Patents

Literature

68results about How to "Excellent UV aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exterior wall waterproofing heat-insulating decorating integrated material and preparation method thereof

InactiveCN105694625AMeet various style requirements of high-end and high-end exterior finishesShort construction periodFireproof paintsAnti-corrosive paintsPolymer scienceSludge

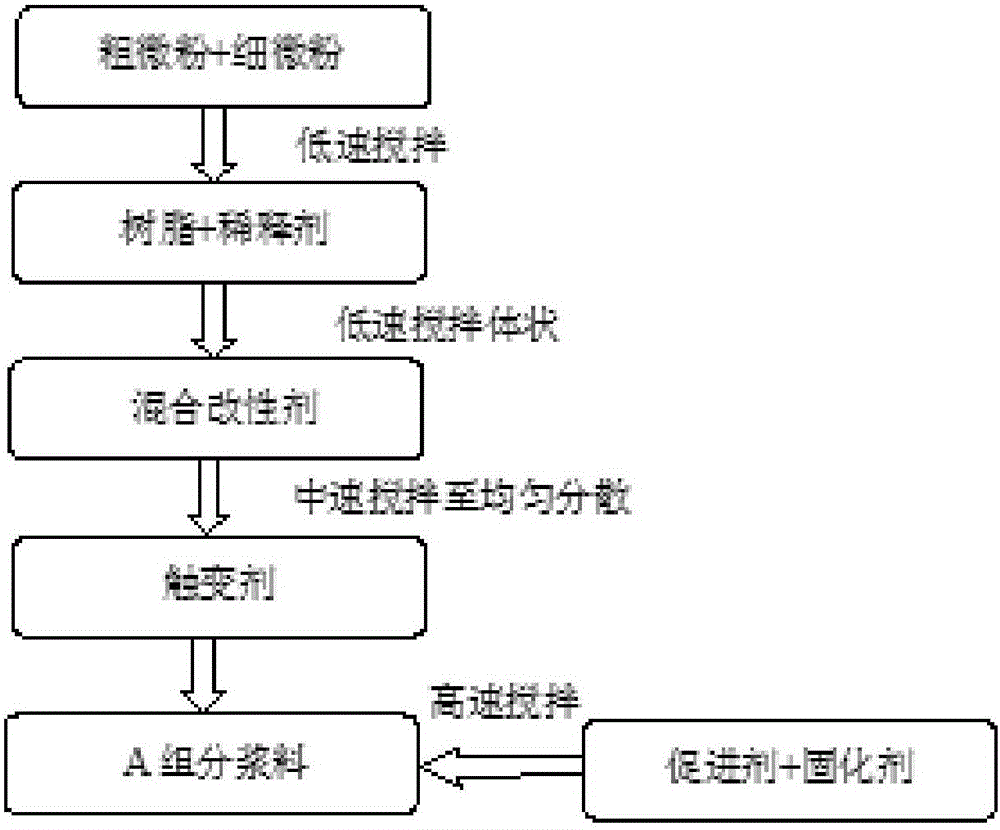

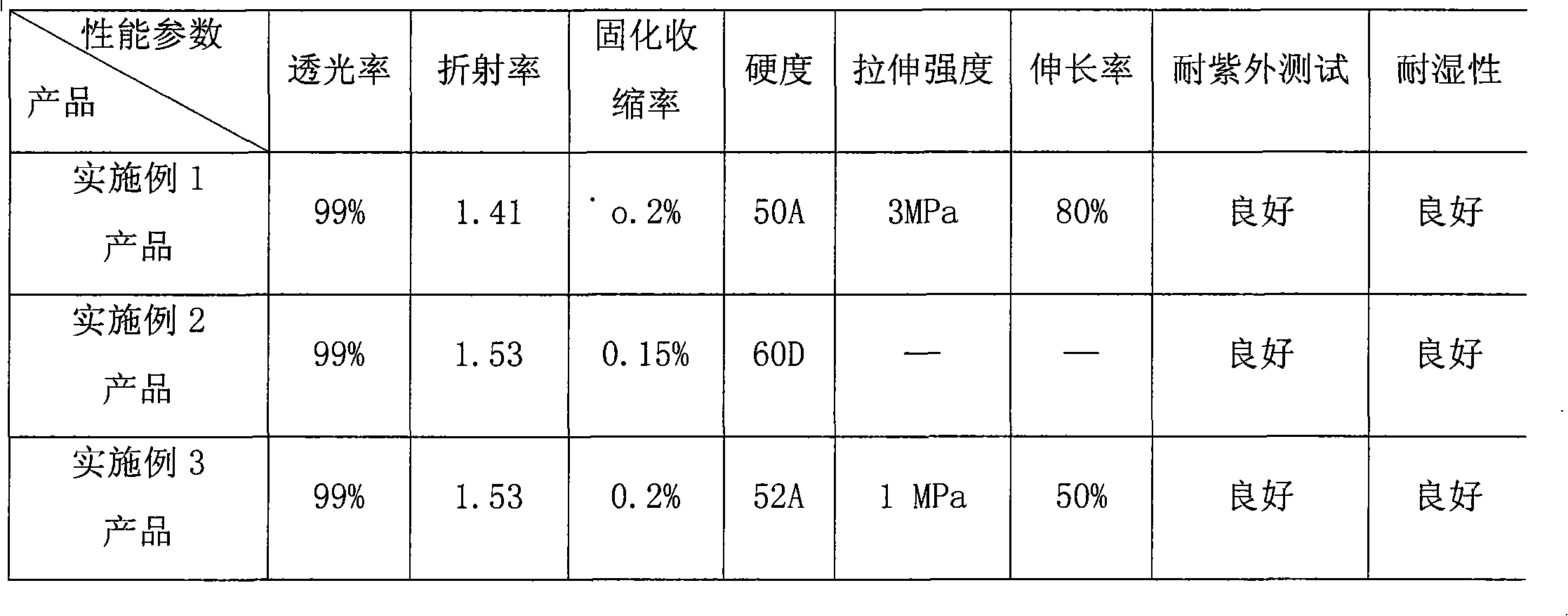

The invention relates to an exterior wall waterproofing heat-insulating decorating integrated material and a preparation method thereof.The preparation method includes: using conventional resin like polyurea and polyurethane as raw materials, adding compound micropowder prepared from solid waste and sludge, and adding a mixed modifier and a thixotropic agent to prepare A-compound slurry; adding a promoter and a hardener, and performing spray coating, brush coating, roll coating and pouring methods to obtain the exterior wall waterproofing heat-insulating decorating integrated material.The material has the comprehensive advantages of good waterproof effect, high heat insulativity, high hardness, high hole closing rate, low density, good anti-seepage performance, high corrosion resistance, low linear expansion coefficient, high softening temperature, oxidization resistance, aging resistance, flame retardancy and firmness in binding with a substrate.When the material is used for building exterior walls, multiple times of leveling, waterproofing, heat insulating and decorating construction are not needed, on-site moisture-free operation and one-time forming can be realized, and the material is short in construction period, extremely low in cost and great in market prospect.

Owner:NANJING KAIBA ADVANCED MATERIALS CO LTD +1

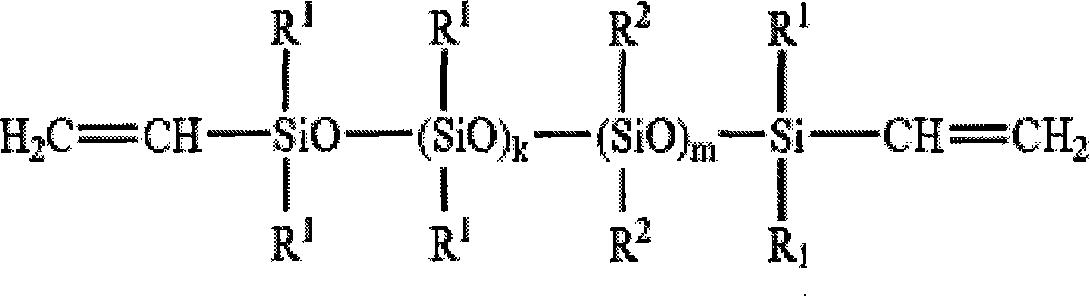

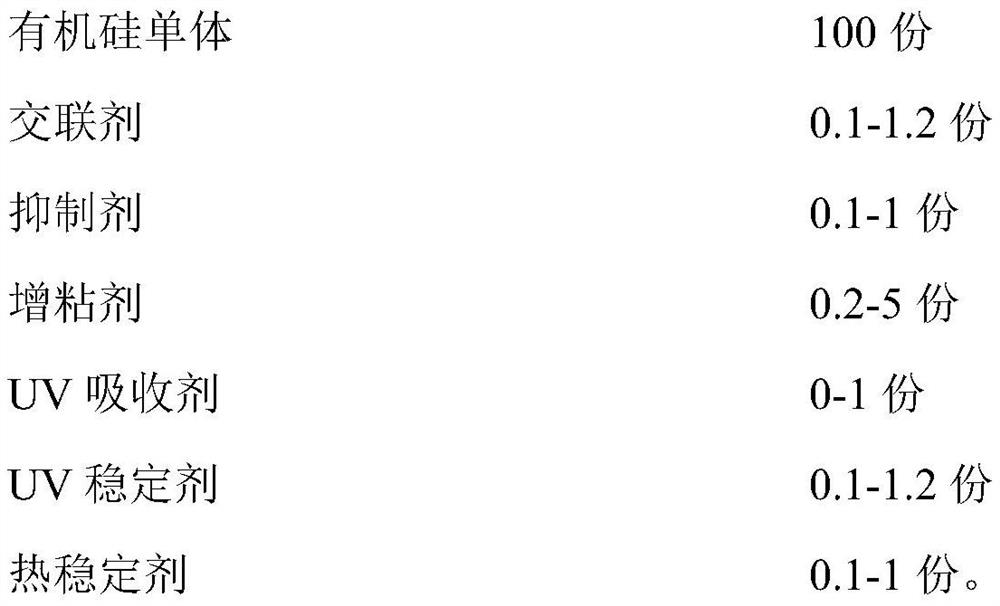

Organ silicon material for encapsulating power-type LED and synthetic method thereof

ActiveCN101608068AFully curedEven distribution of phenyl groupsSemiconductor devicesCross-linkMass ratio

The invention discloses an organ silicon material for encapsulating a power-type LED and a synthetic method thereof. The organ silicon material is mixed with a component A and a component B according to a mass ratio of 1:1 to 1:20, wherein the component A is a mixture of vinyl silicon polymer and a solidify catalyst, and the vinyl silicon polymer comprises vinyl silicon resin and polysiloxane with vinyl; and the component B comprises vinyl hydro silicon resin, poly hydro siloxane and an inhibitor. The organ silicon material has a higher refractive index, high transparency, excellent ultraviolet ageing resistance, good heat ageing resistance, and the like and is an ideal encapsulating material of the power type LED. The invention also discloses a synthetic method of an organ silicon material for encapsulating the power-type LED, the solidification of resin is more complete, and the light transmission and the hardness of the cross-link resin are effectively increased.

