Patents

Literature

88results about How to "Improve sticking power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-component low temperature self-crossing emulsion adhesive for paper and plastic compounds and preparing method thereof

InactiveCN101928534ALess slagHigh affinityNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceAdhesive

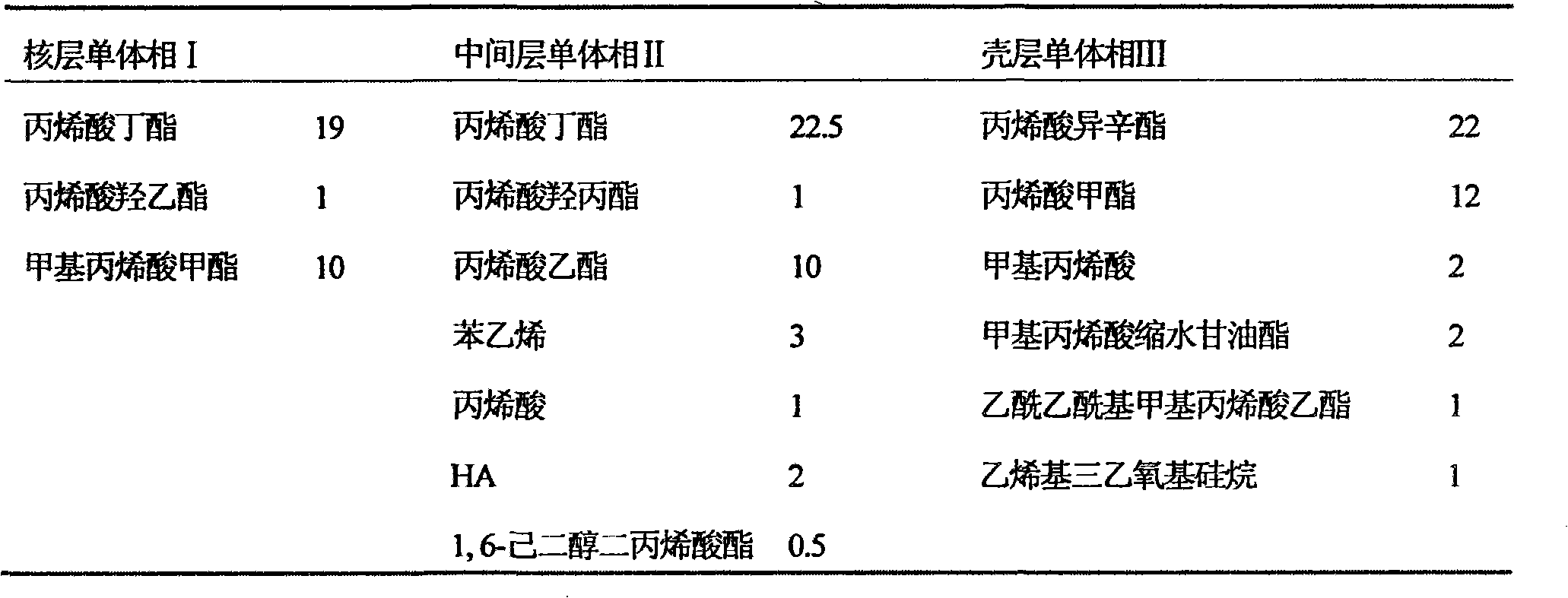

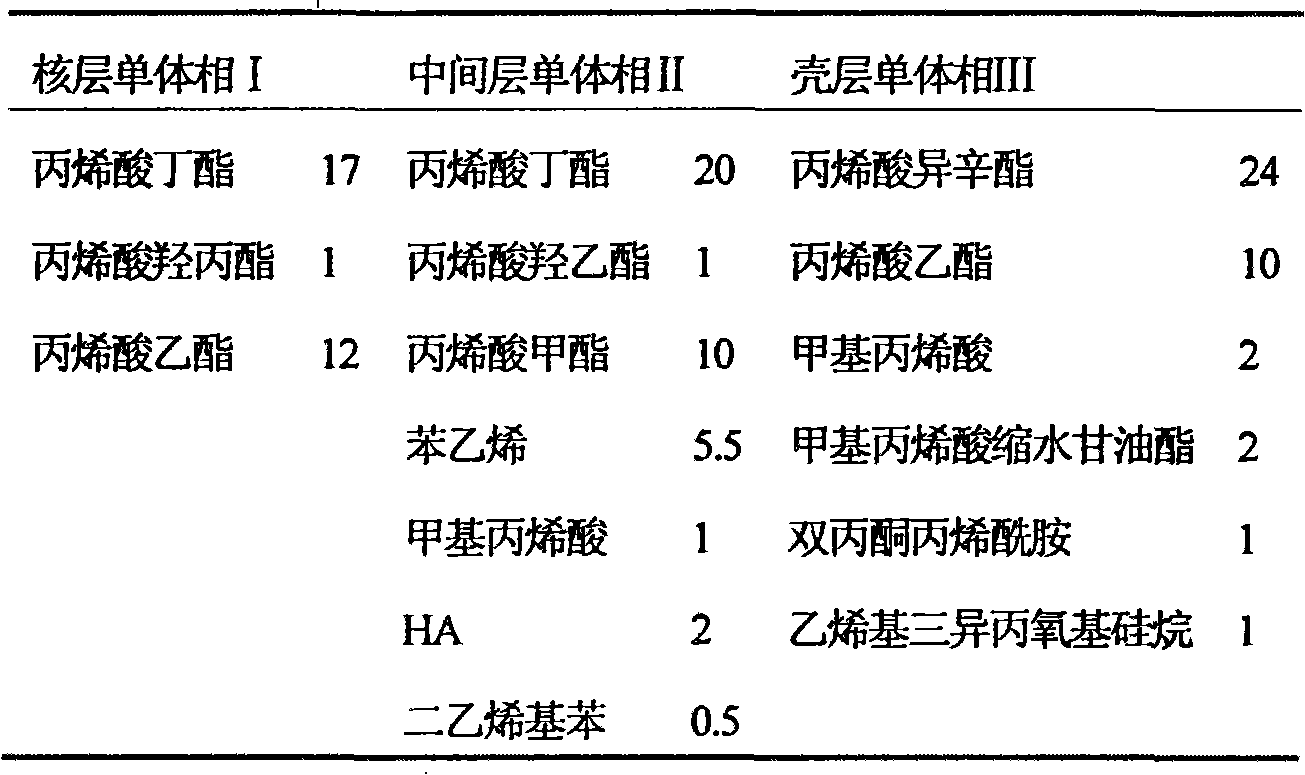

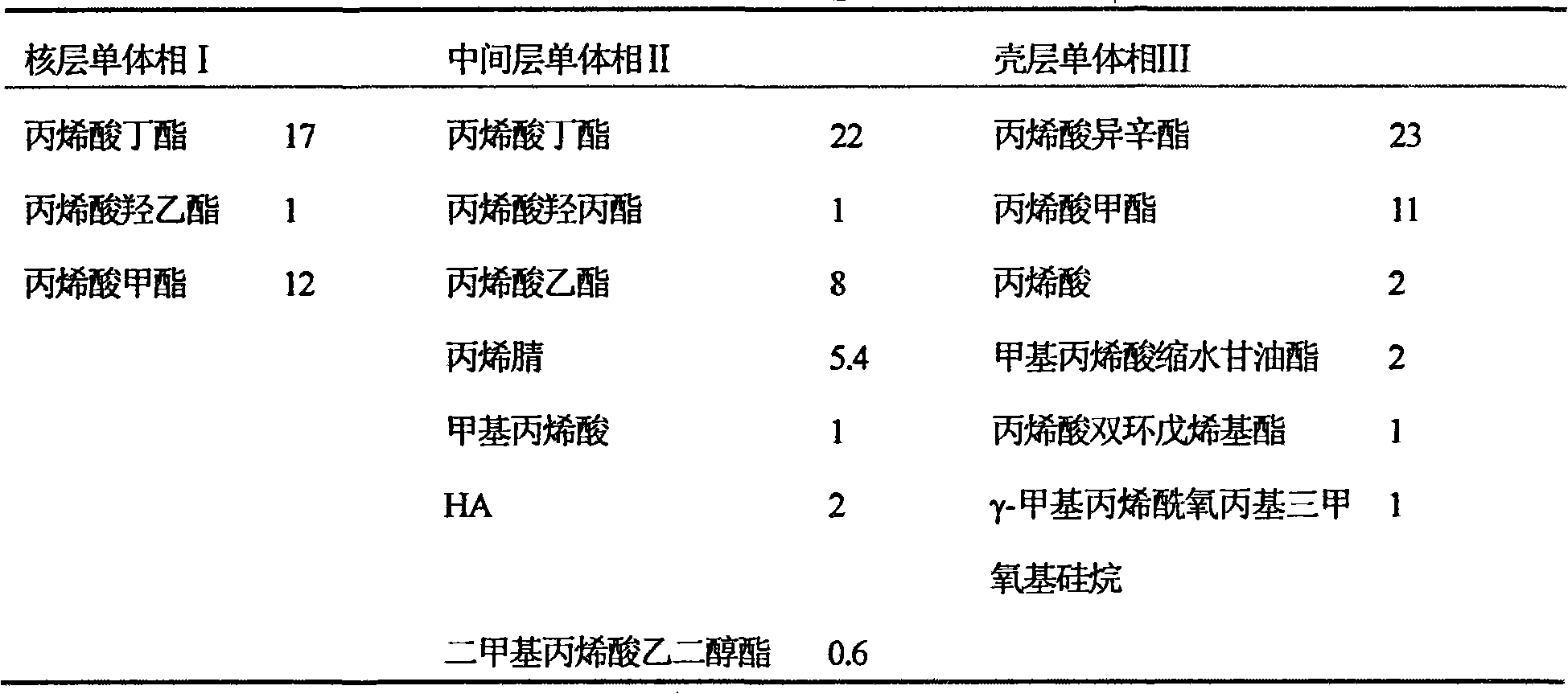

The invention discloses a single-component low temperature self-crossing emulsion adhesive for paper and plastic compounds and a preparing method thereof. The raw materials of the self-crossing emulsion adhesive comprise the following components in part by weight: 100-150 parts of de-ionized water, 0.8-3.0 parts of emulsifier, 20-40 parts of nuclear layer monomer, 30-50 parts of interlayer monomer, 20-40 parts of shell layer monomer, and 0.2-0.6 part of initiator. The invention uses a small amount of anionic emulsifier to prepare nuclear emulsion, uses polymerisable emulsifier to prepare interlayer and shell layer pre-emulsion, and adopts semi-continuous seeded low emulsion polymerization process to prepare emulsion particles that have a three-layer core-shell microstructure to obtain the exquisite and stable emulsion. The product has no organic solvent, and does not release methanal, contains no APEO and no phthalate; the film coating has high transparency, high water resistance and high heat and humidity resistance; and the emulsion adhesive is applied to plastic and paper compounds, has high adhesive strength, peel strength and permanent adhesion, is also compatible to oil and ink and has high oil / ink transferring rate.

