External rubber sleeve material of cable for wind power generation

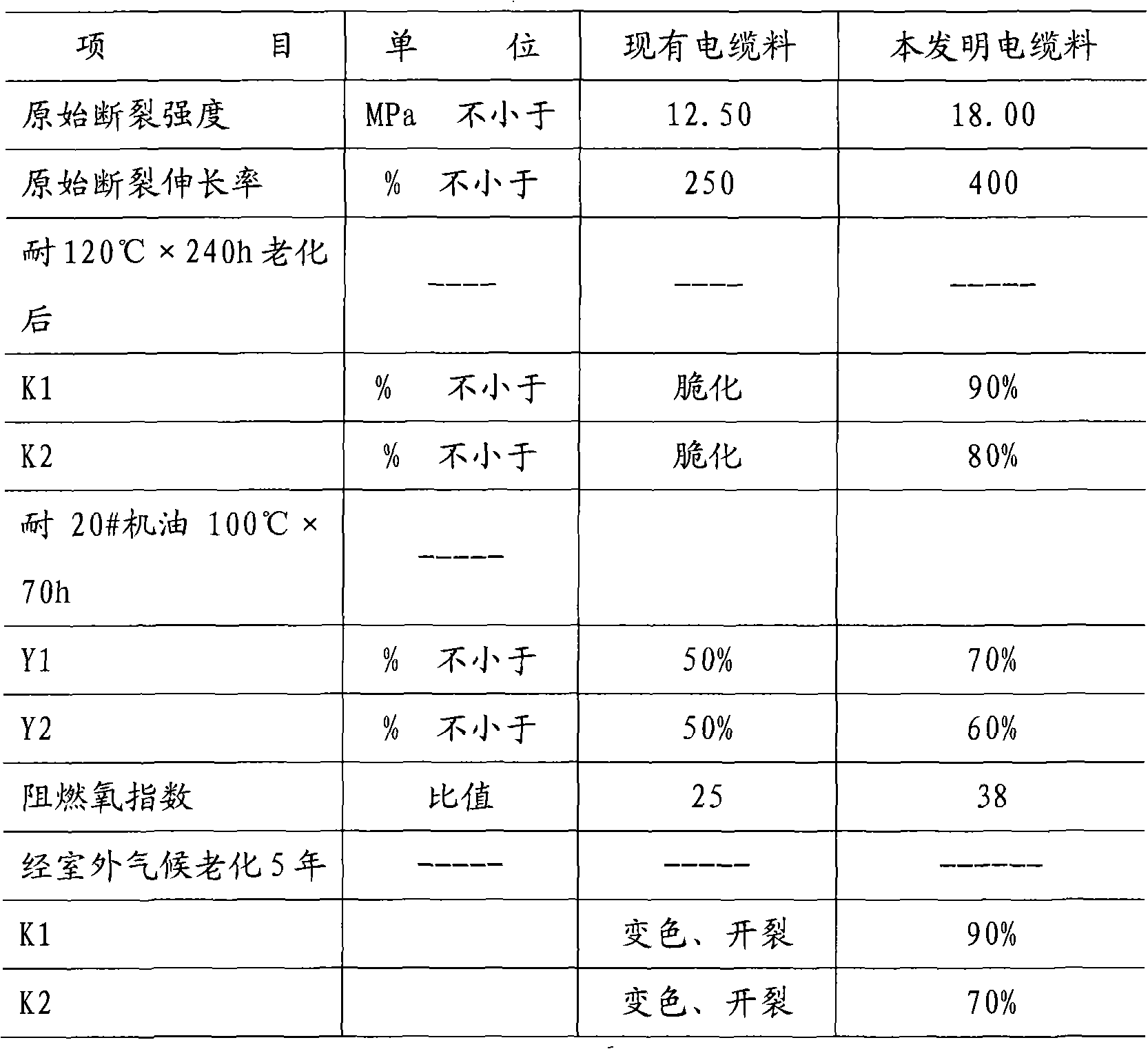

A sheathing material, wind energy power generation technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor weather resistance, oil resistance and flame retardancy, and soft performance, etc., and achieves small permanent deformation. , Excellent UV aging resistance and excellent process operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

