Chromium(vi)-free black passivation of surfaces containing zinc

A black, passivation layer technology, applied in the field of black conversion layer treatment solution, can solve the problem of black zinc alloy surface that cannot be successfully

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

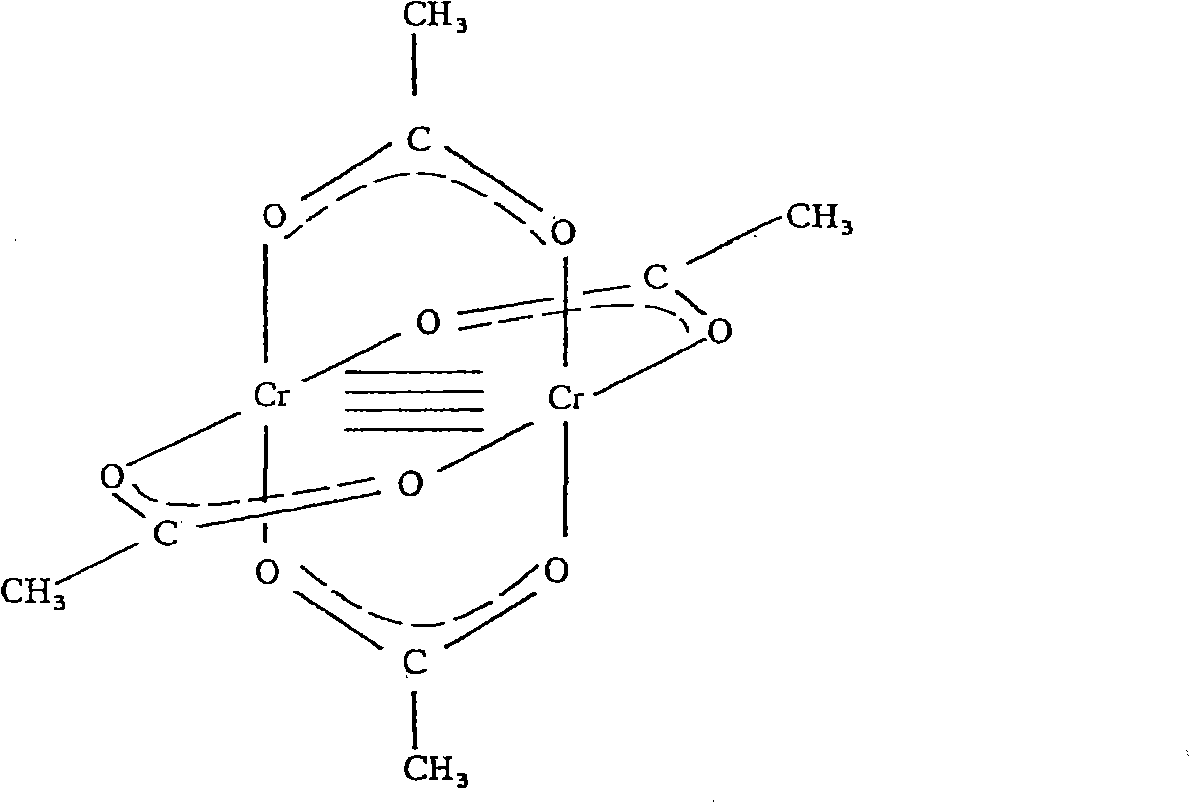

Method used

Image

Examples

example 1-6

[0076] An aqueous reaction solution having the composition shown in Table 1 was prepared (individual components were added in the same form as in Comparative Example 2). The pH of each solution was adjusted to the value shown in Table 1 with nitric acid and sodium hydroxide.

[0077] Steel structural elements are coated electrochemically with the zinc-containing alloys indicated under the respective headings in Table 1 and, after electrochemical coating, rinsed thoroughly with demineralized water and subsequently in 0.3% nitric acid at 20-30°C 10 seconds of activation followed by a full rinse. Next, the elements were immersed in the reaction solution under the conditions (temperature, treatment time) shown in Table 1. Subsequently, the surface coating ("Versiegelung") was carried out with Corrosil 501, which consists of an aqueous polymer dispersion with a silicate component. The results of a visual (color) evaluation and a salt spray test according to DIN 50021 SS before an...

PUM

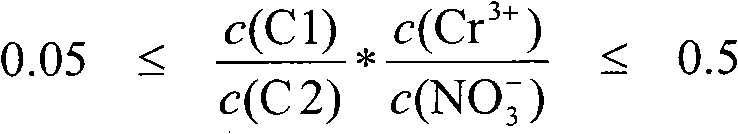

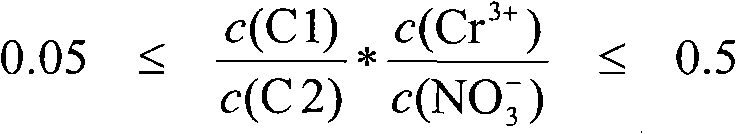

| Property | Measurement | Unit |

|---|---|---|

| composition ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com