Anti-ultraviolet antibacterial polypropylene filament yarn and preparation method thereof

An anti-ultraviolet and filament technology, applied in the field of polypropylene filament, can solve the problems of limited fiber, easy oxidation degradation of methyl side chain, poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

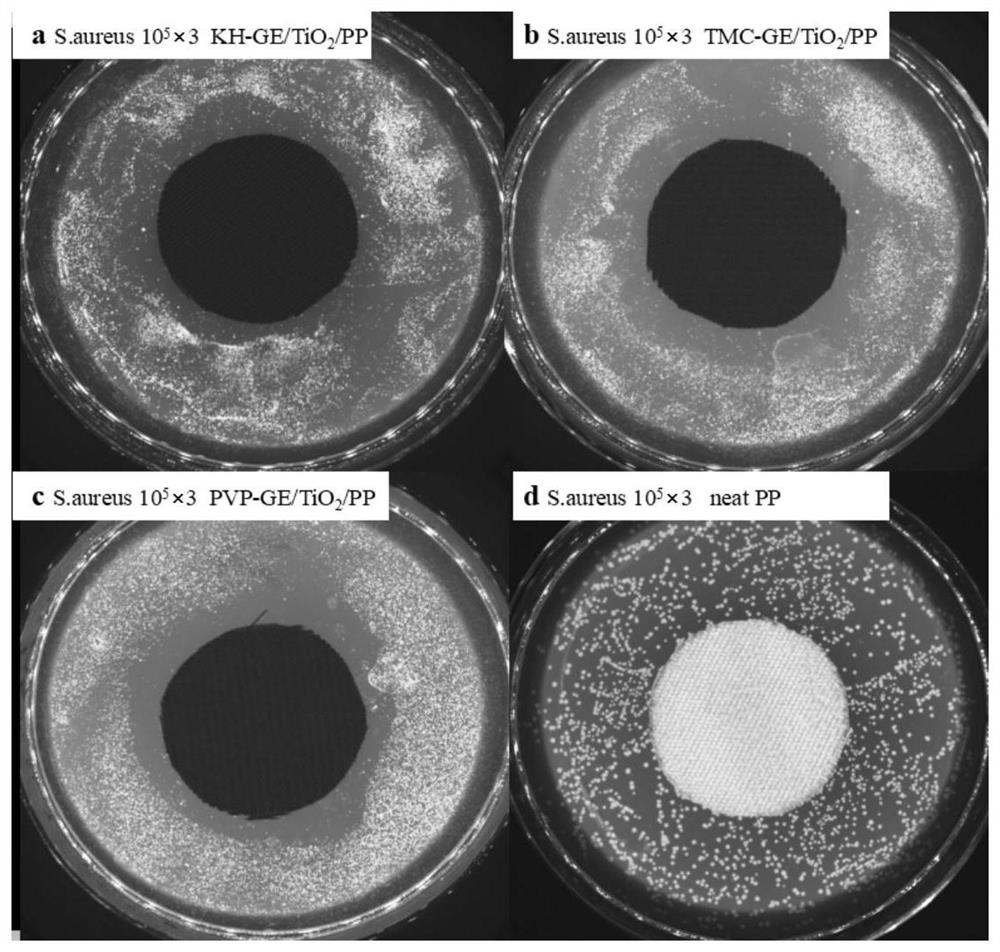

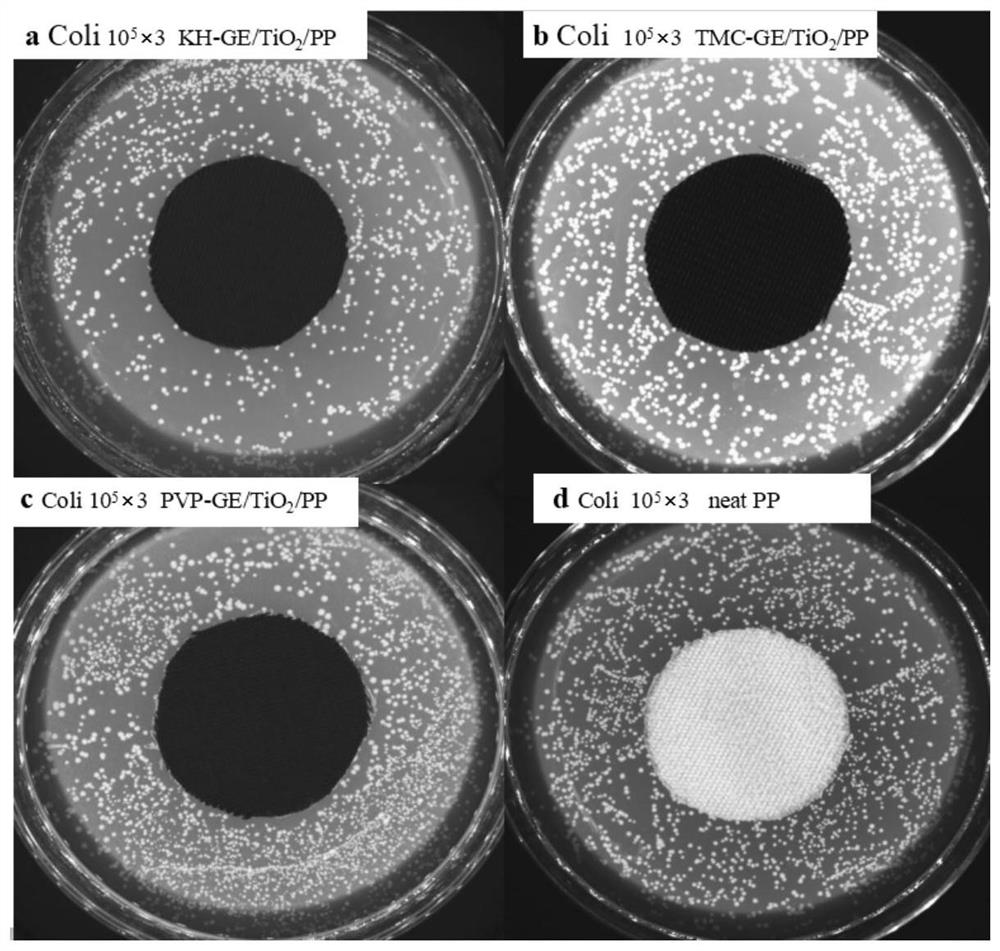

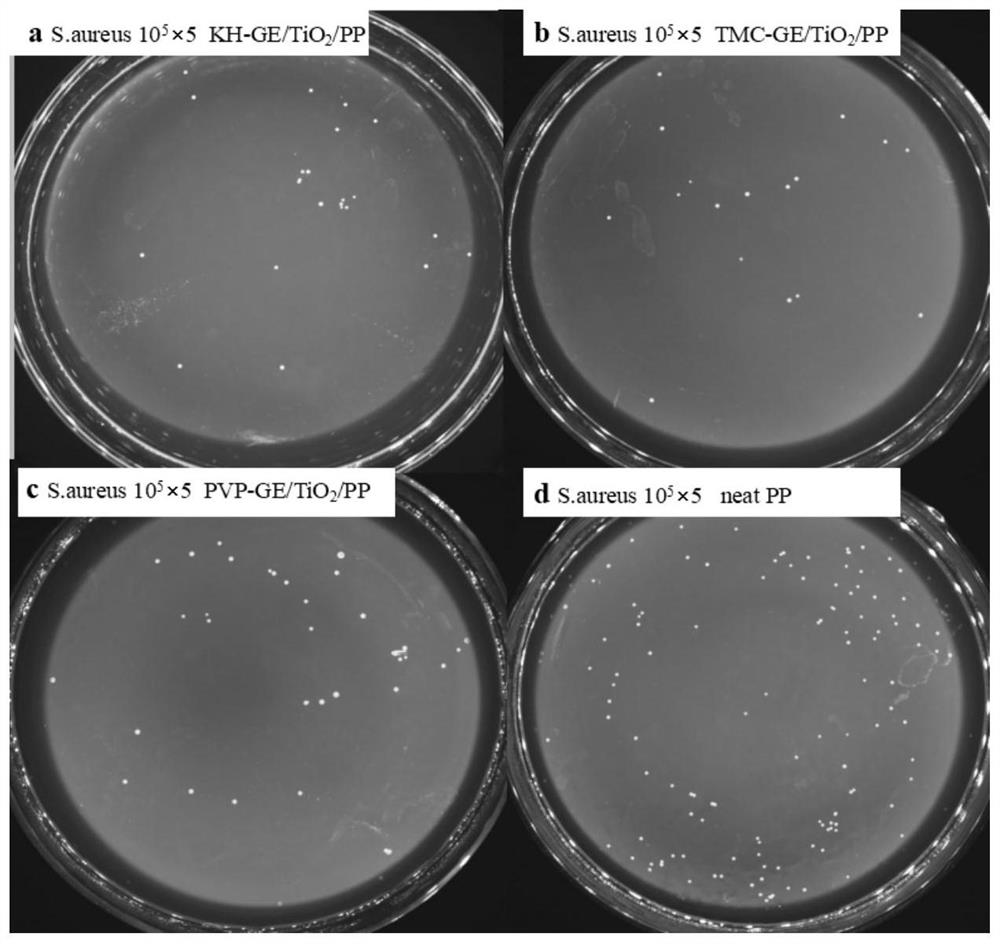

Image

Examples

Embodiment 1

[0025] (1) Preliminary material preparation

[0026] Graphene modification: absolute ethanol (mass fraction is 95%) and water are made into aqueous ethanol solution A containing 90% ethanol; take 40g of the above-mentioned A solution and 10gKH560 and make it into a hydrolyzate containing 20wt% of KH560, stir and hydrolyze for 30min Disperse 10g of graphene in a certain amount of aqueous solution and ultrasonically disperse for 30min; add the above-mentioned 50gKH560 dehydrated alcohol hydrolyzate dropwise into the dispersion of graphene, mix and stir, and ultrasonically treat for 30min; The water in the water dispersion of graphene / KH560 evaporates, and the ethanol volatilizes; then dry and then obtain KH560 modified graphene, and then grind it for later use;

[0027] TiO 2 Modification: Add the silane coupling agent KH570 dropwise into absolute ethanol with a mass fraction of 95% for hydrolysis to obtain an ethanol solution containing a silane coupling agent, and then add 5%...

Embodiment 2

[0039] Compared with Example 1, this embodiment is only different in raw material proportioning:

[0040] Polypropylene 96.4%

[0041] Modified graphene 0.5%

[0042] Modified TiO 2 1%

[0043] Maleic anhydride grafted polypropylene 2%

[0044] Dispersant (a mixture of sodium cellulose sulfonate and sodium lignosulfonate with a mass ratio of 50:50) 0.1%

Embodiment 3

[0046] Compared with example 1, this example is only different in the ratio of raw materials:

[0047] Polypropylene 95.9%

[0048] Modified graphene 0.5

[0049] Modified TiO 2 1.5

[0050] Maleic anhydride grafted polypropylene 2%

[0051] Dispersant (a mixture of sodium cellulose sulfonate and sodium lignosulfonate with a mass ratio of 50:50) 0.1%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com