Thermal-aging anti-adhesion-failure hot-melt pressure-sensitive adhesive and preparation method thereof

A heat-aging, hot-melt technology, applied in the direction of adhesive types, adhesives, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problem of inability to achieve waterproof effect, failure to meet performance requirements, and decreased peel strength of bonded aluminum plates, etc. Problems, achieve excellent UV aging resistance, increase wetting effect, and increase adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 provides a heat-aging non-sticky hot-melt pressure-sensitive adhesive and a preparation method thereof.

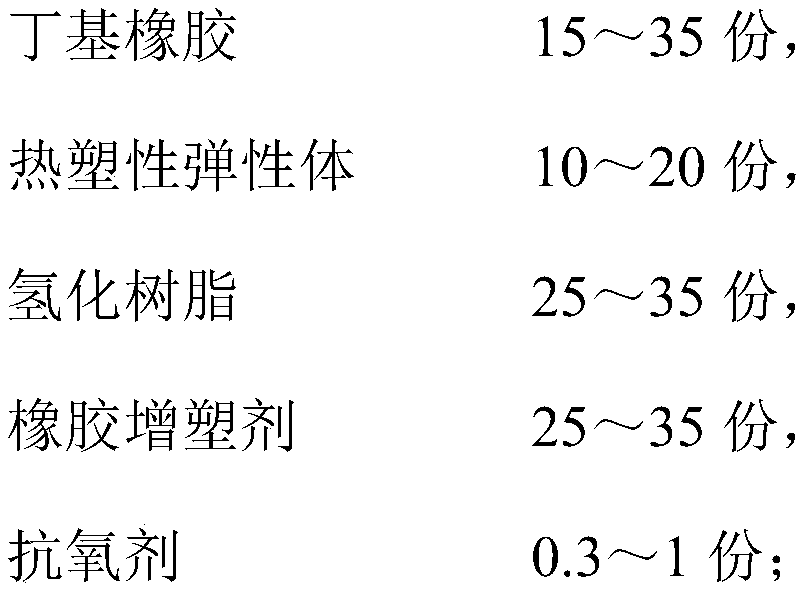

[0040] The raw materials (see Table 1) of the heat-aging non-viscosity hot-melt pressure-sensitive adhesive include:

[0041]

[0042] Described thermoplastic elastomer is the mixture that the mass ratio of SEBS and SEPS is 3:3;

[0043] Described hydrogenated synthetic resin is perhydrogenated C5 petroleum resin;

[0044] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester.

[0045] The preparation method of the heat aging non-sticky hot-melt pressure-sensitive adhesive comprises:

[0046] Add butyl rubber, SEBS, SEPS, liquid polyisobutylene rubber and antioxidant into the kneader according to the required ratio; then, slowly heat to 150 ° C, stir until all the materials are melted, and the reaction is stable for 5 minutes; then, in Under stirring, add the remaining other materials according to the re...

Embodiment 2

[0048] Embodiment 2 provides a hot-melt pressure-sensitive adhesive that does not lose viscosity after heat aging and a preparation method thereof.