Owner:SOUTH CHINA UNIV OF TECH

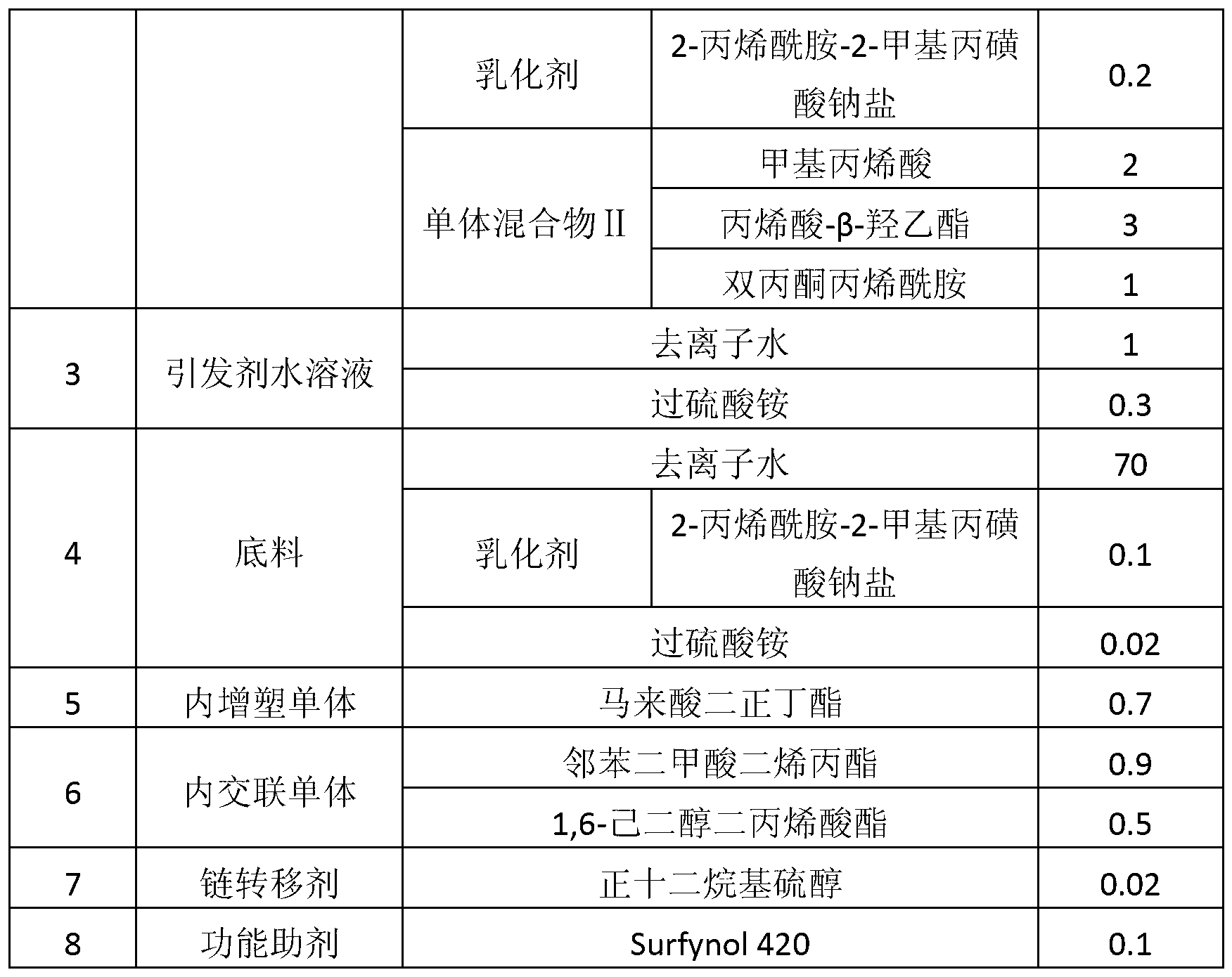

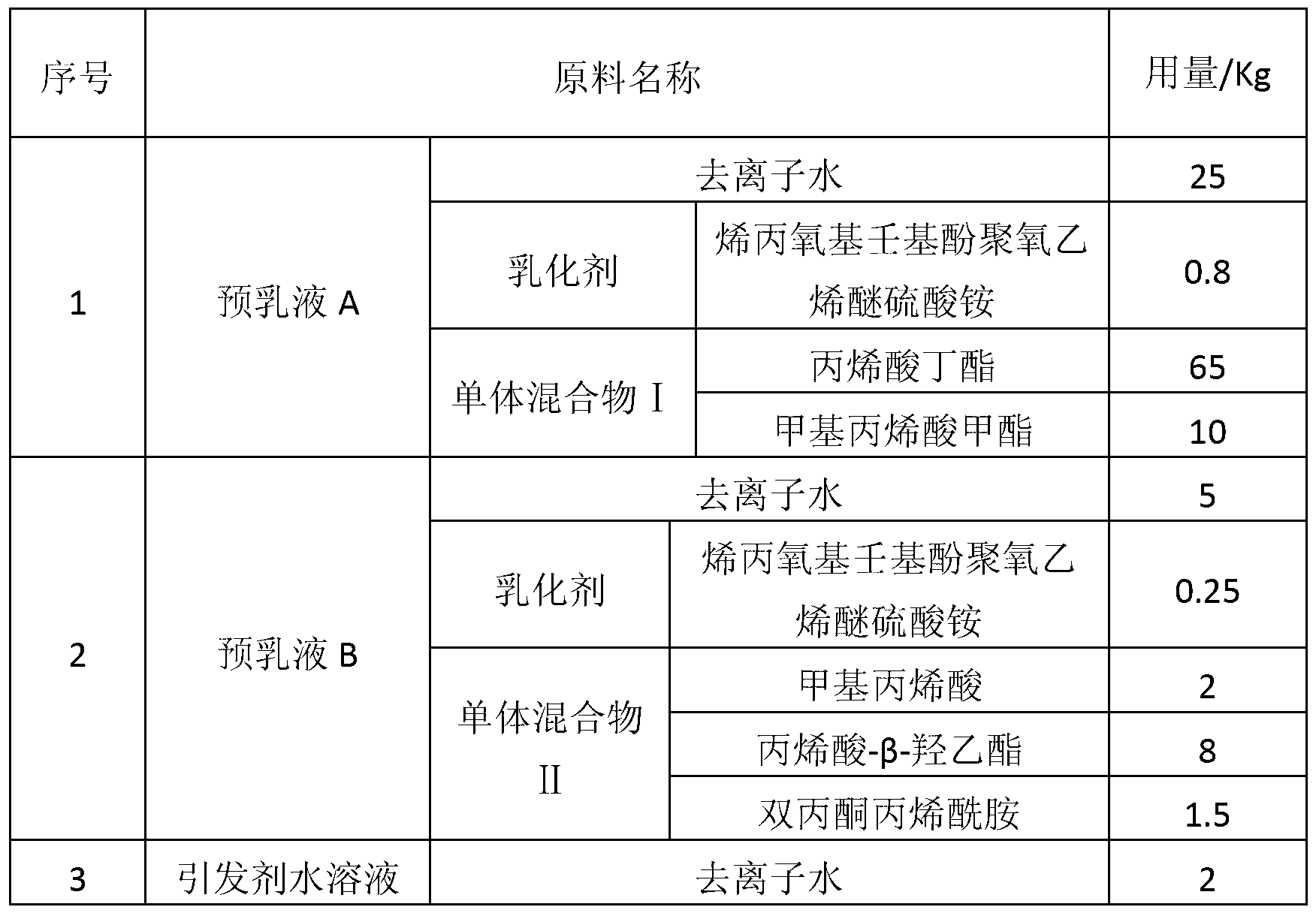

Water-based plastic-plastic compound adhesive for food and drug flexible package and preparation method thereof

ActiveCN103059784AHigh bonding strengthImprove stabilityEster polymer adhesivesWater basedPolyurethane adhesive

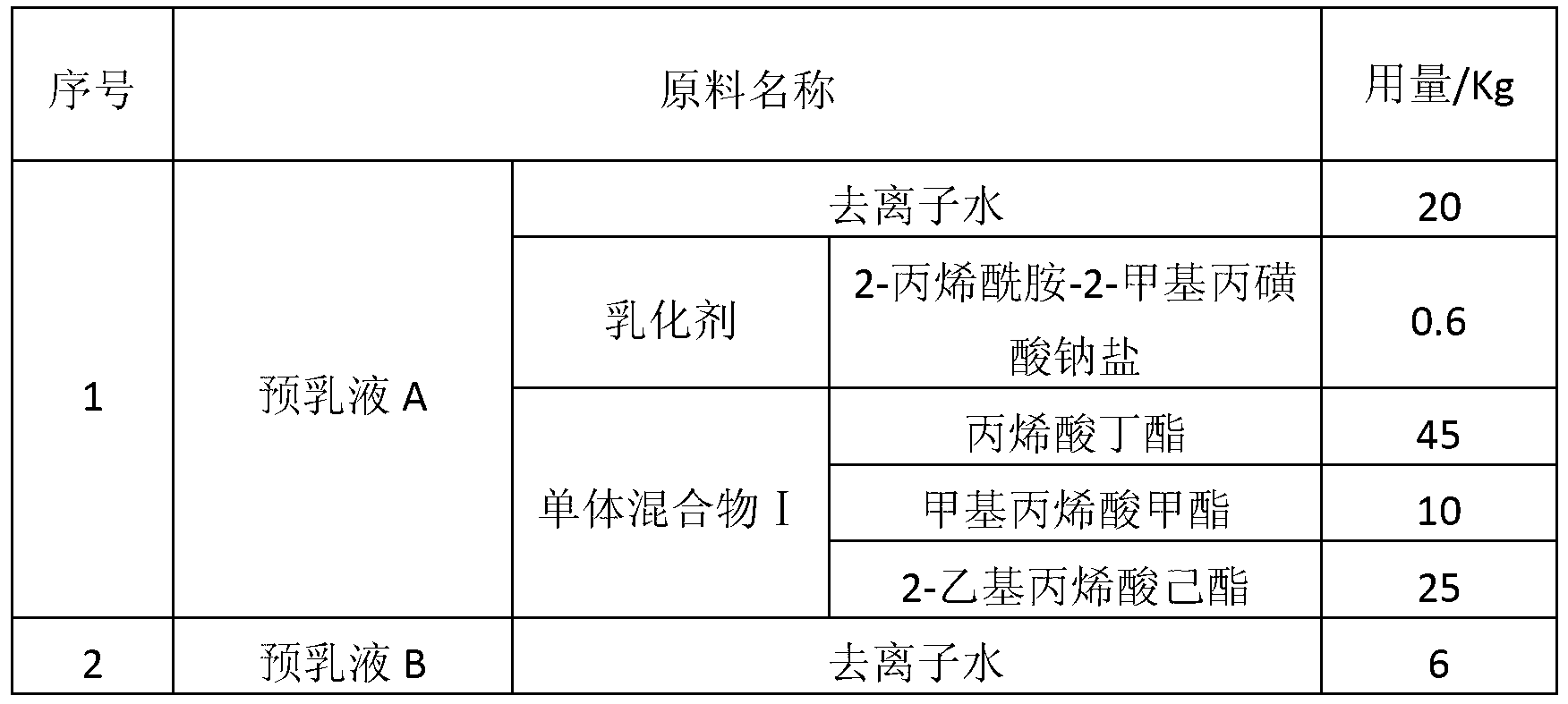

The invention discloses a water-based plastic-plastic compound adhesive for food and drug flexible packages and a preparation method thereof. The preparation method comprises the following steps of: carrying out pre-emulsification by using 20-30 parts by weight of deionized water, 0.4-1.0 part by weight of emulsifying agents and 75-90 parts by weight of monomer mixtures to obtain a pre-emulsion A; then carrying out the pre-emulsification by using 5-8 parts by weight of the deionized water, 0.2-0.3 part of the emulsifying agents and 3-20 parts by weight of the monomer mixtures to obtain a pre-emulsion B; preparing an initiator water solution C by using 1-3 parts by weight of the deionized water and 0.2-0.8 part by weight of initiators; and dropping the monomer mixture I with lower polarity and the monomer mixture II with higher polarity step by step by adopting a pre-emulsification seed emulsion polymerization process to obtain the water-based plastic-plastic compound adhesive for the food and drug flexible packages. The water-based plastic-plastic compound adhesive disclosed by the invention has the advantages of no organic solvent, no formaldehyde release, good adhesivity and high stripping strength and permanent adhesion and can be applied to a flexible package industry and substitute for a solvent type two-component polyurethane adhesive maturely applied to the present market.

Owner:DONGGUAN STAR COSM POLYMER

Single-component self-crosslink emulsion adhesive for dry type composite film and preparation method thereof

InactiveCN101168650AHigh solid contentLow viscosityLaminationLamination apparatusCross-linkSodium bicarbonate

The invention discloses single component self-cross linking emulsion tackiness agent used for dry type compound and the preparation method thereof. The invention has the preparation method as follows: firstly, part of aqueous medium, part of emulsifying agent, and part of initiating agent and baking soda are measured and added in a reactor, and are warmed up 70 to 85 DEG C; secondly, then hard monomer, soft monomer, (methyl) acrylic acid and cross linking monomer are mixed, and form pre-emulsion together with part of the emulsifying agent and water; thirdly, 1 / 10 pre-emulsion is added firstly to form assistant emulsion by reacting, and then the pre-emulsion and initiating agent aqueous solution are added synchronistically to perform reaction, the time lasts for 3 to 5 hours. The water emulsion tackiness agent obtained has good stability, and is free from poison and dissolving agent, and is favor of good health of a worker and environmental protection. A compound produced product obtained by utilizing the emulsion tackiness agent of the invention has the advantages that the ageing resistance is excellent, the viscous force is high, and the foaming is not existent during the impressing and sagging process, and the invention has wide application market.