Owner:矽时代材料科技股份有限公司

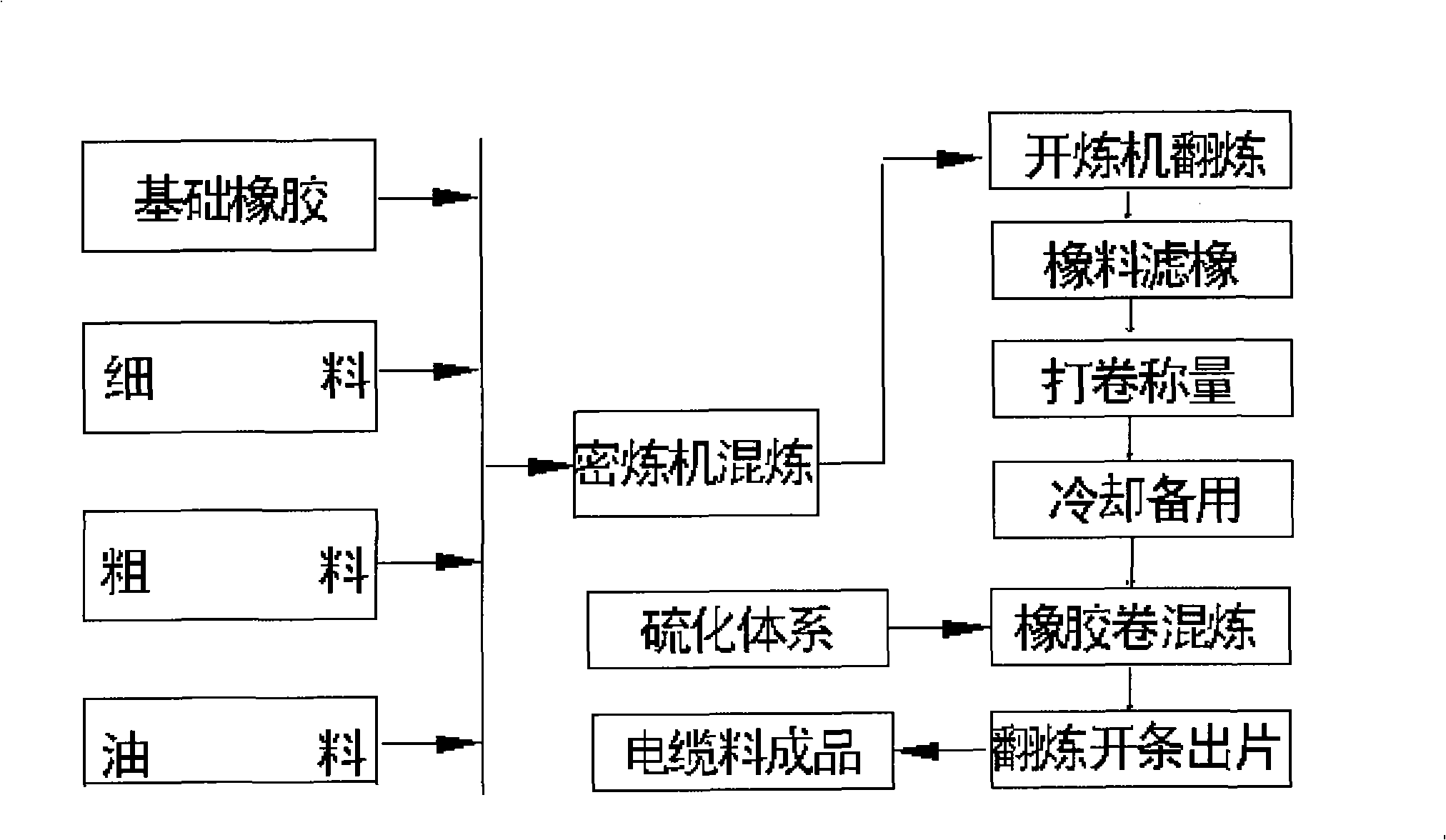

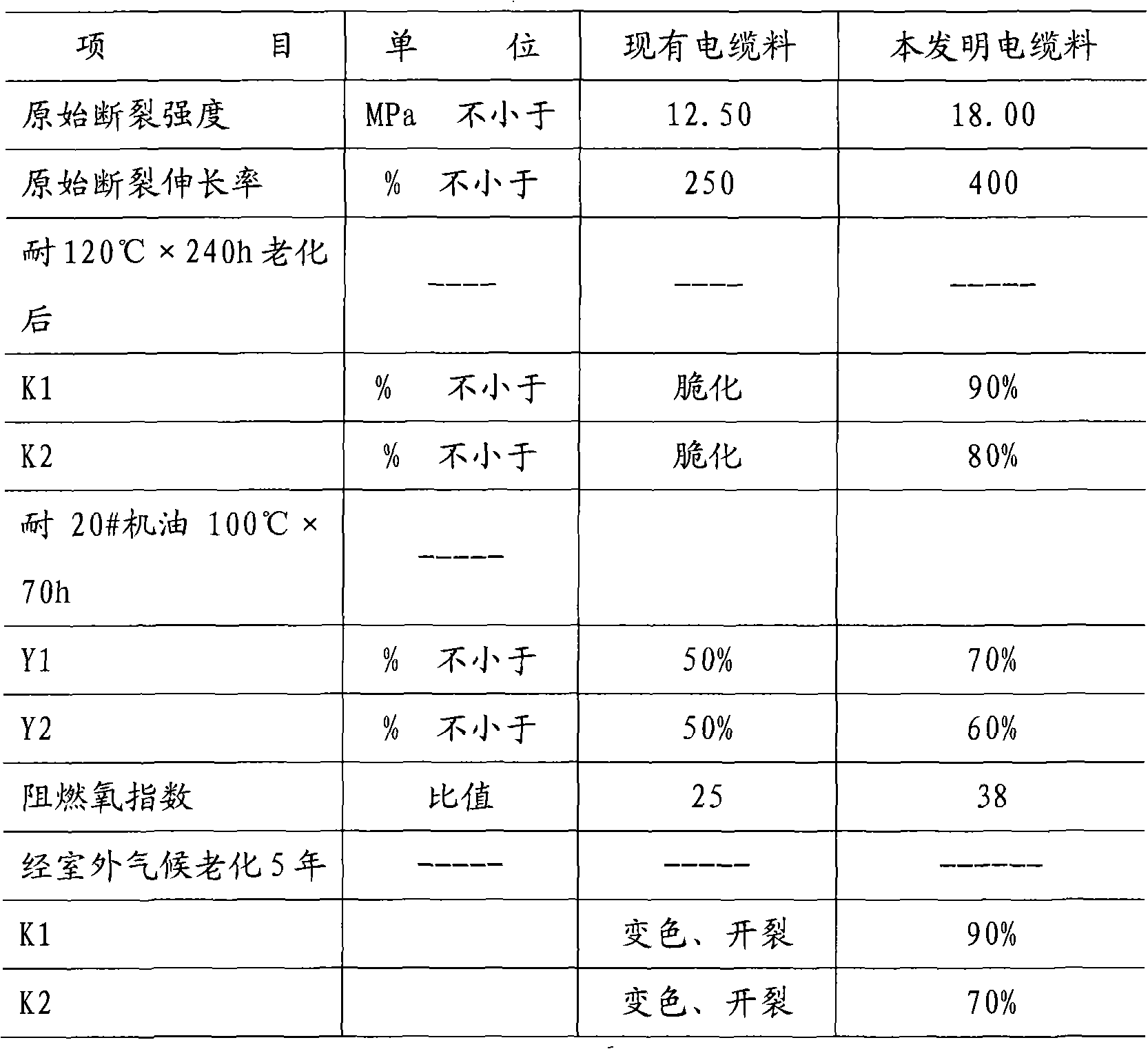

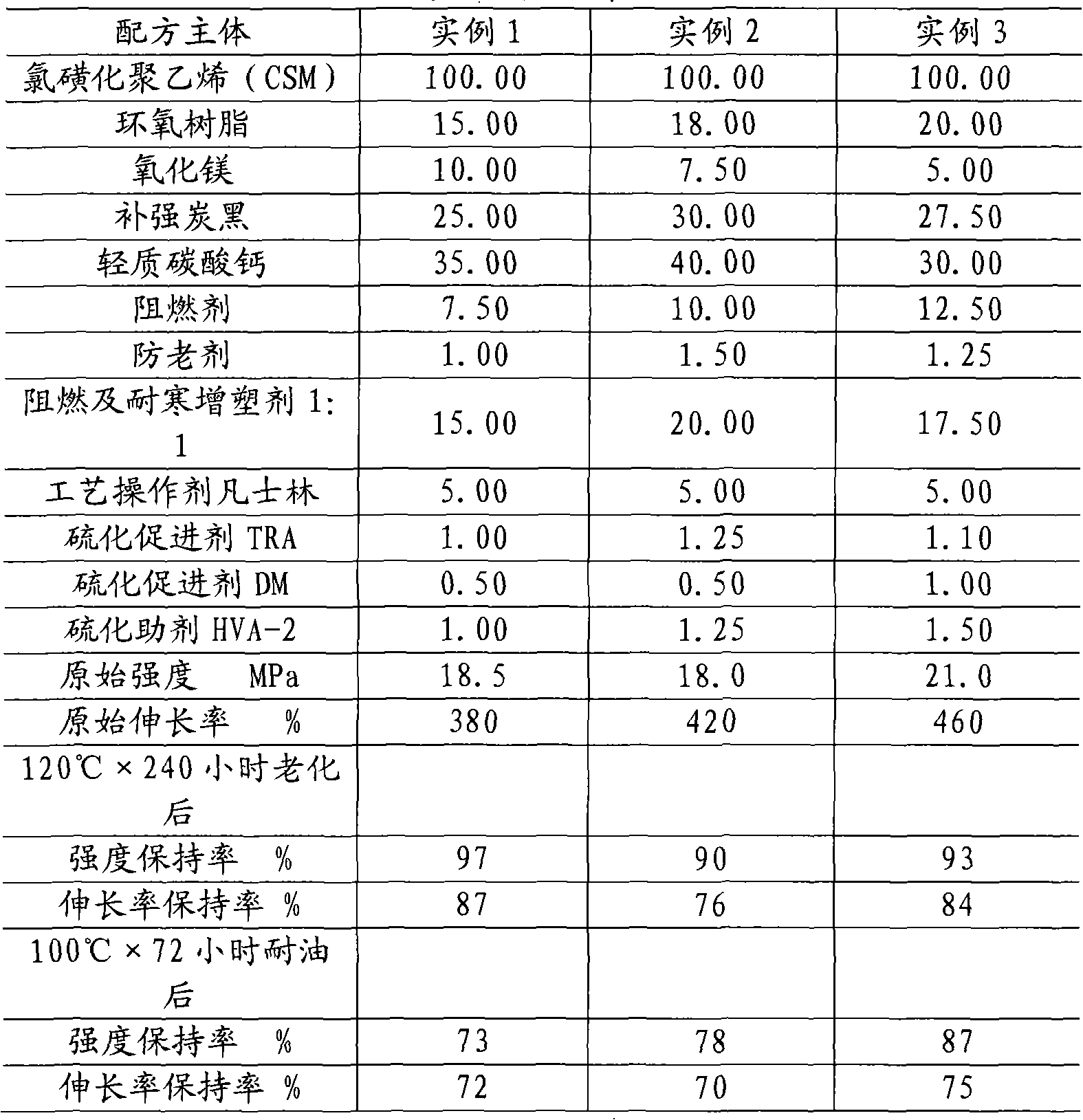

External rubber sleeve material of cable for wind power generation

InactiveCN101538391AEasy to operateImprove water resistanceInsulated cablesInsulated conductorsEpoxyVulcanization

The invention discloses an external rubber sleeve material of a cable used for wind power generation, comprising the following components by weight parts: 100.00 parts of chlorosulfonated polyethylene rubber, 15.00-20.00 parts of vulcanizing agent epoxy resin, 5.00-10.00 parts of magnesium oxide acid acceptor, 1.00-1.50 parts of vulcanization aid, 0.20-1.50 parts of vulcanization accelerator, 10.00-15.00 parts of fire-retardant plasticizer, 5.00-10.00 parts of cold resistant plasticizer, 30.00-40.00 parts of reinforcing agent, 40.00-50.00 parts of filling agent, 0.50-2.00 parts of anti-ageing agent, 0.50-2.00 parts of process operation agent, and 10.00-15.00 parts of flame retardant. The external rubber sleeve material of the cable used for wind power generation has the greatest advantages of extremely high physical and mechanical performance, excellent oil resistance and climate resistance, extremely softness and flame retarding, and the like.

Owner:ANHUI ZONGHENG HI TECH CABLE +1

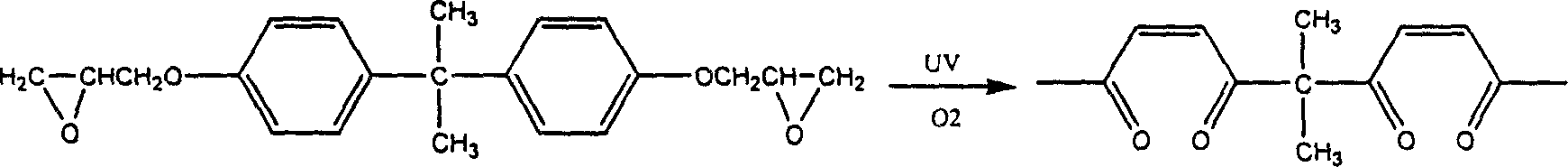

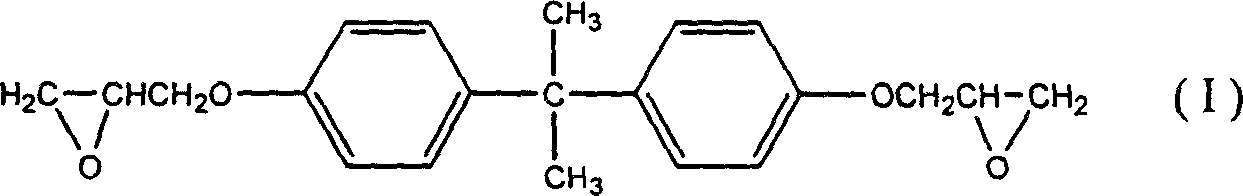

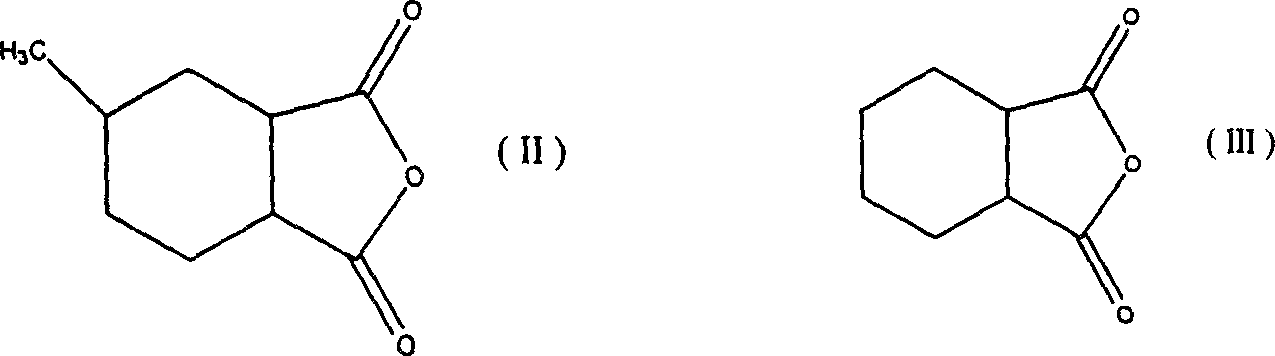

Uvioresistant epoxy composition and its preparing method and use

InactiveCN1858112AExcellent UV aging resistanceImprove heat resistanceSemiconductor/solid-state device detailsSolid-state devicesEpoxyLuminous intensity

The present invention relates to uvioresistant epoxy composition and its preparation process and use. The uvioresistant epoxy composition is prepared through heating the mixture of curing agent 50-150 weight portions, curing promoter 0.1-5.0 weight portions, ultraviolet stabilizer 0.001-5.0 weight portions and light scattering agent 0.001-1 weight portion to 80-100 deg.c for dissolving completely; cooling; and mixture the mixture with epoxy resin 100 weight portions. It may also include antioxidant 0.1-3.0 weight portions. The uvioresistant epoxy composition has excellent uvioresistant performance, excellent heat resistant performance, glass transition temperature higher than 130 deg.c and high transparency, and is suitable for use in white light LED package. When it is used in package for white light LED based on ultraviolet ray, it can prevent ultraviolet ray from leaking and improve the LED luminous intensity homogeneity.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Production method of high refractive index nano modified organosilicon encapsulating material

InactiveCN101457022AHigh transparencyHigh refractive indexOther chemical processesSemiconductor/solid-state device detailsRefractive indexCaking

A producing method for a high-refractive index modified organic silicon sealing material adopts a two-pack route and uses a plurality kinds of organic silicon polymer bodies provided with special function genes and produces ropy nanometer modified organic silicon polymer sealing solution together with the inorganic nanometer oxide sol through a certain technique; a thick coat on the chip is produced in a simple method before the solidification and the sealing coat with the needed performance is gained after a certain temperature process. The gained sealing material is provided with the performances of high refractive index, high transmittance, high-temperature resistance, being UV resistant and aging resistant and strong caking, thus can be applied in the sealing of the power typed LED lighting fittings.

