Method for preparing graphene film on surface of titanium alloy

A graphene film, titanium alloy technology, applied in metal material coating process, solid-state chemical plating, coating and other directions, can solve the problems of easy detachment of the film and insufficient bonding force, and achieve biological tribological performance and wear resistance. Good performance, low cost, mild reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

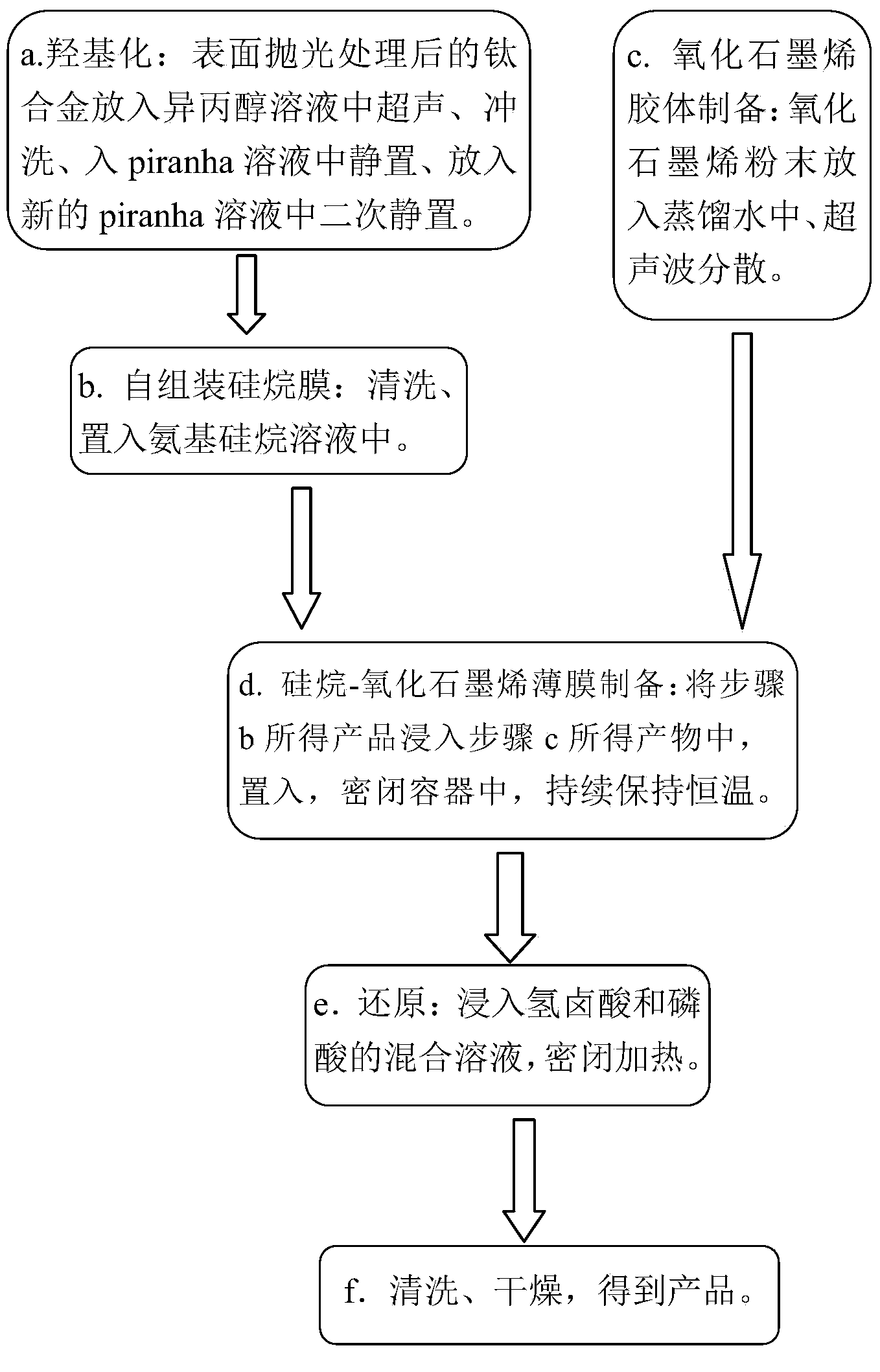

[0029] A preparation method for a titanium alloy surface graphene film, comprising the following steps:

[0030] a. The polished titanium alloy Ti 6 al 4 Put V into 70% isopropanol solution and ultrasonically for 30min, here Ti 6 al 4 Ti can also be used for V 6 al 7 Nb or Ti 12 Mo 5 Replace it with Ta; wash it with ultrapure water for 5 times, then slowly put it into the piranha solution for 10 minutes, take it out and put the treated titanium alloy into the new piranha solution for 5 minutes again, so that the surface of the titanium alloy is hydroxylated.

[0031] b. After the hydroxylated titanium alloy was washed 5 times with deionized water, it was placed in an aminosilane solution with a propyltrimethoxysilane content of 2 mmol / L to self-assemble a silane film for 2 hours.

[0032] c. Put the graphene oxide powder into distilled water and disperse it by ultrasonic wave for 30 minutes to obtain a stable graphene oxide colloid with a concentration of 0.1 mg / mL.

...

Embodiment 2

[0039] A preparation method for a titanium alloy surface graphene film, comprising the following steps:

[0040] a. The polished titanium alloy Ti6 al 4 Put V into a 70% isopropanol solution and sonicate for 60min, where Ti 6 al 4 Ti can also be used for V 6 al 7 Nb or Ti 12 Mo 5 Ta is replaced, and then rinsed with ultrapure water for 3 times, and then slowly put into the piranha solution for 30 minutes. After taking it out, put the treated titanium alloy into the new piranha solution for 10 minutes again, so that the surface of the titanium alloy is hydroxylated.

[0041] b. After the hydroxylated titanium alloy was washed 5 times with deionized water, it was placed in an aminosilane solution with a propyltrimethoxysilane content of 0.5 mmol / L to self-assemble a silane film for 12 hours.

[0042] c. Put the graphene oxide powder into distilled water and disperse it by ultrasonic wave for 2 hours to obtain a stable graphene oxide colloid with a concentration of 2 mg / mL....

Embodiment 3

[0049] A preparation method for a titanium alloy surface graphene film, comprising the following steps:

[0050] a. The polished titanium alloy Ti 6 al 4 Put V into 70% isopropanol solution and sonicate for 45min, where Ti 6 al 4 Ti can also be used for V 6 al 7 Nb or Ti 12 Mo 5 Replace it with Ta, rinse it with ultrapure water for 3 times, and then slowly put it into the piranha solution for 20 minutes. After taking it out, put the treated titanium alloy into the new piranha solution for 5 minutes again to make the surface of the titanium alloy hydroxylated.

[0051] b. After the hydroxylated titanium alloy was washed three times with deionized water, it was put into an aminosilane solution with a propyltrimethoxysilane content of 2 mmol / L to self-assemble a silane film for 2 hours.

[0052] c. Put the graphene oxide powder into distilled water and disperse it by ultrasonic wave for 30 minutes to obtain a stable graphene oxide colloid with a concentration of 0.1 mg / mL....

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com