Owner:吴达文

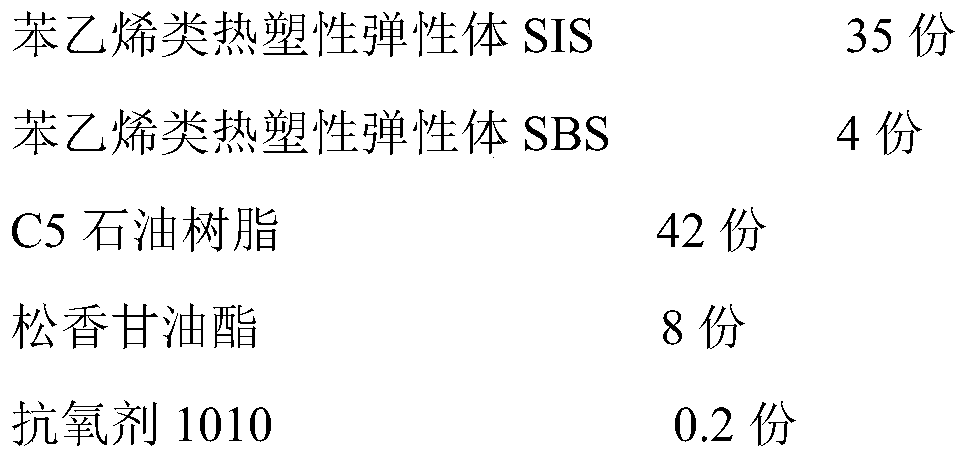

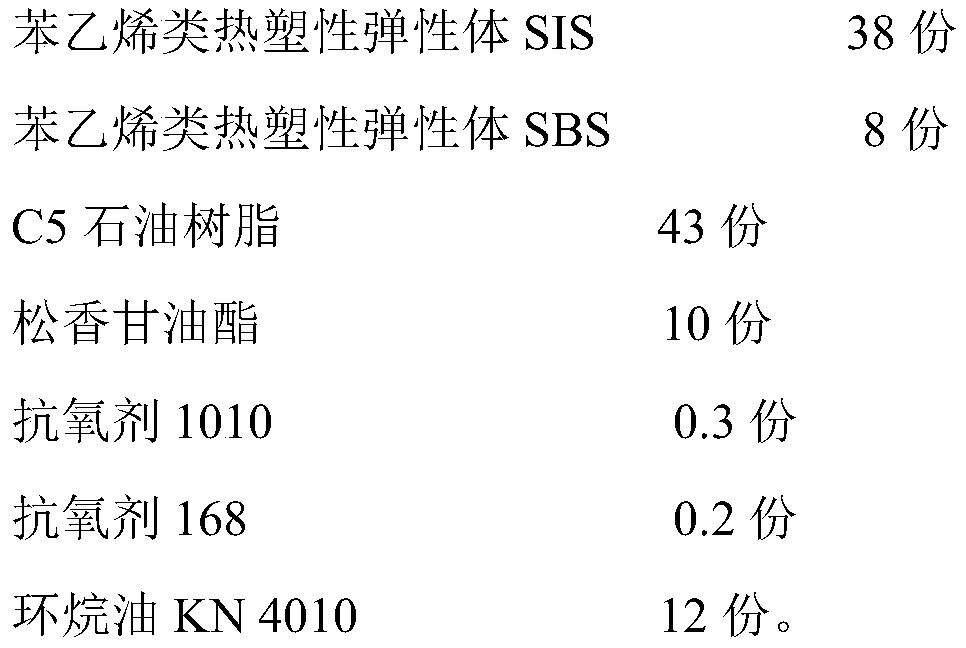

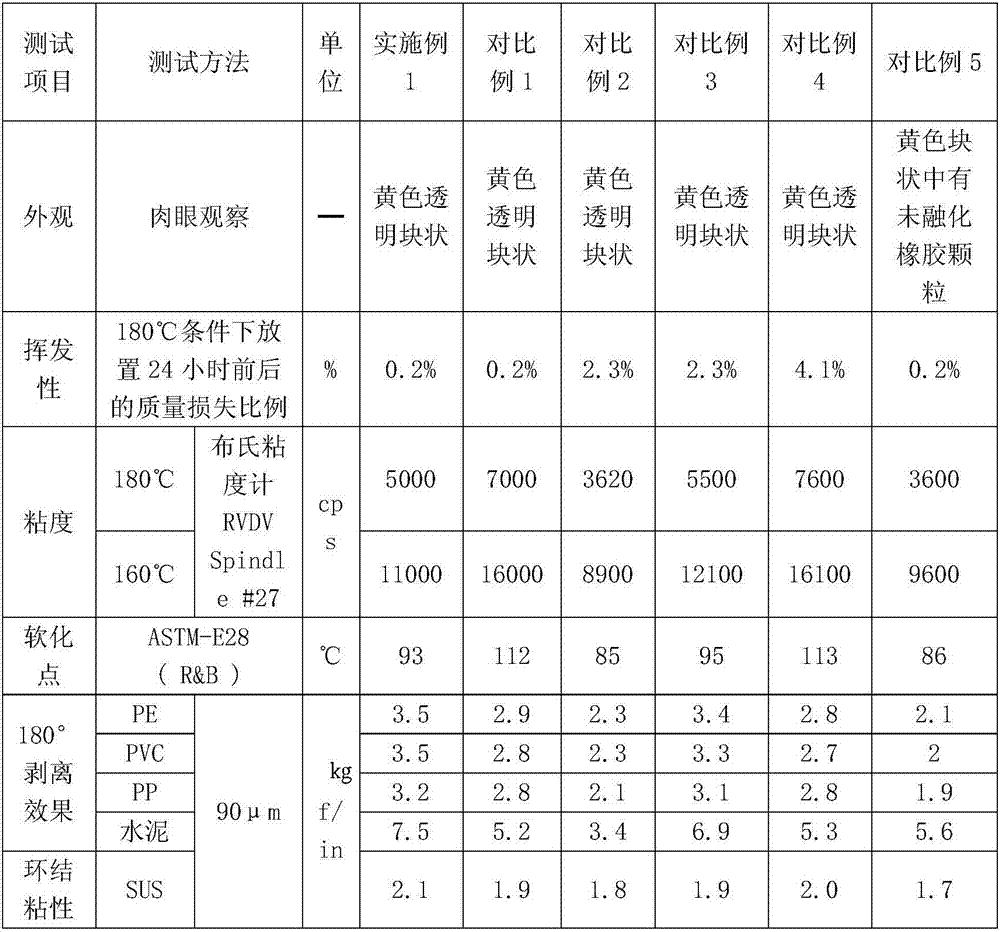

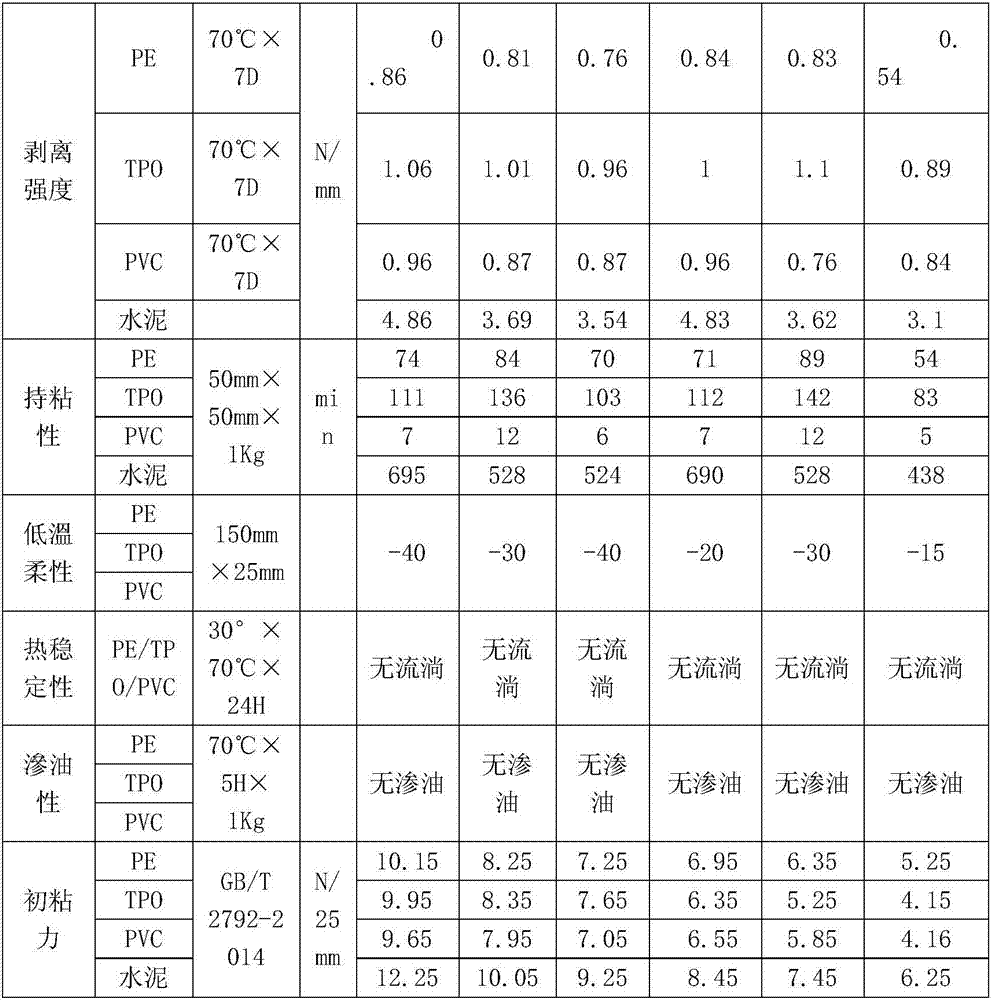

Hot-melt pressure sensitive adhesive for adhesive tapes, and preparation method thereof

InactiveCN110437778AImprove ring tackImprove peel forceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPetroleum resinAntioxidant

The invention relates to a hot-melt pressure sensitive adhesive, and concretely relates to a hot-melt pressure sensitive adhesive for adhesive tapes, and a preparation method thereof. The hot-melt pressure sensitive adhesive comprises a styrenic thermoplastic elastomer SIS, a styrenic thermoplastic elastomer SBS, petroleum resin, rosin glyceride, a primary antioxidant, an auxiliary antioxidant anda softener, wherein the styrenic thermoplastic elastomer SIS is a linear structure, the styrene content is 20-28%, and the diblock content is 20-28%; and the styrenic thermoplastic elastomer SBS is astar structure, the styrene content is 28-32%, and the diblock content is 12-18%. The purpose of the invention is to solve the problem of poor use performance of the adhesive tapes, caused by failedcombination of the initial adhesion, the permanent adhesion and the aging resistance of existing hot-melt pressure sensitive adhesives for adhesive tapes. The initial adhesion (the initial adhesion includes ring initial adhesion and 180 DEG peel strength) of the hot-melt pressure sensitive adhesive of the invention meets use requirements, and has a high adhesion and a good aging resistance. The present invention also provides the preparation method of the hot-melt pressure sensitive adhesive for adhesive tapes.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

Adhesive for die-cutting pressure-sensitive film and preparation method thereof

InactiveCN102268233AImprove performanceImprove cohesive strengthFilm/foil adhesivesEster polymer adhesivesBuffering agentAmmonia

The invention discloses an adhesive for die-cutting pressure-sensitive film, which is characterized in that it includes components and a post-treatment agent, and the components include butyl acrylate, acrylic acid, hydroxyethyl acrylate, methyl methacrylate Ester, anionic emulsifier, nonionic emulsifier, buffering agent, initiator, chain transfer agent, deionized water; wherein, the proportion of each component in the component is (by weight): butyl acrylate 40%~ 54%, acrylic acid 0.4%~0.6%, hydroxyethyl acrylate 0.5%~2%, methyl methacrylate 3%~6%, anionic emulsifier 0.27%~0.4%, nonionic emulsifier 0.1%~0.2% , buffering agent 0.05% ~ 0.08%, initiator 0.2% ~ 0.5%, chain transfer agent 0.005% ~ 0.02%, deionized water 39% ~ 53%, post-treatment agent is ammonia water with a concentration of 10% ~ 36%, the amount In order to adjust the pH of the adhesive to 6-8. It also relates to a preparation method of the adhesive. The adhesive of the invention does not come off during die-cutting, has good adhesive performance and aging resistance, and has no pollution to the environment.

Owner:永大(中山)有限公司

Solvent-free ultraviolet light dual-curing hot melting pressure-sensitive adhesive

ActiveCN109111878AHigh bonding strengthImprove sticking powerMonocarboxylic acid ester polymer adhesivesPressure sensitive film/foil adhesivesSolvent freeUltraviolet lights

The invention relates to solvent-free ultraviolet light dual-curing hot melting pressure-sensitive adhesive, which is prepared from acid-free (methyl) acrylate copolymer (A) capable of being subjectedto ultraviolet light curing by a free radical, acid-free (methyl) acrylate copolymer (B) capable of being subjected to ultraviolet light curing by a positive ion and a positive ion photoinitiator (C)which occupies 0.1-1.0% of the mass of the composite, and the ratio of a monomer A to a monomer B in the composite can be regulated at will. The pressure-sensitive adhesive formula prepared from thecomposite is subjected to the ultraviolet light curing, a peculiar high molecule interpenetrating network structure is formed, and the bonding strength and the permanent adhesion of the pressure-sensitive adhesive can be effectively improved.

Owner:SHENZHEN GUANGYE ELECTRONICS TECH

Hot melt adhesive for waterproof roll and preparation method of hot melt adhesive

ActiveCN106893536AImprove initial tackImprove cold resistanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantUltraviolet lights

The invention relates to the technical field of chemical modification high polymer materials, and in particular to a hot melt adhesive for waterproof roll and a preparation method of the hot melt adhesive. The hot melt adhesive is prepared from the following components in parts by weight: 50-200 parts of butadiene styrene rubber, 200-300 parts of benzene alkene thermoplastic elastomer rubber, 200-300 parts of tackifying resin, 5-20 parts of an antioxidant, 5-20 parts of an ultraviolet light absorbent, 0-200 parts of naphthenic oil, 0-200 parts of base oil and 100-200 parts of polyisobutene, wherein the tackifying resin is one or any combination of petroleum resin, hydrocarbon resin and monomer resin. As the butadiene styrene rubber and the benzene alkene thermoplastic elastomer rubber are compounded as a rubber matrix, the hot melt adhesive is high in compatibility; due to addition of the petroleum resin, the hydrocarbon resin and the monomer resin as the tackifying resin, the initial adhesion, the cold resistance, the thermal stability and the adhesion strength of the hot melt adhesive can be improved, the volatility of the hot melt adhesive is reduced, and particularly the adhesion property of the hot melt adhesive in damp building environments such as cement, concrete and big sand can be improved.

