Load and freeze-thaw cycle coupled concrete durability testing device and evaluation method

A freeze-thaw cycle and test device technology, applied in measuring devices, using stable tension/pressure test materials, instruments, etc., can solve the problems of complex operation, inability to meet, difficult to popularize application, etc., to achieve convenient load application, The effect of ensuring accuracy and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Concrete is prepared, and the concrete components are configured according to the following mass ratios:

[0050] P.O42.5 ordinary silicon cement: mineral powder: water: medium sand: 5-25mm crushed stone: superplasticizer = 1:0.25:0.45:2.0:3.1:0.008, the design strength grade is C40, and the measured compressive strength is 47.6MPa, slump 160mm, gas content 3.0%

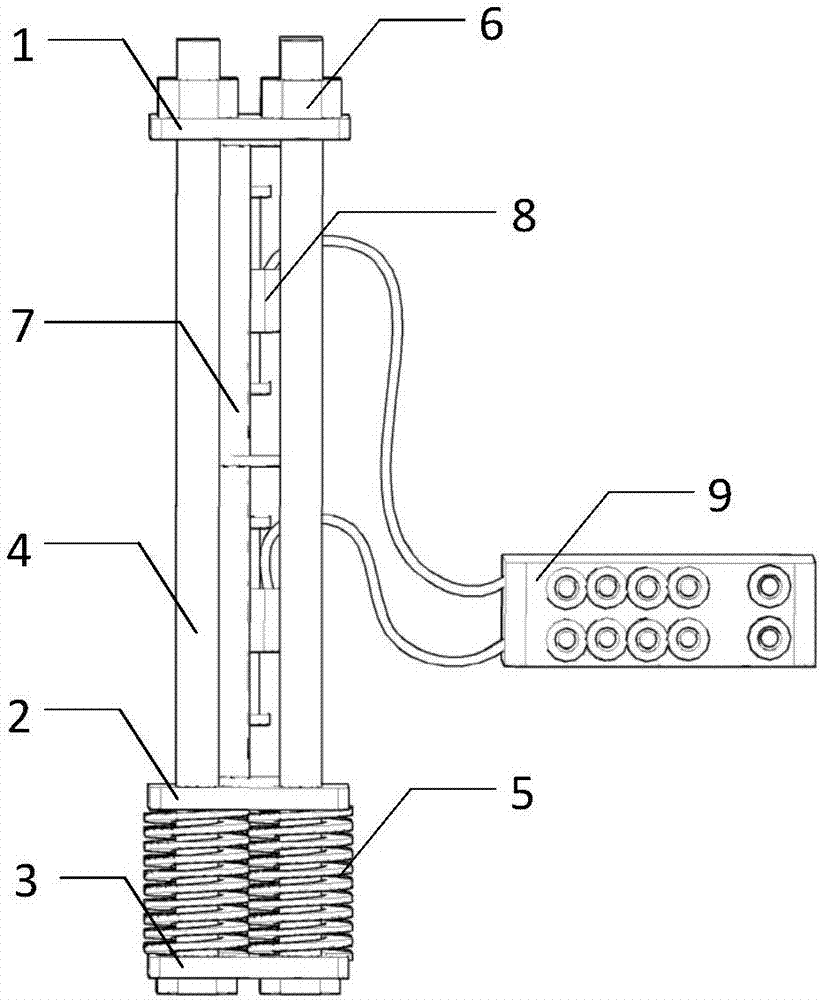

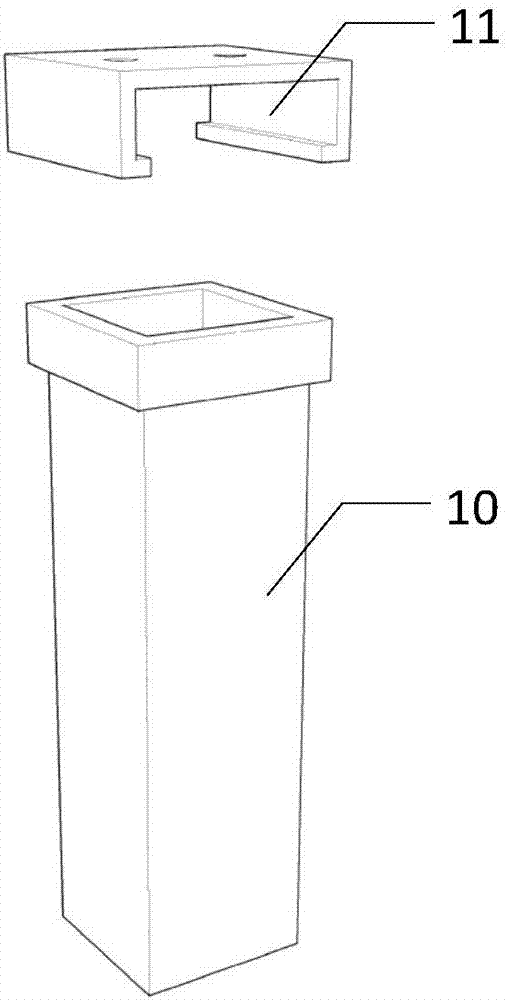

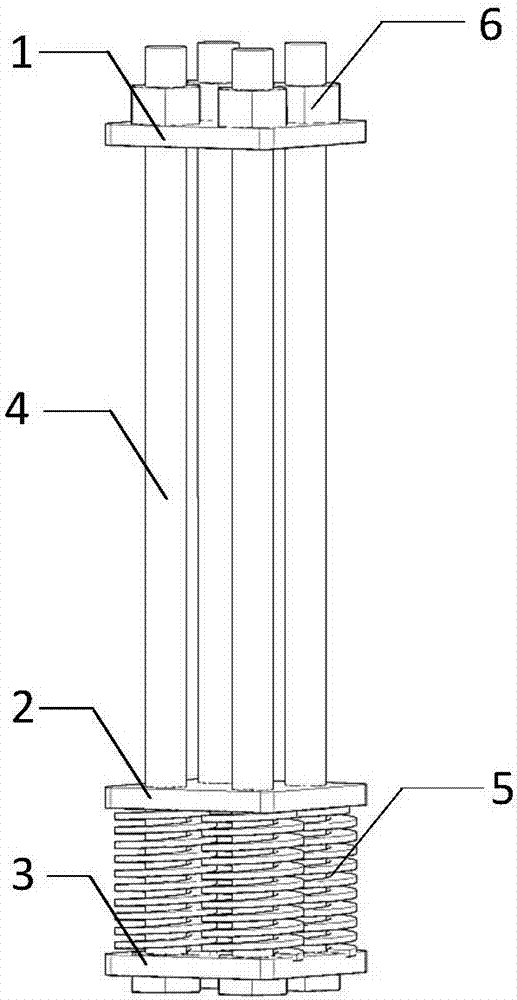

[0051] 2. The concrete cylinder specimen 7 (Ф50×150mm) to be tested and evaluated is prepared by using a steel mold, and the strain sensor 8 is carefully embedded in the concrete forming process, and then the mold is removed and maintained until the predetermined age.

