanical and protective propertyAnodisationCellsSurface layerCeramic coating

A ceramic coating is formed on a conductive article by immersing a first anodic electrode, including the conductive article, in an electrolyte comprising an aqueous solution of alkali metal hydroxide and an alkali metal silicate, providing a second cathodic electrode in contact with the electrolyte, and passing an alternating current from a resonant power source through the first electrode and to the second electrode while maintaining the angle φ between the current and the voltage at zero degree, while maintaining the voltage within a predetermined range. The resulting ceramic coated article comprises a coating which includes a metal, silicon, and oxygen, wherein the silicon concentration increases in the direction from the article surface toward an outer surface of the ceramic coating surface layer.

Owner:OLIMEX GROUP

Resin-coated stainless steel foil, container and secondary battery

ActiveCN101331020AStrong adhesionImprove corrosion resistanceAlkaline accumulatorsChromatisationPolyolefinElectrical polarity

A resin-coated stainless steel foil that can maintain strong adherence to films even in an electrolyte solution and exhibit good corrosion resistance, excelling in processability, designability and stab resistance; and, making use of the same, a container and secondary battery. There is provided a resin-coated stainless steel foil characterized by having a chromate-treated layer of 2 to 200nm superimposed on at least one major surface of stainless steel foil and having, superimposed on the chromate-treated layer, at least a layer of polyolefin resin (A) containing a polar functional group. Further, there are provided, making use of the same, a container and secondary battery.

Owner:NIPPON STEEL CHEM &MATERIAL CO LTD

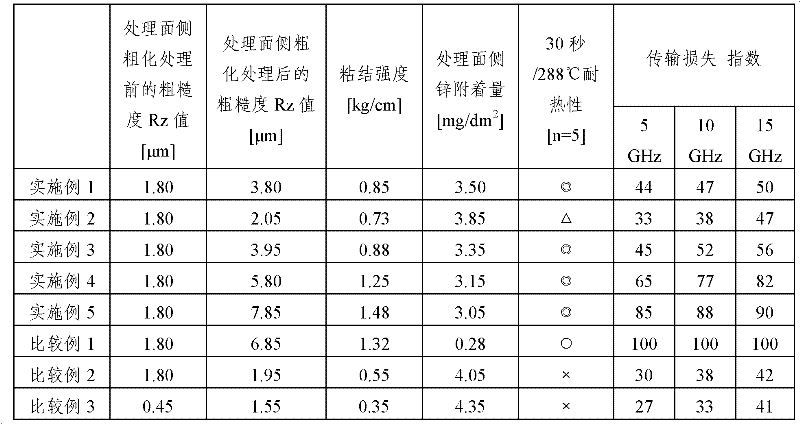

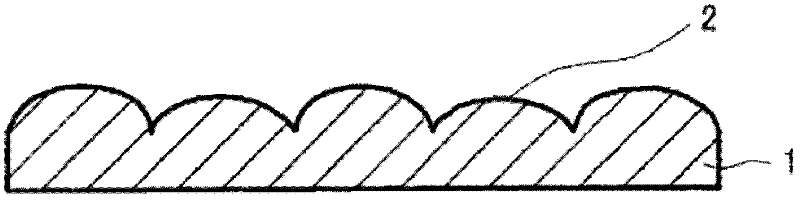

Copper foil for printed wiring board having excellent chemical resistance and heat resistance

InactiveUS6329074B1Bond strength is sufficientHigh bonding strengthInsulating substrate metal adhesion improvementChromatisationAcrylic resinAlloy

This invention provides a copper foil for a printed wiring board, which comprises a copper foil, an alloy layer (A) comprising copper, zinc, tin and nickel which is formed on a surface of the copper foil, said surface to be brought into contact with a substrate for a printed wiring board, and a chromate layer which is formed on a surface of the alloy layer (A,. The copper foil for a printed wiring board has the following features: even if a printed wiring board is produced using a long-term stored copper foil, the interface between the copper foil and the substrate is only slightly corroded with chemicals; even if the copper foil contacts a varnish containing an organic acid, e.g., a varnish for an acrylic resin, in the formation of a copper-clad laminate, the bond strength is sufficient. Even if a printed circuit board made by using the copper foil is placed in a high temperature environment, e.g., in an engine room of an automobile, for a long period of time, blistering of the copper circuit from the substrate due to deterioration of the interface between the copper circuit and the substrate does not take place.

Owner:MITSUI MINING & SMELTING CO LTD

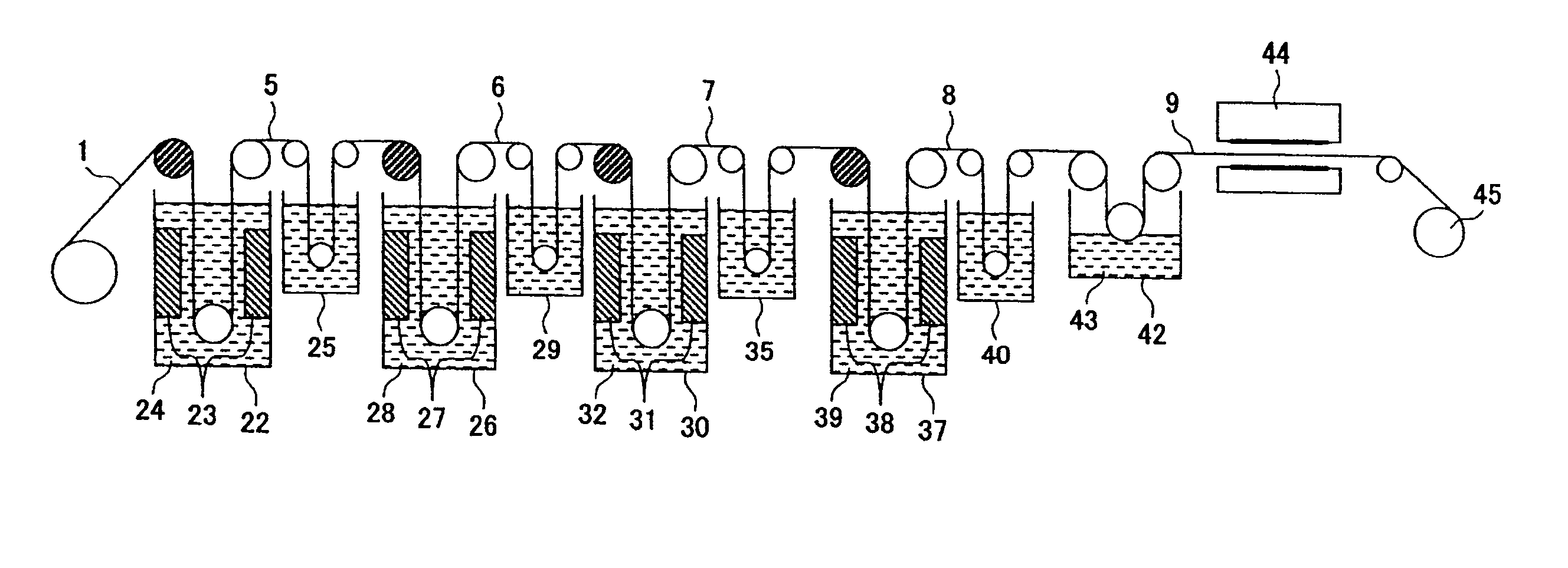

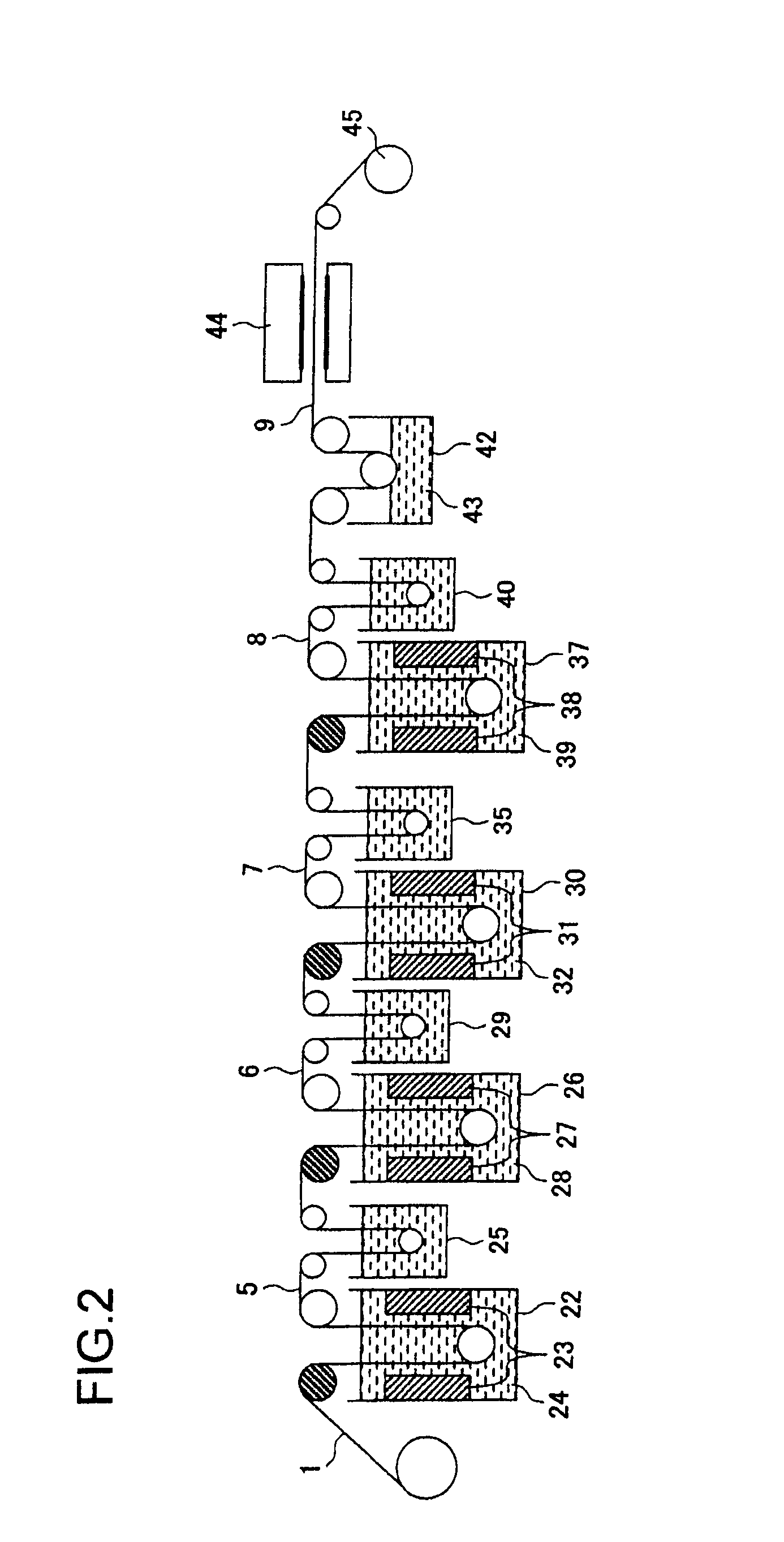

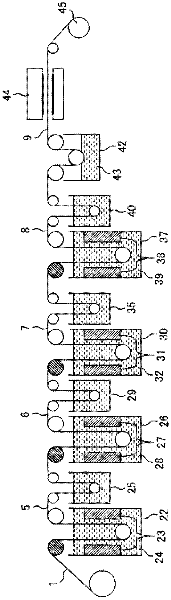

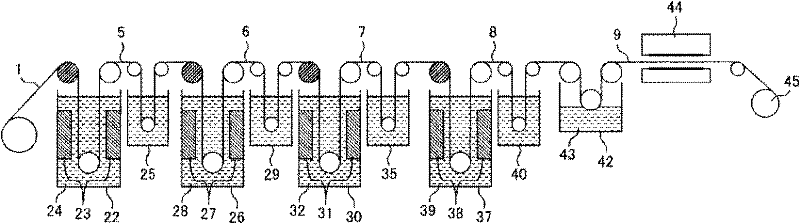

Thermoplastic resin coated aluminum alloy sheet, and method and apparatus for production thereof

InactiveUS6238783B1Cost advantageIncrease speedLiquid surface applicatorsChromatisationShell moldingAlloy

A thermoplastic resin coated aluminum alloy sheet has excellent processing adhesion and high adhesion after retort processing such that laminated thermoplastic resin layers do not peel off even when the alloy sheet is subjected to severe processing such as stretching after deep drawing and furthermore, ironing. A production method and a production apparatus for the alloy sheet are also described. A treatment by an alkaline solution and a treatment by an acidic solution are sequentially applied to bring the surface of an aluminum alloy sheet into a specific surface state and then electrolytic chromic acid treatment is carried out by a known method so as to laminate a thermoplastic resin to an aluminum alloy sheet having a two-layered film which comprises metallic chromium as the lower layer and a chromium hydrate as the upper layer and has a specific surface condition. As a result, a thermoplastic resin coated aluminum alloy sheet having excellent processing adhesion capable of withstanding molding and processing can be obtained.

Owner:TOYO KOHAN CO LTD

Corrosion-resisting surface treatment method for stainless steel in high-corrosion environment