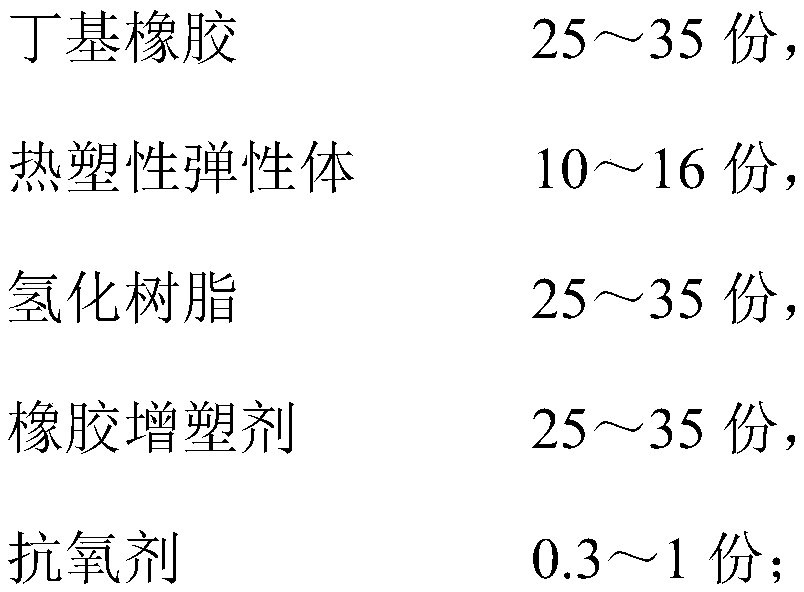

[0049] The raw materials (see Table 1) of the heat-aging non-viscosity hot-melt pressure-sensitive adhesive include:

[0050]

[0051] Described thermoplastic elastomer is the mixture that SEBS and SEPS mass ratio are 4:2;

[0052] Described hydrogenated synthetic resin is perhydrogenated C9 petroleum resin;

[0053] The antioxidant is tris[2.4-di-tert-butylphenyl]phosphite.

[0054] The preparation method of the heat aging non-sticky hot-melt pressure-sensitive adhesive comprises:

[0055]Add butyl rubber, SEBS, SEPS, liquid polyisobutylene rubber and antioxidant into the kneader according to the required ratio; then, slowly heat to 155 ° C, stir until all the materials are melted, and the reaction is stable for 8 minutes; then, in Under stirring, add the remaining other materials according to the required ratio, and keep ...

Embodiment 3

[0057] Embodiment 3 provides a hot-melt pressure-sensitive adhesive without loss of viscosity after heat aging and a preparation method thereof.

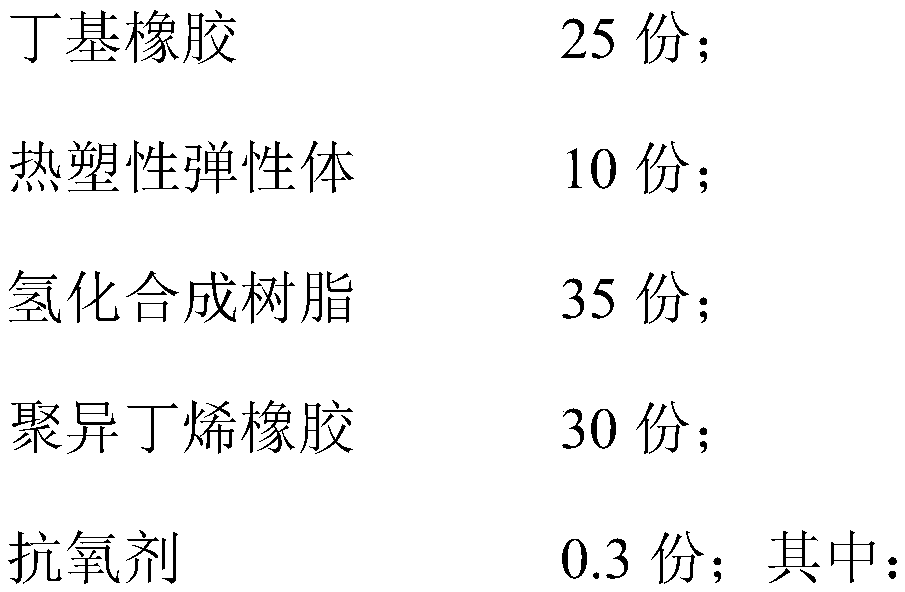

[0058] The raw materials (see Table 1) of the heat-aging non-viscosity hot-melt pressure-sensitive adhesive include:

[0059]

[0060] Described thermoplastic elastomer is the mixture that SEBS and SEPS mass ratio are 3:1;

[0061] Described hydrogenated synthetic resin is perhydrogenated C5 petroleum resin;

[0062] The antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate.

[0063] The preparation method of the heat aging non-sticky hot-melt pressure-sensitive adhesive comprises:

[0064] Add butyl rubber, SEBS, SEPS, liquid polyisobutylene rubber and antioxidant into the kneader according to the required ratio; then, slowly heat to 160 ° C, stir until all the materials are melted, and the reaction is stable for 10 minutes; then, in Under stirring, add the remaining other materials according to the requ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com