Owner:XINXIANG HUAYANG ADHESIVE

Environmental protection type aqueous release film

InactiveCN104961902AHigh tensile strengthDecontaminationNatural rubber coatingsPolyurea/polyurethane coatingsEmulsionPolyvinyl alcohol

The present invention provides an environmental protection type aqueous release film, which comprises a thin film layer and a release layer positioned on the thin film layer, wherein the release layer comprises, by weight, 35-45 parts of an aqueous polyethylene wax emulsion, 45-55 parts of an aqueous polyurethane emulsion, 20-30 parts of an aqueous modified polyvinyl alcohol solution, 5-10 parts of natural latex, 3-5 parts of a silane coupling agent, 0.3-0.5 part of a defoamer, and 0.3-0.5 part of a thickener, and the aqueous modified polyvinyl alcohol solution comprises, by weight, 100 parts of polyvinyl alcohol, 700-800 parts of deionized water, and 30-50 parts of modified calcium carbonate. The release film of the present invention is the aqueous environmental protection type release film, has characteristics of good peel strength and good stretching strength, and is the release film having the good comprehensive performance.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

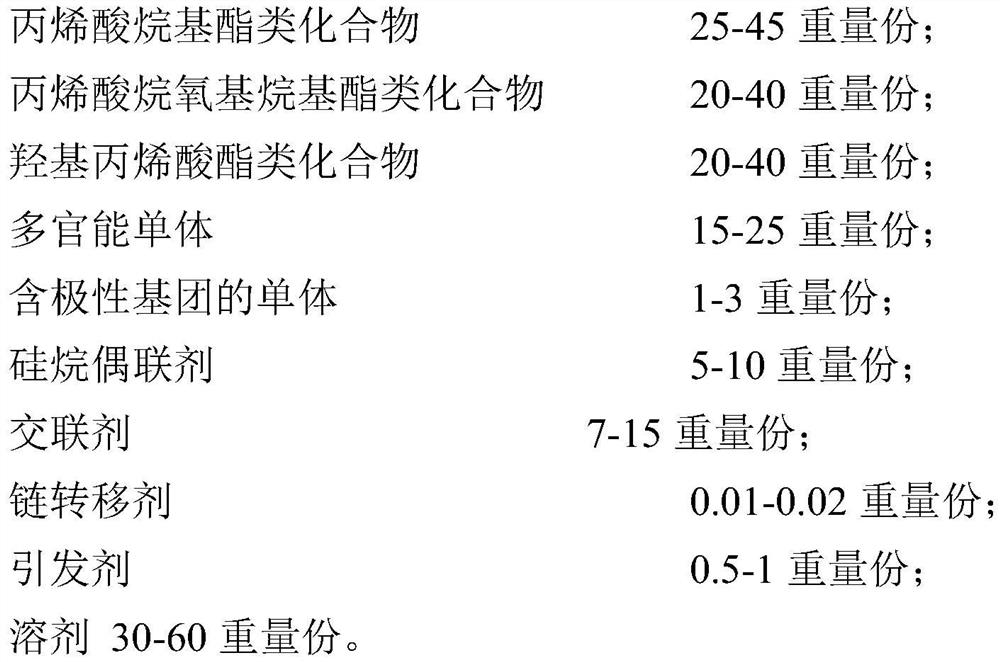

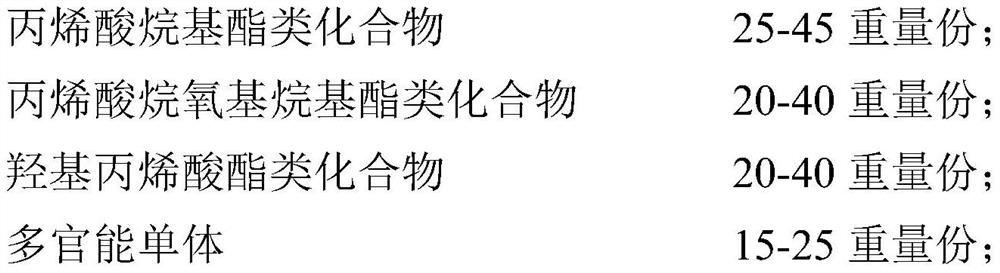

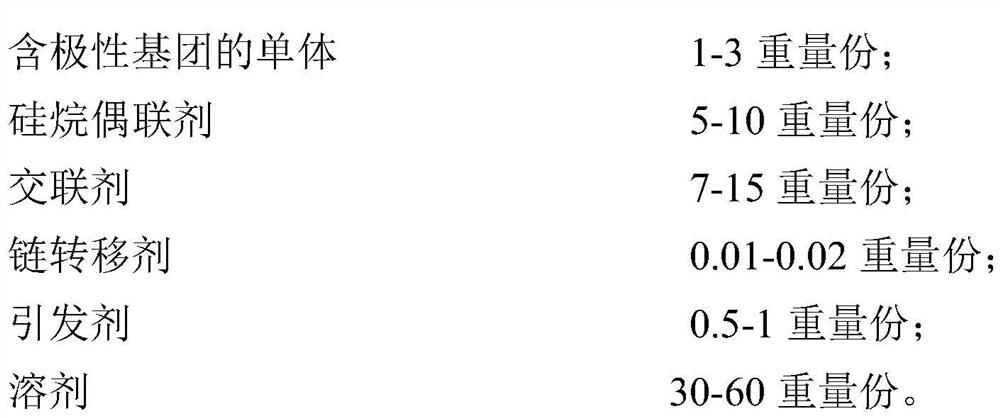

High-performance optical adhesive as well as preparation method and application thereof

InactiveCN111607341AEfficient strippingExcellent peelabilityNon-macromolecular adhesive additivesNitrile polymer adhesivesPolymer scienceChemical reaction

The invention discloses a high-performance optical adhesive as well as a preparation method and application thereof. The high-performance optical adhesive is obtained through a chemical reaction of acomposition, and the composition comprises an acrylic polymer monomer, a multifunctional monomer, a polar group-containing monomer, a silane coupling agent, a cross-linking agent, a chain transfer agent, an initiator and a solvent. The adhesive film prepared by the invention is a pressure-sensitive adhesive film, the initial adhesive force is moderate, no displacement is generated during lamination, the lamination process is similar to the existing process, and no new equipment needs to be added.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

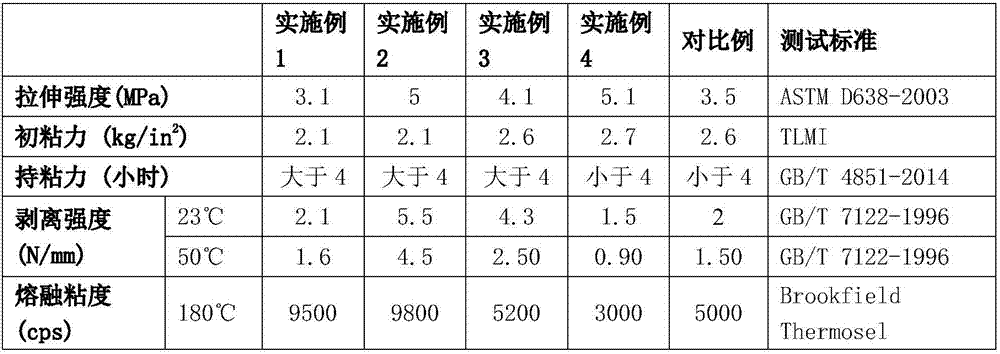

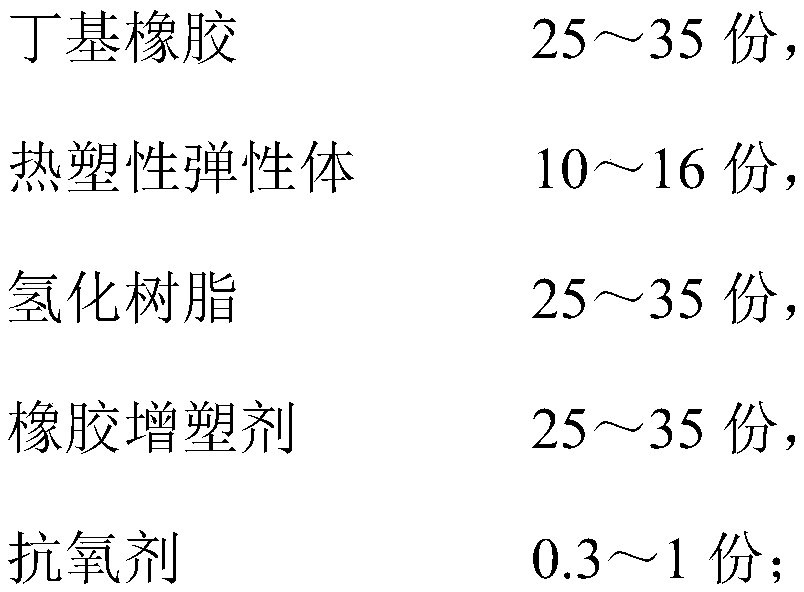

Butyl rubber hot-melt pressure-sensitive adhesive with enhanced cohesion strength and preparation method of butyl rubber hot-melt pressure-sensitive adhesive

ActiveCN107057607AImprove sticking powerHigh peel strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPlasticizerAntioxidant

The invention discloses a butyl rubber hot-melt pressure-sensitive adhesive with enhanced cohesion strength. The butyl rubber hot-melt pressure-sensitive adhesive comprises components in percentage by weight as follows: 10%-35% of butyl rubber, 3%-20% of brominated butyl rubber, 3%-18% of other matrix resin, 0.05%-1% of imidazole derivatives, 10%-35% of tackifying resin, 5%-35% of a plasticizer, 18%-55% of reinforcing filler and 0.1%-0.6% of an antioxidant. The invention further discloses a preparation method. The butyl rubber hot-melt pressure-sensitive adhesive has reversible hot workability and has the capacity of coating and bonding one more time in the heating state.

Owner:成都微熵科技有限公司

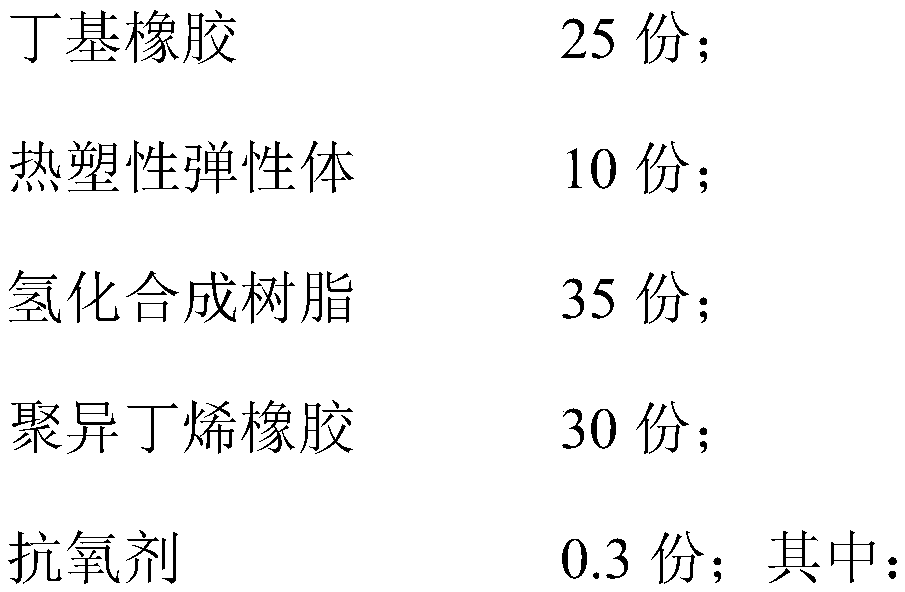

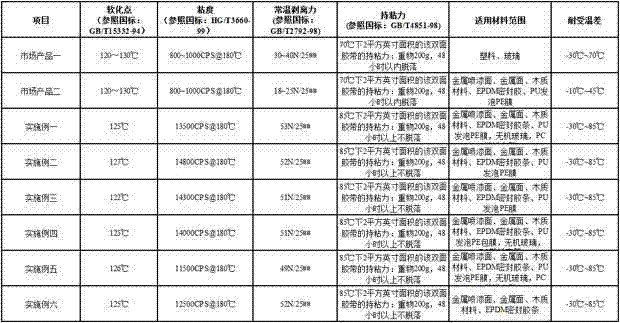

Thermal-aging anti-adhesion-failure hot-melt pressure-sensitive adhesive and preparation method thereof

ActiveCN109054688AHigh peel strengthGood adhesionMineral oil hydrocarbon copolymer adhesivesAntioxidantIsoprene

The invention relates to a thermal-aging anti-adhesion-failure hot-melt pressure-sensitive adhesive and a preparation method thereof. The thermal-aging anti-adhesion-failure hot-melt pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 15 to 35 parts of butyl rubber, 10 to 20 parts of thermoplastic elastomer, 25 to 35 parts of synthetic resin hydride, 25 to35 parts of rubber plasticizer and 0.3 to 1 part of antioxidant, wherein the thermoplastic elastomer is a mixture of a styrene-ethylene-butylene-styrene (SEBS) segmented copolymer and a styrene-ethylene-propylene-styrene (SEPS) segmented copolymer. The SEBS and SEPS are added into the butyl rubber, a proper amount of SEBS and SEPS of appropriate types is added particularly at the same time, and the raw materials together with hydrogenated synthetic resin, the rubber plasticizer and the antioxidant are prepared into the hot-melt pressure-sensitive adhesive of a specific formula. The hot-melt pressure-sensitive adhesive still has higher peeling strength, high substrate adhesive property and thermal-aging anti-adhesion-failure effect.

