Method for preparing colored stainless steels and obtained products thereof

A production method and stainless steel technology, applied in the direction of chromate treatment, etc., can solve the problems of short color time, image distortion, poor anti-fouling and anti-wear ability of the color film, and achieve the effect of slowing down the oxidation speed and improving the corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

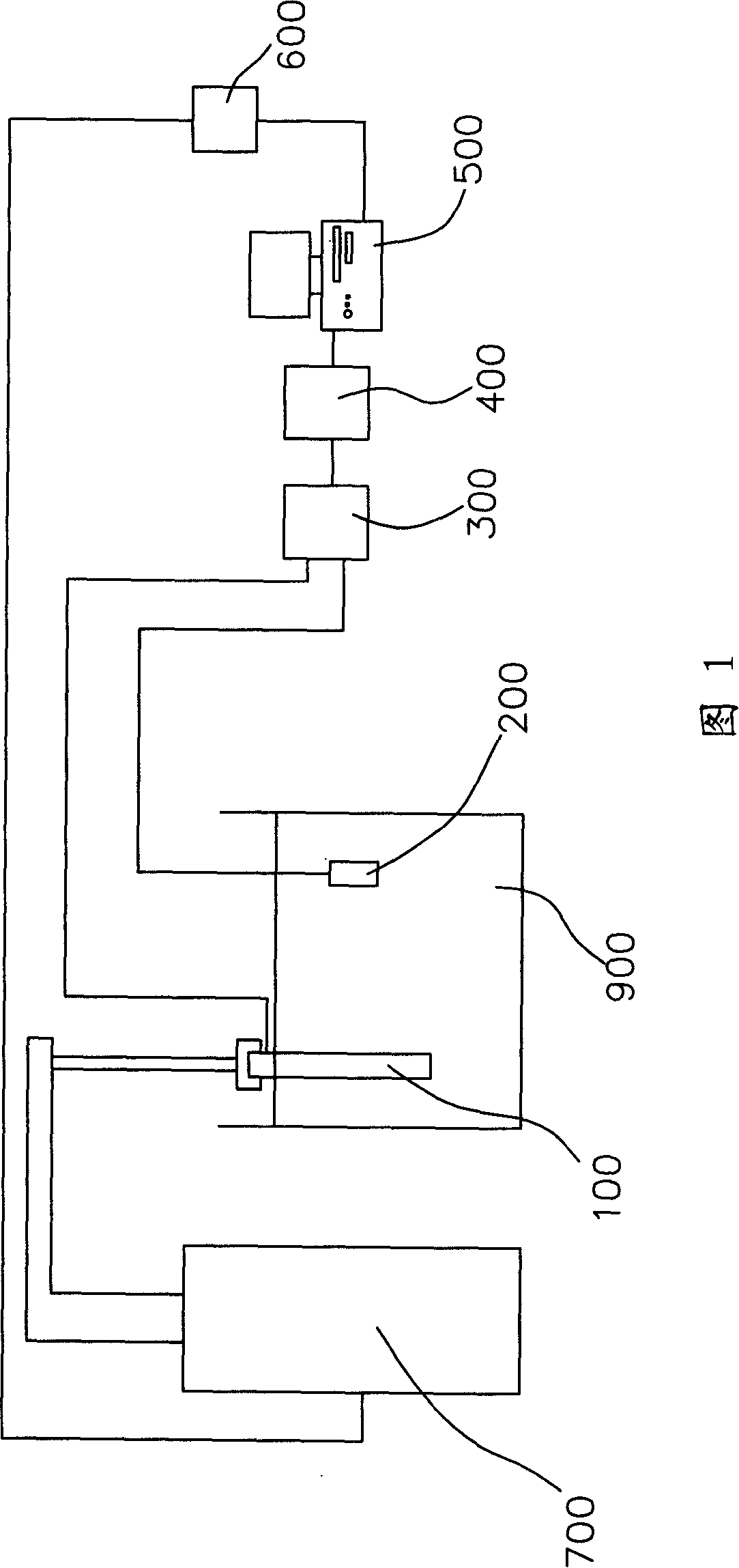

Image

Examples

Embodiment 1

[0042] The colored stainless steel manufacturing method of the present invention is used to form a light interference oxide film with a desired color, such as brown, blue-black, on one side surface of a stainless steel plate with a thickness of 0.3-2.0 mm (hereinafter referred to as the film-forming surface). , Fuchsia, purple blue, purple green, green and other colors. The method includes the following steps:

[0043] Firstly, the film-forming surface is mechanically polished, for example, iron red is used as an abrasive to plan the film-forming surface into a mirror surface.

[0044] The polished stainless steel plate is washed with clean water at least once to remove the stains on the surface of the film, and then the stainless steel plate is installed on the fixing frame to make the surface of the stainless steel plate smooth.

[0045] Immerse the fixed frame and the stainless steel plate into the pickling pool through the spreader for electrolytic activation treatment. T...

Embodiment 2

[0051] As another embodiment of the present invention, it is similar to Example 1, except that:

[0052] The temperature in the coloring tank is 82-85 degrees centigrade, the concentration of sulfuric acid is 460-520 g / l, such as about 480 g / l, and the concentration of chromic anhydride is 180-240 g / l, such as about 200 g / l.

[0053] At this time, the predetermined value used when the computer equipment sends out the indication signal is selected from the following potential difference ranges: the potential difference of sapphire blue is about 9-11 millivolts, and the potential difference of champagne gold is about 14-16 millivolts.

Embodiment 3

[0055] As another embodiment of the present invention, it is similar to Example 1, except that:

[0056] The computer equipment is a microcomputer, and the indication signal sent by the computer equipment is a sound signal or a light signal. According to the indication signal, the staff controls a manual / automatic / semi-automatic lifting device to quickly lift the stainless steel away from the coloring pool.

[0057] Two or more stainless steel plates are immersed in a coloring pool for oxidation coloring at the same time, and these stainless steel plates can be taken out of the coloring pool at the same time, so that each stainless steel plate forms a light interference oxide film of the same color, or can also be sequentially taken out from the coloring pool. The coloring pool is taken out, so that each stainless steel plate forms a light interference oxide film of different colors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com