Owner:SHENZHEN UNIV

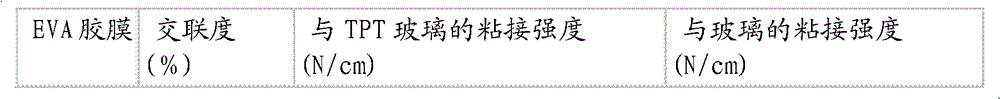

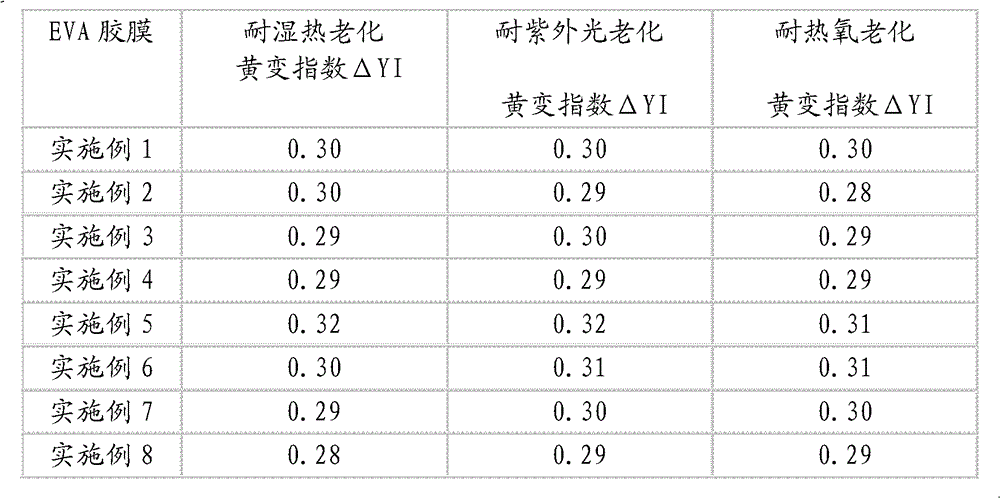

EVA (ethylene vinyl acetate) adhesive film for solar cells

InactiveCN102504715BFast curingIncrease productivityNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkHindered amine light stabilizers

Owner:NINGBO HUAFENG PACKAGE

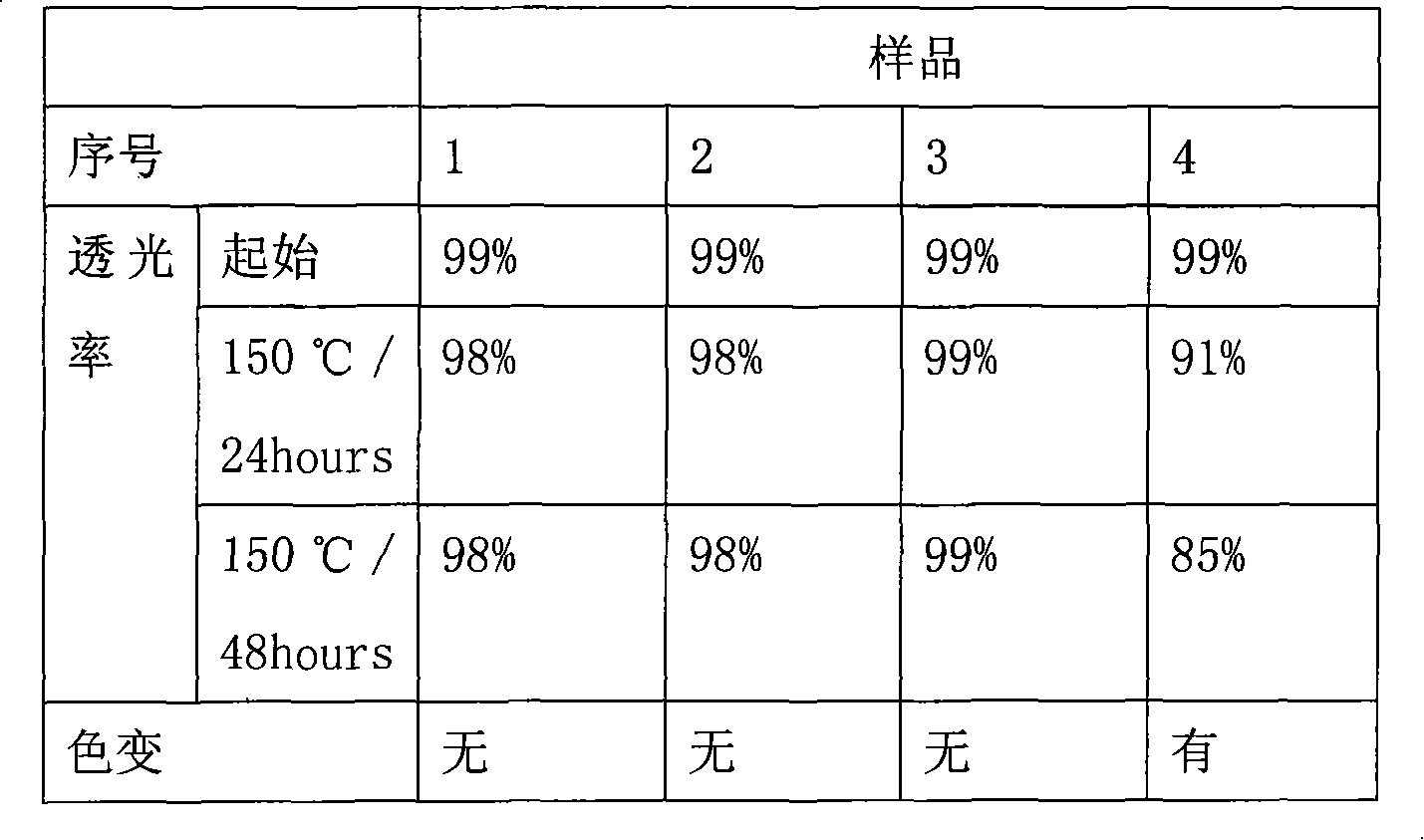

Preparation and application of silica gel for LED packaging

InactiveCN101619170AHigh transparencyExcellent UV aging resistanceOther chemical processesSilanesMoisture resistance

The invention relates to preparation of bi-component organic silica gel, which comprises the following steps: firstly, preparing a component A by the co-hydrolysis of vinyl-containing silane and chlorine-containing silane; secondly, preparing a component B by the co-hydrolysis of hydrogen-containing silane and the chlorine-containing silane; and finally, mixing the two components according to certain proportion to obtain a colorless and transparent LED packaging material with heat resistance and low water absorption and without color change under the action of a catalyst C. The material solves the problems of color change, light attenuation and the like caused by poor heat resistance of the conventional thermoplastic packaging materials, plays a role of mechanical support, environment sealing and chip protection to a certain extent, and has good light transmission, adhesiveness, moisture resistance and heat resistance. In addition, the hardness, the adhesion and the heat resistance of the material can be regulated according to the demand of application. The material not only is suitable for LED packaging, but also can be applied to the fields of optical lenses, solar cell substrates, touch screens and the like.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

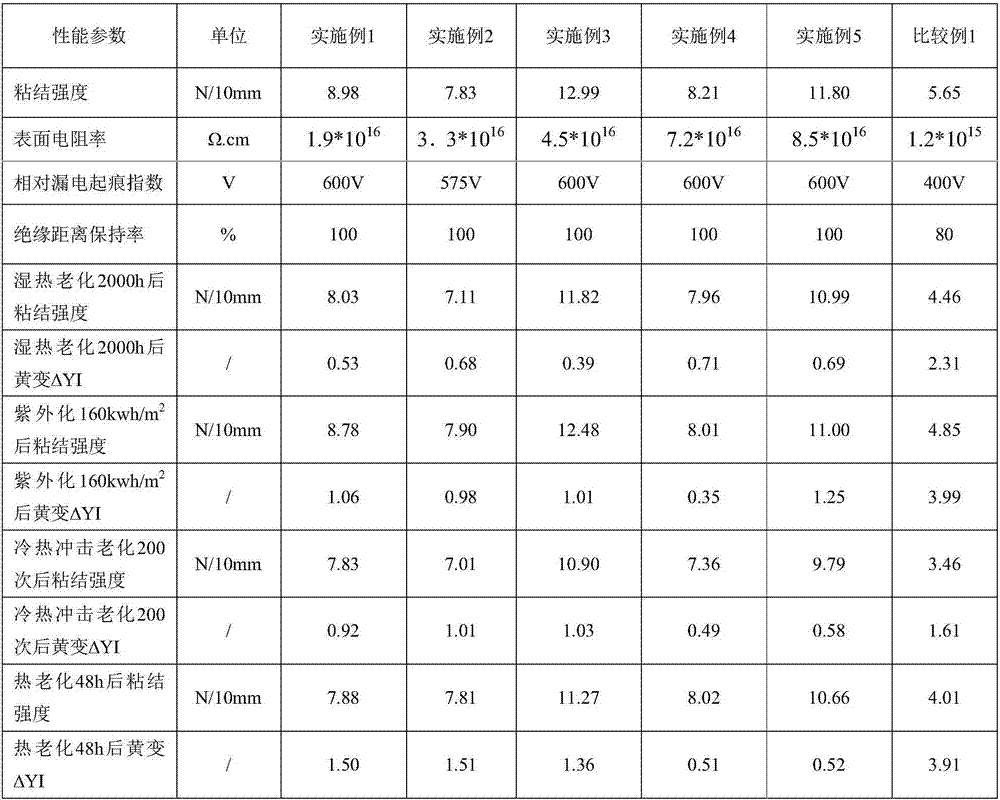

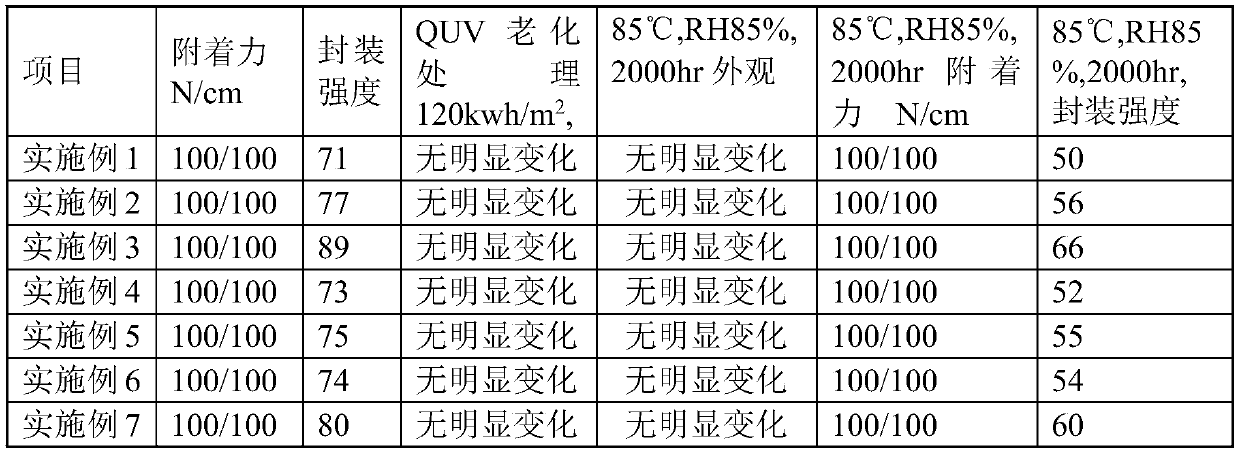

Insulation adhesive material for compound photovoltaic backsheet and application

ActiveCN107353859AImprove insulation performanceImprove cohesive energyPolyureas/polyurethane adhesivesEpoxy resin adhesivesHeat resistanceAcid value

The invention discloses an insulation adhesive material for a compound photovoltaic backsheet and application. The insulation adhesive material is composed of a component A and a component B. The component A contains matrix resin, assistant resin and an assistant, wherein the matrix resin is hydroxyl polyester resin, which has a hydroxyl value of 5-30mgKOH / g, an acid value of 0.2-5mgKOH / g, a number-average molecular weight of 5000-50000, a glass transition temperature ranging from -40DEG C to 30DEG C, and is prepared by esterification polycondensation reaction of small molecular polyprotic acid and polyol under inert gas protection. The component B is a crosslinked component. During use, the component A and the component B are mixed in different proportions according to requirements. The insulation adhesive material provided by the invention not only has long-term and stable bonding performance, but also has excellent performance in heat resistance, insulation and weatherability, and can be used for preparation of high weather resistant compound photovoltaic backsheets. Also, the raw materials are easily available, the process is controllable, and the operation is simple.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Thermal-aging anti-adhesion-failure hot-melt pressure-sensitive adhesive and preparation method thereof

ActiveCN109054688AHigh peel strengthGood adhesionMineral oil hydrocarbon copolymer adhesivesAntioxidantIsoprene