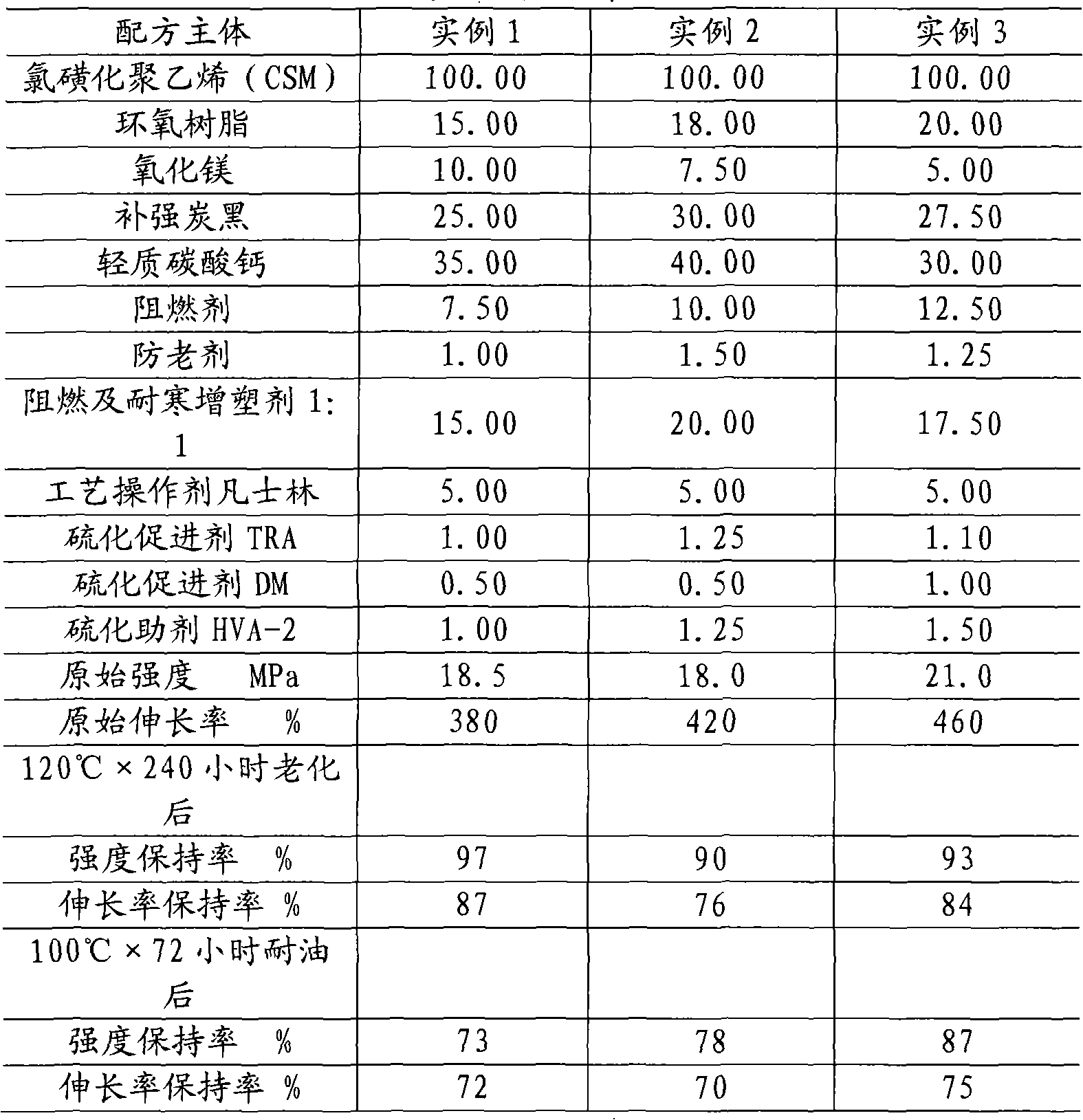

Embodiment 1

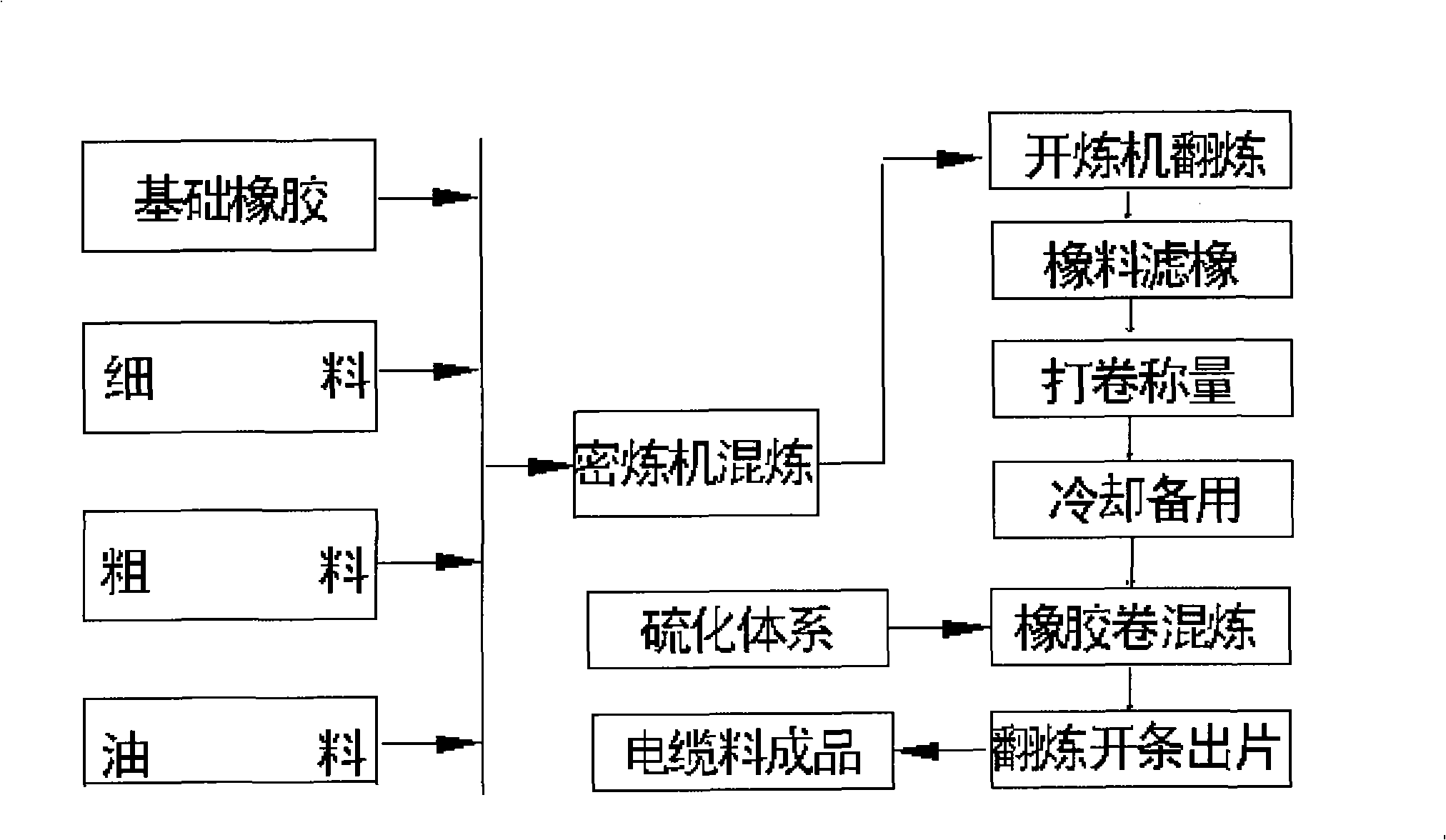

[0066] Preparation:

[0067] First take 200 grams of base rubber, knead on a small open mill, fully cover the rolls, add chlorosulfonated polyethylene rubber base rubber, acid acceptor, reinforcing agent, flame retardant, anti-aging agent, process operating agent, and some fillers As well as flame retardant plasticizers, cold-resistant plasticizers, etc. After basic molding, add the remaining fillers, flame-retardant plasticizers, and cold-resistant plasticizers, and then add vulcanizing agents, vulcanization aids, and vulcanization accelerators after molding. The distance between the rollers is reduced at the small start-up, and the rubber is punched into thin sheets, and the triangle bag is punched at least 3 times, and the thickness of the sheet is about 5mm, and then cooled for later use.

Embodiment 2

[0069] Put 40kg of the basic rubber that has been masticated into the internal mixer for 30 seconds to 1 minute, then add acid acceptor, flame retardant plasticizer, cold-resistant plasticizer, reinforcing agent, flame retardant, anti-aging agent, process Operating agents, fillers, flame retardant plasticizers, cold-resistant plasticizers, etc. excluding vulcanizing agents, vulcanization aids, and vulcanization accelerators, etc. 47.75 kg of compounding ingredients, after mixing for about 5 minutes, discharge the material, press the tablet and open the filter After the rubber is weighed, it is coiled and cooled, and each sulfur-free rubber roll is 21.94 kg. After parking for at least 2 hours, weigh 4 unvulcanized rubber rolls and put them into the internal mixer for about 3 minutes, then add 2.25 kg of vulcanizing agent, vulcanization assistant, and vulcanization accelerator for 30 seconds to 1 minute. Afterwards, the strips are turned and cooled, and the thickness of the stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com