Hydraulic fracturing and grouting solidification combined rock cross-cut coal uncovering method

A technology of hydraulic fracturing and coal excavation in Shimen, which is applied in the fields of earthwork drilling, mining equipment, gas discharge, etc., can solve the problems of inconvenience of direct popularization and application, limited damage scope and cracks, etc., so as to reduce the amount of outburst elimination engineering and shorten the construction period. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

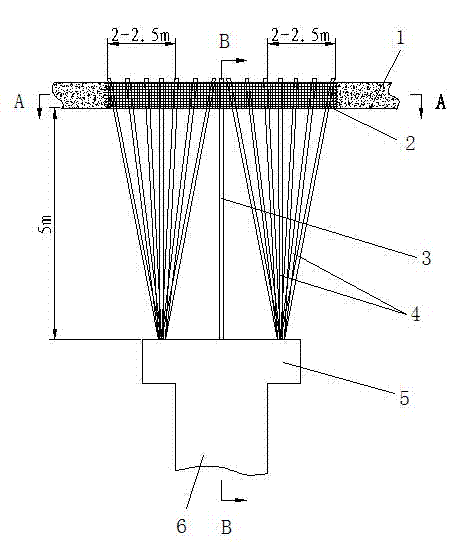

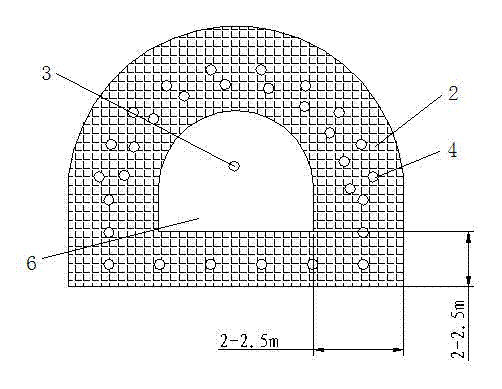

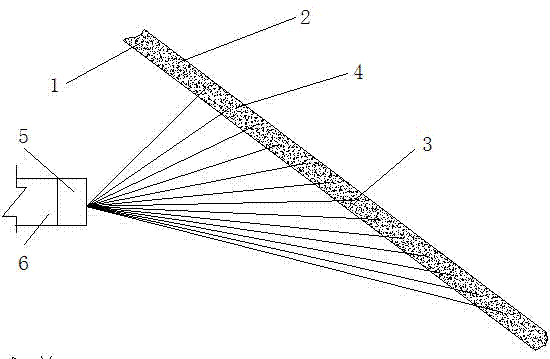

[0028] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

[0029] see figure 1 , figure 2 , image 3 , Figure 4 , a method for unmasking coal in Shimen combined with hydraulic fracturing and grouting solidification, characterized in that it comprises the following steps:

[0030] a. When the roadway 6 is excavated to a vertical distance of 10m from the coal seam 1, the fracturing hole 3 is drilled along the tunneling direction of the roadway 6 until the coal seam 1 is penetrated, the fracturing hole 3 is sealed, and the fracturing hole 3 is drilled. Coal seam 1 is injected with water for hydraulic fracturing. When the fracturing pressure continues to rise to a set value of pressure drop △P, keep fracturing until the water injection volume reaches the expected value and then stop fracturing;

[0031] b. When the roadway 6 is excavated to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com