Owner:HUIZHOU NENGHUI CHEM CO LTD

OPP release film

InactiveCN104945731AGood weather resistanceHigh tensile strengthSynthetic resin layered productsPolymer sciencePolyvinyl alcohol

The present invention provides an OPP release film, wherein the thin film layer comprises the following components: OPP, OPP weathering resistance masterbatch, nanometer silica, 3-aminopropyltriethoxysilane, butyl acrylate, methyl methacrylate 15, octadecyl methylacrylate, polyethylene glycol, ethanol, deionized water, natural latex, a defoamer and a thickening agent, the release layer comprises the following components: an aqueous polyvinyl acetate emulsion, an aqueous polyurethane emulsion, an aqueous modified polyvinyl alcohol solution, natural latex, 3-aminopropyltriethoxysilane, a defoamer and a thickening agent, and the aqueous modified polyvinyl alcohol solution comprises polyvinyl alcohol, deionized water, and modified calcium carbonate. The release film of the present invention has characteristics of good peel strength, good mechanical property, and good weather resistance, and is the release film having the good comprehensive performance.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

Preparation method of high-solid-content low-viscosity pressure-sensitive adhesive

InactiveCN106349982AHigh solid contentImprove sticking powerEster polymer adhesivesFunctional monomerPh control

The invention relates to a preparation method of a high-solid-content low-viscosity pressure-sensitive adhesive. The preparation method specifically includes the steps of 1), preparation of raw materials; 2), preparation of pre-emulsion; 3), preparation of the high-solid-content low-viscosity pressure-sensitive adhesive; the raw materials include, by weight, 40-70 parts of butyl acrylate, 5-15 parts of acrylate esters, 0.5-10 parts of carboxyl containing functional monomers, 0.01-0.1 part of a buffering agent, 0.7-3 parts of an emulsifying agent, 0.3-3 parts of an initiating agent, 0.5-1.5 parts of a defoaming agent WBA, 20-40 parts of deionized water, 0.1-1 part of an oxidizing agent, 0.1-1 part of a reducing agent and 0.5-10 parts of a pH controlling agent. The preparation method has the advantages that the raw materials and use amount of the same are changed, the type of the monomers is reduced, the polymers capable of promoting stability of the pressure-sensitive adhesive and reducing viscosity of the adhesive are selected, high solid content of the pressure-sensitive adhesive is guaranteed, and viscosity of the pressure-sensitive adhesive is lowered.

Owner:JIANGSU GUOJIAO CHEM TECH

Formula of environment-friendly particle hot-melt type pressure-sensitive adhesive and preparation method for adhesive

InactiveCN104610892ASolve the problem that cannot be recycledSolve process problemsMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantPolystyrene

The invention discloses a formula of an environment-friendly particle hot-melt type pressure-sensitive adhesive. The hot metal adhesive is prepared from the following components in parts by weight: 5-8 parts of polystyrene-polyisoprene-polystyrene segmented copolymer, 5-8 parts of styrene-ethylene / butadiene-styrol copolymer, 5-10 parts of ethylene / vinyl acetate copolymerized resin, 30-40 parts of a softener, 0.5-1 parts of an antioxidant, 53-68 parts of a thickening agent, and 2-5 parts of polyisobutene. The invention further provides a method for preparing the environment-friendly particle hot-melt type pressure-sensitive adhesive. According to the formula and the preparation method disclosed by the invention, the particle hot-melt type pressure-sensitive adhesive is prepared by mixing a reproducible naturally synthesized epoxy plant oil as a raw material, synthetic rubber and resin as well as rubber oil, so that the problems that in the current pressure-sensitive adhesive industry, most of the raw materials cannot be recycled and toxic reagents are added in the process can be solved; and the product is environment-friendly, safe and harmless, easy to adhere, low in possibility to remove and non-destructive while being peeled off, and can be widely applied to the fields of sanitary material, medical treatment and the like.

Owner:湖南鑫湘环保胶业科技有限公司

Hot melt pressure-sensitive adhesive

ActiveCN103937431AImprove sticking powerImprove peel forceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceMethacrylate methyl

The invention relates to a hot melt pressure-sensitive adhesive, and particularly relates to a hot melt pressure-sensitive adhesive which can be especially applicable to fixed sealing of display screens of hand-held electronic devices such as mobile telephones, tablet computers and the like and for example preparation of door / window sealing rubber strips. The hot melt pressure-sensitive adhesive mainly comprises 100 parts of methyl methacrylate and butyl acrylate copolymer, 1-20 parts of butadiene-styrene random copolymer, 50-350 parts of tackifier (pentalyn or petroleum resin), 10-100 parts of naphthenic oil and 5-100 parts of fluid rubber. The hot melt pressure-sensitive adhesive provided by the invention has high permanent viscous force and release force, can resist a high-low temperature difference from -30 DEG C to 85 DEG C, and is favorable in sealing effect; the hot melt pressure-sensitive adhesive is applicable to a wide range of surfaces, is particularly applicable to fixing of display screens of electronic devices and brackets of electronic components, and can also achieve favorable process effect when being used in the aspects of preparation of door / window sealing rubber strips and the like; and the hot melt pressure-sensitive adhesive is simple in preparation process, has low requirements for process and devices, and is suitable for popularization and production.