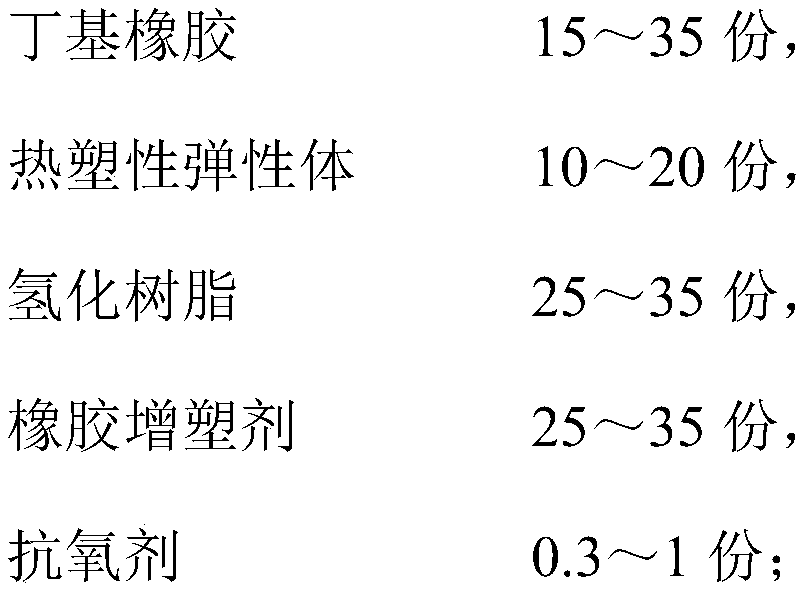

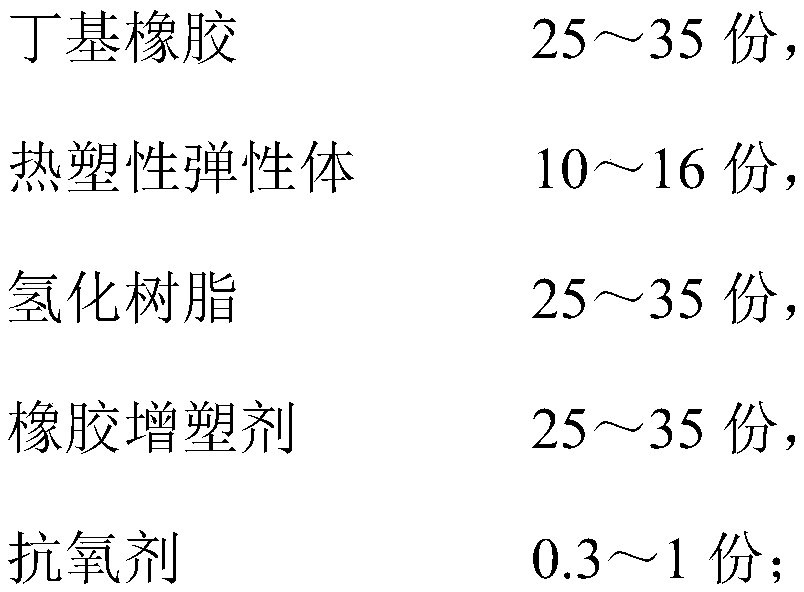

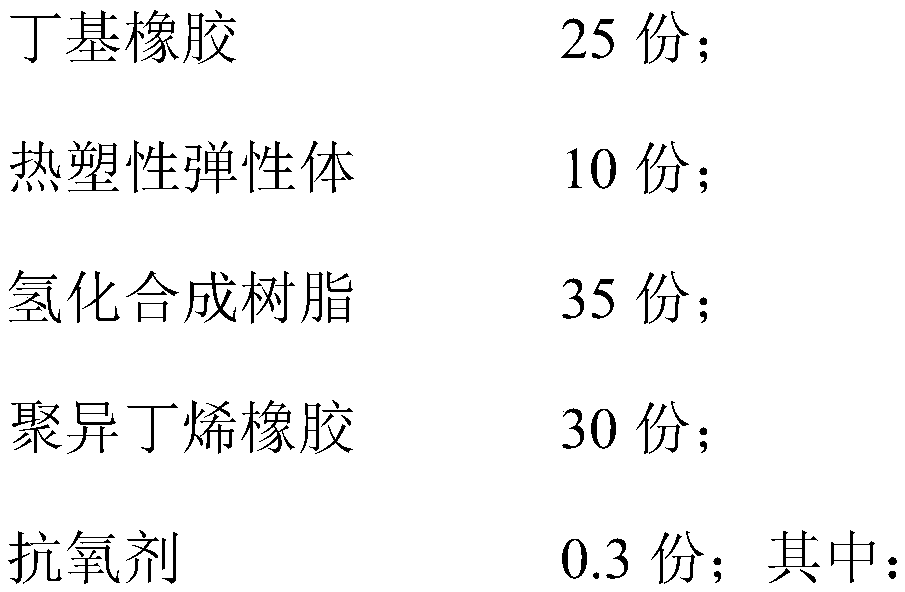

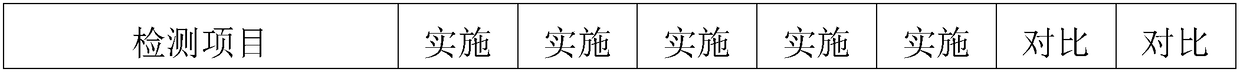

The invention relates to a thermal-aging anti-adhesion-failure hot-melt pressure-sensitive adhesive and a preparation method thereof. The thermal-aging anti-adhesion-failure hot-melt pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 15 to 35 parts of butyl rubber, 10 to 20 parts of thermoplastic elastomer, 25 to 35 parts of synthetic resin hydride, 25 to35 parts of rubber plasticizer and 0.3 to 1 part of antioxidant, wherein the thermoplastic elastomer is a mixture of a styrene-ethylene-butylene-styrene (SEBS) segmented copolymer and a styrene-ethylene-propylene-styrene (SEPS) segmented copolymer. The SEBS and SEPS are added into the butyl rubber, a proper amount of SEBS and SEPS of appropriate types is added particularly at the same time, and the raw materials together with hydrogenated synthetic resin, the rubber plasticizer and the antioxidant are prepared into the hot-melt pressure-sensitive adhesive of a specific formula. The hot-melt pressure-sensitive adhesive still has higher peeling strength, high substrate adhesive property and thermal-aging anti-adhesion-failure effect.

Owner:HUIZHOU NENGHUI CHEM CO LTD

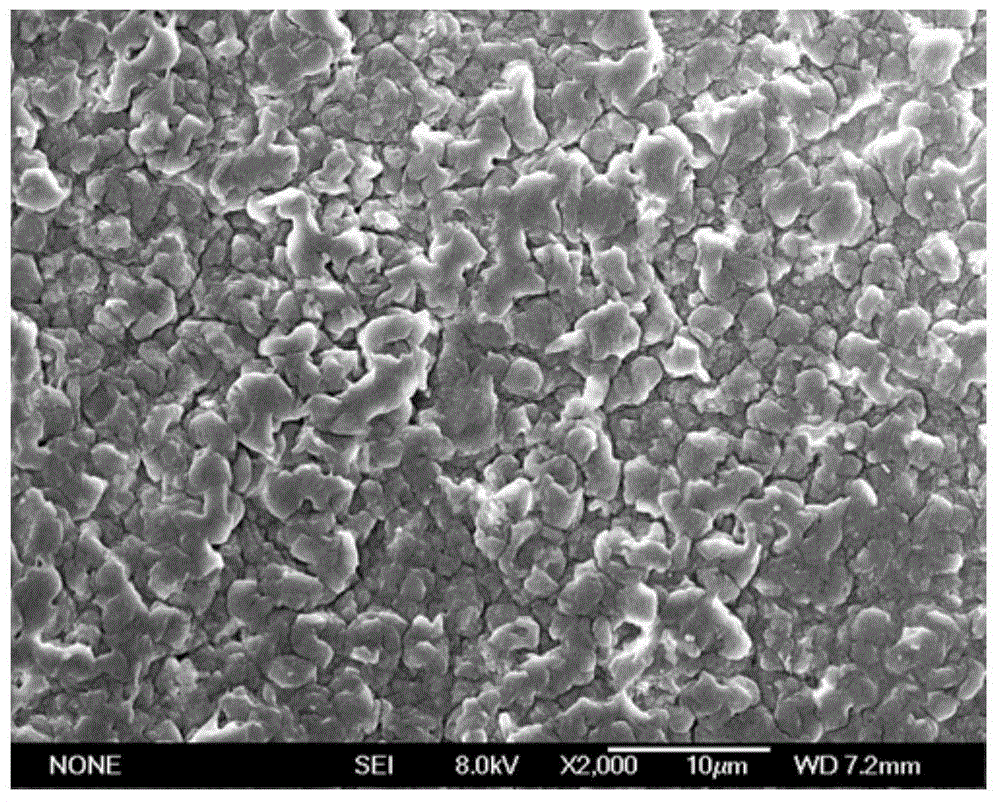

Poly(p-phenylene benzobisoxazole) composite fiber containing nano-TiO2 preparation method

InactiveCN101613892AExcellent UV aging resistanceSuitable for industrial manufacturingSpinning head liquid feederWet spinning methodsChemistryMechanical property

The invention relates to a poly(p-phenylene benzobisoxazole) (PBO) composite fiber containing nano-TiO2 preparation method, comprising the following steps: dissolving 4,6-diaminoresorcinol hydrochloride and terephthalic acid and a certain number of phosphorus pentoxide in equal molar ratio in polyphosphoric acid, removing hydrogen chloride gas, heating and polymerizing to obtain poly(p-phenylene benzobisoxazole), then adding poly(p-phenylene benzobisoxazole) and phosphoric acid solution containing nano-TiO2 in a double-screw extruder and obtaining PBO composite fiber containing nano-TiO2 by dry-jet wet spinning; the invention uses nano-TiO2 particles with ultraviolet shielding property and utilizes the strong shearing and high effective blending of the double-screw extruder to prepare the composite fiber; compared with pure PBO fiber, the ultraviolet aging resistance property is effectively improved while the mechanical properties are not reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

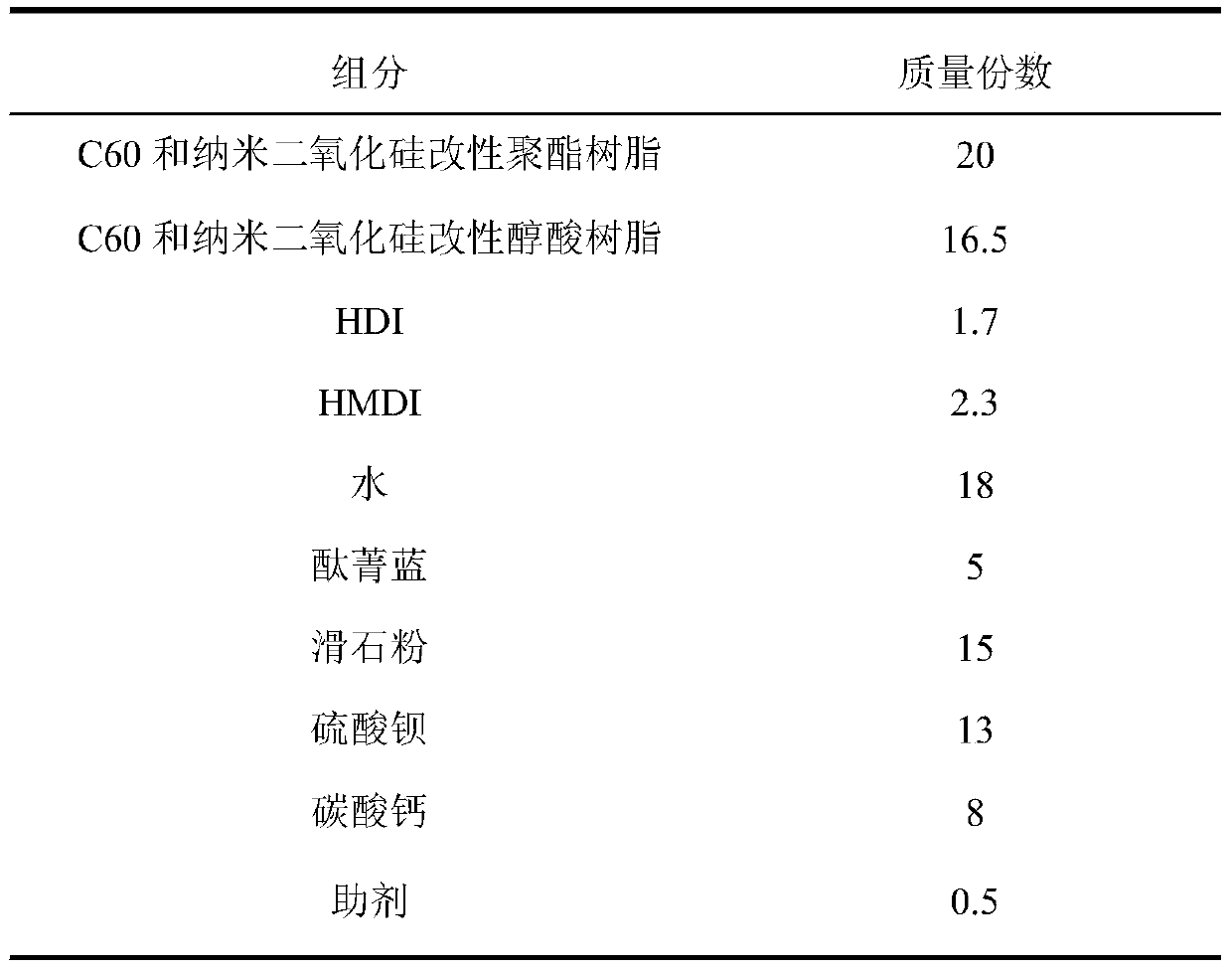

Anti-ultraviolet paint for high-temperature interface construction and preparation method

InactiveCN101161745AExcellent UV aging resistanceGood chemical resistancePolyurea/polyurethane coatingsPolyester coatingsPolyesterPolymer science

The invention relates to an ultraviolet ray resistant coating for high temperature interface construction and the preparation method thereof. One portion of hexa-methylene diisocyanate trimer-modified polyisocyanate, 0.1-0.4 portions of xylene and 0.1-0.3 portions of ammonia ester level butyl acetate are mixed together to obtain A solution; 0.01-0.05 portions of unsaturated polybasic carboxylic acid polymer solution, 0.1-0.4 portions of a mixer which are made of xylene, bivalency mixed acid dimethyl ester, isophorone according to the proportion of 65:25:10, 0.05-0.2 portions of nanometer level zirconia, one portion of hydroxy acrylic acid, 0.1-0.2 portions of organosilicon-modified acrylic resin, 0.2-0.4 portions of saturated polyester, 0.2-0.6 portions of rutile type white titanium pigment which has been enveloped by aluminum and has been worked organically, 0.01-0.1 portions of silicon dioxide powder, 0.01-0.5 portions of calcined kaolin, and 0.002-0.01 portions of acrylic ester copolymer solution are mixed together to obtain B solution; one portion of A solution and 8-12 portions of B solution are mixed together for being used as anticorrosive paint on external surfaces of pipelines, storage tanks and steel constructions in high temperature areas.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

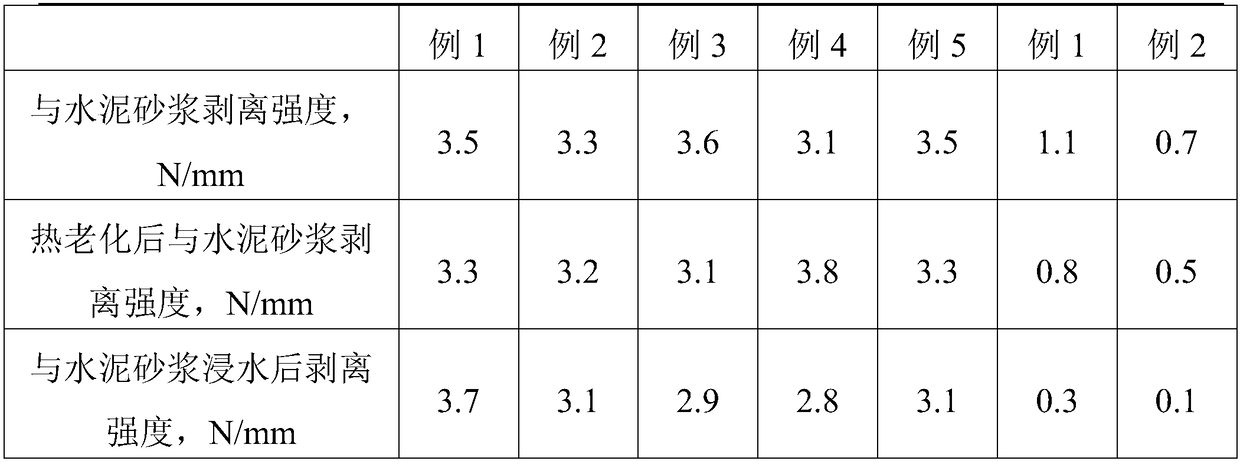

Water-based isolated coating for pre-paved and wet-paved waterproof coiled materials as well as preparation method of coating

InactiveCN108102498AHigh strengthGood low temperature flexibilityAnti-corrosive paintsWater basedPolyvinyl alcohol

The invention discloses water-based isolated coating for pre-paved and wet-paved waterproof coiled materials as well as a preparation method of the coating. The water-based isolated coating for the pre-paved and wet-paved waterproof coiled materials comprises the following components in percentage by mass: 10 to 30 percent of modified acrylic ester copolymer emulsion, 5 to 10 percent of polyvinylalcohol, 10 to 40 percent of crystallization masterbatch, 5 to 20 percent of pigment filler, 0.5 to 1 percent of silane coupling agent, 0.1 to 1 percent of a dispersant, 0.1 to 1 percent of a thickening agent, 0.1 to 0.5 percent of a defoaming agent, 0.1 to 0.5 percent of a leveling agent and 10 to 40 percent of water. The water-based isolated coating for the pre-paved and wet-paved waterproof coiled materials, which is provided by the invention, can be applied to isolated protection of the pre-paved anti-adhesion waterproof coiled material and also can be applied to isolated protection of thewet-paved waterproof coiled material, the production and use processes are environmentally friendly and safe, the waterproof coiled materials are not liable to adhesion return, construction is simpleand convenient, and excellent water tolerance, acid and alkali corrosion resistance, heat ageing resistance and ultraviolet ageing resistance are achieved.

