Denoising device for fan blade

A technology for fan blades and noise reduction, which is applied in wind power engines, engines, wind power generation, etc., can solve the problems of poor response to changes, single noise reduction effect of noise reduction components, etc. Excellent effect of UV radiation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

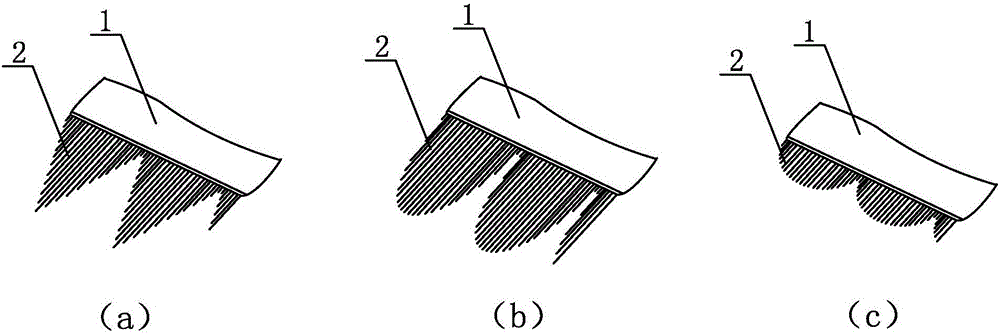

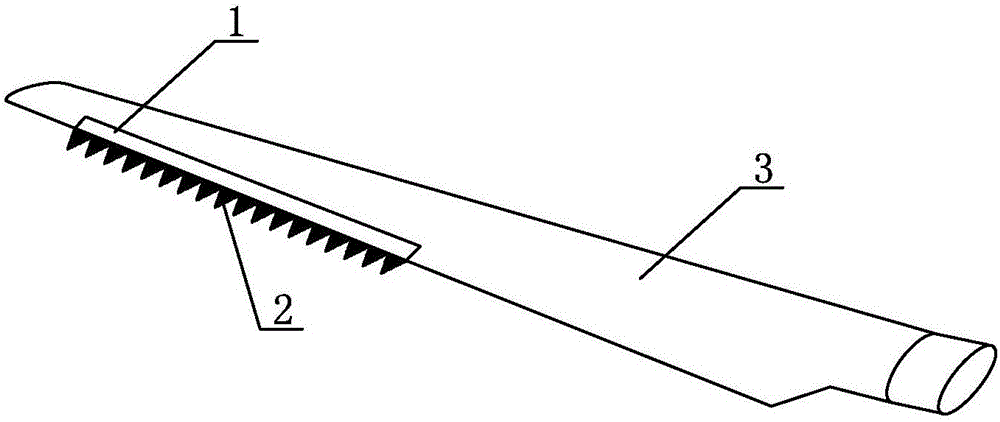

[0030] The fan blade of embodiment 1 is used noise reducing device, as figure 1 (a)~ figure 1 As shown in (c), it includes a substrate 1 and a noise reduction bristle 2 made of ultra-high molecular weight polyethylene. The noise reduction bristle 2 is arranged on the front side of the substrate 1. The front side of the substrate 1 is planar, and the noise reduction bristle 2 is Jagged or wavy. figure 1 (a), figure 1 (b), figure 1 (c) are three forms of the noise reduction device in Example 1, and the noise reduction bristles 2 are jagged or wavy, but in actual operation, the noise reduction bristles can also be cut to fit Any other shape for reducing fan blade noise. After the noise reduction device is installed, the bottom surface of the substrate 1 is fixed on the fan blade 3, figure 2 for figure 1 (a) The effect diagram after the noise reduction device is installed on the fan blade 3, figure 2 In the above, the installation position of the noise reduction device is...

Embodiment 2

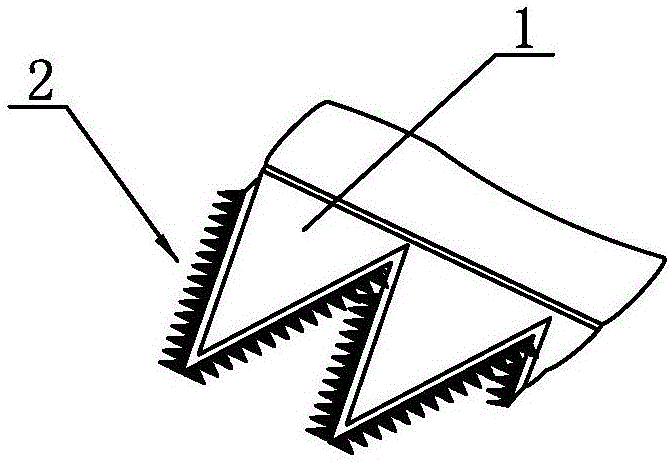

[0031] The fan blade of embodiment 2 is used noise reducing device, as image 3 As shown, it includes a substrate 1 and a noise reduction bristle 2 made of ultra-high molecular weight polyethylene. The noise reduction bristle 2 is arranged on the front side of the substrate 1. The front side of the substrate 1 is in a zigzag shape. After the noise reduction device is installed, the substrate 1 The bottom surface of the base plate 1 is fixed on the fan blade (not shown in the figure), the front side of the substrate 1 is serrated, and the noise reduction bristles 2 can be used figure 1 jagged, wavy, or other shapes shown in . In this embodiment, the front side of the substrate 1 may also adopt a wave shape or other shapes.

Embodiment 3

[0032] The fan blade of embodiment 3 is used noise reducing device, as Figure 4 As shown, it includes a base plate 1 and a noise reduction bristle 2 made of ultra-high molecular weight polyethylene. The noise reduction bristle 2 is arranged on the front side of the base plate 1, and the noise reduction bristle 2 is jagged; the surface of the base plate 1 is provided with several convex And parallel noise-reducing guide rails 3, some noise-reducing guide rails 3 are fin-shaped with front thickness and rear thinness, several noise-reduction guide rails 3 are arranged at intervals, the front ends of several noise-reduction guide rails 3 protrude from the front side of the base plate 1, and each noise-reduction guide rail 3 Auxiliary bristles 4 are arranged on the noise guide rail 3, and the auxiliary bristles 4 are arranged at intervals along the length direction of each noise reduction guide rail 3; after the noise reduction device is installed, the bottom surface of the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com