Owner:广州伟一胶粘制品有限公司

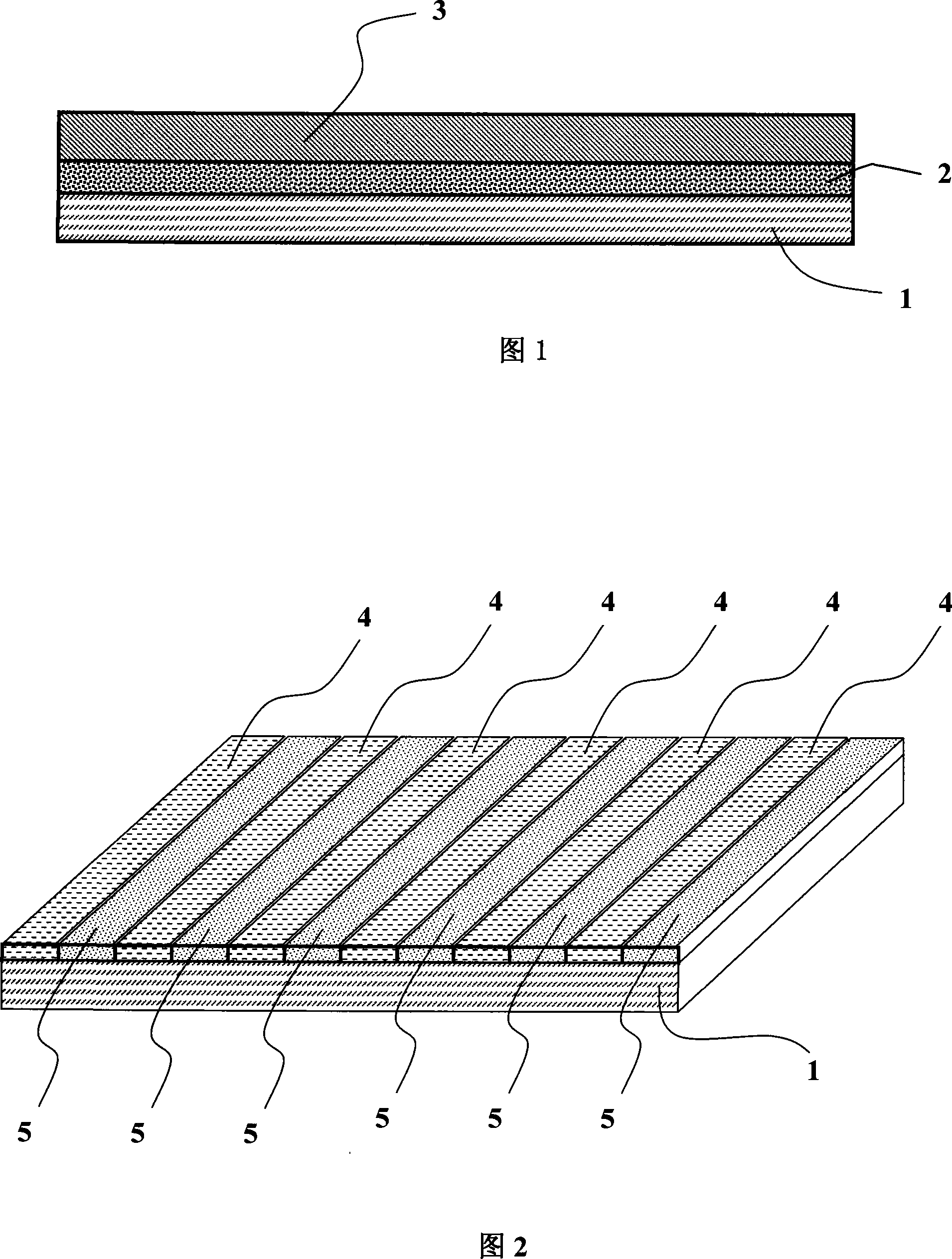

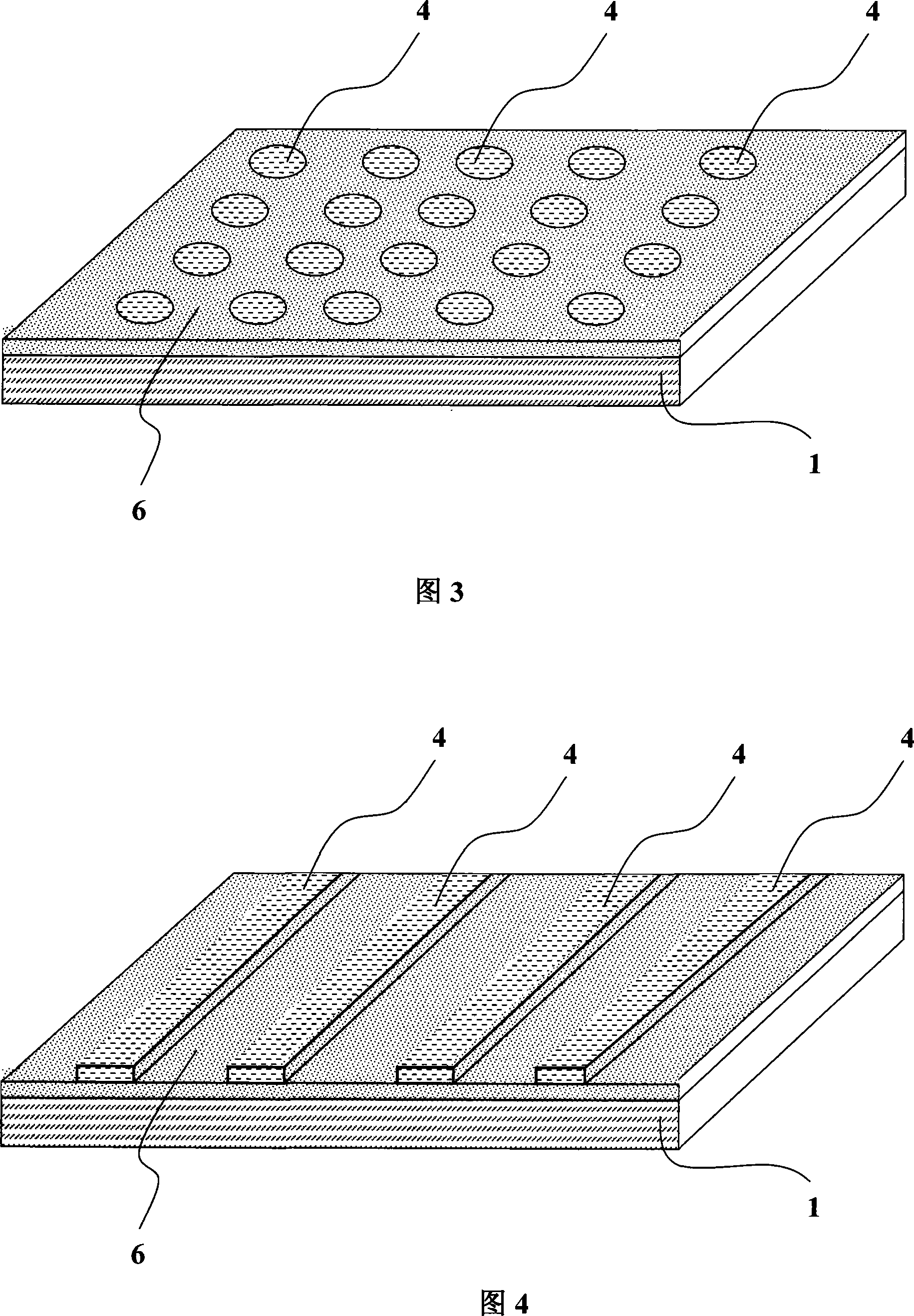

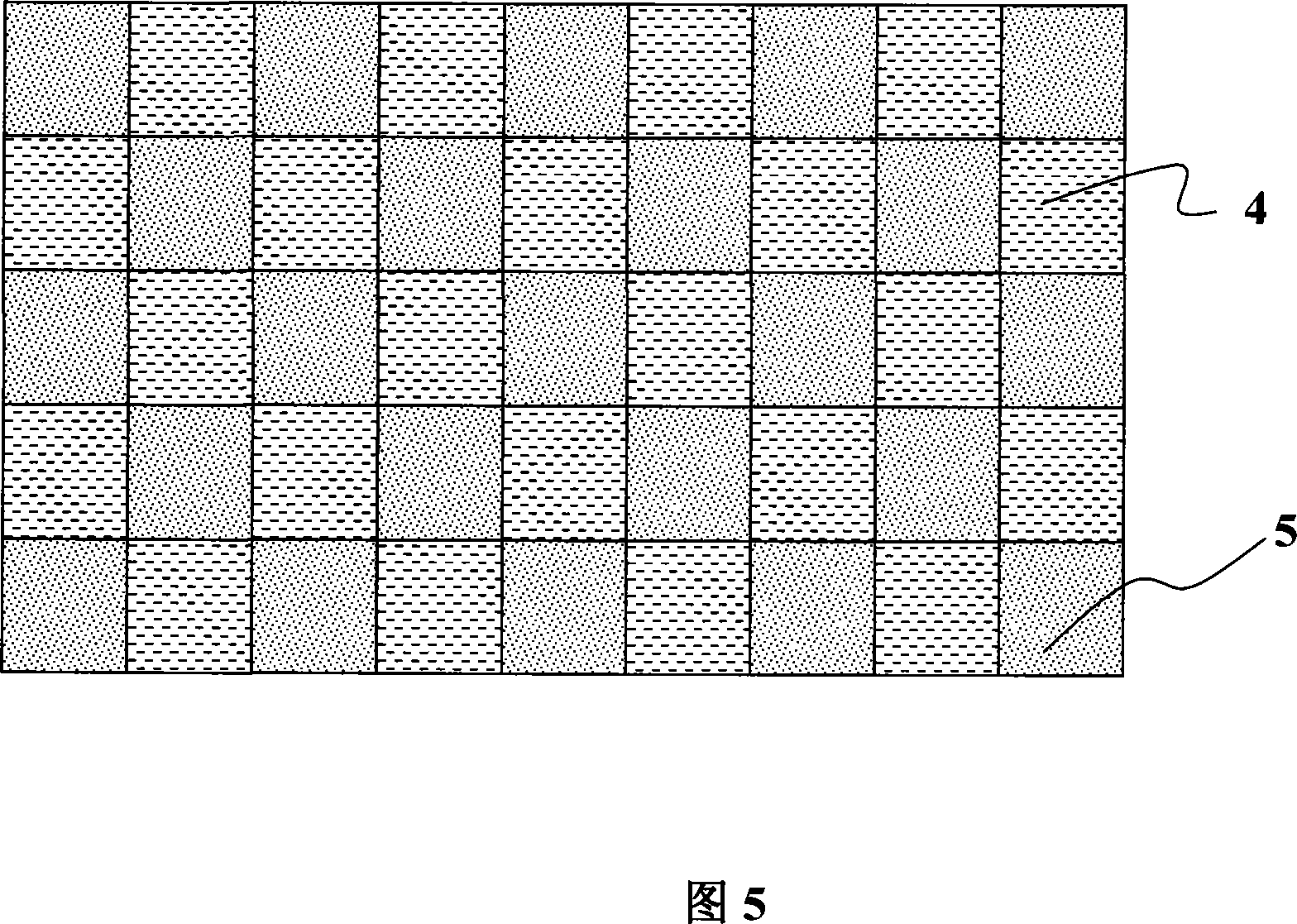

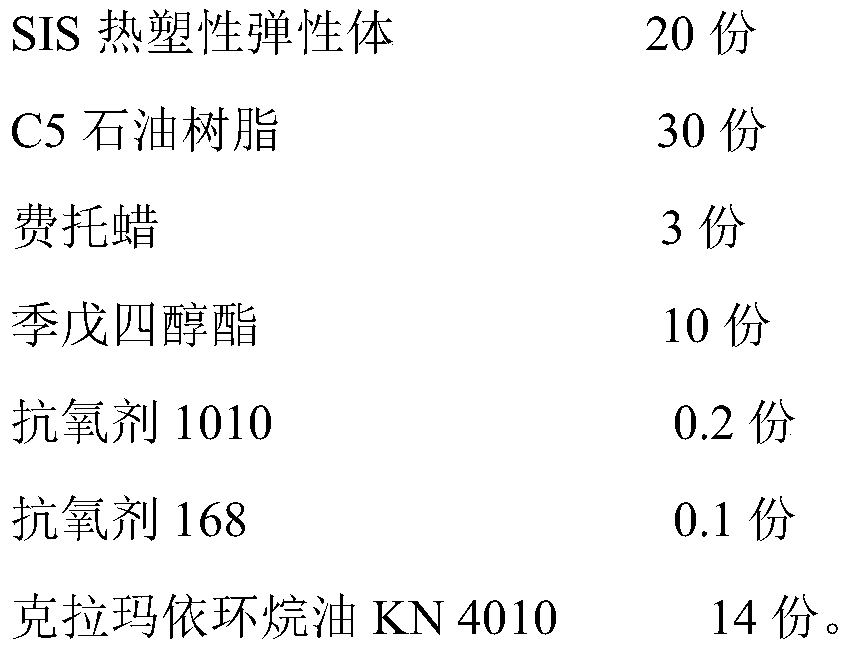

Multi-component scotch tape products

InactiveCN101205446AImprove initial tackImprove sticking powerFilm/foil adhesivesScotch tapeEngineering

The invention provides a multi-component self-adhesive product, wherein an adhesive layer is at least divided into a plurality of components such as several A component units and several B component units, etc.; the A component units and the B component units are arranged at intervals and are respectively coated on the backside of a surface material layer. The invention improves the initial viscidity and hold tack of the self-adhesive at the same time, thereby realizing fast and firm automatic labeling; moreover, the invention is suitable to paste A type material and B type material, in particular to be used in the anti-fake field.

Owner:KHAINAN YAYUAN ANTI TSOUNTERFEIT TECH RES INST

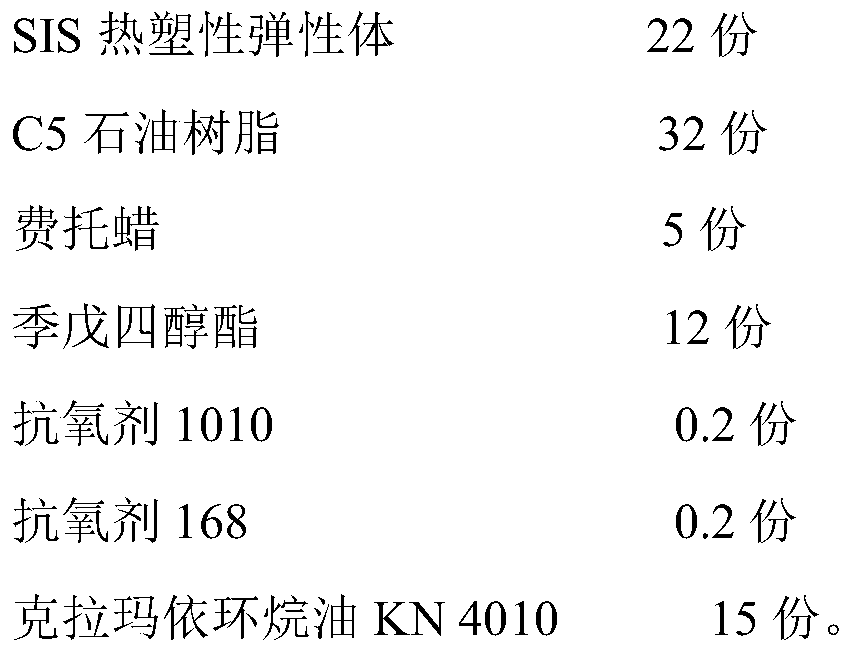

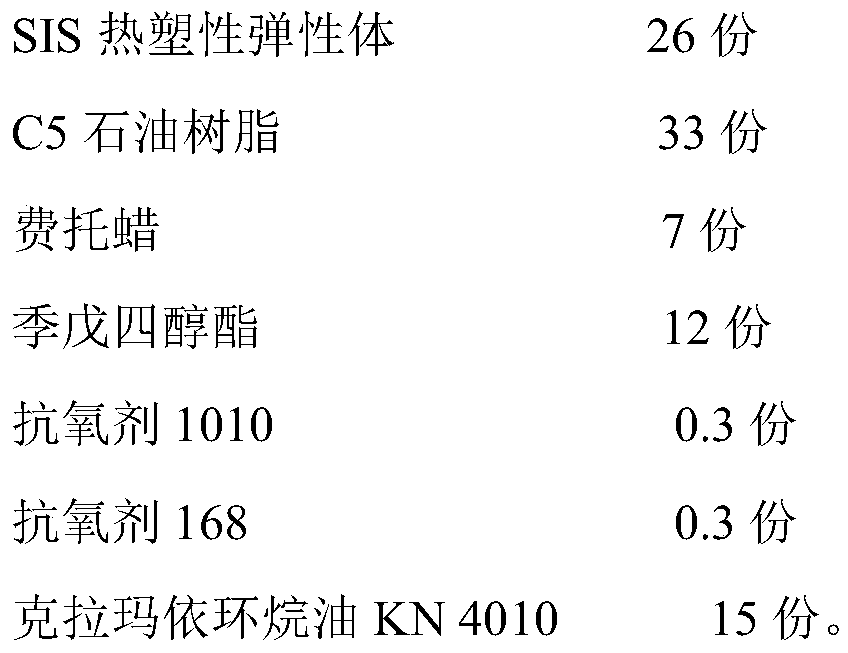

Modified hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN110734719AReduce the amount of glue remainingImprove sticking powerMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAnoxomerPolystyrene

The invention relates to a hot-melt pressure-sensitive adhesive, in particular to a modified hot-melt pressure-sensitive adhesive and a preparation method thereof. The modified hot-melt pressure-sensitive adhesive comprises the following components: a styrene thermoplastic elastomer, petroleum resin, Fischer-Tropsch wax, pentaerythritol ester, a main antioxidant, an auxiliary antioxidant and a softener; wherein the styrene thermoplastic elastomer is of an SIS linear structure, the content of styrene is 15%-21%, and the content of diblock is 50%-75%. The C5 petroleum resin and the pentaerythritol ester are dissolved in both the rubber phase (polyisoprene phase) and the hardness phase (polystyrene phase) of the thermoplastic elastomer. The two tackifying resins act together to improve the compatibility of the hot melt pressure sensitive adhesive. The raw materials cooperate with each other to obtain the hot melt pressure sensitive adhesive which has good fluidity, meets the use requirements of adhesive force, does not increase peel strength with time, and can be peeled off from the substrate cleanly.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

Environment-friendly release film

InactiveCN105733429AHigh tensile strengthDecontaminationPolyurea/polyurethane coatingsEmulsionUltimate tensile strength

The invention discloses an environmentally friendly release film, which comprises a film layer and a release layer located on the film layer. The release layer comprises the following components in proportion by weight: 40 parts of water-based polyethylene wax emulsion; water-based polyurethane emulsion 50 parts; 25 parts of water-based modified polyvinyl alcohol solution; 7 parts of natural latex; 4 parts of silane coupling agent; 0.4 part of defoamer; 0.4 part of thickener; It includes the following components: 90 parts of polyvinyl alcohol; 750 parts of deionized water; 40 parts of modified calcium carbonate. The environmentally friendly release film of the invention has the characteristics of high peel strength and high tensile performance, and can be widely used in various fields of electronics, communication, machinery and the like.

Owner:李文东

Sulfur-free polyacrylate emulsion pressure-sensitive adhesive and preparing method thereof

ActiveCN103351832AAvoid introducingAvoid yellowingNon-macromolecular adhesive additivesEster polymer adhesivesEmulsionSulfur

The invention discloses a sulfur-free polyacrylate emulsion pressure-sensitive adhesive and preparing method thereof. The sulfur-free polyacrylate emulsion pressure-sensitive adhesive includes the following raw materials in parts by weight: 95-100 parts of sulfur-free polyacrylate emulsion, 0.05-1.0 part of HD-M wetting agent and 0.05-0.2 part of mineral oil defoamer. According to the invention, raw materials such as the sulfur-free polyacrylate emulsion emulgator, HD-M wetting agent and azo initiator are adopted, and the introduction of sulfur is completely avoided, so that the problems of yellowed emulsion films and color change caused by the contact with metal base materials are solved, the appearance of used products is improved; selected materials are reasonably matched, a high-transparency adhesive tape can be obtained, besides, the peel strength and permanent adhesion of the adhesive tape are higher.