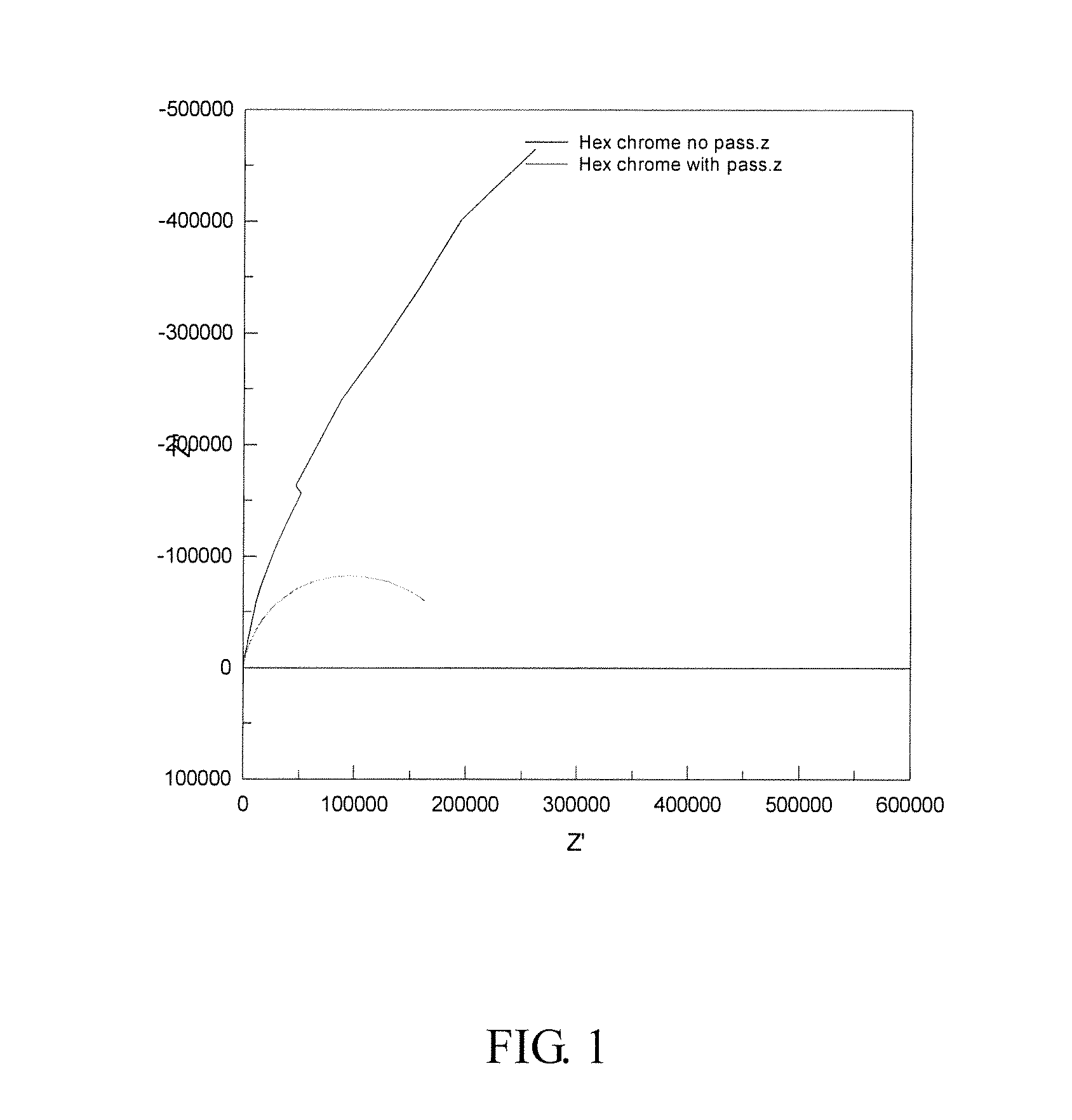

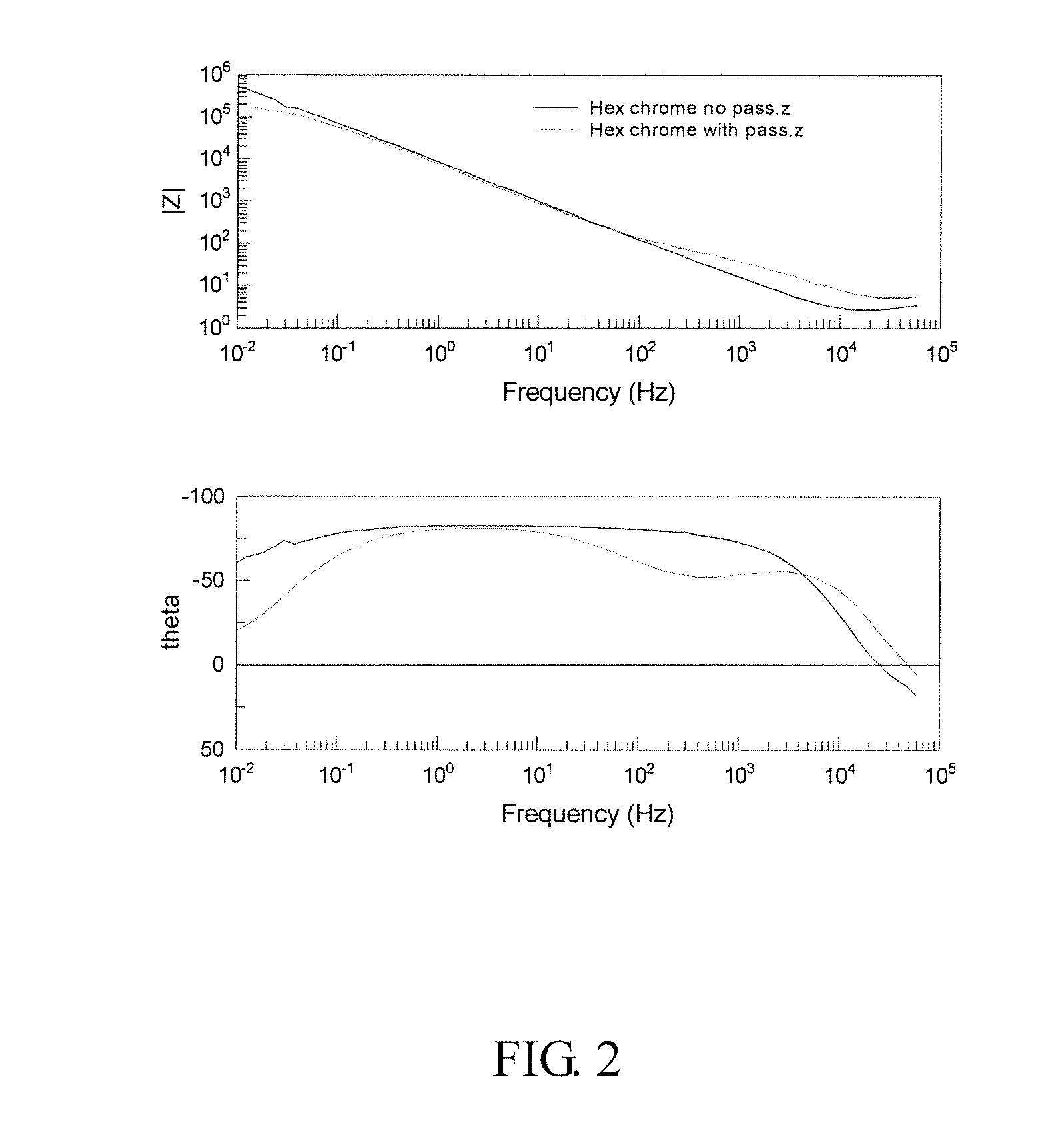

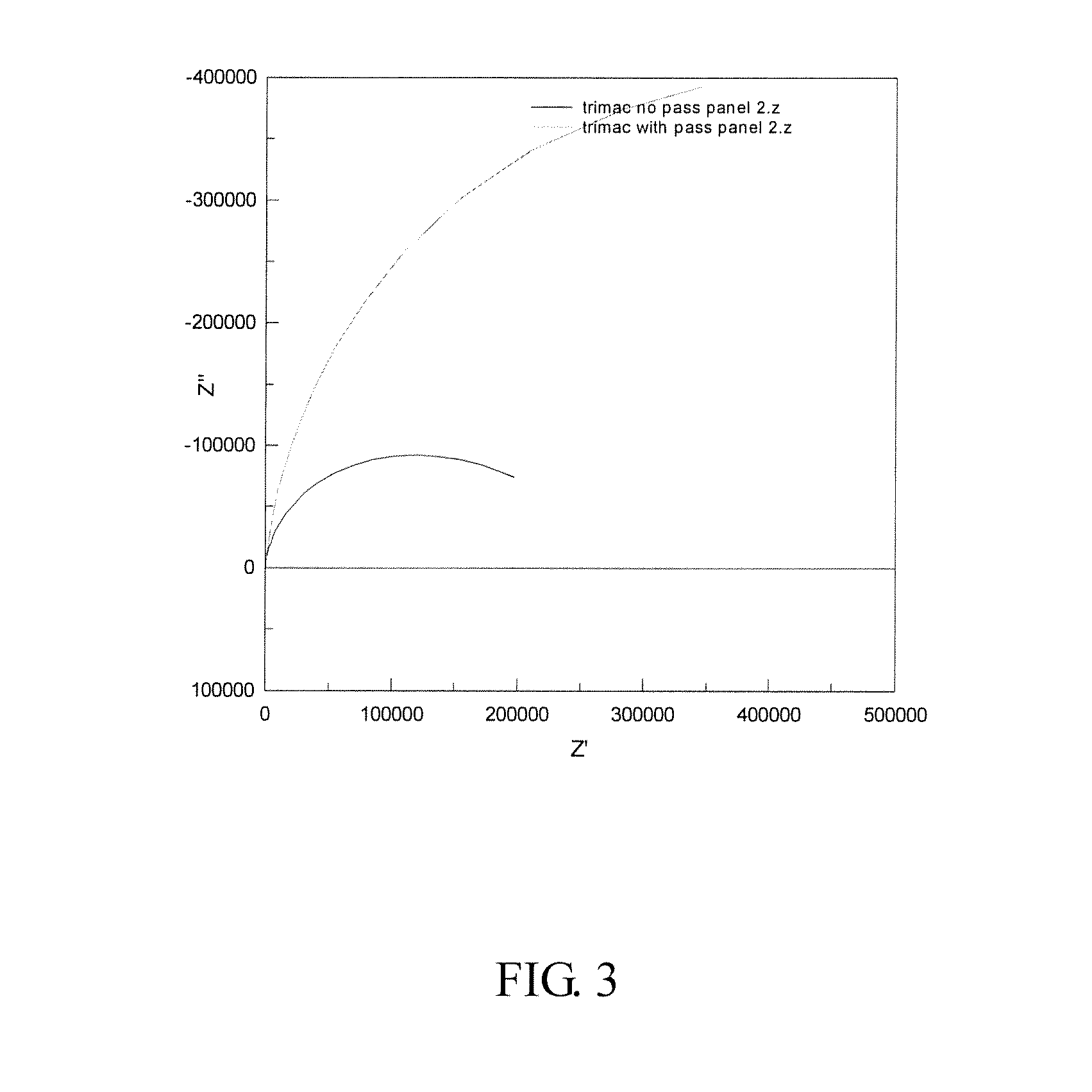

InactiveCN102691059AImprove electrochemical impedanceIncrease Mo element contentChromatisationElectrolytic inorganic material coatingElectrolysisMolybdate

The invention relates to a corrosion-resisting surface treatment method for stainless steel in a high-corrosion treatment. The corrosion-resisting surface treatment method is characterized by comprising a treatment link comprising a washing step, an oxidizing step, an electrolyzing step, a cleaning step and a drying step; carrying out chemical oil removal with thermokalite, and eliminating oil stains of a stainless steel part in a processing process; and carrying out total immersion oxidization passivating treatment on the stainless steel part with oxidizing solution added with molybdate, so as to generate oxide in high oxidization valence state on the surface of the stainless steel, wherein electrolyzing comprises that a metal part is taken as a cathode, the metal part is immersed into an electrolyte containing the molybdate, electrolyzing is carried out for 10 minutes at normal temperature, then washing is carried out for 3-5 times with clear water, and then the metal part is suspended and drained. Through the treatment, a protective film with the thickness of 100-700nm is generated on the surface of the stainless steel, the Cr content in the protective film reaches up to 40-50%, while the Fe content is only 10-20%, and the Mo content is doubled. The method disclosed by the invention adopts common reagents, can be completed on relatively simple equipment, consumes less time and has a simple process while the effect that the stainless steel part with excellent corrosion resistance, heat resistance and scaling resistance can be obtained is realized.