Owner:KESHUN WATERPROOF TECH CO LTD

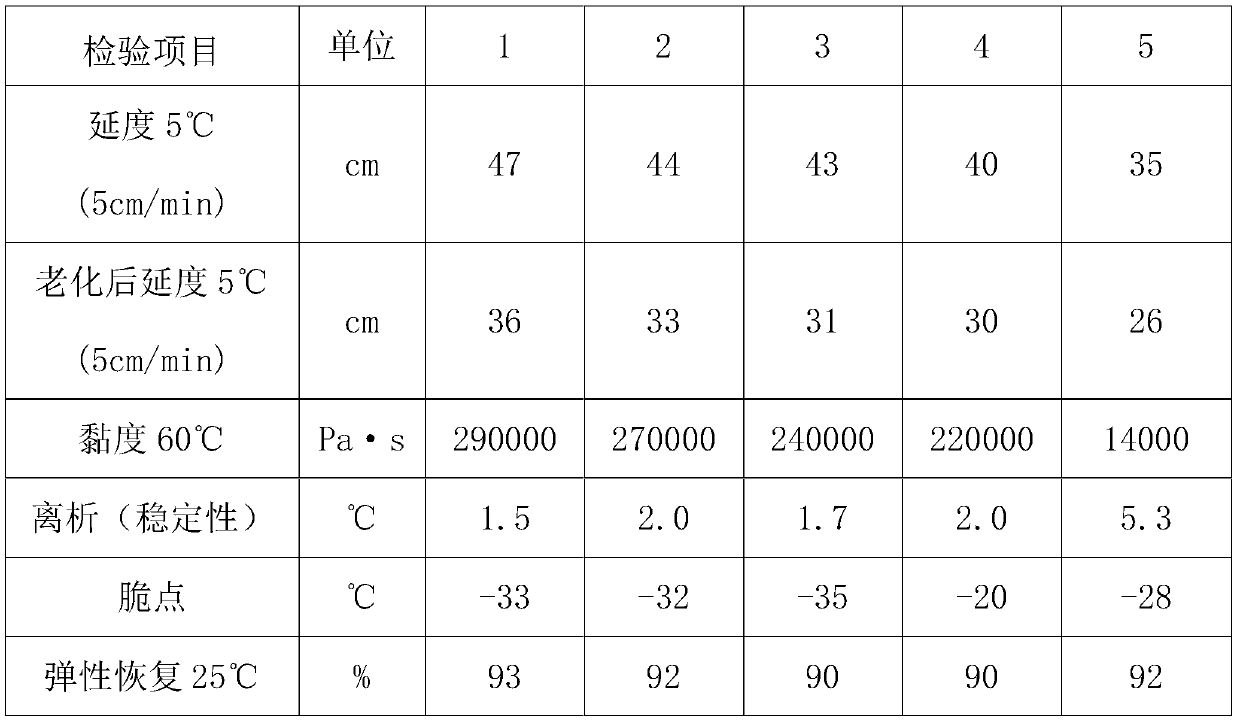

Preparation method of highly-elastic self-repairing odorless weather-proof modified asphalt

InactiveCN111073323AAchieve clean tasteIncrease elasticityBuilding insulationsPolymer scienceAsphalt

The invention discloses a preparation method of highly-elastic self-repairing odorless weather-resistant modified asphalt, which comprises the following three steps: preparation of reclaimed rubber particles, preparation of reclaimed rubber mother liquor and SBS co-crosslinking development. The method includes 1) a step of preparing the reclaimed rubber particles, namely a step of desulfurizing tire rubber powder by a double-screw extrusion method, and carrying out shear granulation to obtain the reclaimed rubber particles; 2) a step of preparing the reclaimed rubber mother liquor, namely a step of mixing the reclaimed rubber particles obtained in the step 1 with matrix asphalt according to a mass ratio of 34 / 66 to 68 / 32, enabling the reclaimed rubber particles to be soaked and developed in the matrix asphalt for 0.8-1.6 hours at the temperature of 163-173 DEG C, and then shearing for 20-30 minutes in high-speed shearing equipment to obtain the reclaimed rubber mother liquor; and 3) astep of co-crosslinking development. According to the preparation method disclosed by the invention, the cost can be saved while a large amount of waste tires are consumed, the environmental protection property in the production process is extremely good, and a finished product not only has excellent elasticity, high and low temperature properties, medium temperature fatigue resistance, noise reduction property and ultraviolet aging resistance, but also is higher in hardness and has a self-repairing capability.

Owner:江苏宝利路面材料技术有限公司

Single-component printing ink used for 3C glass and water-based printing ink coating

ActiveCN109852136AHigh surface hardnessSmall thermal expansion and contractionInksWater basedCross-link

The invention discloses single-component printing ink used for 3C glass and a water-based printing ink coating. The single-component printing ink used for the 3C glass comprises the following components of, in parts by weight, 25-45 parts of organic and inorganic compound water-based resin, 5-10 parts of pigment, 32-55 parts of filler, 10-25 parts of water, 1-5 parts of blocked water-based curingagent and 0.01-1.0 part of assistant. The organic and inorganic compound water-based resin used for producing the single-component printing ink used for the 3C glass is good in chemical resistance, excellent in ultraviolet light aging resistance and good in 3C glass adhesion, and has ultra-high surface hardness and low thermal expansion and contraction. In a high-temperature curing process, hydroxy or carboxyl in the organic and inorganic compound rein and the blocked water-based curing agent are subjected to cross-linking reaction to form a Interpenetrating network structure, performance of the components are brought into full play, and the printing ink coating is formed on the surface of the 3C glass. The blocked water-based curing agent can also provide reasonable thermocuring speed sothat the requirements of short thermocuring time of the industry of 3C glass can be met by the printing ink.

Owner:HUNAN SOKAN NEW MATERIAL

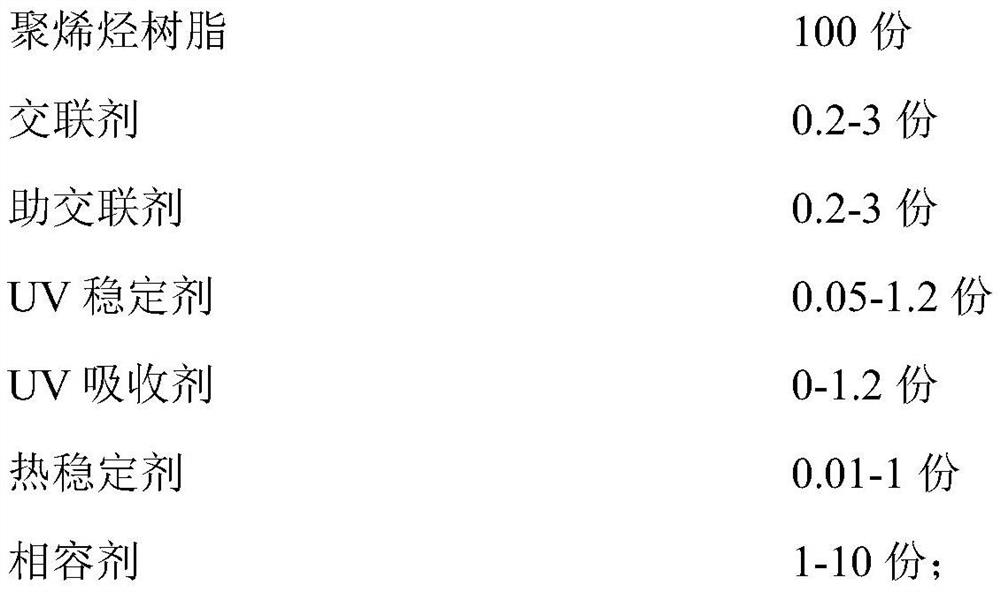

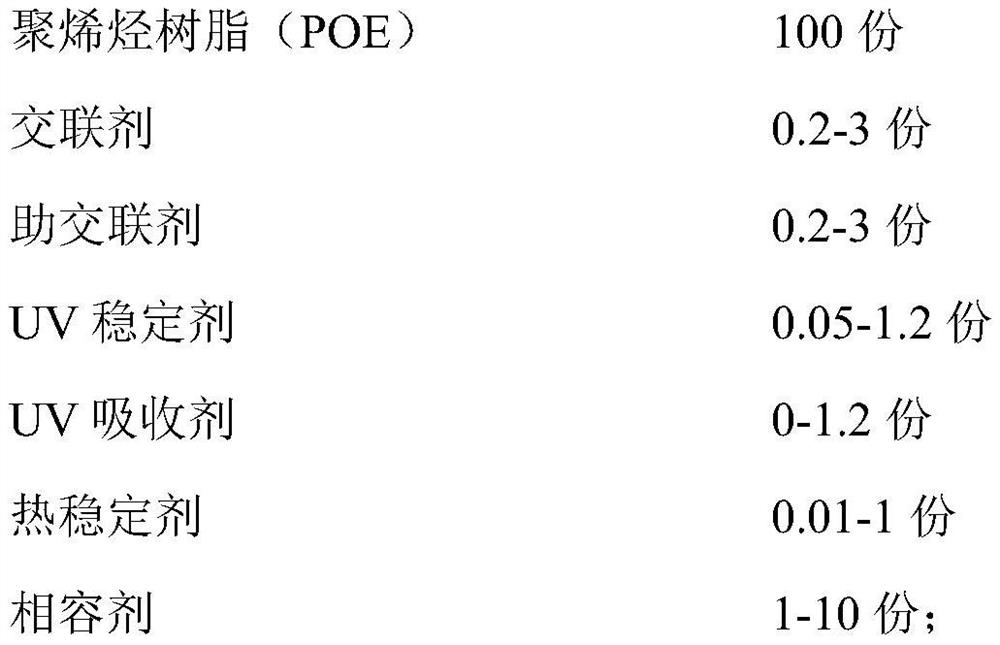

Photovoltaic cell module packaging adhesive film, and preparation method and application thereof

ActiveCN113913117AMitigating pitfalls in solar cell applicationsMitigate defectsMacromolecular adhesive additivesFilm/foil adhesives without carriersPolymer sciencePolyolefin

The invention discloses a photovoltaic cell module packaging adhesive film, and a preparation method and application thereof. The photovoltaic cell module packaging adhesive film comprises a polyolefin adhesive film layer, and the polyolefin adhesive film layer comprises polyolefin resin, a cross-linking agent, an assistant cross-linking agent, a UV stabilizer, a UV absorbent, a heat stabilizer and a compatilizer. According to the invention, after the compatibilizer is added into a POE layer, the compatibilizer has polarity, so that the compatibilizer can be well compatible with the auxiliary agent, the auxiliary agent is not easy to separate out and is not easy to slip when being combined with a battery piece, the defects of the POE in the application of the solar battery are relieved, and meanwhile, the compatibilizer still has the advantages of the POE in the application of the solar battery. In addition, due to the addition of the compatilizer, the POE layer and the organic silicon layer can be effectively combined, and the invention further discloses a photovoltaic cell module composite packaging adhesive film comprising a polyolefin adhesive film layer and a silicon rubber film layer located on the surface of the polyolefin adhesive film layer.