Owner:DONGGUAN FURONG CHEM

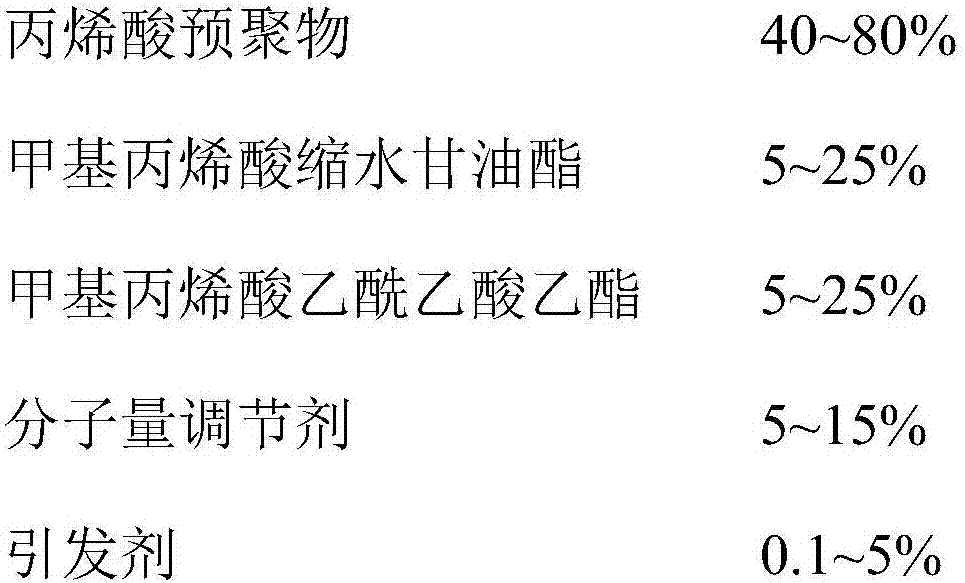

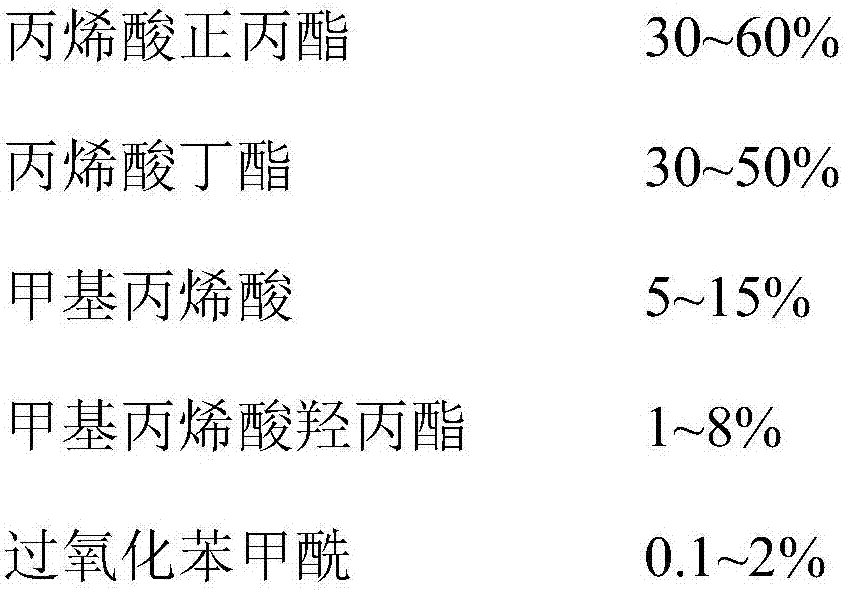

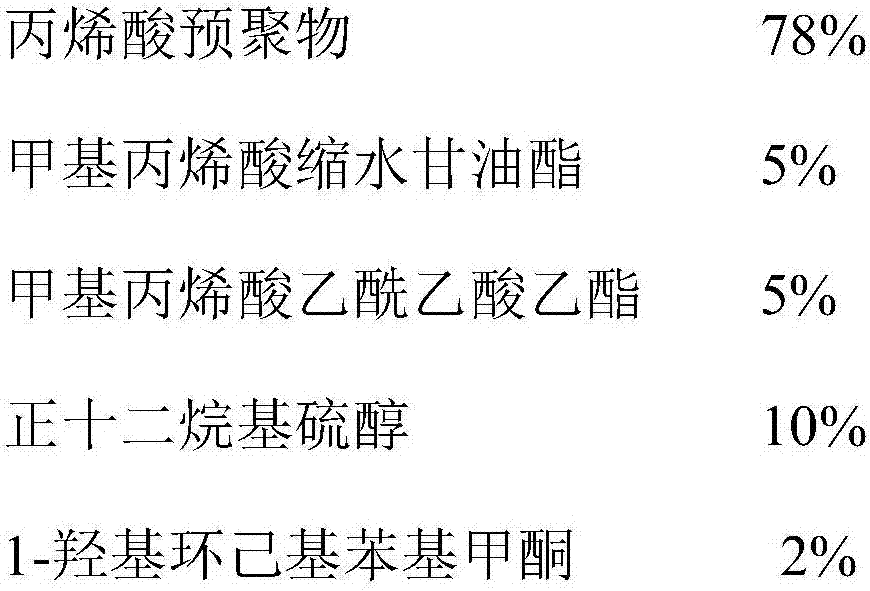

OCA optical cement for bonding frame of cell phone

InactiveCN106916538ALow initial viscosityLow costFilm/foil adhesivesOrganic non-macromolecular adhesiveBenzoyl peroxideGlycidyl methacrylate

The invention provides an OCA optical cement for bonding the frame of a cell phone. The optical cement is prepared from the following substances in percentage by weight: 40 to 80% of acrylic acid prepolymer, 5 to 25% of glycidyl methacrylate, 5 to 25% of acetoacetoxy ethyl methacrylate, 5 to 15% of molecular weight modifier, and 0.1 to 5% of initiator; wherein the molecular weight modifier is one of n-dodecyl mercaptan, tert-dodecyl mercaptan, and isooctyl 3-mercaptopropionate; and the acrylic acid prepolymer is prepared from the following substances in percentage by weight after reactions: 30 to 60% of n-propyl acrylate, 30 to 50% of butyl acrylate, 5 to 15% of methacrylic acid, 1 to 8% of hydroxypropyl methacrylate, and 0.1 to 2% of benzoyl peroxide. The OCA optical cement has the advantages of low initial bonding, high permanent adhesion, good light-admitting quality, and low cost.

Owner:广东鼎立森新材料有限公司

Environment-friendly type polyester hot-melt pressure-sensitive adhesive, and preparation method thereof

ActiveCN109957372AImprove cohesive strengthImprove sticking powerPolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolyesterPolyol

The invention discloses an environment-friendly type polyester hot-melt pressure-sensitive adhesive, and a preparation method thereof, and belongs to the field of hot-melt pressure-sensitive adhesive.The environment-friendly type polyester hot-melt pressure-sensitive adhesive comprises, by weight, 90 to 100 parts of polyester polyol A, 0.01 to 10 parts of polyester polyol B, 0.01 to 30 parts of isocyanate, 0 to 5 parts of an accelerator, and 0.01 to 1 part of a catalyst. The polyester hot-melt pressure-sensitive adhesive of the invention can be prepared from bio-based monomers, is excellent in adhesive properties, possesses biodegradability, is an environment-friendly pressure sensitive adhesive, and can be widely used in the fields of adhesive tape, sticky notes, electronic packaging, and plaster.

Owner:JIANGNAN UNIV

Water-based environment-friendly adhesive suitable for adhesion between ground decoration layer and cushion layer

ActiveCN105754521AImprove initial tackImprove sticking powerNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterWater based

The invention provides a water-based environment-friendly adhesive suitable for adhesion between a ground decoration layer and a cushion layer. The adhesive is prepared from following components by weight through evenly mixing: 35%-60% of an acrylic resin emulsion, 10%-50% of a tackifying resin emulsion and 2%-10% of a plasticizer, wherein the acrylic resin emulsion is one or more of a styrene-modified acrylic resin emulsion, a fluorine-modified acrylic resin emulsion, a polyurethane acrylic resin emulsion and a silicone-modified acrylic resin emulsion which have the glass transition temperature ranging from subzero 30 DEG C to 0 DEG C, the solid content percentage ranging from 57wt% to 75wt% and the molecular weight ranging from 100,000 to 500,000; the tackifying resin emulsion is one or more of a petroleum resin emulsion, a terpene resin emulsion and a rosin resin emulsion which have the softening temperature ranging from 20 DEG C to 80 DEG C, the solid content percentage ranging from 35% to 55% and the molecular weight ranging from 2,000 to 3,000; the plasticizer is one or more of a benzoate plasticizer, a phthalic acid ester plasticizer, a polyester plasticizer and a polyol ester plasticizer. The adhesive has good initial adhesion and wonderful flexibility, can be uncovered and adhered repeatedly and can be produced with the simple production technology.

Owner:广东龙湖科技股份有限公司

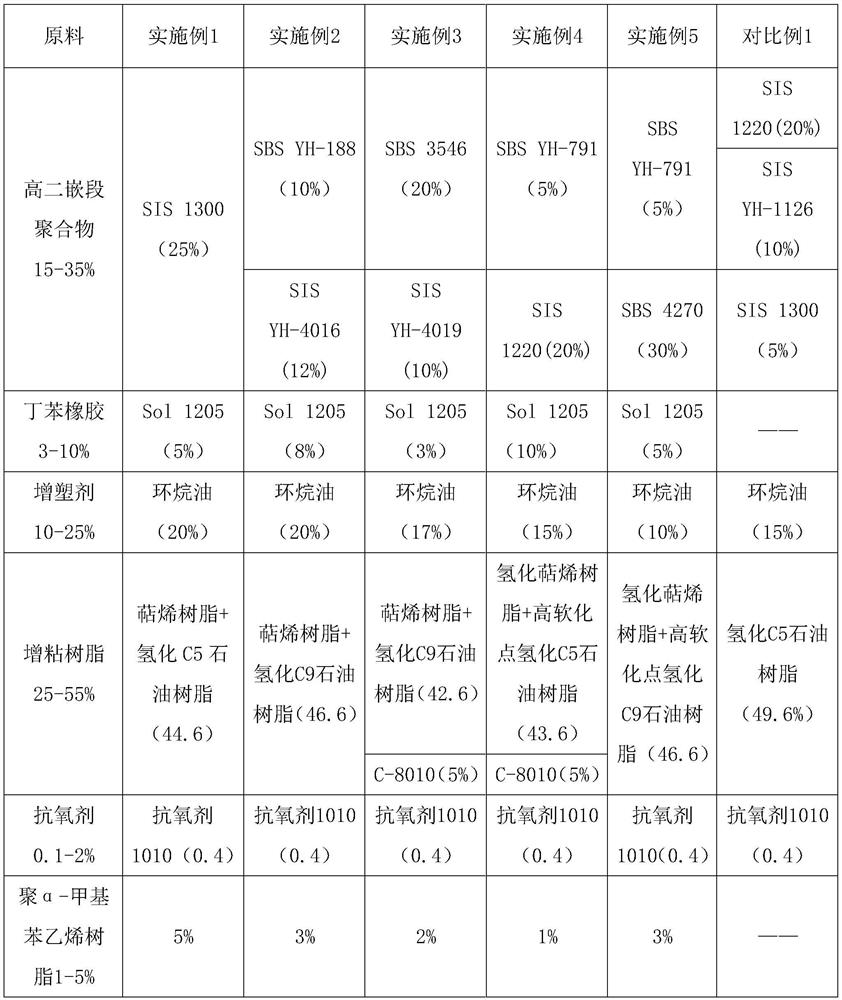

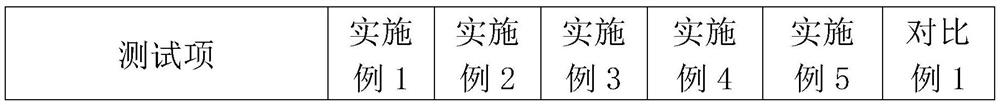

High-performance left and right paste hot melt adhesive and preparation method thereof

ActiveCN113388348AImprove mechanical propertiesGood initial adhesionMineral oil hydrocarbon copolymer adhesivesHydrocarbon polymer adhesivesPolymer sciencePlasticizer

The invention discloses a high-performance left and right paste hot melt adhesive and a preparation method thereof. The high-performance hot melt adhesive comprises the following components in percentage by mass: 15-35% of a polymer, 3-10% of butadiene styrene rubber, 10-25% of a plasticizer, 25-55% of tackifying resin, 0.1-2% of an antioxidant and 1-5% of poly-alpha-methylstyrene resin. The sum of the mass percentages of the components is 100%. According to the prepared high-performance left and right paste hot melt adhesive, excellent mechanical properties are achieved through the butadiene styrene rubber and the fully hydrogenated petroleum resin, so that the hot melt adhesive has excellent initial adhesion and stripping force, and by adding SEBS or SBS or SIS with high tensile strength and matching with the poly-alpha-methylstyrene resin, the hot melt adhesive can resist high temperature and has excellent holding power and high thermal stability; and the hot melt adhesive is applied to the fields of magic buckles of paper diapers, PP stickers, magic tapes and the like , and the function of repeated sticking can be achieved through the left and right paste hot melt adhesive.

Owner:佛山南宝高盛高新材料有限公司

Glue with high permanent adhesive force

ActiveCN102010681ANot easy to warpNot easy to ageMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesTemperature resistanceWeather resistance

The invention relates to glue with high permanent adhesive force, which is prepared from the following components in percentage by mass: 13-17 percent of natural rubber, 18-22 percent of petroleum rubber SIS, 18-22 percent of petroleum resin, 18-22 percent of naphthenic oil, 18-22 percent of natural terpene resin, 0.5-1.5 percent of antioxidant, and 3.5-4.5 percent of rubber accelerator. The glue has the beneficial effects that packed boxes are difficult to curl and permanent adhesive force is improved to above 100H from below 3H; the glue is difficult to age; the fusing property of molten raw materials is good; the temperature resistance and weather resistance of the glue are stable; and nationalized natural resources are fully utilized, production cost is effectively reduced and market competitiveness of products is improved.

Owner:江西永冠科技发展有限公司

Adhesive for alkali resistant acrylate glass fiber mesh cloth shaping, and preparation method thereof

InactiveCN102533186BImprove sticking powerExcellent dry resistanceGraft polymer adhesivesPolymer adhesivePolymer science

Owner:BEIJING COMENS NEW MATERIALS

High-performance water-based acrylate pressure-sensitive adhesive and manufacturing process thereof

ActiveCN103665253AImprove stabilityImprove performanceEster polymer adhesivesIsooctyl acrylatePotassium persulfate

A high-performance water-based acrylate pressure-sensitive adhesive comprises the following components in parts by weight: 75-120 parts of monomers, 0.3-0.5 part of sodium bicarbonate, 1.5-3 parts of an emulsifier, and 0.2-0.5 part of an initiator, wherein the monomer comprises the following components in parts by weight: 40-60 parts of 2-ethylhexyl acrylate, 20-30 parts of vinyl acetate, and 15-30 parts of glycidyl methacrylate; the emulsifier comprises the following components in parts by weight: 0.5-1 part of sodium dodecyl sulfate and 1-2 parts of double phenethyl polyoxyethylene ether; the initiator is 0.2-0.5 part of potassium persulfate. The pressure-sensitive adhesive has relatively high initial adhesion, permanent adhesion and solvent resistance.