Owner:SHENZHEN CANDORTECH INC CO

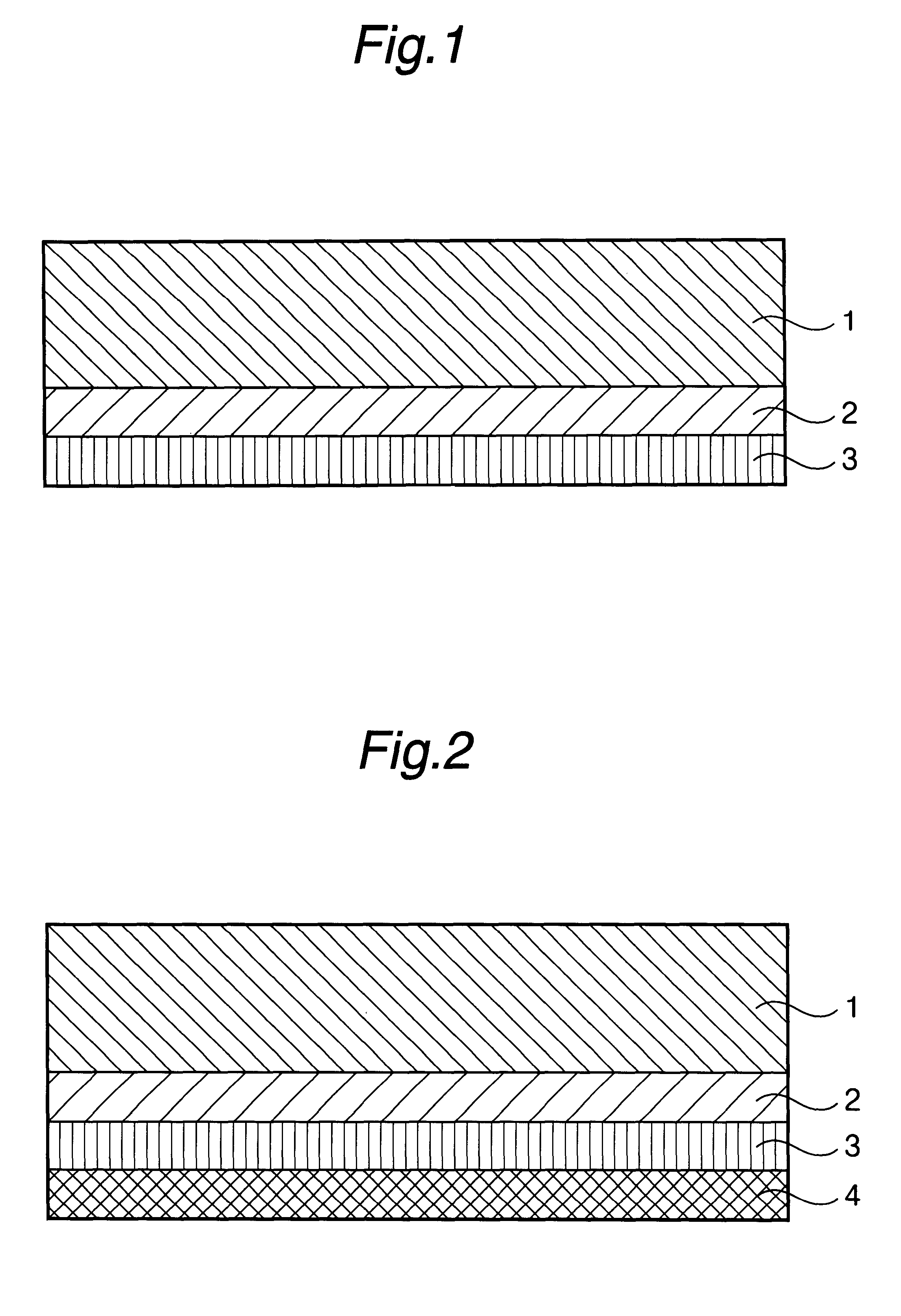

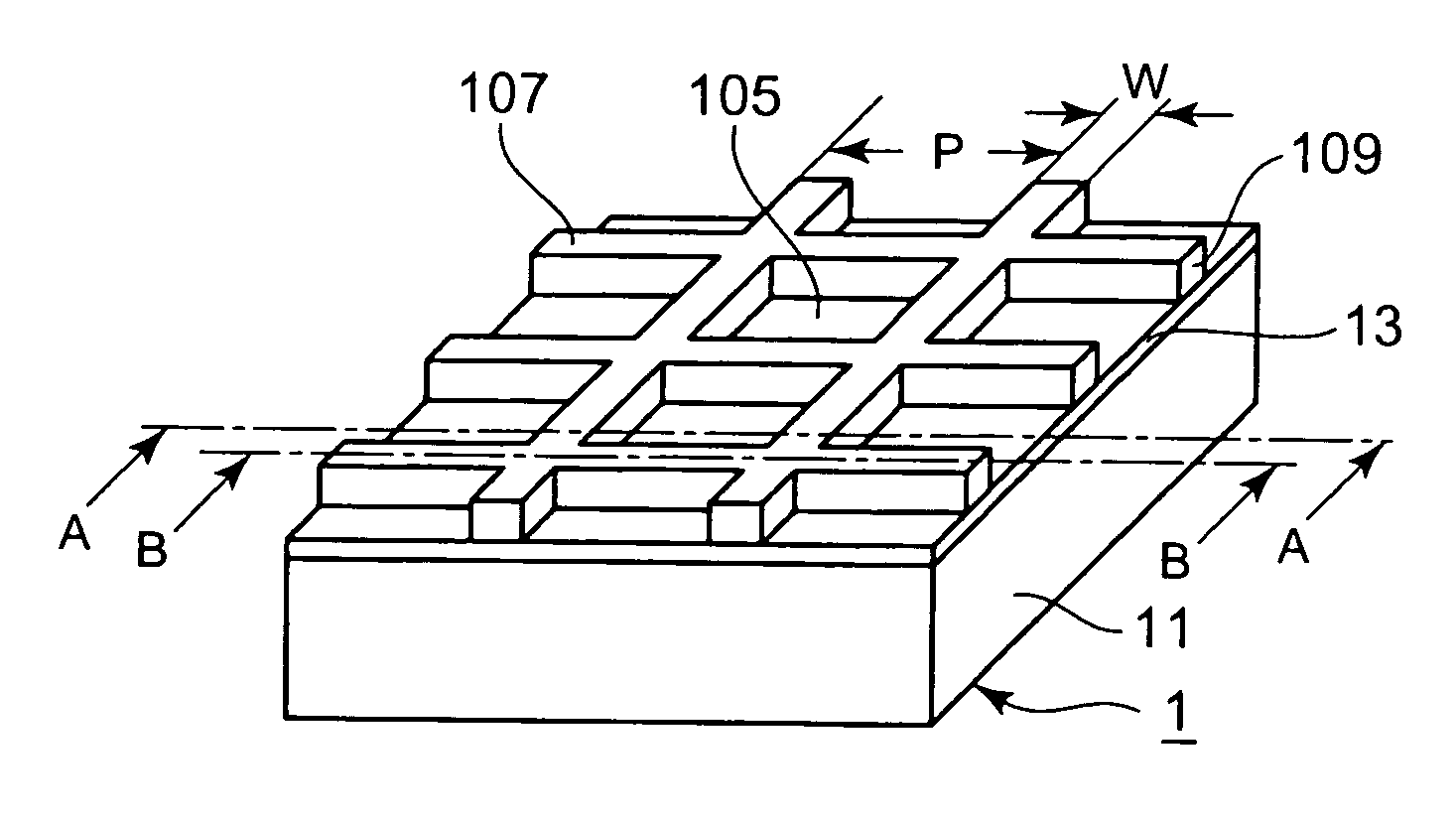

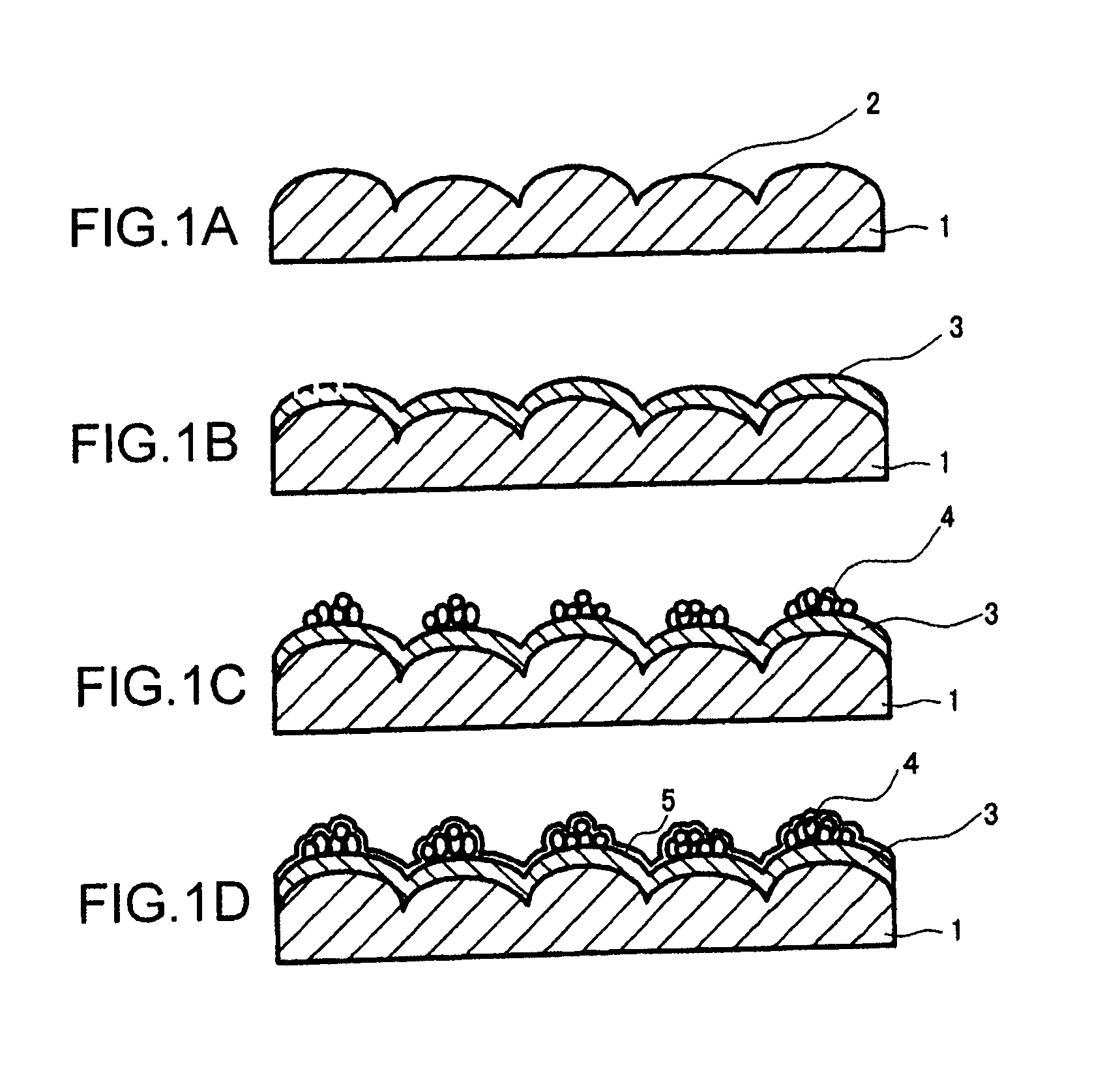

Electromagnetic Wave Shielding Sheet and Process For Producing the Same

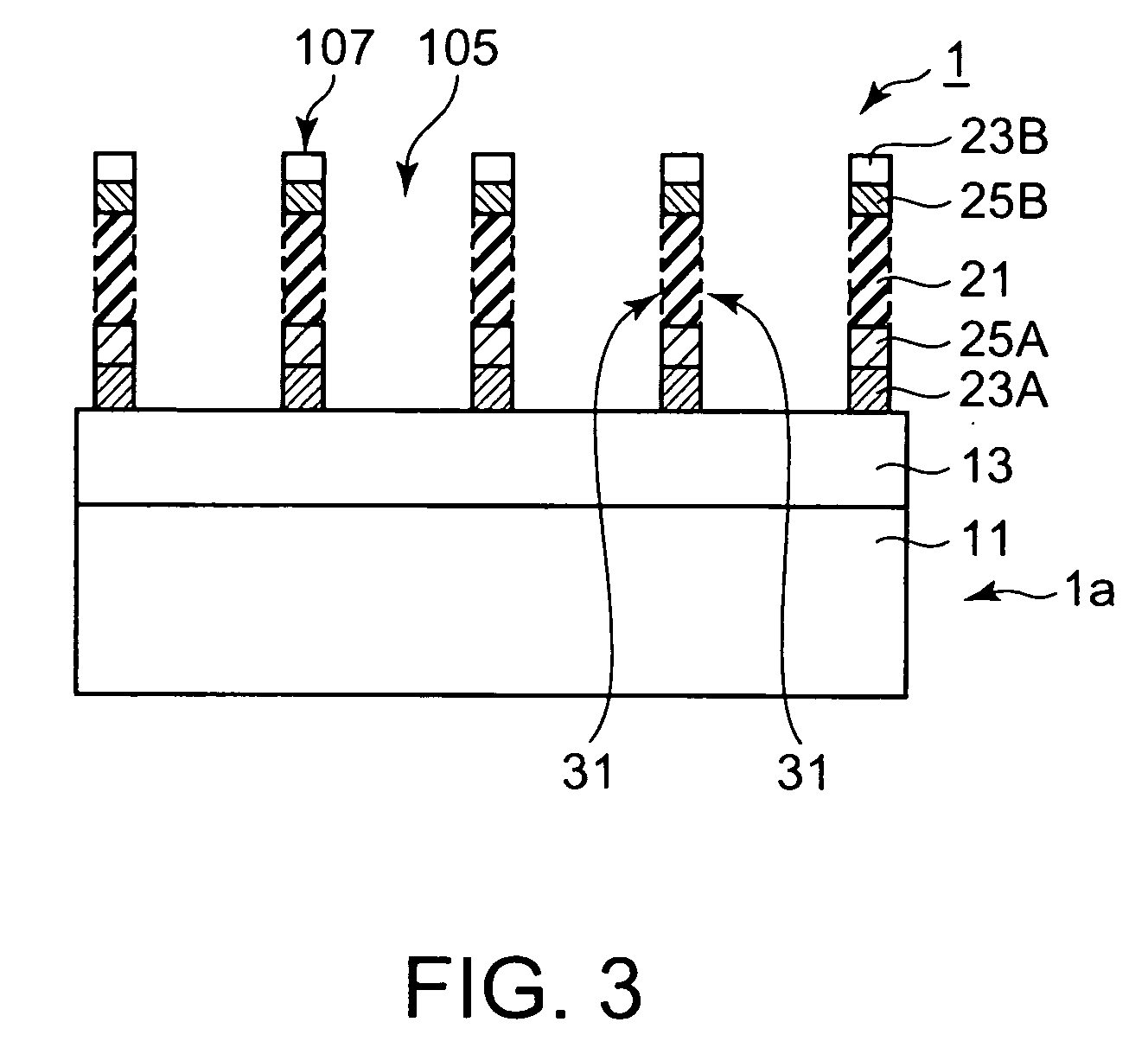

InactiveUS20080277157A1Moderate transparencyImprove shielding effectChromatisationMagnetic/electric field screeningMetal meshEngineering

An electromagnetic wave shielding sheet 1 comprises a transparent substrate 11, and line parts 107 that define openings 105, provided on the transparent substrate 11. The line parts 107 have a metal mesh layer 21, and a blackening layer 25A formed on the surface of the metal layer 21, on the side of the transparent substrate 11. Matted layers 31 are formed on the side faces of the line parts 107, and an anticorrosive layer 23A is provided between the blackening layer 25A and the transparent substrate 11.

Owner:DAI NIPPON PRINTING CO LTD

Copper Foil for Printed Wiring Board

InactiveUS20090208762A1Prevent circuit erosion phenomenonMinimal deteriorationChromatisationSynthetic resin layered productsMetallurgyCopper foil

Provided is a copper foil for a printed circuit board comprising a heatproof treatment layer formed on an non-roughened surface of the copper foil to become a joining surface with resin, a chromate coated layer formed on the heatproof treatment layer, and a silane coupling agent layer formed on the chromate coated layer, wherein the Zn amount of the outermost copper foil surface after forming the silane coupling agent layer is 1.5 Atomic % or less, and the Cr amount is 3.0 to 12.0 Atomic %. This copper foil for a printed circuit board is superior in chemical resistance, adhesiveness, and high frequency characteristics.

Owner:JX NIPPON MINING& METALS CORP

Surface-treated steel sheet having improved corrosion resistance after forming

InactiveUS6143422AImprove fuel corrosion resistanceIncrease costChromatisationDomestic articlesAlcoholSheet steel