Owner:上海润势科技有限公司

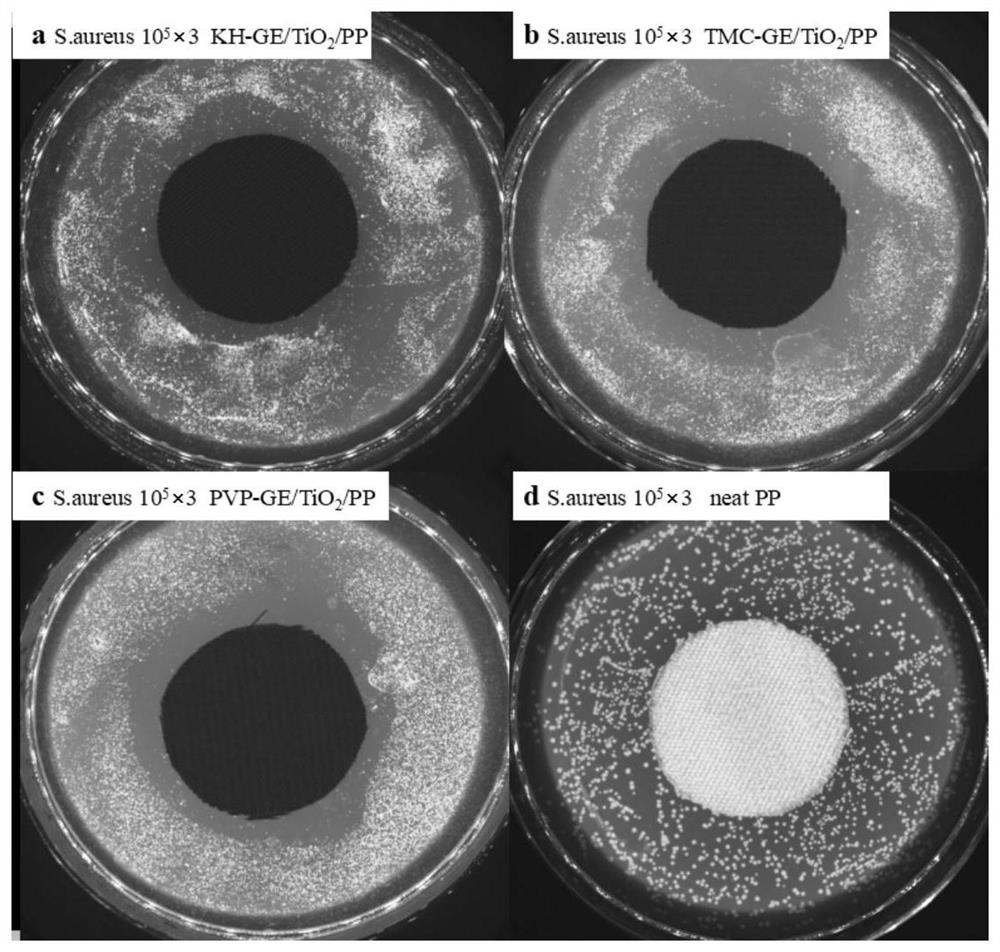

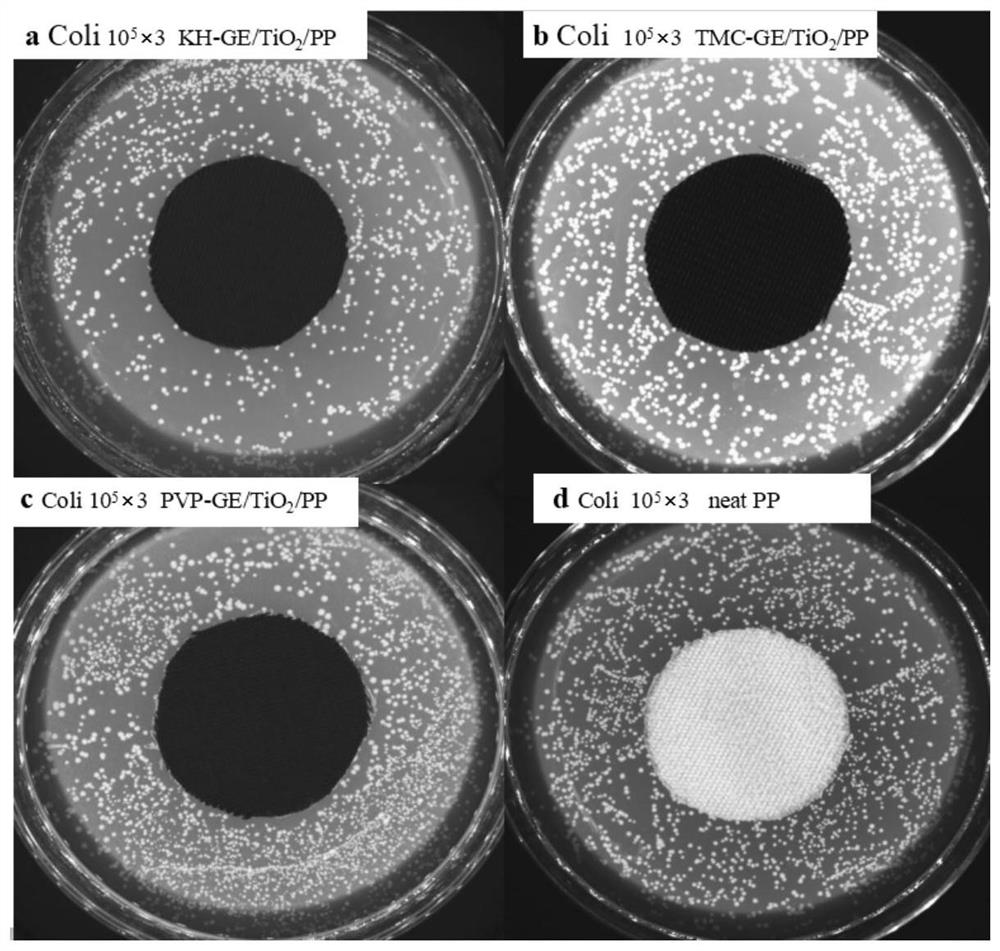

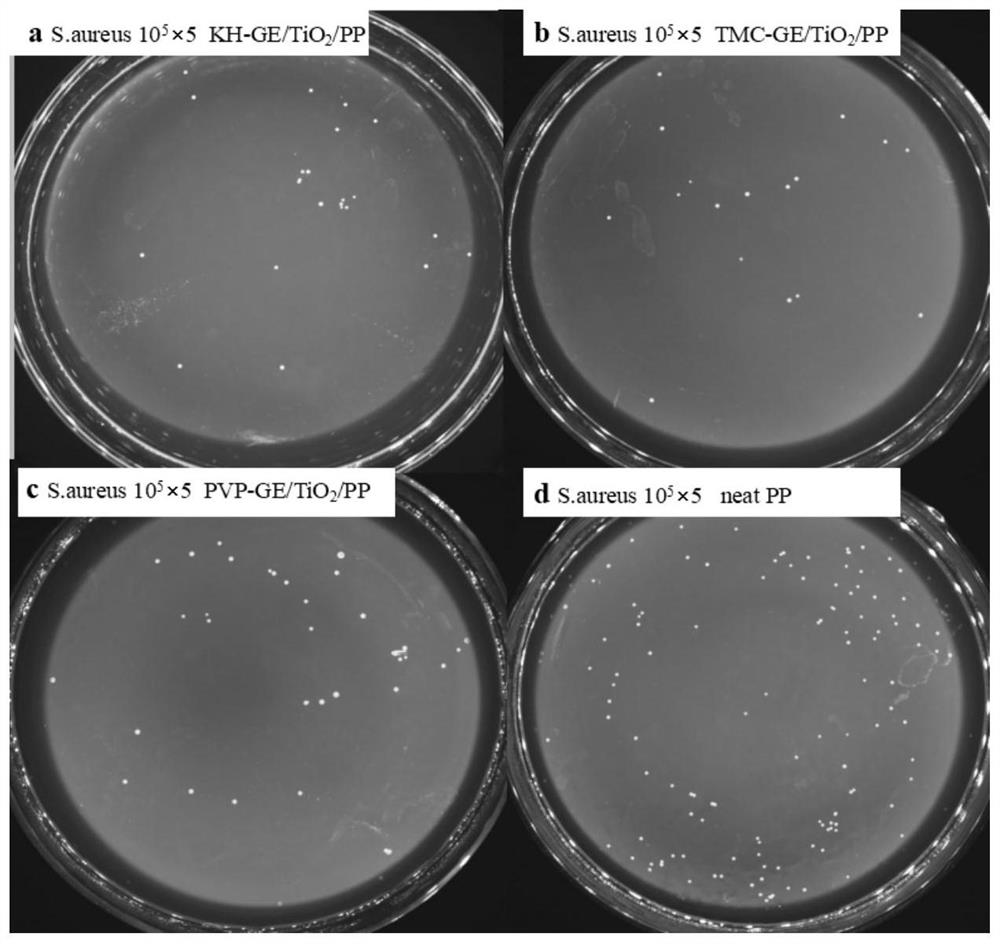

Anti-ultraviolet antibacterial polypropylene filament yarn and preparation method thereof

ActiveCN112522802AExcellent anti-ultraviolet and antibacterial propertiesExcellent UV aging resistanceMelt spinning methodsMonocomponent polyolefin artificial filamentCellulosePolymer science

The invention discloses an anti-ultraviolet antibacterial polypropylene filament yarn and a preparation method thereof. The anti-ultraviolet antibacterial polypropylene filament yarn is prepared fromthe following raw materials in percentage by mass: 0.5%-1% of a modified graphene material, 0.5%-1.5% of modified TiO2, 2% of maleic anhydride grafted polypropylene, 0.1% of a dispersing agent, and the balance of polypropylene, namely PP; and the dispersing agent is a mixture of cellulose sulfonate and lignosulfonate in a mass ratio of 40-60:60-40. The preparation method of the anti-ultraviolet antibacterial polypropylene filament yarn includes the steps of early-stage material preparation, composite granulation, spinning and the like. A product obtained by the preparation method of the anti-ultraviolet antibacterial polypropylene filament yarn has excellent ultraviolet resistance and antibacterial property.

Owner:HUNAN INSTITUTE OF ENGINEERING

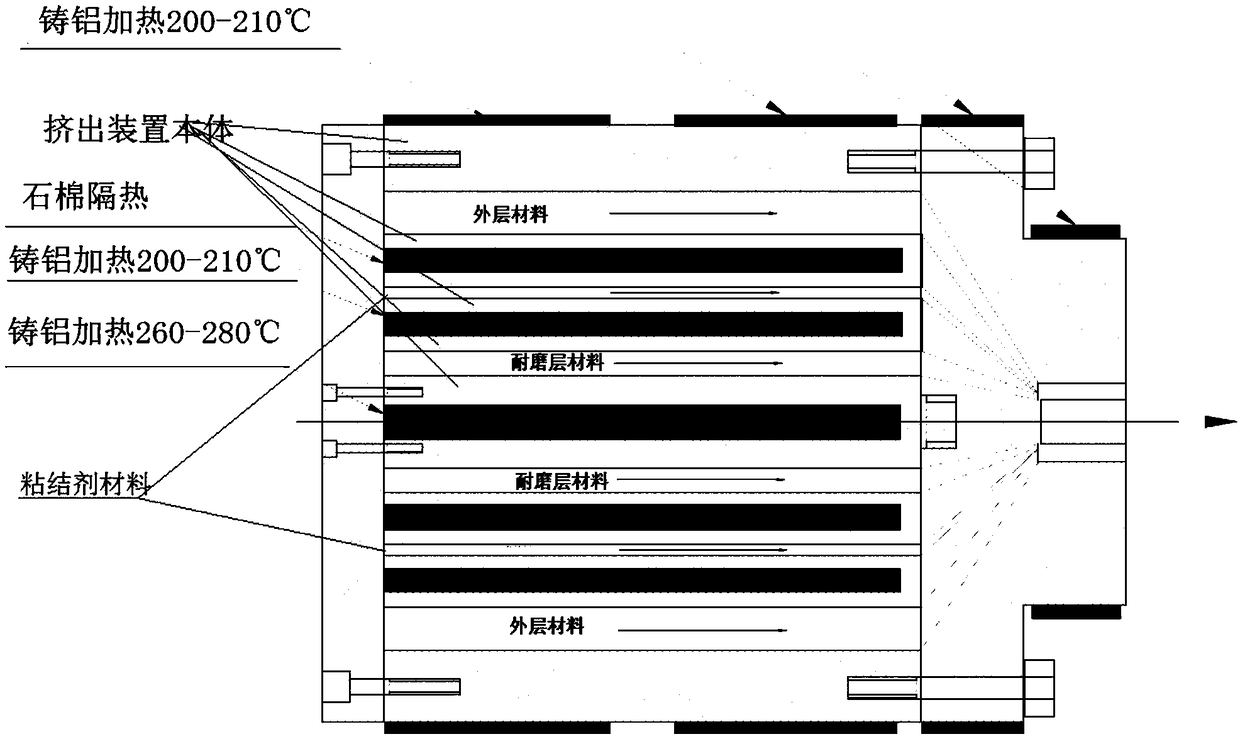

Mineral slurry conveying high-abrasion-resistance anticorrosive composite pipe for wet desulphurization and preparation

The invention discloses a mineral slurry conveying high-abrasion-resistance anticorrosive composite pipe for wet desulphurization and preparation, and belongs to the technical field of conveying pipeline. The pipe comprises a composite inner core pipe jointly formed by a high-abrasion-resistance anticorrosive material inner layer, a high-strength bonding agent layer A and an airtight anti-seepagehigh-shock-resistance layer from inside to outside in sequence. A framework reinforcement layer formed by a high-strength steel wire mesh or a steel rope net or a fibermesh framework and a high-strength bonding agent B is arranged on the outer layer of the composite inner core pipe. A high-strength bonding agent layer B is arranged on the outer layer of the framework reinforcement layer. The high-strength bonding agent layer B and a protection material layer jointly form an outer protection layer of the composite pipe. According to a preparation method, the composite inner core pipe is prepared through a coextruding method. The composite pipe belongs to environment-friendly products, any VOC emission and harmful substance precipitation are avoided, and any influence on the natural environment and production technicians is avoided.

Owner:LANGFANG DEYUAN BUILDING MATERIALS CO LTD +1

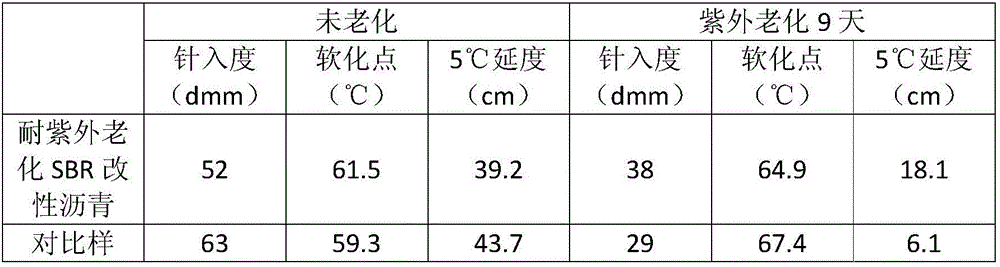

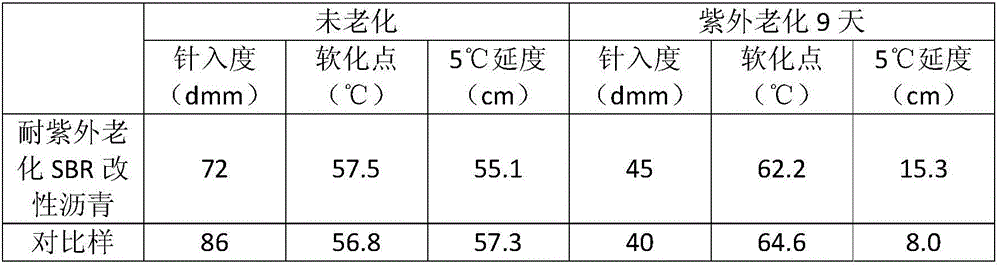

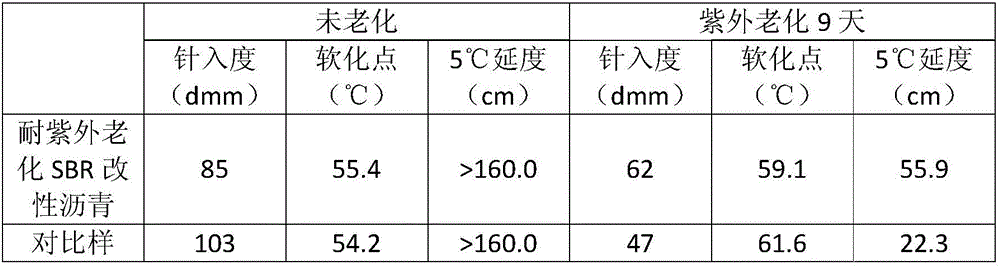

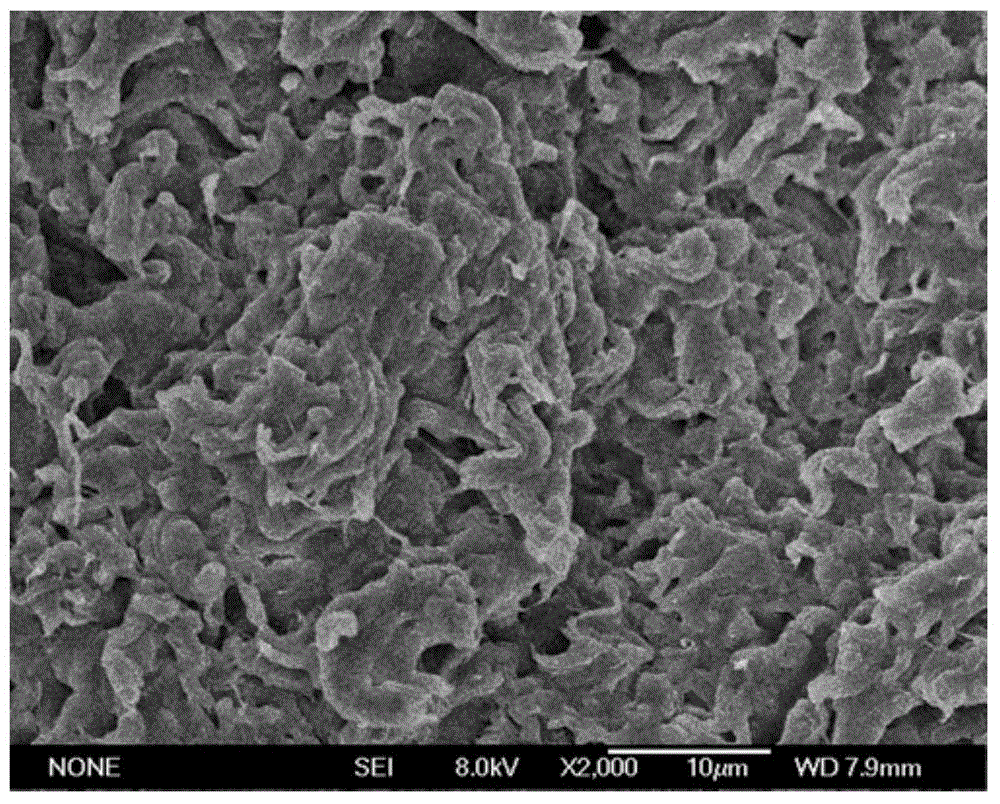

Sodium lignosulfonate grafted magnesium-aluminum-based LDH (layered double hydroxide) modifier, ultraviolet-aging-resistant SBR (styrene-butadiene rubber) modified asphalt and preparation method of ultraviolet-aging-resistant SBR modified asphalt

InactiveCN106832973AExcellent UV reflective abilityGood anti-ultraviolet aging performanceBuilding insulationsPolymer scienceSodium lignosulfonate

The invention relates to a modifier, SBR (styrene-butadiene rubber) modified asphalt and a preparation method of the SBR modified asphalt. A sodium lignosulfonate grafted magnesium-aluminum-based LDH (layered double hydroxide) modifier is characterized by being prepared from lignin and magnesium-aluminum-based LDHs by grafting. Ultraviolet-aging-resistant SBR modified asphalt is characterized by being prepared from raw materials in percentage by mass as follows: 90%-99% of the SBR modified asphalt and 1%-10% of the sodium lignosulfonate grafted magnesium-aluminum-based LDH modifier. The ultraviolet-aging resistance of the SBR modified asphalt can be improved remarkably by adding sodium lignosulfonate grafted magnesium-aluminum-based LDHs to the SBR modified asphalt, magnesium-aluminum-based LDHs can be dispersed in the SBR modified asphalt stably for a long time, and the prepared SBR modified asphalt has excellent ultraviolet-aging resistance.