[0052] 3. See figure 1 , Install and debug the load application device, and install two cylindrical concrete specimens 7 on a set of load application devices, and use a stainless steel backing plate with a diameter of 50mm and a thickness of 5mm to isolate the concrete cylinder specimens 7 ;

[0053] 4. Connect the lead wire of the sensor...

Embodiment 2

[0059] 1. Concrete is prepared, and the concrete components are configured according to the following mass ratios:

[0060]P.O42.5 ordinary silicon cement: mineral powder: fly ash: water: medium sand: 5-25mm gravel: superplasticizer = 1:0.20:0.15:0.45:1.9:3.1:0.008, design strength level C40 , the measured strength is 44.8MPa, the slump is 150mm, and the gas content is 3.5%.

[0061] 2. According to the steps 2 to 5 of Example 1, the mixed solution made of 5% sodium sulfate solution and 3.5% sodium chloride solution is used instead of water as the freeze-thaw medium, and the applied load of the concrete specimen is 40% of the ultimate load of the specimen. %, carry out the load and freeze-thaw coupling test of the specimen.

[0062] The concrete specimen of this embodiment was subjected to a freeze-thaw cycle coupling test under the condition that the applied load was 30% of its ultimate strength, and the critical value of failure of the concrete prepared in Example 1 was 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com