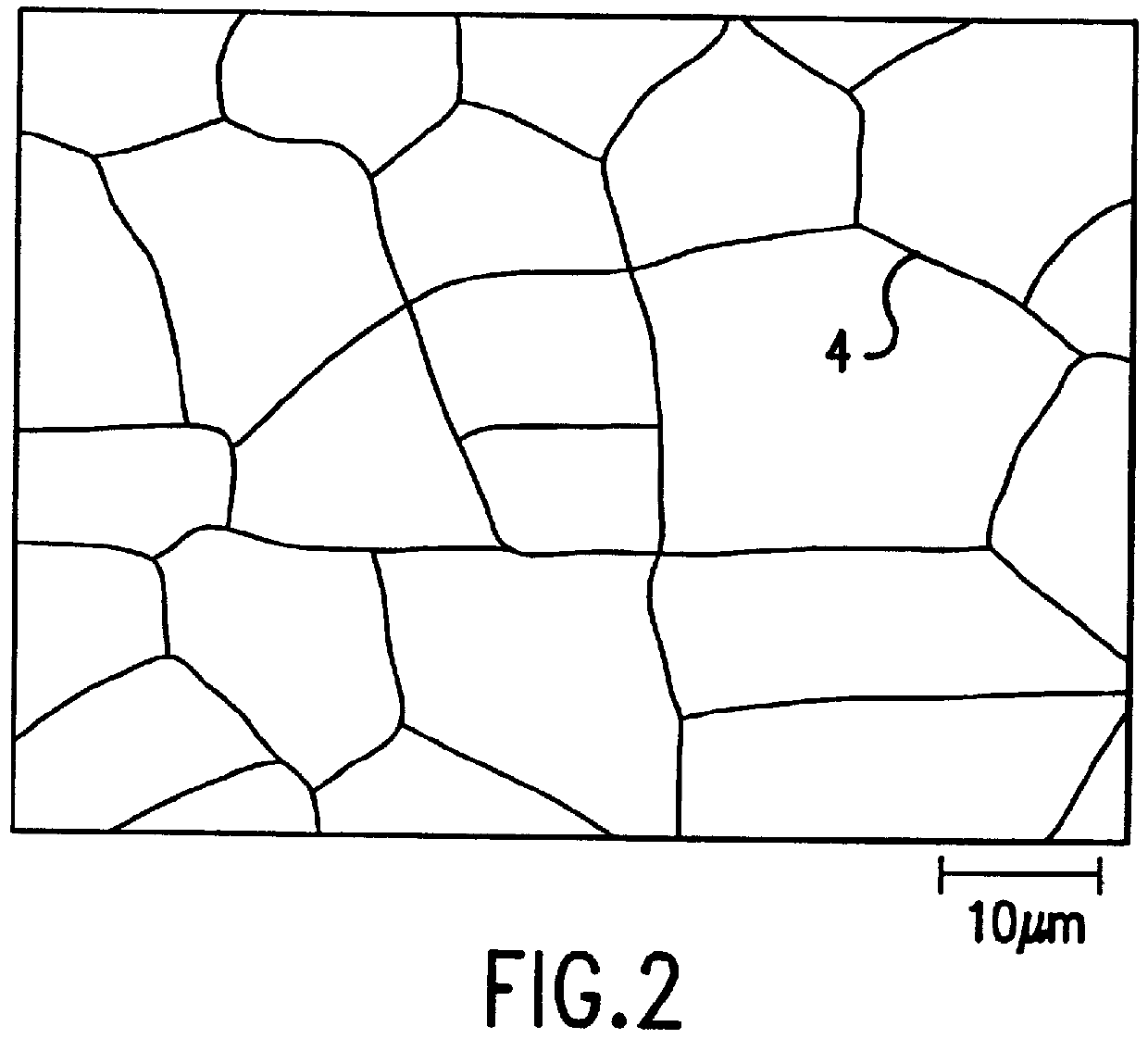

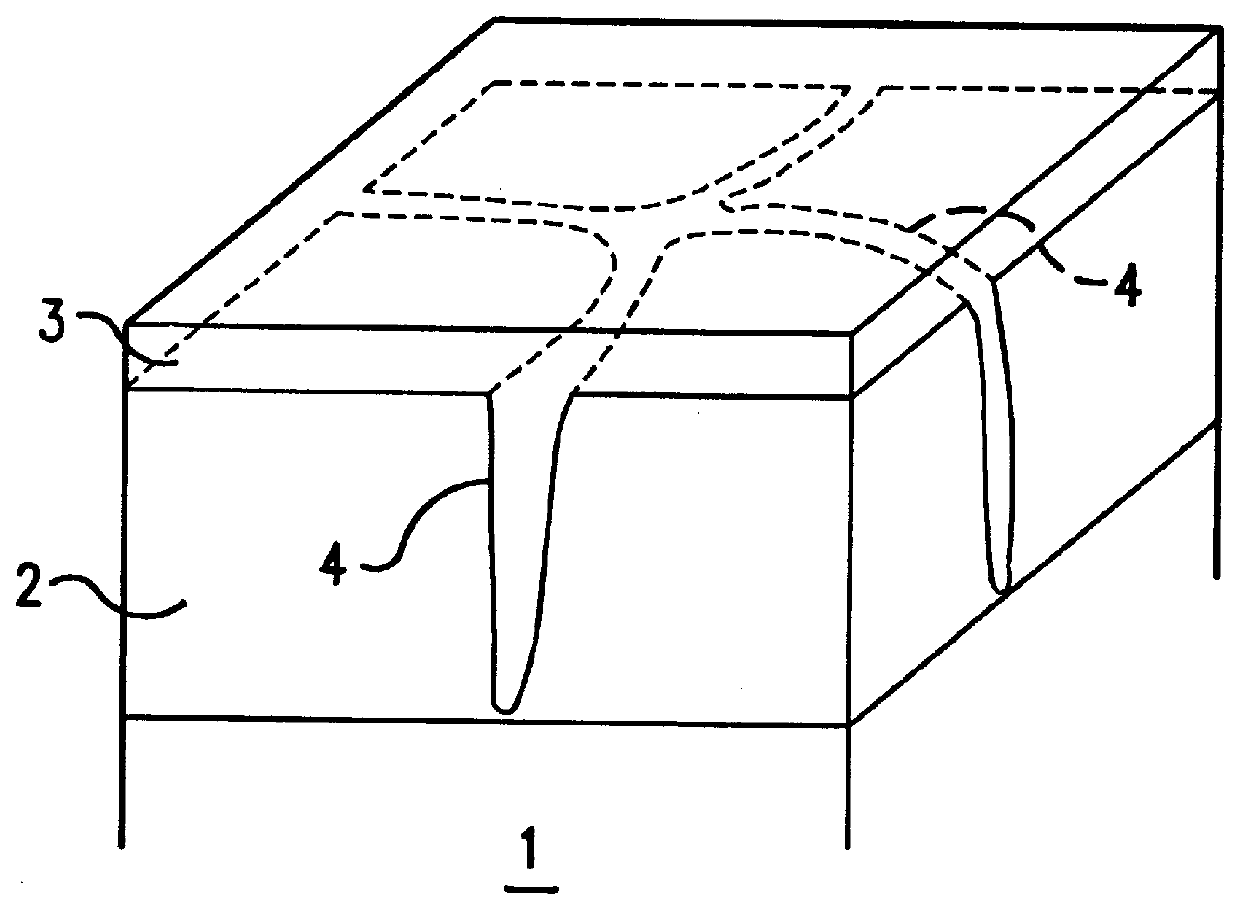

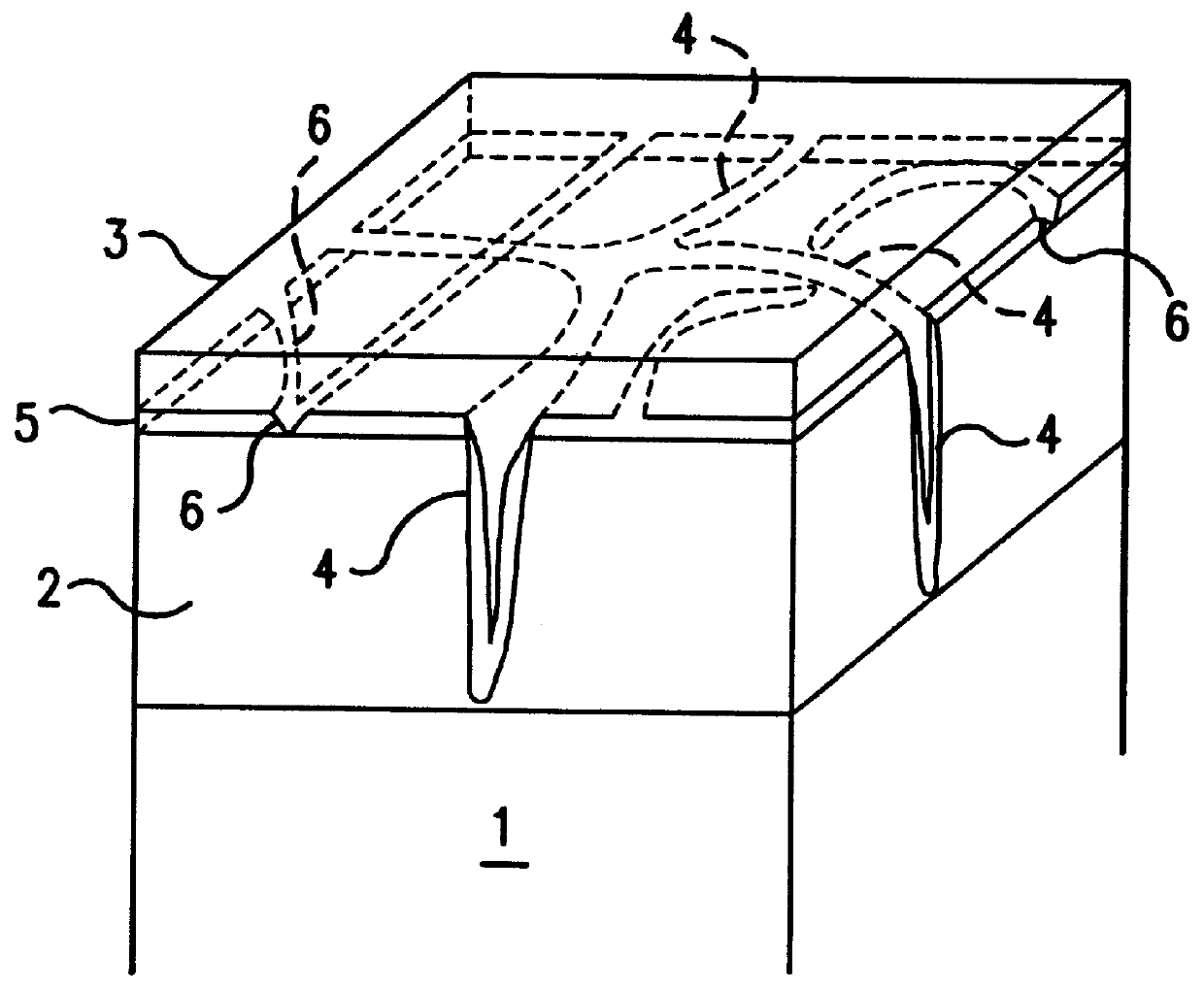

A material which can be improved in its resistance to corrosion caused by alcohol-containing fuels after formation without detriment to weldability and without any substantial cost increase is developed. Constitution A chromate film is applied to a Zn-X alloy electroplating layer, in which X is one or more of Ni: 3-18 wt %, Co: 0.02-3 wt %, Mn: 25-45 wt %, or Cr: 8-20 wt %. The Zn-Ni alloy plating layer underlying the chromate film has cracks with a density of 1000-150000 in terms of the number of plated regions surrounded by cracks in a 1 mmx1 mm visual field, with cracks having a maximum width of 0.5 mu m or less comprising 90% or more of the total number of the cracks, and with cracks having a depth of 80% or more of the thickness of the plating layer comprising 80% or more of the total number of the cracks.

Owner:SUMITOMO METAL IND LTD

Surface blackening treatment method for rolled copper foil

InactiveCN106191980AImprove acid resistanceGood alkali resistanceChromatisationSuperimposed coating processFolding enduranceSurface roughness

The invention discloses a surface blackening treatment method for a rolled copper foil. The surface blackening treatment method orderly comprises the following steps: (1) electrochemical oil removal, (2) coarsening treatment, (3) solidification treatment, (4) nickel-cobalt plating treatment, (5) zinc plating treatment, (6) passivation, (7) silicone coupling agent coating treatment, and (8) drying treatment, and obtaining the product. Current is applied in step (1) to step (6). The surface blackening treatment method for a rolled copper foil provided by the present invention has the advantage that the black appearance of the copper foil obtained after various electric plating steps meets FPC requirements. Through determination, the copper foil has a surface color blackness value of less than 30, surface roughness Ra of less than or equal to 1.0 micron and Rz of less than or equal to 2.0 microns, peel strength of more than 1.4 N / mm, and folding endurance MIT of more than 800; the copper foil has favorable acid resistance, alkali resistance, soldering resistance, and etching performance. With the blackness value RAL7016, a good extinction effect is achieved.

Owner:中铜(上海)铜业有限公司

Copper foil with resistance layer, method of production of the same and laminated board

InactiveUS20120111613A1Suitable elasticitySuitable plasticityChromatisationPrinted circuit aspectsElectrical resistance and conductanceAlloy

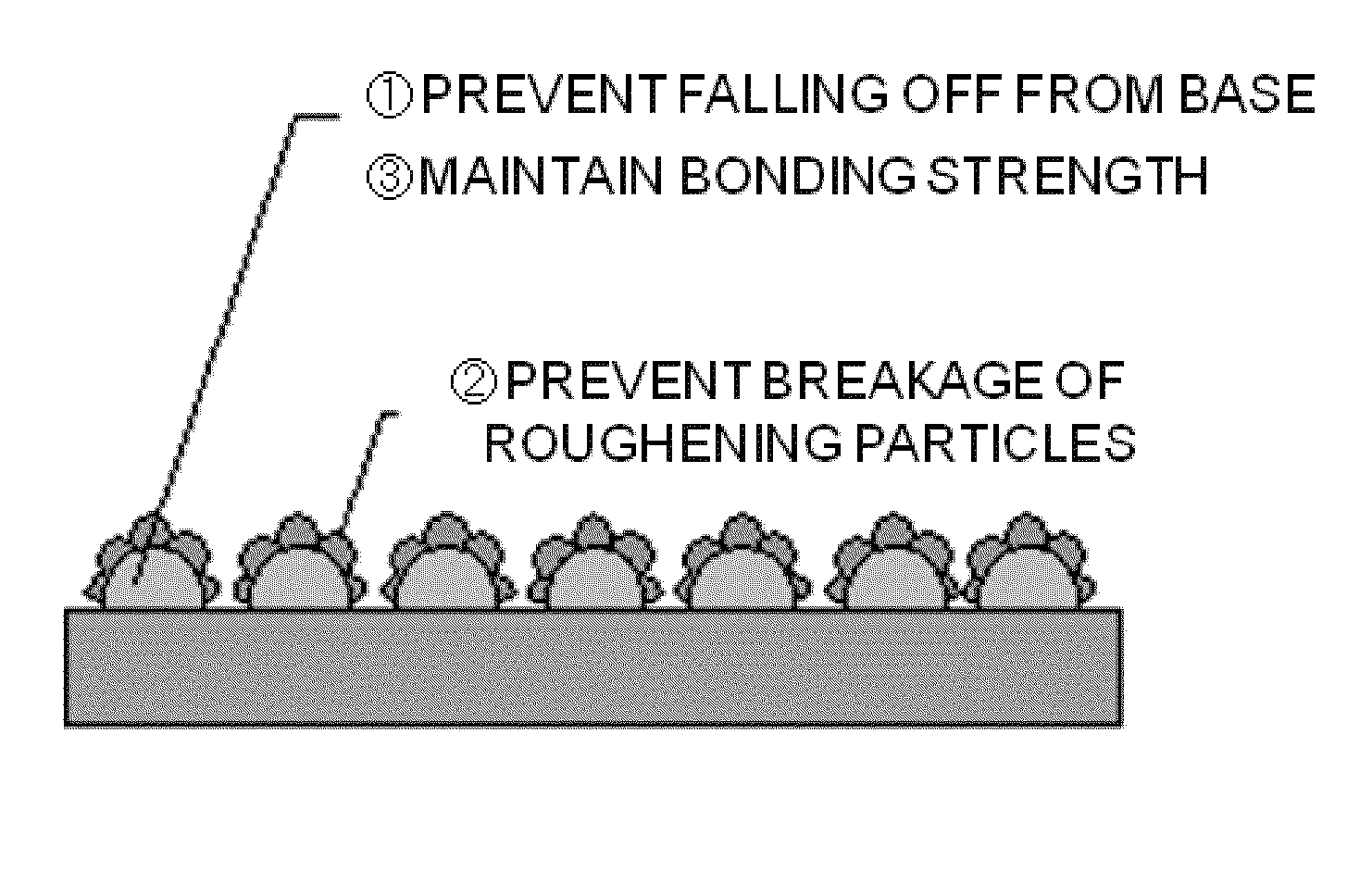

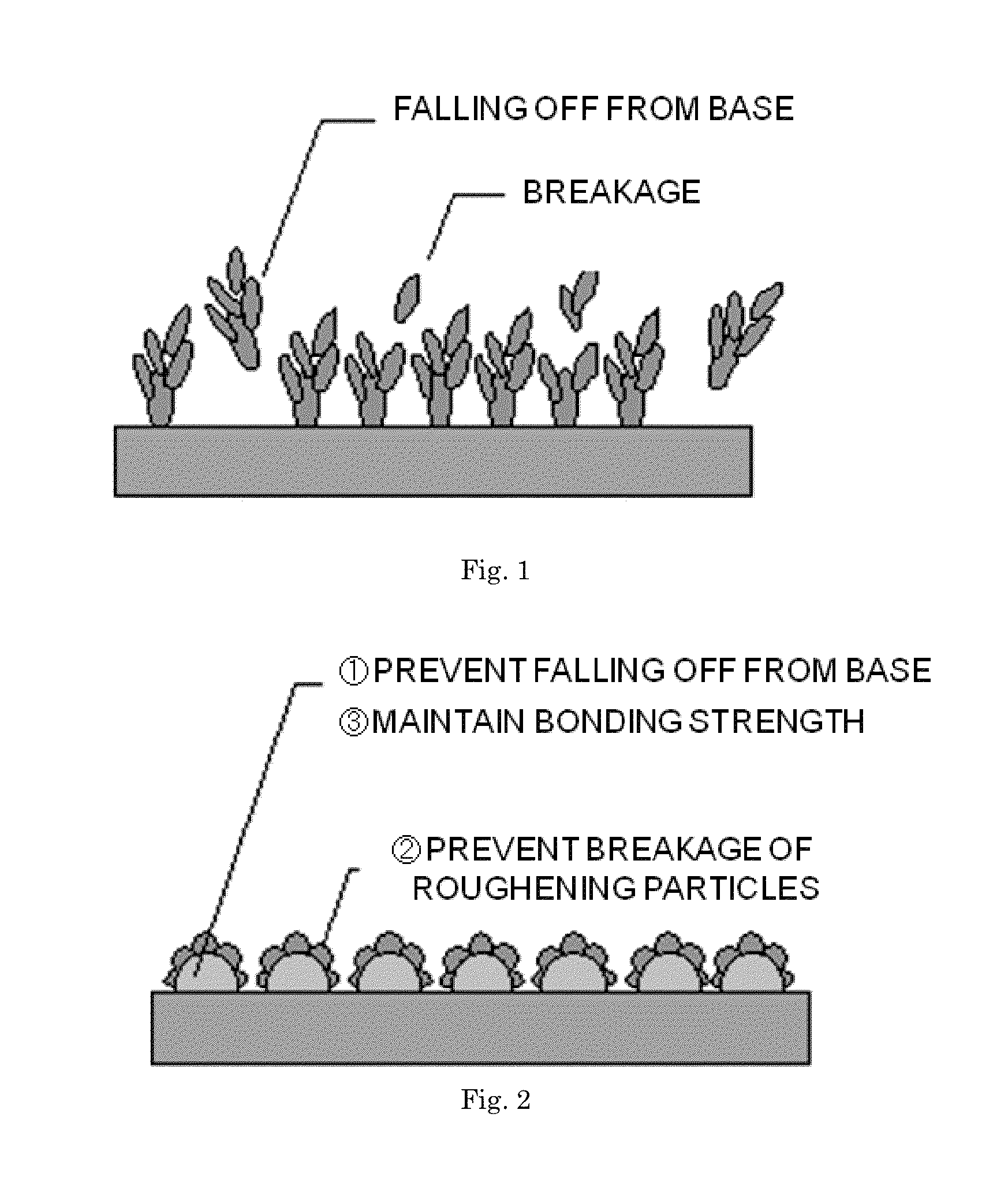

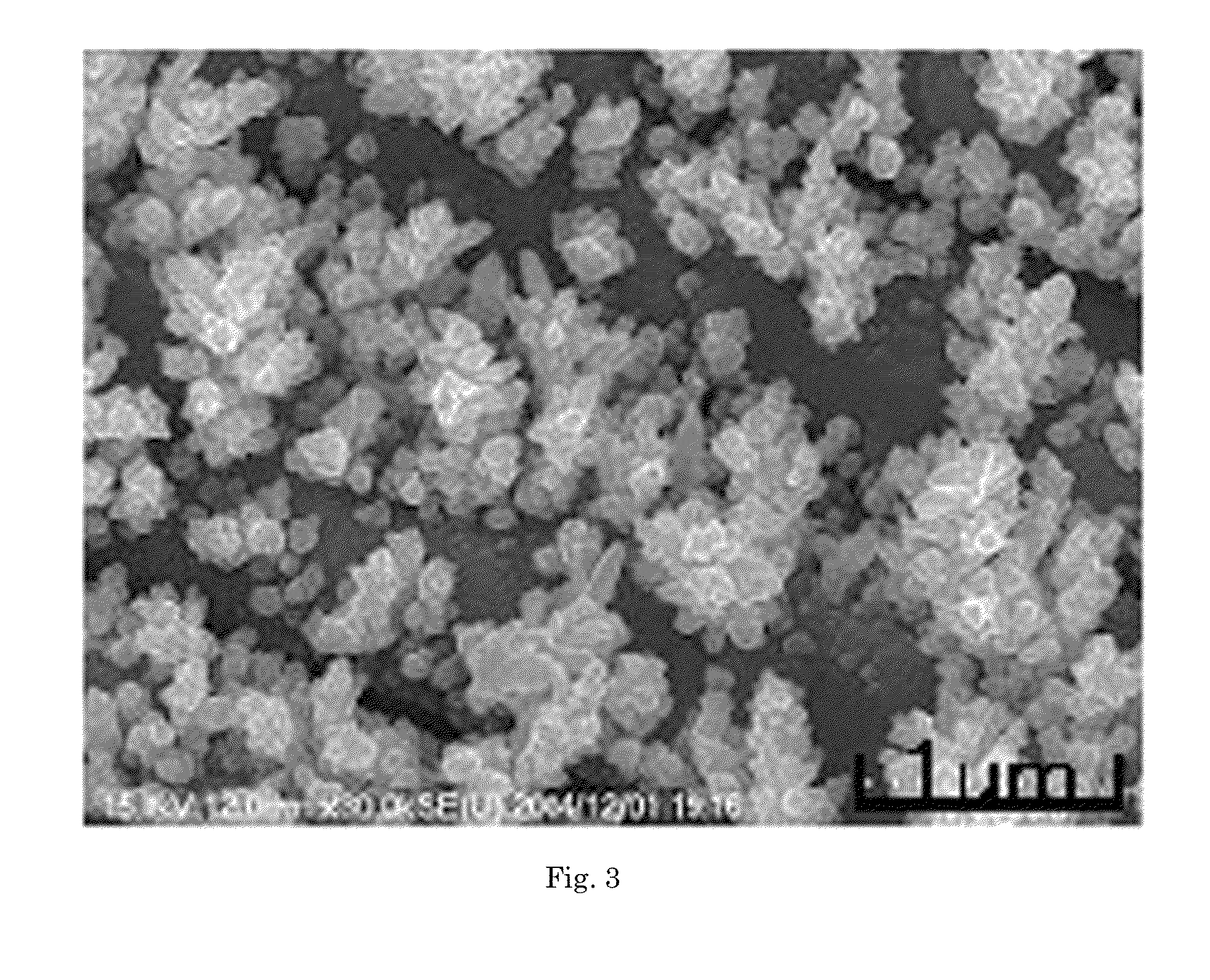

A copper foil with a resistance layer is provided, wherein the variation value is small when it is made into a resistance element, the adhesion with the resin substrate to be laminated with is able to be sufficiently maintained, which has an excellent characteristics as a resistance element for a rigid and a flexible substrate. A copper foil with a resistance layer of the present invention comprises a copper foil on one surface of which a metal layer or alloy layer is formed from which a resistance element is to be formed, the surface of the metal layer or alloy layer being subjected to a roughening treatment with nickel particles. A method of production of a copper foil with a resistance layer of the present invention comprises: forming a resistance layer of phosphorus-containing nickel on a matte surface of an electrodeposited copper foil having crystals comprised of columnar crystal grains wherein a foundation of the matte surface is within a range of 2.5 to 6.5 μm in terms of Rz value prescribed in JIS-B-0601; and performing roughening treatment to a surface of the resistance layer with nickel particles wherein a roughness is within a range of 4.5 to 8.5 μm in terms of Rz value prescribed in JIS-B-0601. The alloy layer is for example formed from phosphorus-containing nickel.