Owner:WUHAN UNIV OF TECH

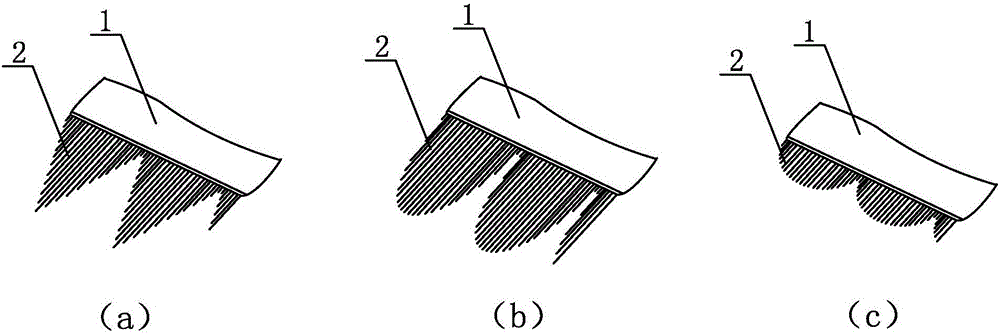

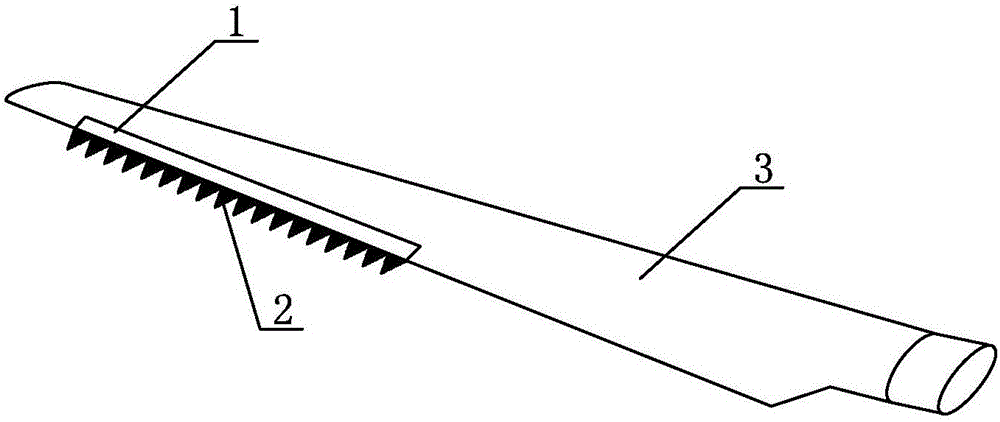

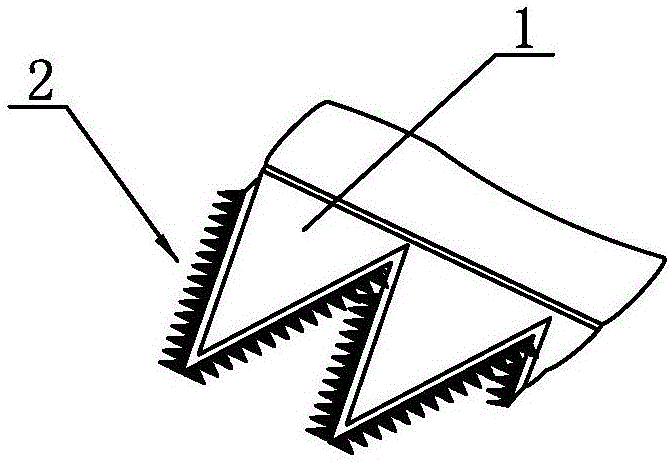

Denoising device for fan blade

ActiveCN106246478AImprove noise reductionOptimal modulusEngine fuctionsMachines/enginesBristleEngineering

The invention discloses a denoising device for a fan blade. The denoising device comprises a base plate and denoising bristles made from ultra-high molecular weight polyethylene (UHMWPE), wherein the denoising bristles are arranged on the base plate, and after the denoising device is mounted, the bottom surface of the base plate is fixed to the fan blade. The denoising device for the fan blade, disclosed by the invention, adopting the denoising bristles made from the UHMWPE, is great in comprehensive performance and can solve the defects of the existing bristle materials. The denoising bristles are great in mechanical performance, light in mass and great in UV aging resistance, the strength, modulus, weatherability and ultraviolet aging resistance of the denoising bristles are all better than those of the existing bristle materials, the tenacity, aging resistance, strength, low temperature resistance, impact resistance and the like meet performance requirements, the water tolerance, humidity resistance, chemical corrosion resistance and ultraviolet radiation resistance are extremely great, and the problems that the response of the existing denoising technology to air current directions is poor and the denoising effect of the existing denoising assembly is single are solved.

Owner:宁波峰微新材料科技有限公司

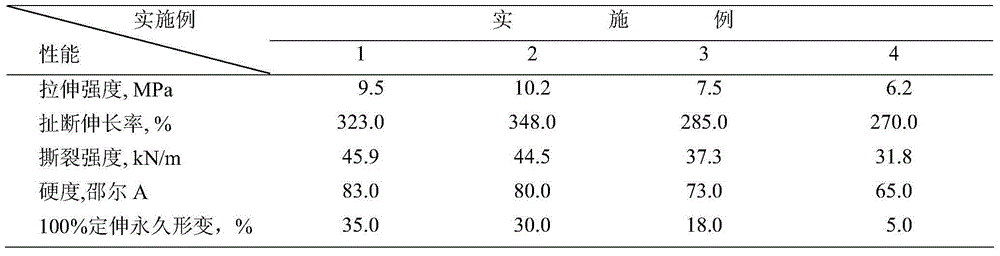

EVA/EVM blending type thermoplastic vulcanizate and preparation method therefor

The invention provides an EVA / EVM blending type thermoplastic vulcanizate and a preparation method therefor. The thermoplastic vulcanizate comprises EVA, EVM, a peroxide vulcanizing agent DCP and a crosslinking coagent TAI, wherein the mass ratio of the EVA to the EVM is 1:1-4, and the dosage of the peroxide vulcanizing agent DCP and the dosage of the crosslinking coagent TAI are respectively 2% and 3% of the mass of the EVM. The method comprises the following steps of: uniformly mixing the EVM with the peroxide vulcanizing agent as well as the crosslinking coagent through mixing so as to obtain a rubber compound; (2) fusing and plasticizing the EVA in a high-temperature mixing instrument so as to obtain an EVA fusant, adding the EVM rubber compound in the EVA fusant, and enabling the EVM rubber compound and the EVA fusant to perform dynamic vulcanization under the effects of a temperature field and a shearing force field; and (3) after finishing dynamic vulcanization, taking out products of dynamic vulcanization, and performing thermoplastic formation according to needs. The thermoplastic vulcanizate disclosed by the invention has good physical and mechanical properties, low hardness and good UV aging resistance.

Owner:QINGDAO UNIV OF SCI & TECH

Fluorocarbon coating solution and solar backplane using fluorocarbon coating

InactiveCN110172282AGood weather resistanceExcellent UV aging resistanceCoatingsPhotovoltaic energy generationWeather resistanceAcrylate ester

The invention relates to the technical field of solar backplanes, in particular to a fluorocarbon coating solution and a solar backplane using the fluorocarbon coating. In order to improve the ultraviolet aging resistance and wet-heat aging resistance of an existing solar backplane, the fluorocarbon coating solution and the solar backplane using the fluorocarbon coating solution are provided. Theprovided fluorocarbon coating solution is prepared from, by weight, 40%-70% of fluorocarbon resin, 20%-50% of titanium dioxide, 1%-5% of matting powder, 0.2%-0.8% of polyacrylate and 3%-10% of isocyanate. The solid content is controlled to be 40-60%, all the components are limited to be within the above content ranges, the fluorocarbon resin can react at high temperature preliminarily and then iscured at 50 DEG C for 48 hours, a high-density fluorocarbon coating is formed on the surface of PET, UV light can be blocked, and it is found that there are no obvious performance degradation throughvarious weatherability tests.

Owner:NINGBO JIANGBEI EXCITON NEW MATERIAL TECH CO LTD

Preparation method of organic silicon material for LED encapsulation

PendingCN106147236AHigh phenyl contentEven distribution of phenyl groupsThermal ageingPolymer science

The preparation method of organic silicon material for LED encapsulation comprises the following steps: component A is synthesized by the following method: vinyl silicon high polymer, polyphenylene phenylene ether oxide silicone oil containing olefin group is put into the reactor to stir, water is added dropwise, and refluxed for 4 hour, add KOH, wash with water to remove alkali, decolorize activated carbon, add solid catalyst, and mix evenly to obtain component A; Stir the reactor, add hydrogen-containing double head, add inhibitor and fluorescent powder, and mix evenly to obtain component B. The product obtained by the invention contains high phenyl content, so it has the characteristics of high refractive index, high transparency, excellent resistance to ultraviolet aging and thermal aging, and is an ideal packaging material for power LEDs.

Owner:西安亚岱新能源科技有限公司

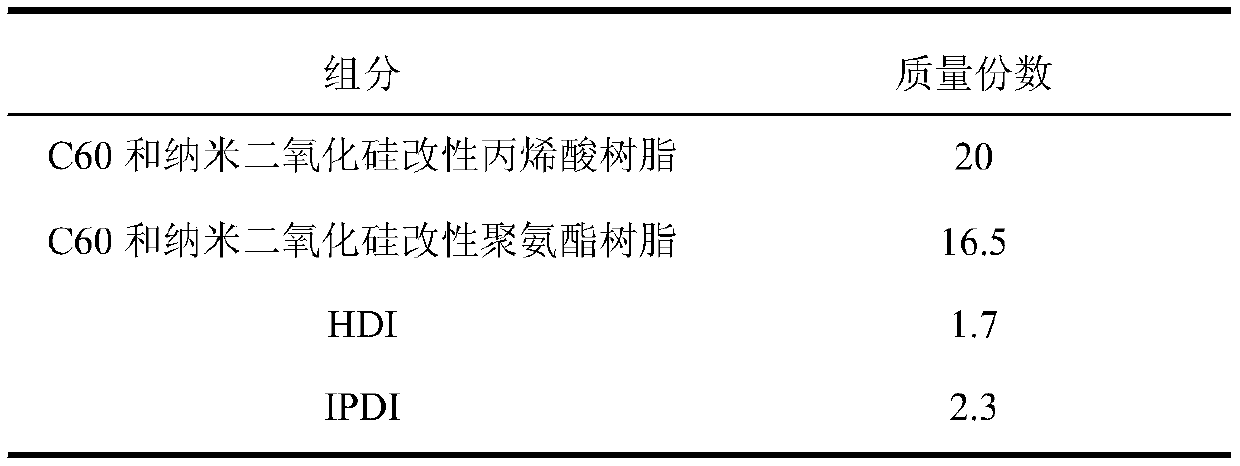

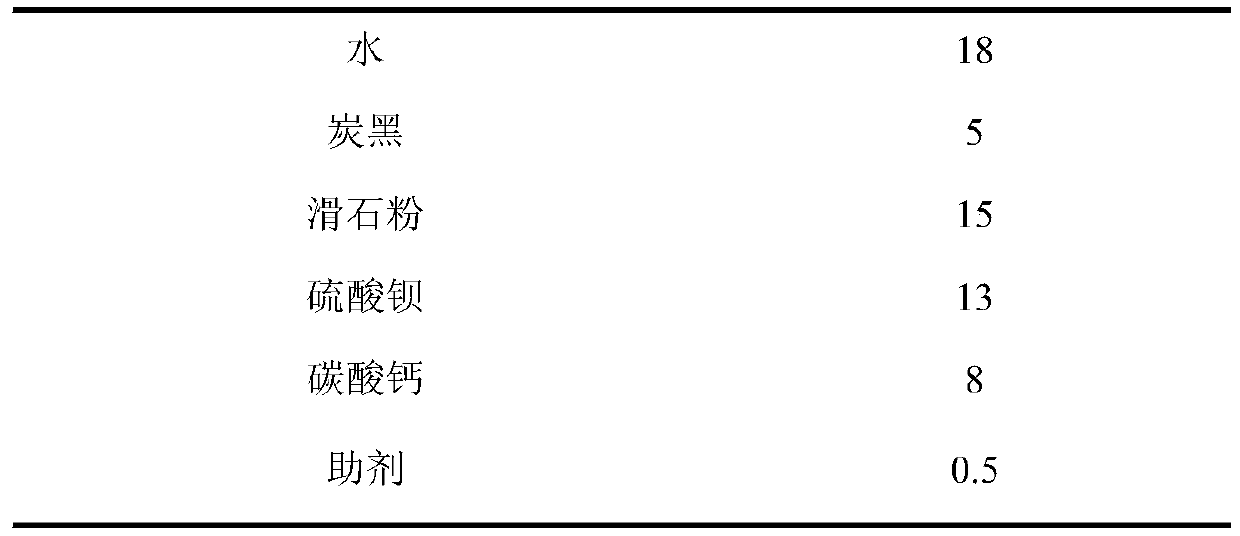

Waterproof paint for decoration and preparation method of waterproof paint

InactiveCN108659677AStrong adhesionExcellent UV aging resistanceStarch dervative coatingsAntifouling/underwater paintsWeather resistanceEmulsion

The invention provides waterproof paint for decoration and a preparation method of the waterproof paint. The waterproof paint is prepared from the following components: epoxy resin, butyl p-hydroxybenzoate, carboxy methyl cellulose, white emulsion, ethylenediamine, nano silicon dioxide, talcum powder, castor oil, polyether glycol, modified starch, diluting agent, polyurethane film forming agent, binder and water. The prepared waterproof paint has the characteristics of adaptability to the deformation of a base layer, and high binding strength, is difficult to separate from the base layer, excellent in ultraviolet aging resistance and low-temperature resistance, also has the characteristics of high weather resistance, water resistance and high contamination resistance, and is simple in preparation method, free from needing special preparation tool, wide in source of raw materials, low in cost, nontoxic, pollution-free, and suitable for mass popularization and production.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

Ageing-resistant environment-friendly lawn particle

The invention provides a preparation method of artificial lawn particles. The formula of the lawn particles comprises the following components: 100 parts of raw rubber, 20-150 parts of filler, 0-20 parts of a plasticizer, 0-6 parts of an active agent, 1-5 parts of an anti-ageing agent, 0-5 parts of a vulcanizing agent, 0-6 parts of an accelerant and 1-8 parts of a coloring agent. The preparation method comprises the following production steps: (1) adding rubber compounds into an internal mixer according to a ratio, sequentially adding the filler, plasticizer, anti-ageing agent, vulcanizing agent and the like, mixing and uniformly discharging, and batching-off so as to obtain a rubber master batch; (2) placing the rubber master batch on an open mill, uniformly mixing, and batching-off sheets; and (3) extruding the sheets in an extruder to form strips, granulating after cross-linking, or performing extrusion granulation and cross-linking. The lawn particles provided by the invention arelightweight, high in strength, environmentally friendly and excellent in ageing resistance. Moreover, the particles have the characteristics of being difficult to discolor and long in service life.

