Copper foil with resistance layer, method of production of the same and laminated board

A technology of resistance layer and electrolytic copper foil, applied in directions including printed resistance, printed circuit manufacturing, coating, etc., can solve the problems of increasing dispersion and obtaining resistance value, and achieve the effect of small dispersion of resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

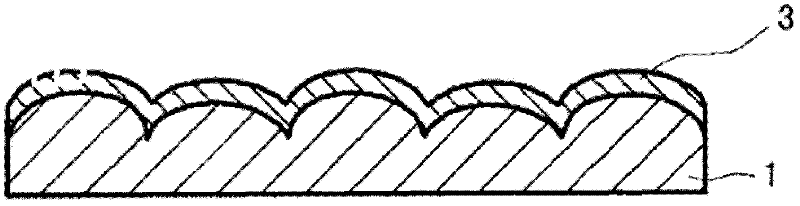

[0060] The reason for using a phosphorus-containing nickel bath in the preparation of the above-mentioned resistance layer 3 is that the bath conditions are easy to build and the resistance value of the resistance layer can be managed by controlling the amount of nickel adhesion and phosphorus content and their ratio, especially when using amino In the case of nickel sulfonate, since the remaining plating stress is small after forming a thin film, warpage can be suppressed, so it has advantages in both improved production efficiency and stable quality.

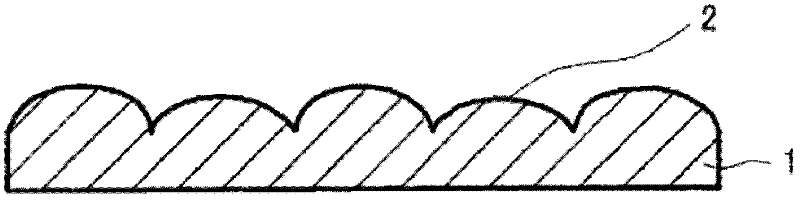

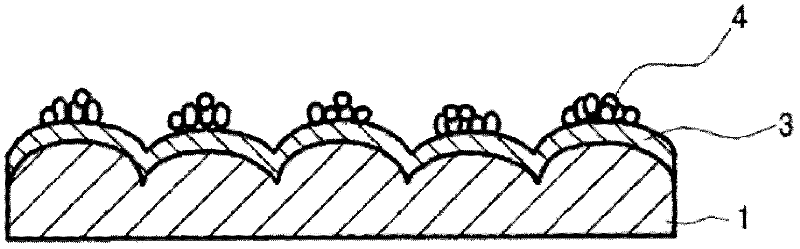

[0061] Here, the reason for using the rough side of the commonly used electrolytic copper foil to form the resistance layer is that if the rough surface shape is in the range of 2.5 to 6.5 μm in terms of Rz value, even if the thickness of the film reaches 250 Ω / □ in terms of resistance value The left and right electroplating thickness can also be plated without air pores. Even if the nickel rough treatment of nickels that attach ...

Embodiment 1

[0065] Using copper foil produced under the conditions of electrolytic foil production, the thickness of the copper foil is 18 μm, the shape roughness of the rough surface side (electrolyte surface side) is 4.8 μm Rz value specified in JIS-B-0601, and in The elongation after heating for 60 minutes at 180°C under atmospheric heating conditions was 14.2% (MP foil manufactured by Furukawa Electric Co., Ltd.). Roughening treatment and implementation of Capsur plating treatment.

[0066] [Bath Composition and Treatment Conditions for Forming Resistance Layer]

[0067] Use nickel sulfamate, calculated as nickel...65g / L

[0068] Phosphorous acid to PO 3 Count...40g / L

[0069] Hypophosphorous acid to PO 4 Count...50g / L

[0070] Boric acid (HBO 3 )......30g / L

[0071] pH: 1.6

[0072] Bath temperature: 55°C

[0073] Plating current density......5.0A / dm 2

[0074] [Nickel roughening treatment conditions]

[0075] Use nickel sulfate, calculated as nickel......18g / L

[0076] ...

Embodiment 2

[0092] In addition to using the following copper foil produced under the conditions of electrolytic foil production, it was processed under the conditions described in Example 1 and provided for evaluation and measurement; the thickness of the copper foil was 18 μm, and the shape roughness of the rough side was JIS- The Rz value specified in B-0601 is 4.5 μm, and the elongation after heating for 60 minutes at 180° C. under atmospheric heating conditions is 14.2% (MP foil manufactured by Furukawa Electric Co., Ltd.).

[0093] The measurement and evaluation results are also shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com