Owner:FURUKAWA ELECTRIC CO LTD

Passification of tin surfaces

PCT No. PCT / US96 / 13859 Sec. 371 Date Feb. 24, 1998 Sec. 102(e) Date Feb. 24, 1998 PCT Filed Aug. 30, 1996 PCT Pub. No. WO97 / 08364 PCT Pub. Date Mar. 6, 1997The present invention provides a method of coating a tin article with a non-hexavelant trivcalent chromium oxide and / or hydoxide in which the tin article is contacted with a trivalent chromium protective coating composition having an acid pH of about 2.0 to 3.0 which is free of chromium complexing agents.

Owner:SAN FU CHEM CO LTD

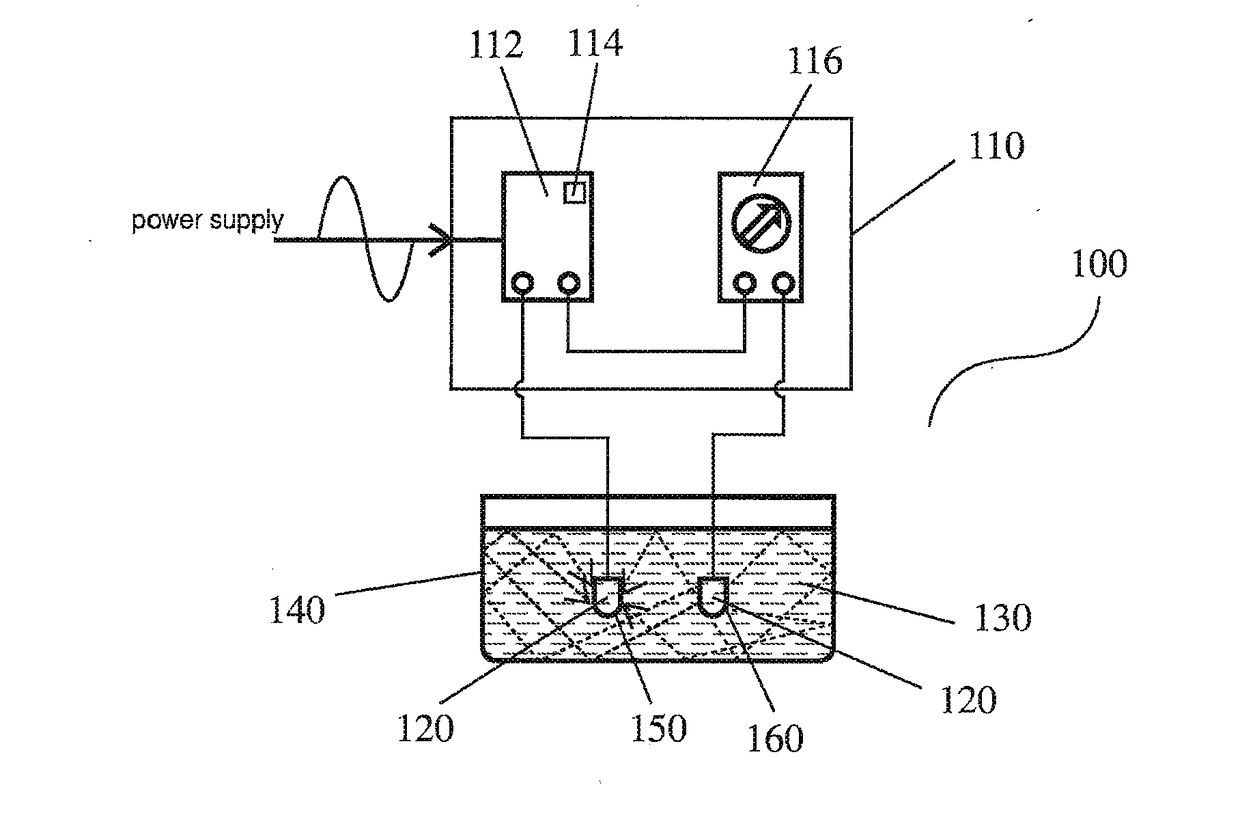

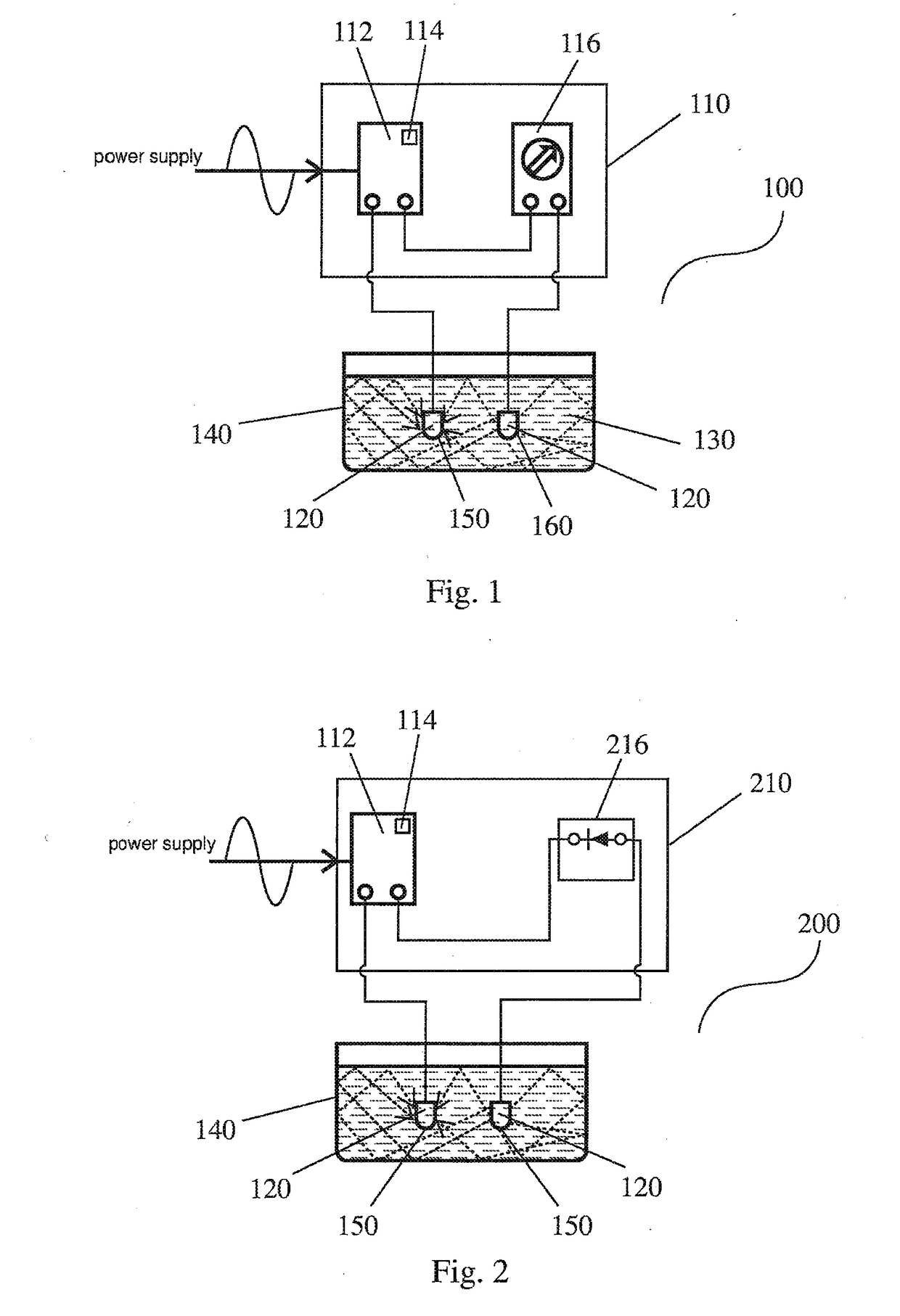

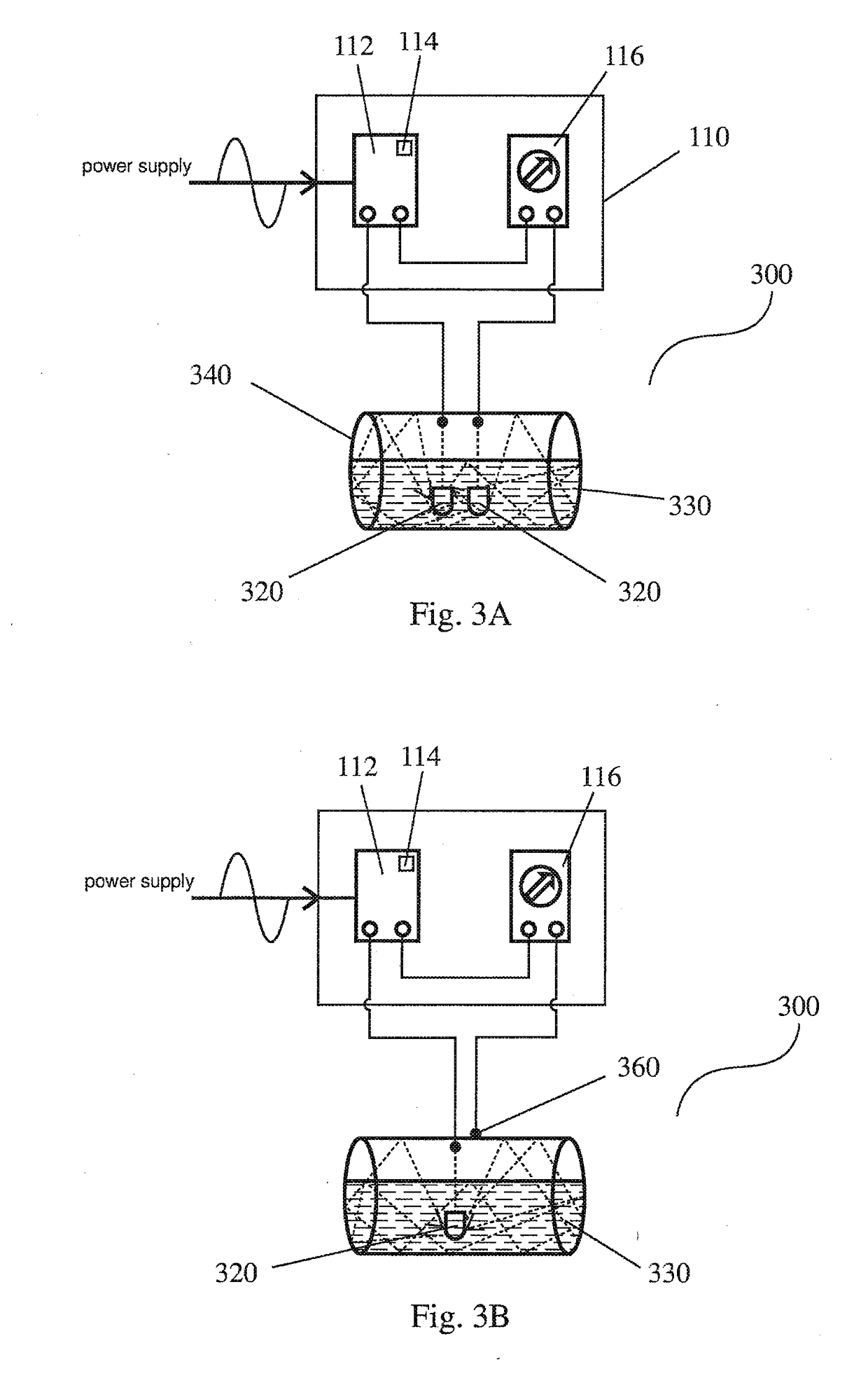

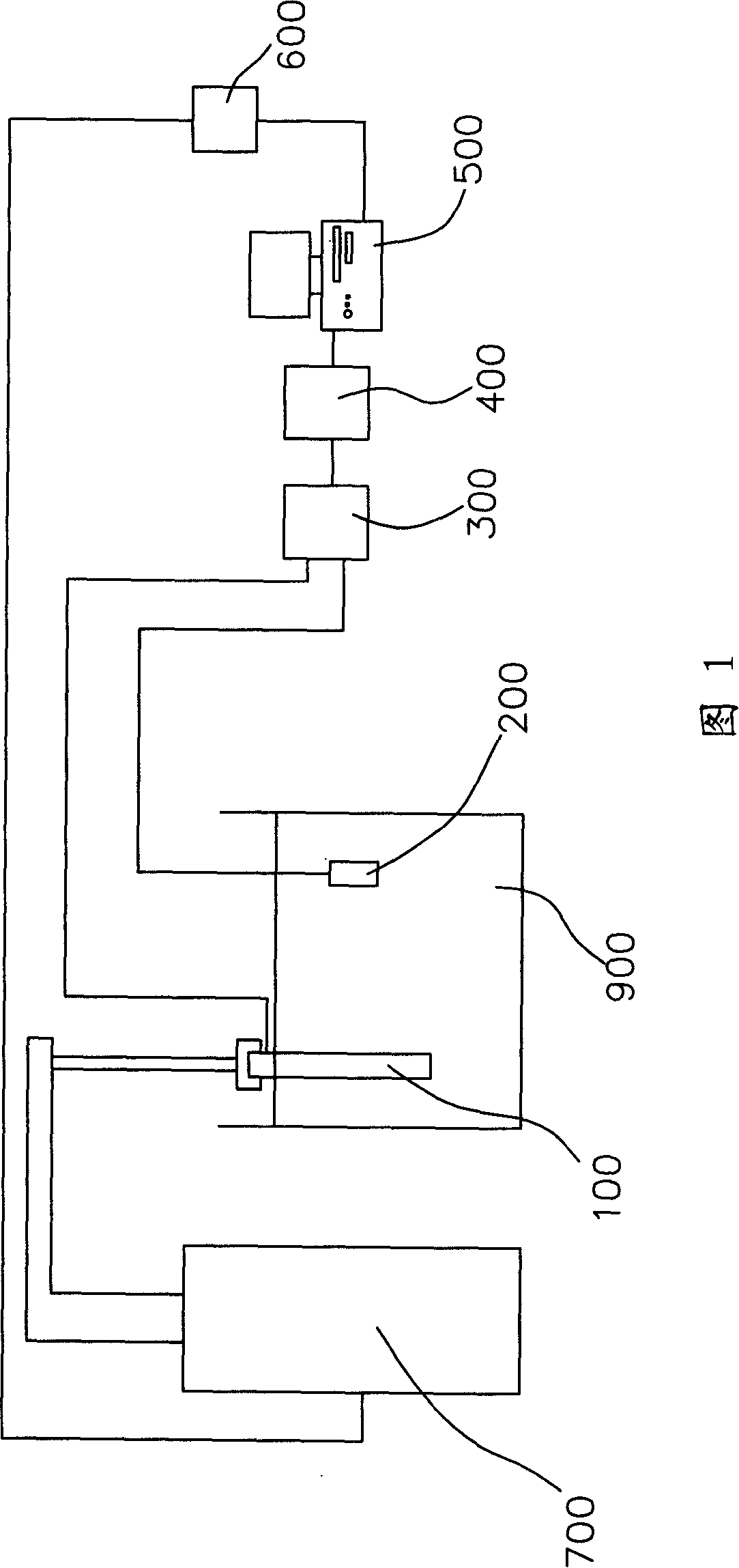

Method and system for applying superimposed time-varying frequency electromagnetic wave for corrosion protection of submerged and/or buried structures

ActiveUS20180216246A1Economical and convenient to utilizeAvoid structureAnodisationChromatisationReturn currentAcoustics

The invention relates to a method and system for preventing corrosion of at least one metallic structure in an electrolyte medium, comprising applying a superimposed time-varying frequency electromagnetic wave to the structure, the method comprising the steps of generating a superimposed time-varying frequency electromagnetic wave (DAC wave) where an AC driving signal with time-varying frequency is riding on a DC output with a predefined DC bias voltage, transmitting the DAC wave current to one or more emitters, emitting the DAC wave via the one or more emitters, placing the one or more emitters at a spaced distance from the metallic structure, subjecting the metallic structure to the DAC wave current, controlling the negative return current of the DAC wave from the metallic structure, such that the DAC wave is distributed across the structure surface and directly excites a target region of the metallic structure, and wherein the excitation induces a flow of ionic current having a DC component travelling in a pulsating and time-varying manner in the target region and effects induced vibration of electrons and molecules in the target region. The method and the system of the invention significantly reduce capital costs and require very low energy, they avoid environmentally unfriendly final products, and are able to result in effective corrosion protection of metallic structures in different surrounding conditions.