Owner:QINGDAO UNIV OF SCI & TECH

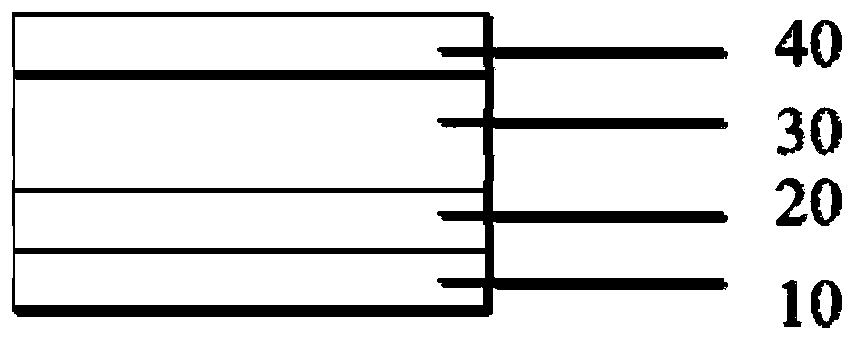

Solar cell back panel

ActiveCN104485379ASimplify the production processExcellent UV aging resistancePhotovoltaic energy generationSemiconductor devicesWeather resistanceChemistry

The invention provides a solar cell back panel with excellent weather resistance. The solar cell back panel comprises a weather resistant layer, an insulating layer and an adhesive layer, wherein the adhesive layer is a coating which is formed through curing of hydroxy acrylic resin and isocyanate and has high weather resistance; the glass-transition temperature of hydroxy acrylic resin is 12-45 DEG C; and the adhesive layer contains inorganic extinction powder subjected to surface treatment with an alcohol ester method. According to the solar cell back panel, the production and processing performance of the coating is improved, and the back panel has good weather resistance and EVA (ethylene vinyl acetate copolymer) adhesion and can effectively protect cell components in a solar cell module.

Owner:乐凯胶片股份有限公司

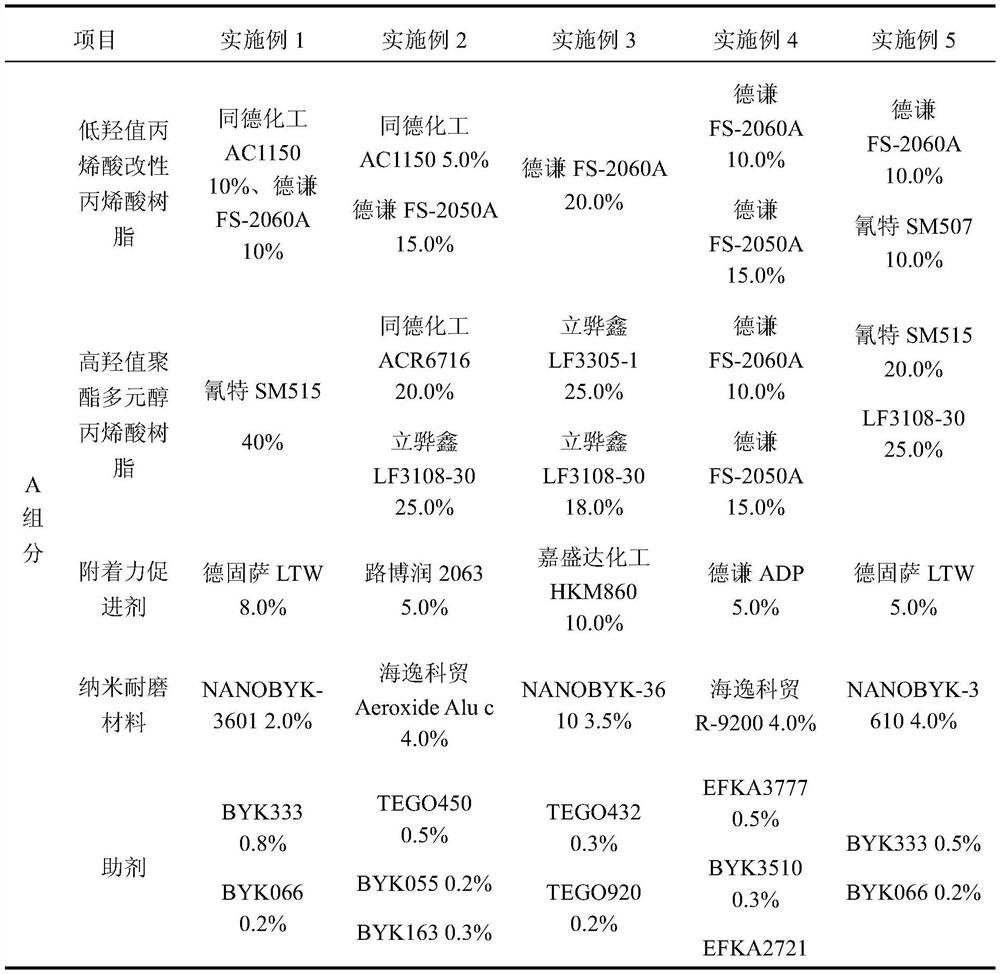

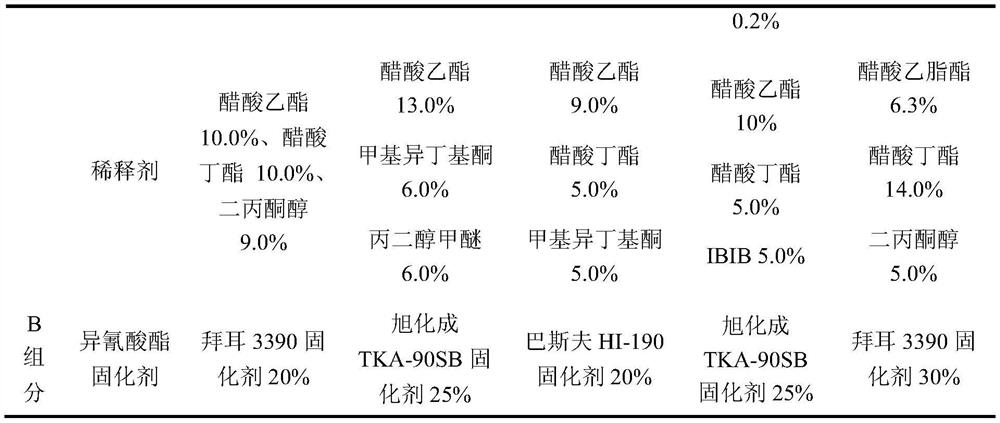

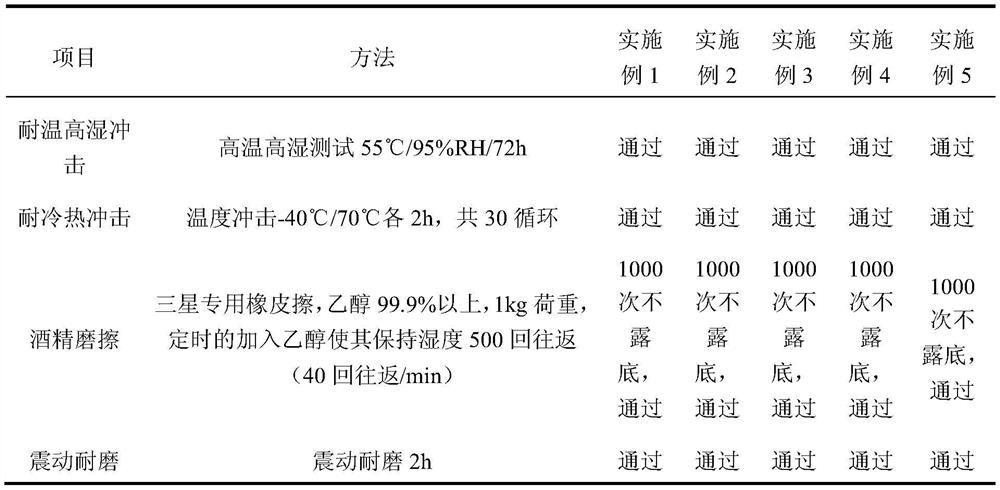

High-wear-resistance vacuum coating hydroxyl acrylic coating as well as preparation method and application thereof

ActiveCN112920693AExtended service lifeExcellent abrasion resistanceFireproof paintsAnti-corrosive paintsPolyesterPolymer science

The invention discloses a high-wear-resistance vacuum coating hydroxyl acrylic coating as well as a preparation method and application thereof. The high-wear-resistance vacuum coating hydroxyl acrylic coating comprises a component A and a component B. The component B comprises an isocyanate curing agent, the component A comprises the following components in percentage by mass: 10%-30% of low-hydroxyl-value acrylic acid modified acrylic resin, 10%-45% of high-hydroxyl-value polyester polyol acrylic resin, 1%-10% of an adhesion promoter, 1%-5% of a nano wear-resistant material, 0.1%-2% of an auxiliary agent and 10%-50% of a diluent. According to the high-wear-resistance vacuum coating hydroxyl acrylic coating, high-hydroxyl-value polyester polyol acrylic resin is used as matrix resin and reacts with isocyanate, and a high polymer containing urethane bonds is generated. And part of acrylic acid modified low-hydroxyl-value acrylic resin and an adhesion promoter are matched, so that the adhesion of the finish paint to a metal coating layer and a material is improved, and then surface enhancement is performed through a nano wear-resistant material. Meanwhile, high impact resistance, wear resistance, tear resistance and corrosion resistance are achieved.

Owner:HUNAN SOKAN NEW MATERIAL

Flame-retardant hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN106753235AExcellent UV aging resistanceImprove heat aging resistanceAdhesivesPolyolefinAntioxidant

The invention discloses a flame-retardant hot-melt pressure-sensitive adhesive and a preparation method thereof. The flame-retardant hot-melt pressure-sensitive adhesive is prepared from the following components in parts by weight: 20-40 parts of a thermoplastic elastomer, 2-4 parts of a halogen-free flame retardant, 1-2 parts of an antioxidant, 5-10 parts of amorphous polyolefin, 20-30 parts of polyolefin resin, 4-6 parts of polyisobutene, 1-2 parts of plasticizer, 1-3 parts of a bio-emulsifier, 50-60 parts of tackifying resin and 3-5 parts of an ultraviolet light absorber. The flame-retardant hot-melt pressure-sensitive adhesive has excellent ultraviolet aging resistance and heat aging resistance as well as good low-temperature bending resistance, has proper cohesive force, stripping force and initial adhesion and has flame retardance; and the defect that a traditional pre-laid waterproof roll can only be constructed above 0 DEG C can be completely avoided.

Owner:钦州市钦南区科学技术情报研究所

PA6 buckle material for fixing sound-absorbing module and preparation method of material

The invention discloses a PA6 buckle material for fixing a sound-absorbing module. The PA6 buckle material is prepared from, by weight, 50-85 parts of injection grade PA6 base material of which the viscosity ranges from 2.6 to 2.9, 15-50 parts of short-cut or continuous glass fibers, 0.1-0.8 part of antioxidant 1010 or 1098, 0.1-0.8 part of antioxidant 168, 0.1-1 part of UV agent 2020 or 770 or 4050, 0.1-1 part of UV agent 234 or 944 or 622, 1-3 parts of carbon black and 0.1-1 part of lubricating agent. According to the PA6 buckle material for fixing the sound-absorbing module, a nylon 6 based high polymer material blending modification technology is adopted, and by means of melting mixing and extruding methods such as glass fiber reinforcing, processing stabilizing and thermal-oxidation stabilizing, the PA6 buckle material for fixing the sound-absorbing module is obtained.

Owner:烟台恒大聚合体有限公司

High-adhesion sealant and preparation method thereof

InactiveCN106634712ALow costImprove solubilityNon-macromolecular adhesive additivesOther chemical processesAntioxidantPolyvinyl chloride

The invention discloses high-adhesion sealant, comprising, by weight, 90-100 parts of chlorinated PVC resin, 40-60 parts of PVC (polyvinyl chloride) resin, 30-50 parts of alkyd resin, 50-60 parts of ultrahigh molecular weight polyvinyl chloride with molecular weight of 1.60 million, 15-25 parts of dibutyl phthalate, 20-30 parts of dioctyl phthalate, 10-15 parts of dioctanoate adipate, 560-672 parts of gasoline, 400-480 parts of ethyl acetate, 240-288 parts of acetone, 23-26 parts of rutile titanium dioxide, 120-140 parts of light calcium carbonate, 250-270 parts of talcum powder, 20-23 parts of sericite, 10-13 parts of vulcanized paste, 30-50 parts of diatomite, 0.4-0.6 part of an ultraviolet stabilizer, and 0.05-0.1 part of an antioxidant. The high-adhesion sealant has the advantages that the sealant with excellent comprehensive properties is acquired by component optimization, usage of harmful matters is reduced, environmental pollution is reduced, and the preparation process is updated according to the optimized composition.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Organosilicon material for LED packaging

InactiveCN107722639AHigh phenyl contentHigh phenyl content and therefore high refractive indexSemiconductor devicesRefractive indexUltraviolet

The invention discloses a silicone material for LED encapsulation, which is characterized in that it comprises: A component and B component, and the A component includes vinyl silicon high polymer, polyphenylene phenylene ether oxide silicone oil containing olefin group and curing Catalyst Mixture; B Component includes Olefinyl Hydrogen Polyphenylene Phenyl Ether, Vinyl Hydrogen Silicone, Inhibitor and Phosphor. The invention makes the phenyl group in the resin evenly distributed and the resin microstructure uniform through the alternate feeding sequence of the low-functionality siloxane and the high-functionality siloxane, and effectively improves the light transmittance and hardness of the crosslinked resin. Moreover, the cured product contains high phenyl content, so it has the characteristics of high refractive index, high transparency, excellent resistance to ultraviolet aging and thermal aging, and is an ideal packaging material for power LEDs.

Owner:SICHUAN KELIXIN NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com