Measuring method for asphalt mixture cryogenic fatigue performance test

A technology for asphalt mixture and fatigue performance, which is used in the test of low-temperature fatigue performance and the field of low-temperature fatigue performance test determination of asphalt mixture. The effect of simple test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

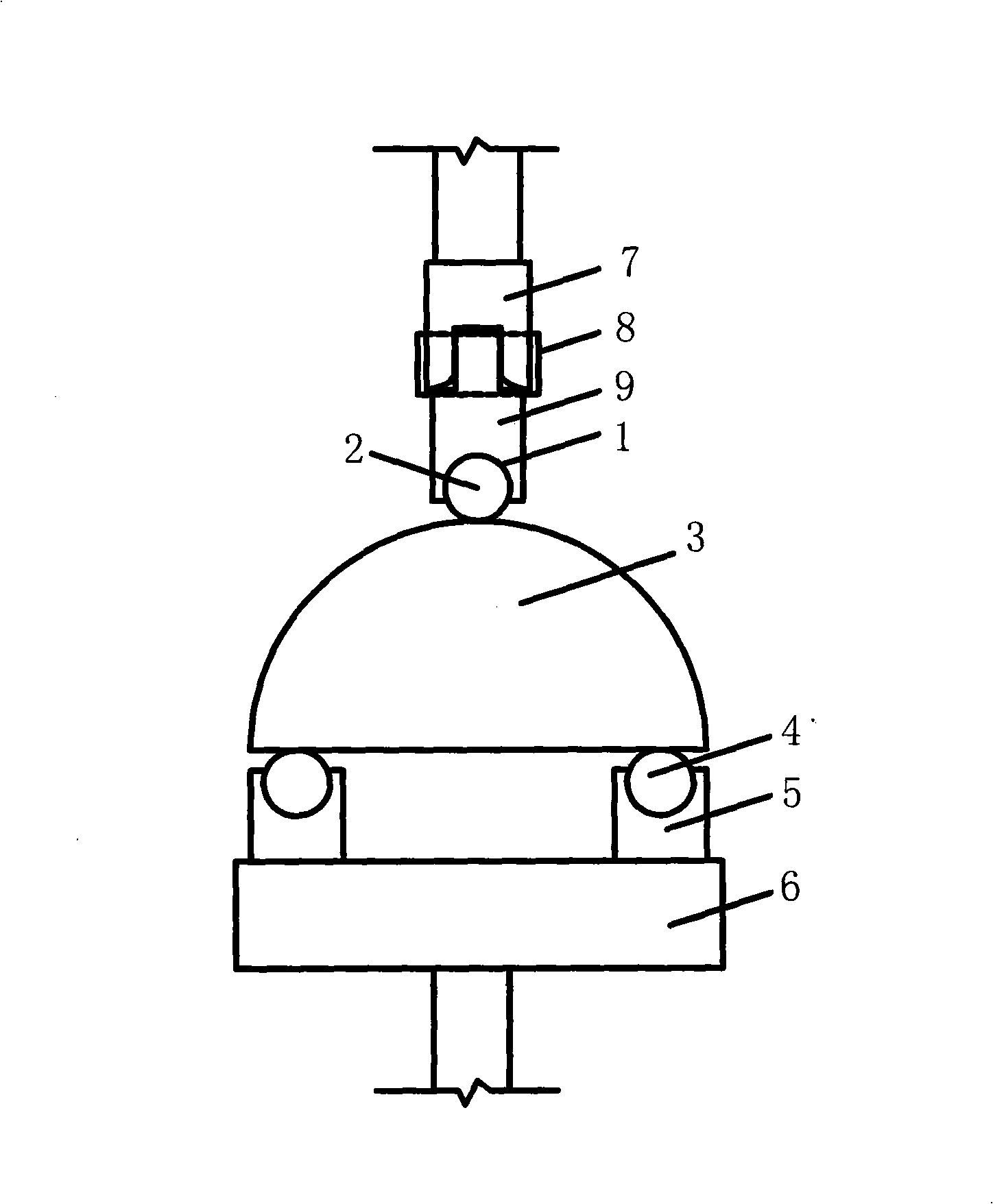

[0018] 1. Use the general computer program ANSYS to calculate, and use the SOLID45 block unit in the program to discretize the hemispherical specimen. In the calculation parameters, the diameter (D) of the hemispherical specimen is 150mm, the elastic modulus is 800E / MPa, and the density is assumed to be 2350Kg / m 3 , the load is simulated with a uniform load of 1515×3N / m, and the boundary conditions are set to be simply supported on both sides. Adjust the distance between the support points, and calculate the change of the maximum normal stress in the middle of the bottom edge of the specimen with the distance between the support points (see Table 1 below).

[0019] Table 1 Stress variation in the middle of the bottom edge of the specimen

[0020] Support point spacing

0.9D

0.8D

0.7D

0.6D

0.5D

0.4D

0.3D

Maximum compressive stress (MPa)

8.95

8.44

7.91

7.36

6.80

6.25

5.76

M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com