Owner:SEMB ECO R&D PTE LTD

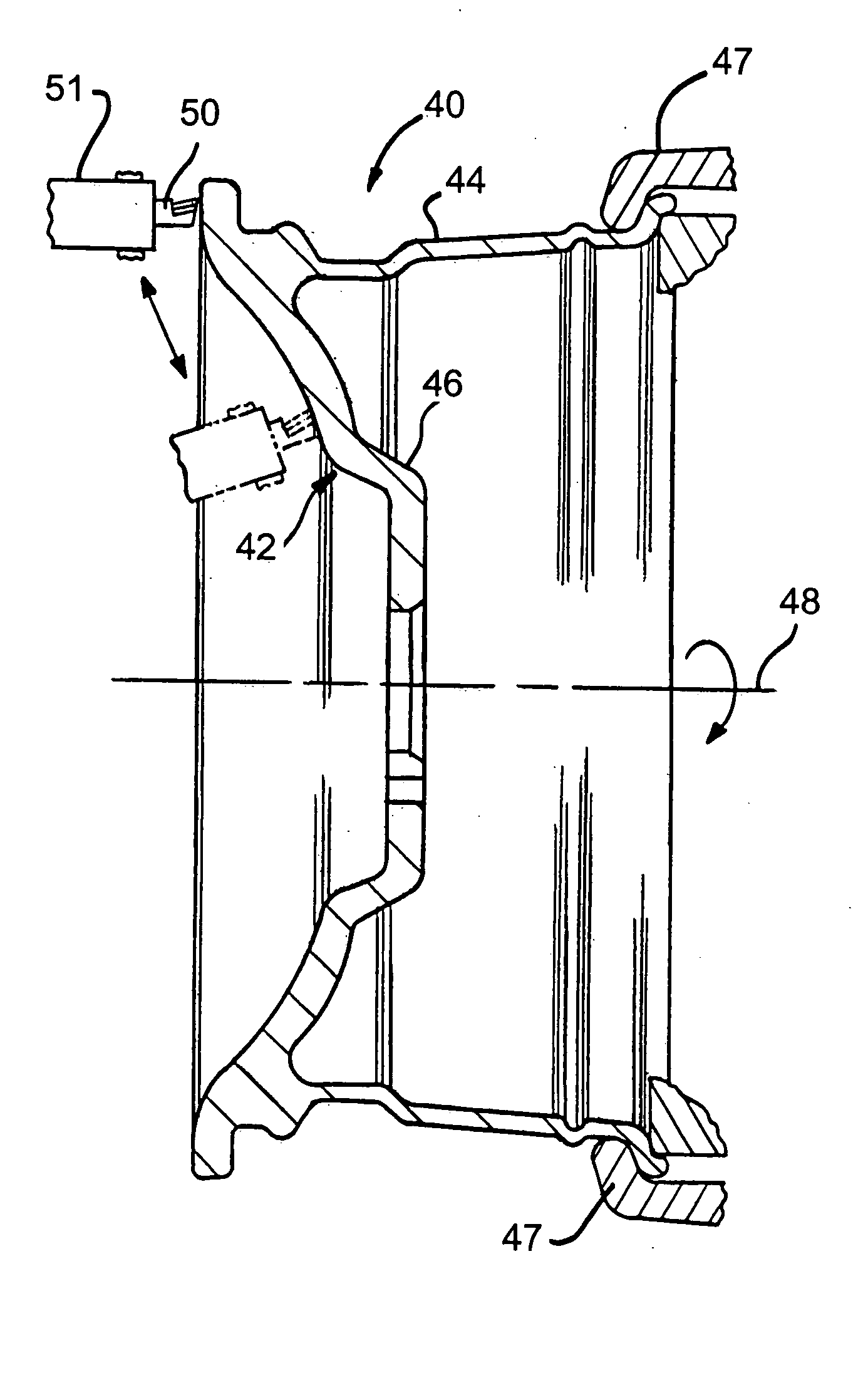

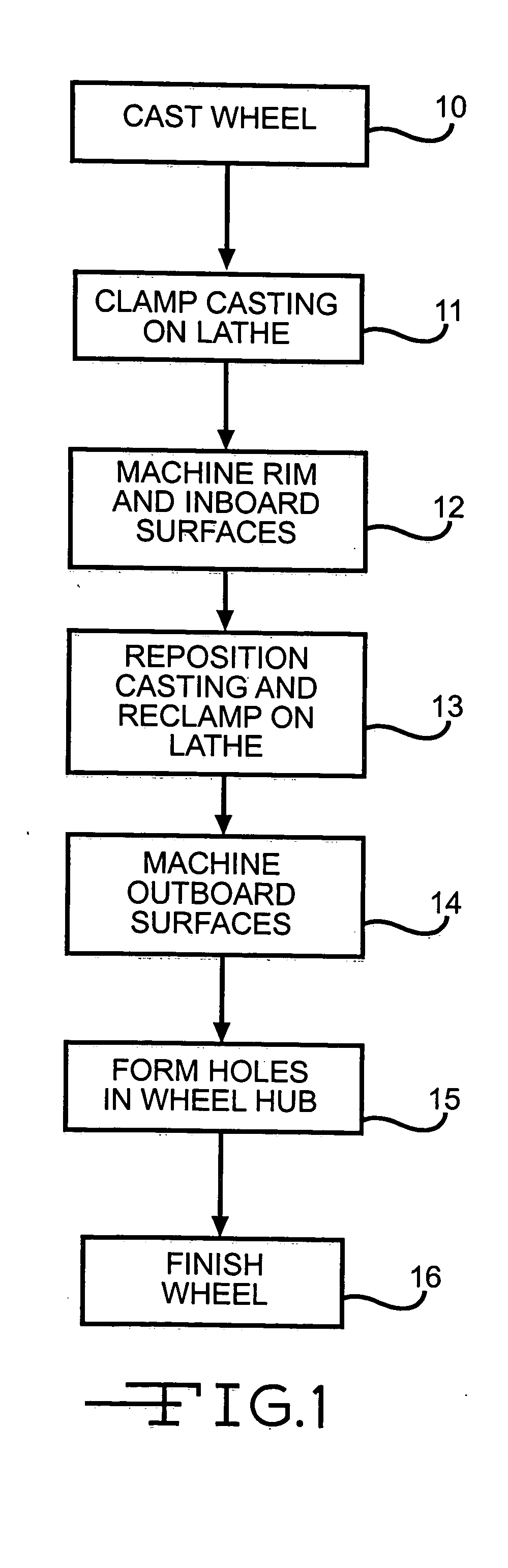

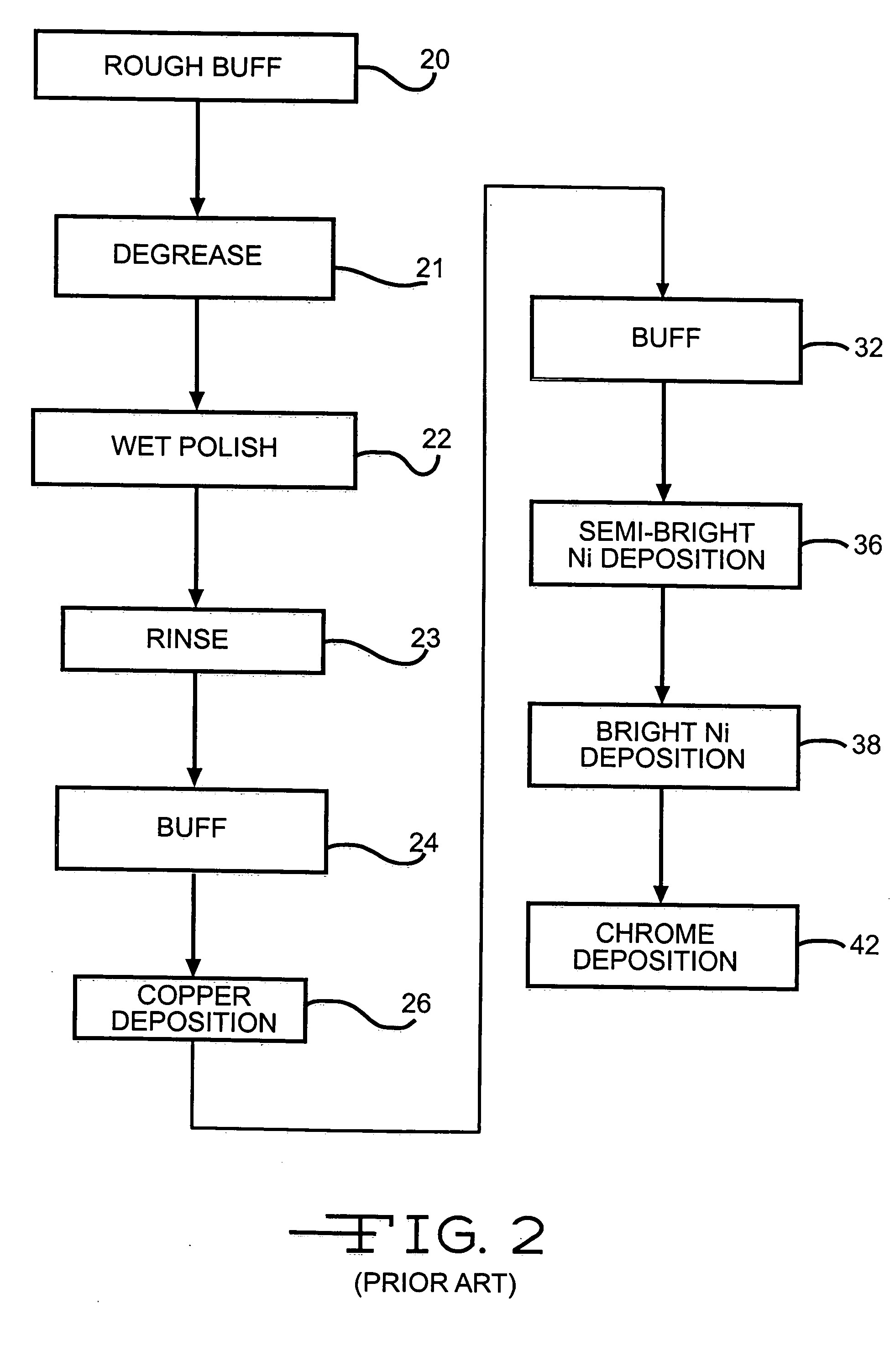

Process for copper free chrome plating of a vehicle wheel surface

A cutting tool having a hard tip is pressed with a uniform pressure against a surface of a vehicle wheel as the wheel is rotated to smooth and seal the surface. The smoothed and sealed wheel surface is then chrome plated with a process that includes applying a nickel layer directly upon smoothed and sealed wheel surface and a chromium layer over the nickel layer.

Owner:HAYES LEMMERZ INT

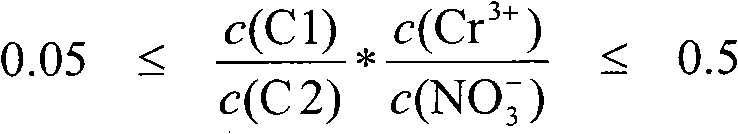

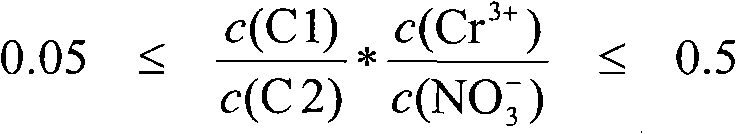

Chromium(vi)-free black passivation of surfaces containing zinc

ActiveCN101668882AUniform colorImprove corrosion resistanceLiquid surface applicatorsChromatisationPhysical chemistryCarboxylic acid

Treatment solution contains first carboxylic acids with 1-8 carbon atoms and having no polar groups with the exception of the carboxyl group, second carboxylic acids with 1-8 carbon atoms having polargroups, 2-400 mmol / l chromium ions and 50-2000 mmol / l nitrate ions. The total concentration of carboxyl groups in the first carboxylic acids is 5-150 mmol / l. The total concentration of carboxyl groups in the second carboxylic acids is 5-150 mmol / l. The ratio of concentration of nitrate ions to chromium ions is at least 1. Independent claims are also included for the following: (1) Composition producing the above treatment solution by diluting with water; and (2) Method for the black passivation of zinc-containing surfaces using the treatment solution.

Owner:ATOTECH DEUT GMBH

Heat-resistant copper foil and method for producing same, circuit board, and copper-clad laminate board and method for manufacturing same

ActiveCN102482795AHigh peel strengthImprove heat resistanceChromatisationPrinted circuit aspectsSurface layerZinc metal

Disclosed is a copper foil which has excellent high frequency characteristics and heat resistance, while achieving high heat-resistant adhesion to a resin substrate at the same time. Specifically disclosed is a heat-resistant copper foil which has a configuration wherein a primary roughened surface layer which has been subjected to a primary roughening process by copper metal, a secondary roughened surface layer which has been subjected to a secondary roughening process by copper metal, and a tertiary processed surface layer which has been subjected to a tertiary processing process by zinc metal are sequentially provided on one surface of an unprocessed copper foil. Also specifically disclosed are: a circuit board which is obtained by laminating the heat-resistant copper foil on a flexible resin substrate or a rigid resin substrate; and a method for manufacturing a copper-clad laminate board wherein the heat-resistant copper foil and a heat-resistant resin substrate are thermally pressure-bonded and the tertiary processed surface layer, which is composed of the roughened copper metal and the zinc metal, is alloyed.

Owner:FURUKAWA ELECTRIC CO LTD

Copper foil with resistance layer, method of production of the same and laminated board

A copper foil with a resistance layer is provided, wherein the variation value is small when it is made into a resistance element, the adhesion with the resin substrate to be laminated with is able to be sufficiently maintained, which has an excellent characteristics as a resistance element for a rigid and a flexible substrate. A copper foil with a resistance layer of the present invention comprises a copper foil on one surface of which a metal layer or alloy layer is formed from which a resistance element is to be formed, the surface of the metal layer or alloy layer being subjected to a roughening treatment with nickel particles. A method of production of a copper foil with a resistance layer of the present invention comprises: forming a resistance layer of phosphorus-containing nickel on a matte surface of an electrodeposited copper foil having crystals comprised of columnar crystal grains wherein a foundation of the matte surface is within a range of 2.5 to 6.5 [mu]m in terms of Rz value prescribed in JIS-B-0601; and performing roughening treatment to a surface of the resistance layer with nickel particles wherein a roughness is within a range of 4.5 to 8.5 [mu]m in terms of Rz value prescribed in JIS-B-0601. The alloy layer is for example formed from phosphorus-containing nickel.

Owner:FURUKAWA ELECTRIC CO LTD

Two manufacturing method of color intagliated images on surface of stainless steel

InactiveCN101628525AWill not harmAging resistanceChromatisationDecorative surface effectsColor imageWeather resistance

The invention relates to two manufacturing methods of color intagliated images on the surface of stainless steel, in particular to two manufacturing methods of color intagliated images on the stainless steel surfaces of stainless steel wares (like stainless steel vacuum cup, etc), articles of daily use, shells of home appliances, crafts and other products. The two manufacturing methods are simple and convenient, the image colors thereof are generated by using stainless steel coloration technology, the anti-corrosion performance, weather resistance, anti-ultraviolet irradiation property and appearance decorative effect thereof are superior to ordinary stainless steel, and the images can be stored for a long time. The two methods not only overcome the defects of poor anti-corrosion and anti-aging performance, poor novelty and the like by using the method of spraying paint or printing ink on the surface of stainless steel products to obtain decorative patterns, but also lead the color decorative pattern layers to be sunken while the relief layer is the natural color layer (silvery white) of the stainless steel, so that color decorative pattern layers can not be damaged when often be contacted and rubbed by hands in use, and the color images are endurable in use.

