High-strength wicking-resistance polyester industrial yarn and preparation method thereof

An anti-wicking, industrial yarn technology, applied in conductive/anti-static filament manufacturing, rayon manufacturing, cyanide reaction preparation, etc., can solve problems such as unusability and no anti-wicking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] A preparation method of high-strength anti-wicking polyester industrial yarn, comprising the following steps:

[0105] (1) Preparation of anti-wicking agent

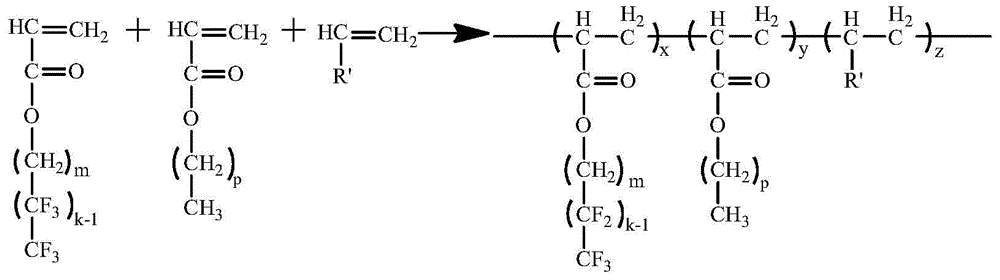

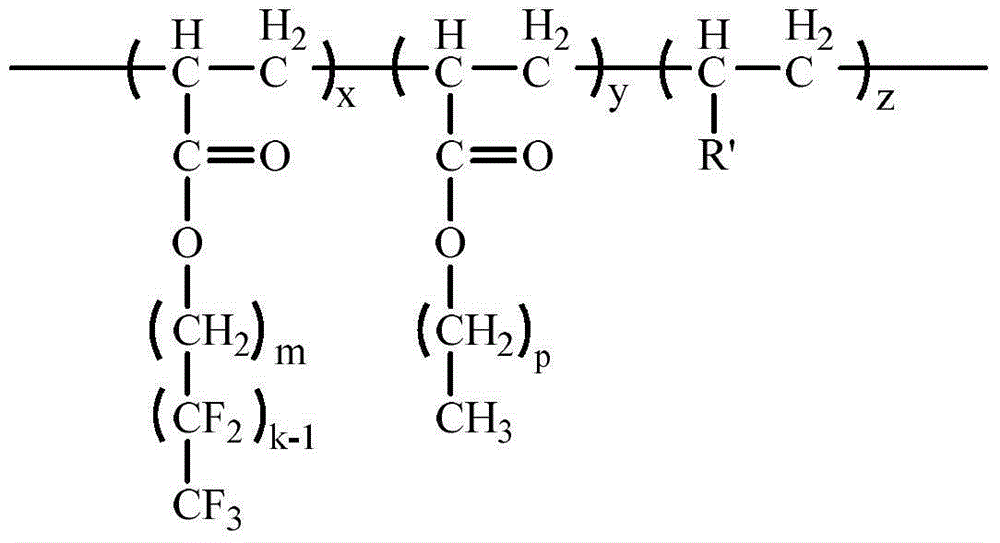

[0106] The synthetic steps of perfluoroalkyl (meth) acrylate, non-fluorinated alkyl (meth) acrylate and ternary block copolymer containing anti-ultraviolet groups are:

[0107] 1) Preparation of brominated end-capped polyperfluoroalkyl (meth)acrylate macroinitiator:

[0108] In a container under nitrogen protection, add catalyst CuBr, monomer perfluoroalkyl (meth)acrylate, solvent toluene, complexing agent pentamethyldiethyltriamine, initiator 2-ethyl bromopropionate , wherein initiator: catalyst: complexing agent: the molar ratio of monomer is 1:1:2:120, be warming up to 65 ℃, constant temperature reaction 6h; Dissolve with tetrahydrofuran after reaction finishes, pass column separation copper salt through alumina, The filtrate was precipitated with absolute ethanol to obtain a polymer, and the polymer was drie...

Embodiment 2

[0136] A preparation method of high-strength anti-wicking polyester industrial yarn, comprising the following steps:

[0137] (1) Preparation of anti-wicking agent

[0138] The synthetic steps of perfluoroalkyl (meth) acrylate, non-fluorinated alkyl (meth) acrylate and ternary block copolymer containing anti-ultraviolet groups are:

[0139] 1) Preparation of brominated end-capped polyperfluoroalkyl (meth)acrylate macroinitiator:

[0140] In a container under nitrogen protection, add catalyst CuBr l, monomer perfluoroalkyl (meth)acrylate, solvent toluene, complexing agent pentamethyldiethyltriamine, initiator 2-bromopropionic acid ethyl Ester, wherein the molar ratio of initiator:catalyst:coordinating agent:monomer is 1:1:2:120, the temperature is raised to 75°C, and the temperature is reacted for 6h; after the reaction is completed, it is dissolved in tetrahydrofuran, and the copper salt is separated through the column of alumina , the filtrate is precipitated with absolute ...

Embodiment 3

[0167] A preparation method of high-strength anti-wicking polyester industrial yarn, comprising the following steps:

[0168] (1) Preparation of anti-wicking agent

[0169] The synthetic steps of perfluoroalkyl (meth) acrylate, non-fluorinated alkyl (meth) acrylate and ternary block copolymer containing anti-ultraviolet groups are:

[0170] 1) Preparation of brominated end-capped polyperfluoroalkyl (meth)acrylate macroinitiator:

[0171] In a container under nitrogen protection, add catalyst CuBr l, monomer perfluoroalkyl (meth)acrylate, solvent toluene, complexing agent pentamethyldiethyltriamine, initiator 2-bromopropionic acid ethyl Ester, wherein the molar ratio of initiator:catalyst:coordinating agent:monomer is 1:1:2:120, the temperature is raised to 66°C, and the reaction is carried out at constant temperature for 6h; after the reaction is completed, it is dissolved in tetrahydrofuran, and the copper salt is separated through the column of alumina , the filtrate is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Wicking height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com