Owner:HUBEI UNIV +1

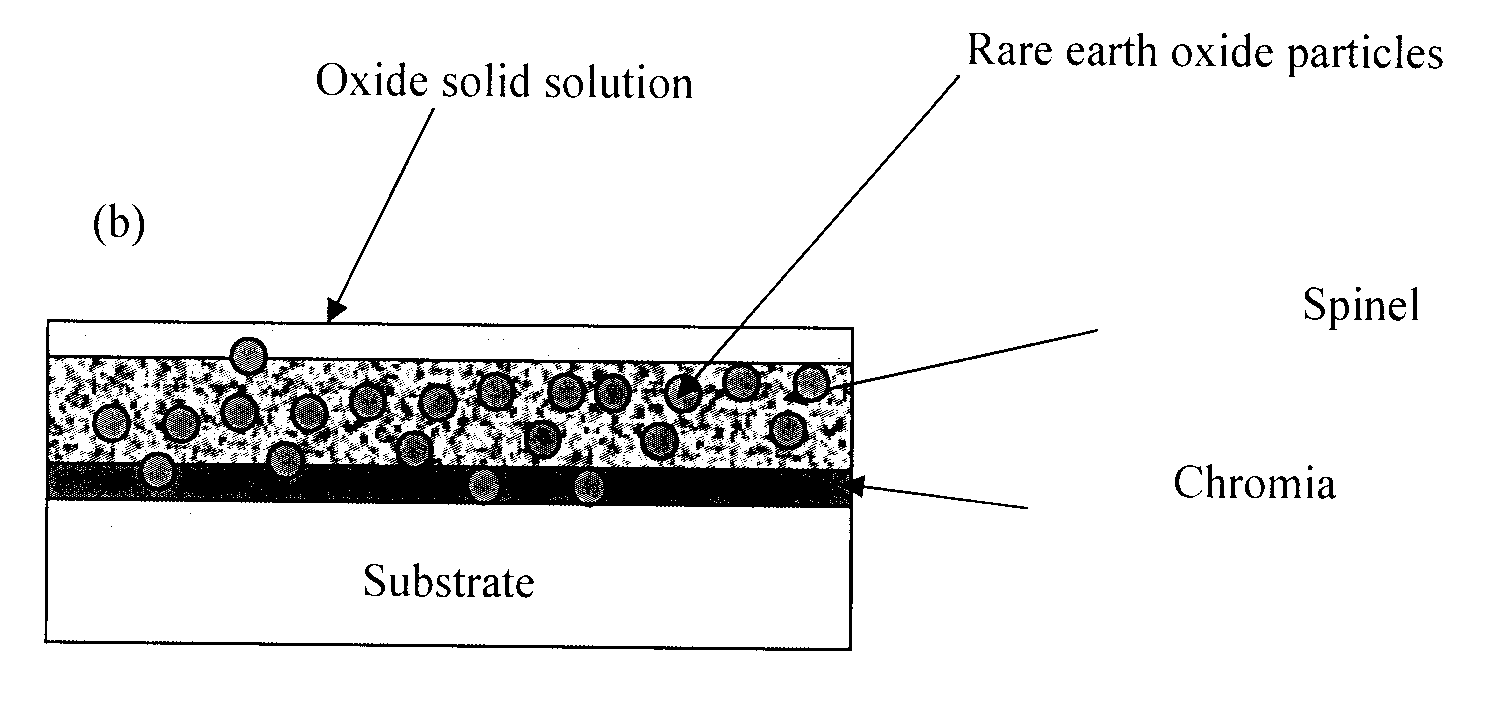

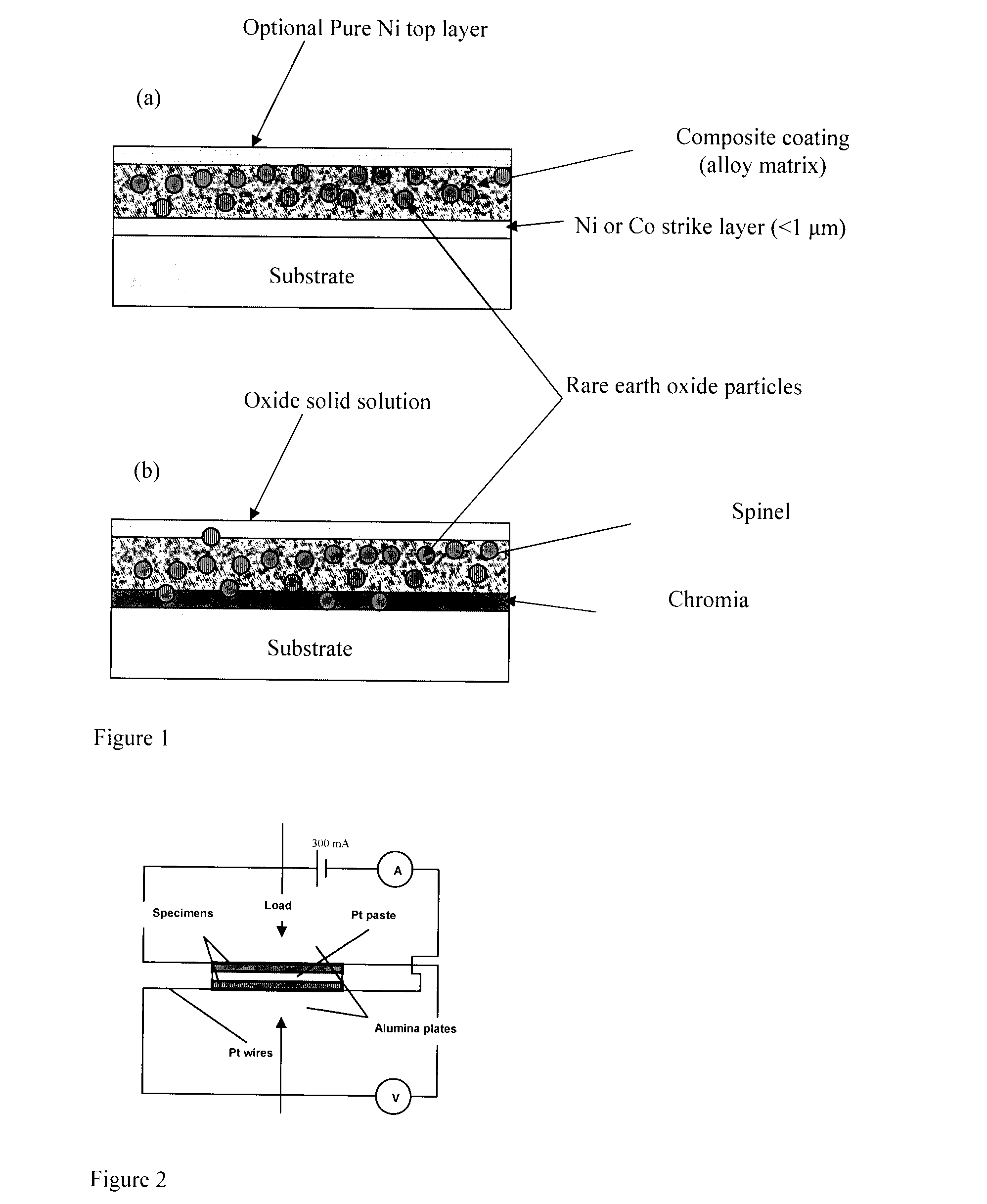

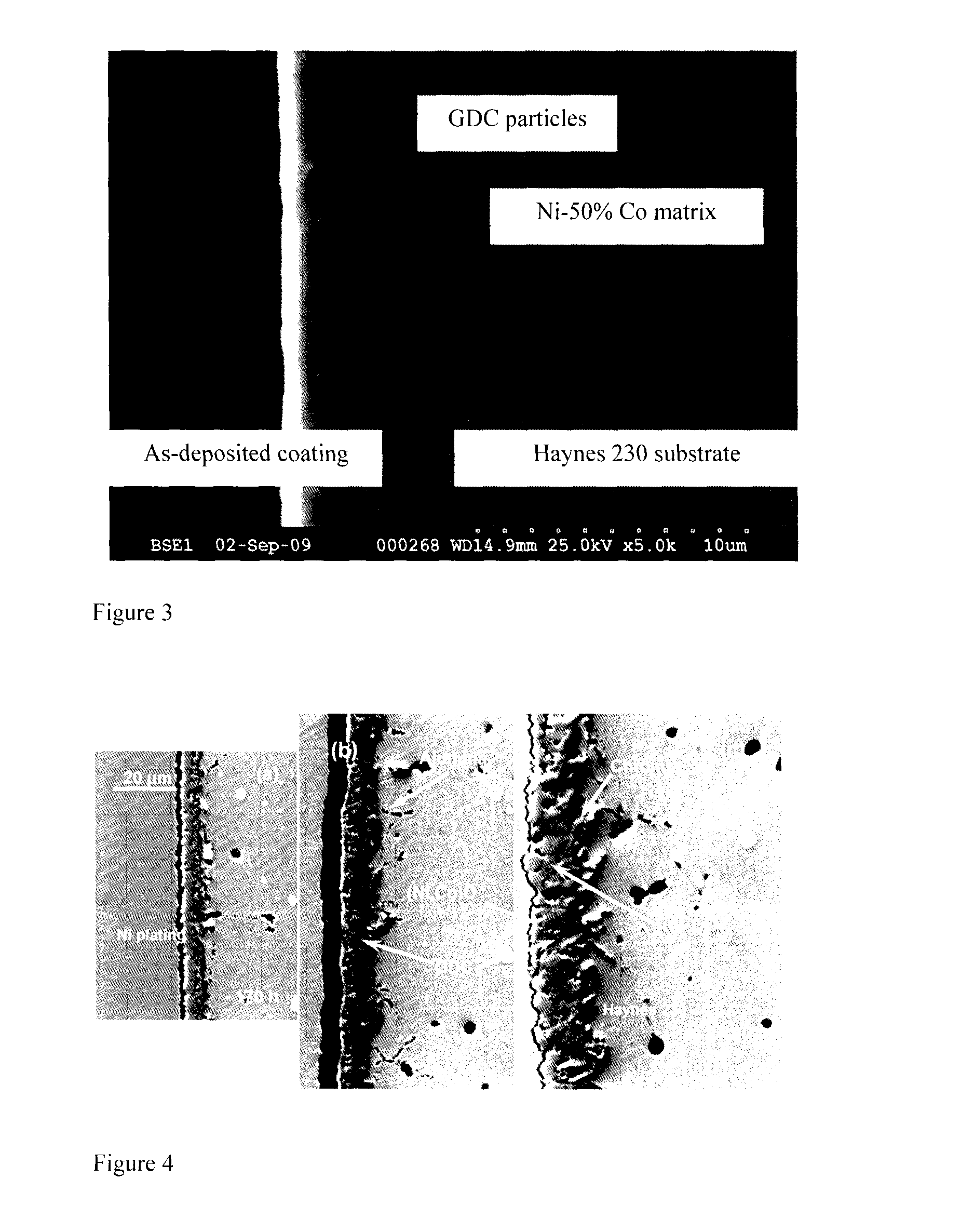

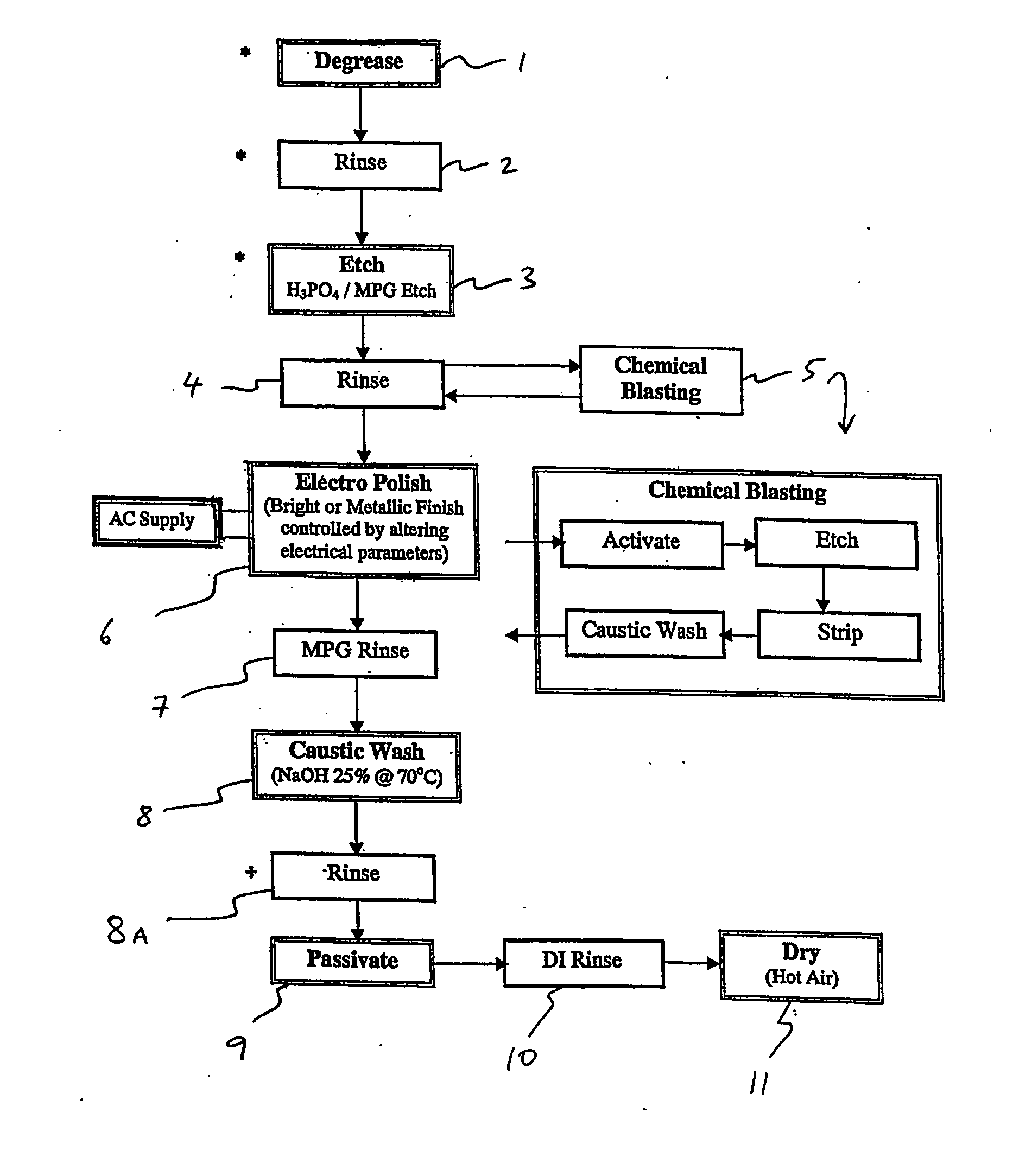

Composite coatings for oxidation protection

InactiveUS20130004881A1Reduce contact resistanceImprove the immunityChromatisationFuel cells groupingMischmetalRare earth

The invention disclosed relates to an oxidized metal matrix composite coated substrate, comprising a substrate made of a material selected from the group consisting of a chromia-forming Fe, Ni and / or Co based alloy containing an amount of Cr ranging from 16 to 30 wt %, and an oxide-dispersion strengthened Cr-based alloy and a plain Cr-based alloy, and an oxidized metal matrix composite coating comprising at least two metals and reactive element oxide particles in the form of a tri-layer scale on the substrate surface comprising an inner chromia layer, an intermediate layer of a spinel solid solution formed by Cr and one or more of the deposited metals selected from the group consisting of Ni, Co, Cu, Mn, Fe and Zn and a mixture thereof, and an electrically conductive top layer comprising oxides of one or more deposited metals selected from the group consisting of Ni, Co, Cu, Fe, Mn, Zn and a mixture thereof, which is substantially free from Cr ions, and wherein one or more of such layers contain particles of doped or undoped oxides of a rare earth metal selected from the group consisting of Ce, Y, La, Hf, Zr, Gd and a mixture thereof.

Owner:NAT RES COUNCIL OF CANADA

Conductive anodic oxidation process for aluminum and alloy part

The invention provides a conductive anode oxidation technology of aluminum and alloy parts thereof, which comprises the following steps: (a) alkaline corrosion: the aluminum and the alloy parts are put into an alkaline solution for removing an oxide skin generated in natural state; (b) bright dipping: the aluminum and the alloy parts are put into 40 to 70 percent nitric acid solution for removing the dust so as to lead the aluminum and the alloy parts to expose metal luster; (c) anode oxidation: the aluminum and the alloy parts are put into a mixed electrolytic solution prepared by chromic salts and villaumite, 10 to 35V of voltage and 0.5 to 5A / dm<2> anodic current density are exerted to the solution at normal temperature, and the time for anode oxidation is 5 to 30min; and (e) drying. A film layer presents slightly transparent rainbow color and is bright, and has smooth and compact appearance. The technology has excellent welding performance, good electric conductivity and better antirust property, and solves the contradiction between the aluminum and the alloy parts, and the electric conductivity and the welding performance.

Owner:四川泛华航空仪表电器有限公司

Electrolytic copper foil, negative electrode for lithium ion secondary battery, and lithium ion secondary battery

ActiveUS20160013493A1Improve conductivityHigh tensile strengthChromatisationDuplicating/marking methodsLithiumElectrolysis

Provided are an electrodeposited copper foil, a negative electrode that is for a lithium ion secondary battery, and a lithium ion secondary battery into which the electrode is incorporated. The electrodeposited copper foil exhibits good electrical conductivity and superior tensile strength, with no significant decline in tensile strength exhibited even after one hour of heating at 300° C. The negative electrode has heightened cycle properties due to the use of the electrodeposited copper foil as a current collector. Using x-ray diffraction, in the electrodeposited copper foil, in normal conditions, the diffraction intensity (I)<220> in the <220> orientation, the diffraction intensity (I)<200> in the <200> orientation, and the diffraction intensity (I)<111> in the <111> orientation, satisfy the following formula (1):I<220> / {I<220>+I<200>+I<111>}>0.13 (1).

Owner:FURUKAWA ELECTRIC CO LTD

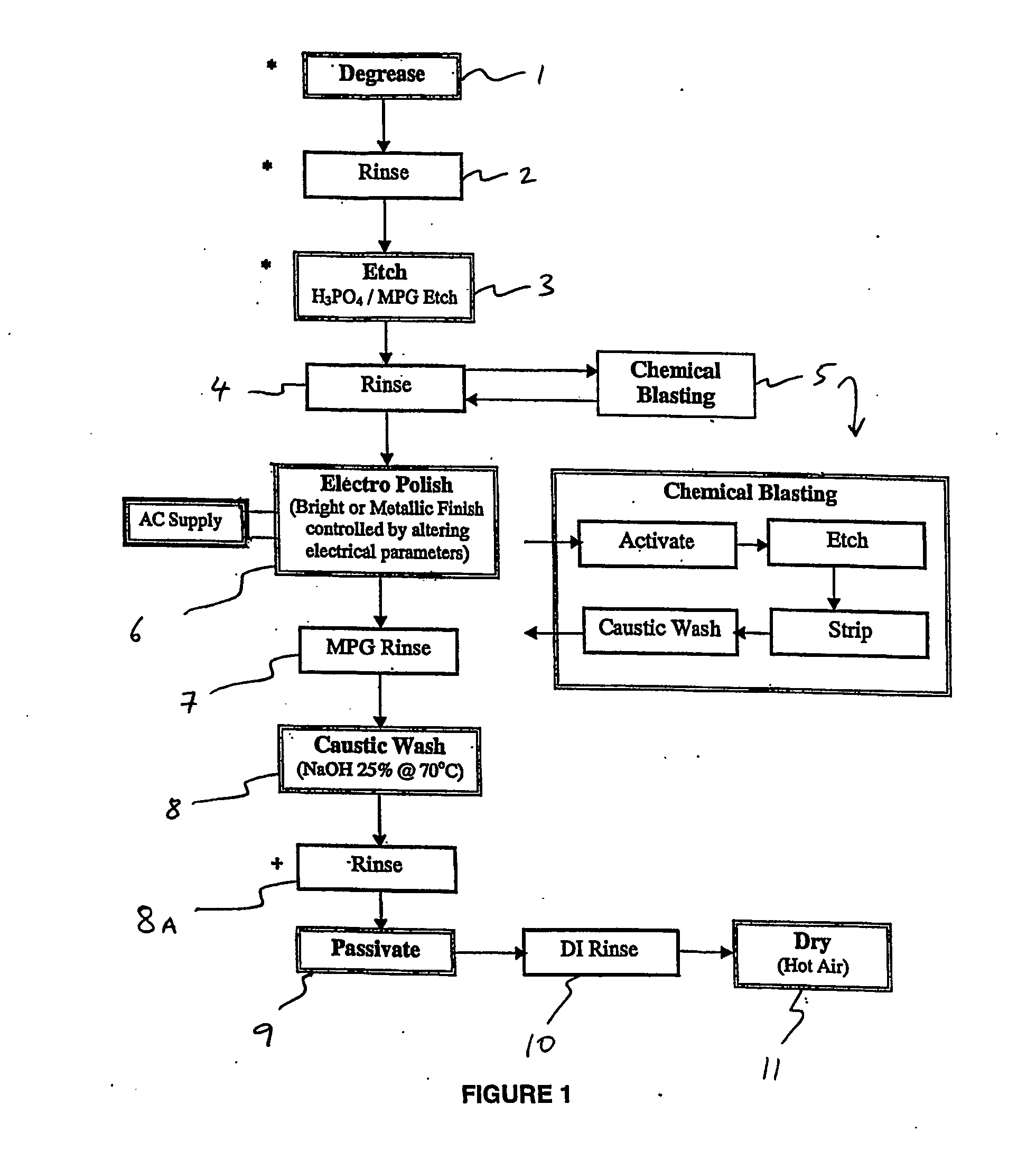

Surface treatment of magnesium and its alloys

InactiveUS20060130936A1Provide protectionReduces microscopic high pointAnodisationChromatisationControl aspectsCorrosion resistant

Methods of polishing and / or brightening surfaces of magnesium or magnesium alloy are disclosed. Polishing and / or brightening methods suitable to both high and low aluminium content magnesium articles are disclosed. In each of the methods, the surface is polished and then passivated. Using the disclosed methods it is possible to control aspects of the appearance of the surface to thereby, for example, obtain a bright and shiny surface to a magnesium or magnesium alloy article which is both stable and corrosion resistant. It is also possible to provide a predetermined texture to the surface using optional steps.

Owner:KERONITE INT LTD

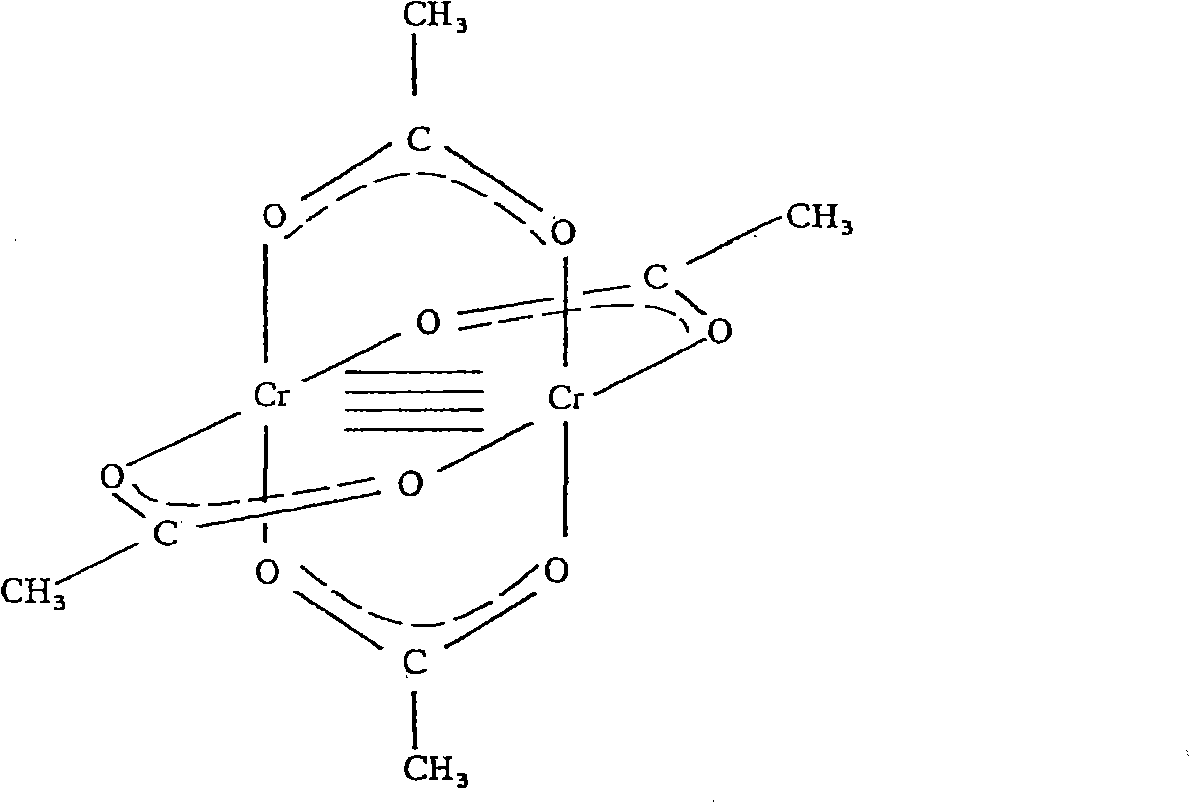

Passivation of Micro-Discontinuous Chromium Deposited From a Trivalent Electrolyte

ActiveUS20150252487A1Increased corrosionImprove corrosion resistanceChromatisationElectrolytic inorganic material coatingElectrolyteElectrical current

A method of treating a substrate, wherein the substrate comprises a layer deposited from a trivalent chromium electrolyte, is described. The method includes the steps of providing an anode and the chromium(III) plated substrate as a cathode in an electrolyte comprising (i) a trivalent chromium salt; and (ii) a complexant; and passing an electrical current between the anode and the cathode to passivate the chromium(III) plated substrate. The substrate may be first plated with a plated nickel layer so that the chromium(III) plated layer is deposited over the nickel plated layer.

Owner:MACDERMID ACUMEN INC

Method for preparing colored stainless steels and obtained products thereof

InactiveCN101191249AReduce oxidation rateTake it out promptlyChromatisationPotential differenceSapphire

The invention discloses a colored stainless steel manufacturing method, including that the stainless steel is submerged in a coloring pool containing the chromic anhydride solution and the sulphuric acid solution for generating the light interference oxide film; the potential difference between the stainless steel and the reference electrode, which is read out by a millivolt potential instrument, is outputted to an A / D switching circuit by an output interface, the A / D switching circuit outputs the switched digital type potential difference to a computer which monitors the change of the potential difference by a control program, when the potential difference reaches the preset value, the computer sends out indicator signals for taking the stainless steel out of the coloring pool. By the invention, the light interference film with various colors such as sapphire, champagne gold, tawny, atroceruleous, amaranth, hyacinth, purple green, green, etc. can be steadily and reproducibly acquired.

Owner:梁振辉

Preparation method of tin-plated plate and application of tin-plated plate prepared by preparation method

ActiveCN108950613AImprove uniformityGuaranteed corrosion resistanceChromatisationTin platingStrip steel

The invention provides a preparation method of a tin-plated plate and an application of the tin-plated plate prepared by the preparation method. The preparation method comprises the following steps that a strip steel sequentially undergoes tin plating, soft melting, passivation and oil coating to obtain a finished product, wherein in the tin plating process, the current density of the first pass and the last pass is 10-20 A / dm<2>, and the current density of the middle pass is 5-10 A / dm<2>, in the soft melting process, a pure induction soft melting process is adopted, the temperature of soft melting is 240-245 DEG C in the soft melting process, the soft melting time is 0.5-1.5 s, and in the passivation process, a sodium dichromate solution with the concentration being 27-31 g / L is used as apassivation solution. Through the preparation method, the tin-plated plate which is uniform in coating, good in welding performance, good in binding force with a PET film and extremely low in tin quantity is prepared, and the tin-plated plate can be used for replacing a chromium plated plate to be applied to the coated iron.

Owner:SHOUGANG CORPORATION

Surface-Treated Copper Foil

ActiveUS20150079415A1High bonding strengthGood effectChromatisationPrinted circuit aspectsCopper foilUltimate tensile strength

This surface-treated copper foil is characterized in that the amount of adhesion of Si on the copper foil surface is from 3.1 to 300 μg / dm2, and the amount of adhesion of N on the copper foil surface is from 2.5 to 690 μg / dm2. The objective of the present invention is to obtain a copper foil having improved peel strength in providing a copper foil for a flexible printed substrate (FPC), in which a copper foil is laminated to a liquid crystal polymer (LCP) suitable for high-frequency applications.

Owner:JX NIPPON MINING& METALS CORP

Complex acid and oxalic acid anodization method for processing aluminum and aluminum alloy

ActiveCN101476144AImprove corrosion resistanceImprove insulation performanceChromatisationAnodizingOxalic acid

The invention discloses an oxalic chromic acid anodizing method for processing aluminium and aluminium alloy which includes steps: removing oil, washing with hot water, washing with cool water, corrupting, countercurrent rinsing, washing with cool water, anode oxidating, countercurrent rinsing, closing and drying. The method has characteristics of confecting tank liquor in anode oxidating working procedure, confecting tank liquor in removing oil working procedure, confecting tank liquor in corrupting working procedure and confecting tank liquor in closing working procedure. The aluminium and the aluminium alloy treated by the method has characteristics of micromesh film crystal, stronger corrosion resistance, better insulating property and decoration.

Owner:GUIZHOU HONGLIN MACHINERY

Liquid Crystal Polymer Copper-Clad Laminate and Copper Foil Used For Said Laminate

ActiveUS20140093743A1High peel strengthEtching property can be improvedChromatisationCircuit optical detailsCopper foilCopper plating

Provided is a copper-clad laminate obtainable by bonding a copper foil on which roughening treatment including copper-cobalt-nickel alloy plating is performed and a liquid crystal polymer to each other, wherein the copper-clad laminate is free from a roughening particle residue on a surface of the liquid crystal polymer resin after copper foil circuit etching. The copper-clad laminate obtainable by bonding a copper foil and a liquid crystal polymer to each other, wherein the copper foil includes a copper primary particle layer formed on a surface bonded to the liquid crystal polymer and a secondary particle layer formed on the primary particle layer and made from a ternary alloy including copper, cobalt, and nickel; the primary particle layer has an average particle size of 0.25 to 0.45 μm; and the secondary particle layer has an average particle size of 0.05 to 0.25 μm.

Owner:JX NIPPON MINING& METALS CORP

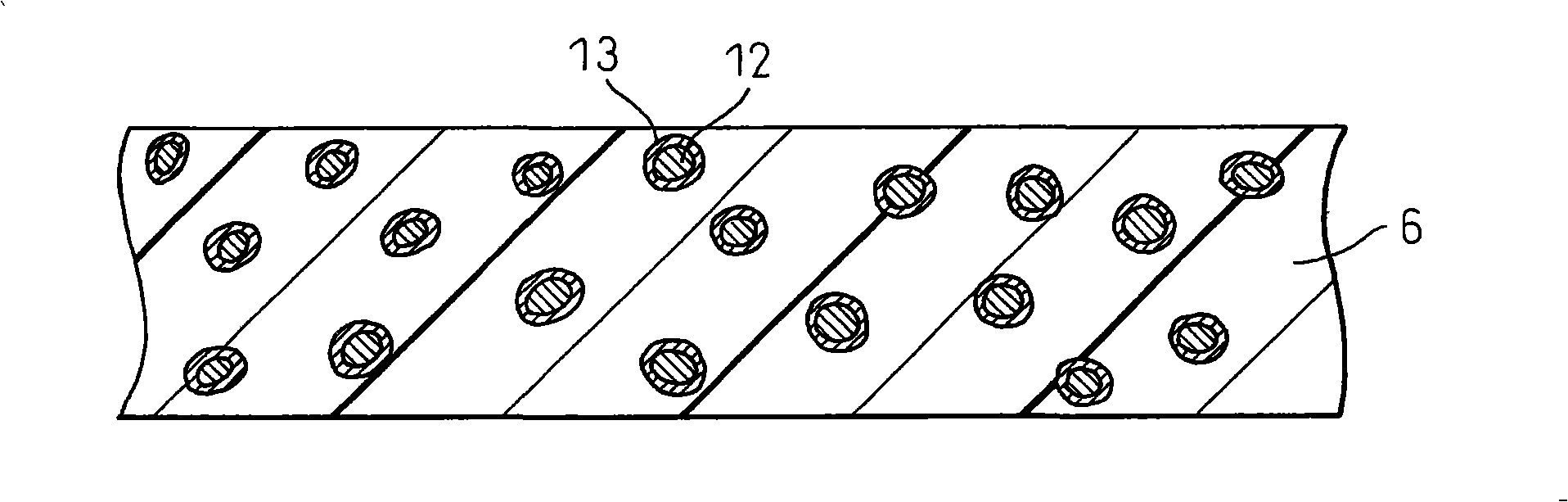

Tinned steel sheet excellent in corrosion resistance

InactiveCN101384753AImprove corrosion resistanceHot-dipping/immersion processesChromatisationTinningAlloy

A corrosion resistant surface-treated steel sheet suitable for an uncoated can accommodating an acidic food or beverage. The surface-treated steel sheet comprises: an alloy layer (1) on a surface of steel sheet (4) to be an inner wall of can (after being formed into can), wherein the alloy layer (1) contains, by mass %, Sn of 50-75%, Fe of 20-40% and Ni of 7-20%; an alloy layer (2) on the alloy layer (1), wherein the alloy layer (2) contains, by mass %, Sn of 70-80%, Fe of 15-25% and Ni of 0.1-7%; and an unalloyed Sn plating layer (3) of which coating weight is 1.5 - 15.0g / m<2> are formed in the named order; wherein a total amount of Sn per unit area in the alloy layers (1) and (2) is 0.2 - 2.0g / m<2> and a total amount of Ni per unit area in the alloy layers (1) and (2) is 0.001-0.3g / m<2>.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com