Owner:永一胶粘(中山)有限公司

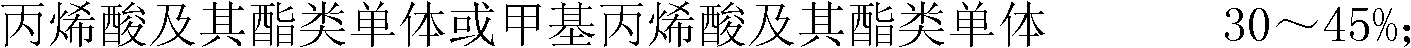

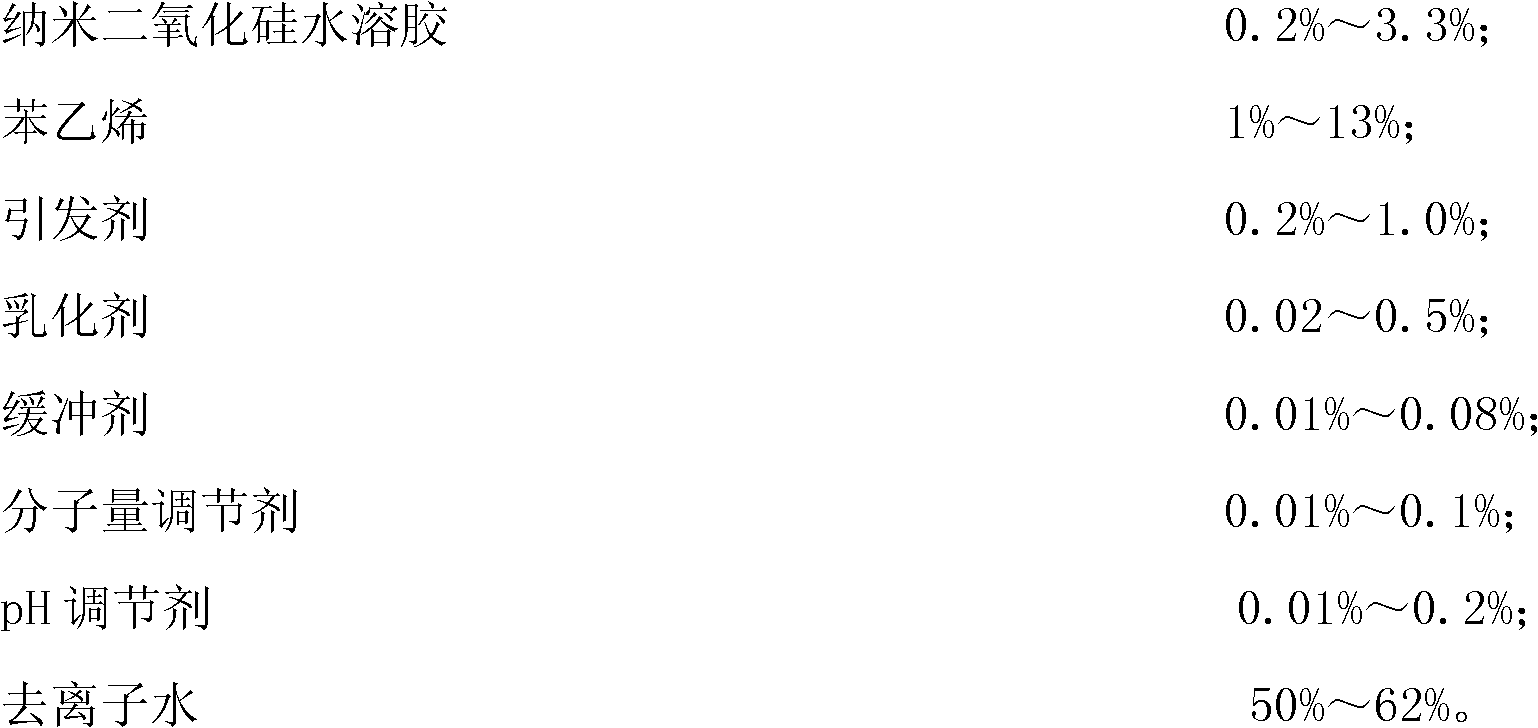

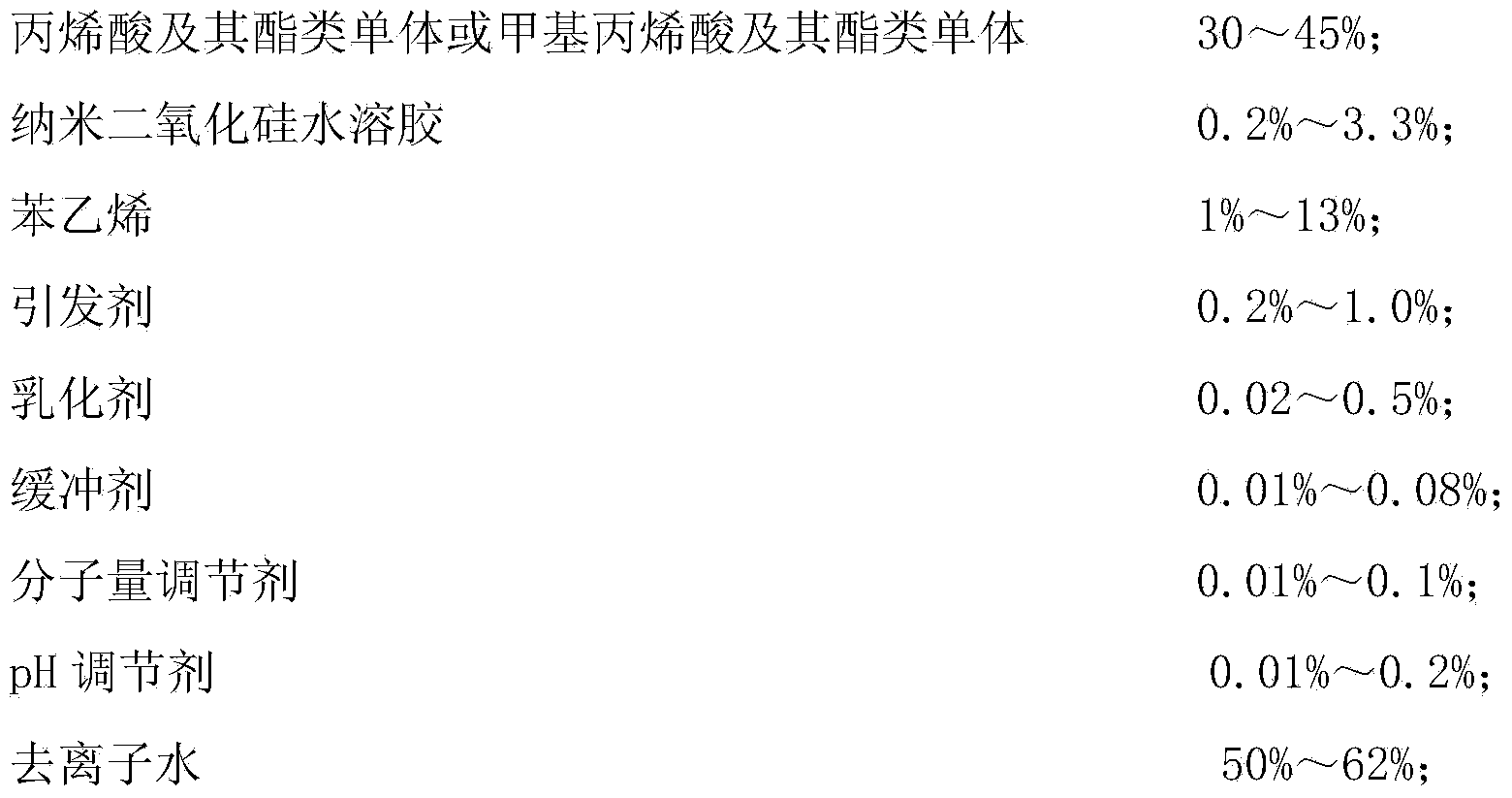

Twist-woven glass fiber adhesive tape and preparation method thereof

The invention relates to a twist-woven glass fiber adhesive tape. The twist-woven glass fiber adhesive tape comprises twist-woven glass fiber gauze, wherein the substrate of the twist-woven glass fiber gauze is formed based on the twist-woven structure technology, two warp yarns, a single weft yarn and two glass fiber yarns are adopted, and the glass fiber yarns are independently wrapped with the warp yarns and then twist-woven with the weft yarns to form the twist-woven glass fiber adhesive tape; after being twist-woven, the two warp yarns are combined to firmly wrap and clamp the weft yarn. The twist-woven glass fiber adhesive tape has the following beneficial effects: 1) in the production and manufacturing processes of the adhesive tape, the glass fiber gauze does not move or deform, and thus the appearance of the adhesive tape is beautiful; 2) in the twist-weaving process, the previously separate warp yarns are automatically combined into the double-strand wrap yarn, so that the longitudinal tensile strength is improved by two times, and super strong tensile strength and impact resistance are realized; 3) a solvent parting agent is used for forming the coating, and the cases of falling and color change of a solvent-free parting agent are overcome; 4) the glue is high in perspectivity and high in permanent adhesion; 5) the twist-woven glass fiber adhesive tape has excellent comprehensive properties such as water resistance, insulation, shock resistance, explosion resistance and the like.

Owner:SHANGHAI YONGGUAN ADHESIVE PROD CORP LTD

Hot-melt adhesive for parchment paper heat-transfer hot stamping and preparation method thereof

ActiveCN105969259AImprove bondingImprove initial tackMineral oil hydrocarbon copolymer adhesivesHot stampingAcrylic resin

The invention discloses a hot-melt adhesive for parchment paper heat-transfer hot stamping and a preparation method thereof. The hot-melt adhesive is prepared from the following raw materials in percentage by weight: 5-15% of ester-soluble polyamide, 8-15% of polyvinyl acetal, 5-15% of acrylic resin, 1-3% of vinyl chloride-vinyl acetate resin, 2-4% of tackifying resin and 59-79% of solvent. The hot-melt adhesive is mainly used for parchment paper heat-transfer hot stamping, and the pattern obtained by hot stamping has favorable completeness, cutting property and adhesive force.

Owner:FOSHAN JIAEN NEW MATERIALS CO LTD

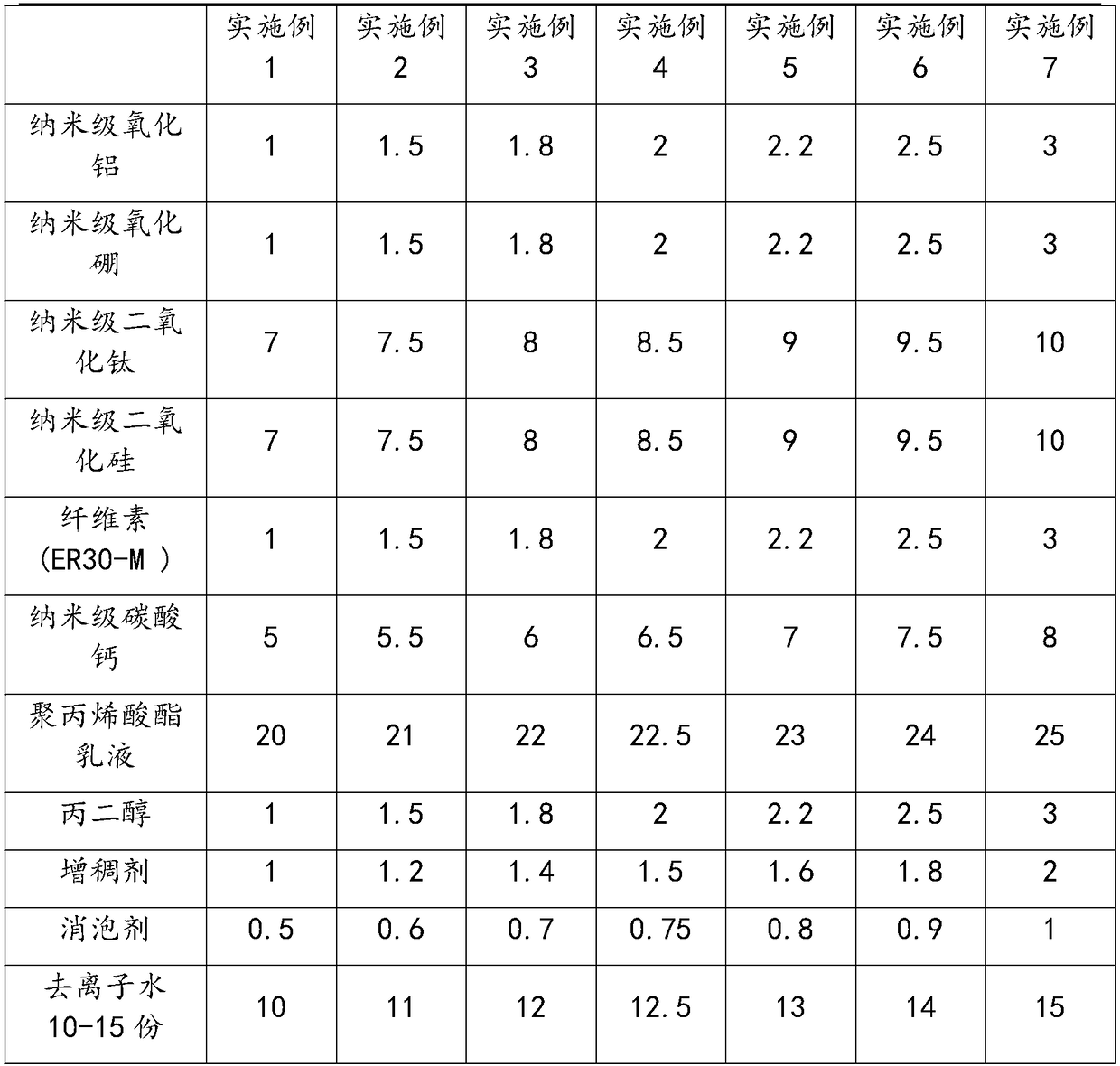

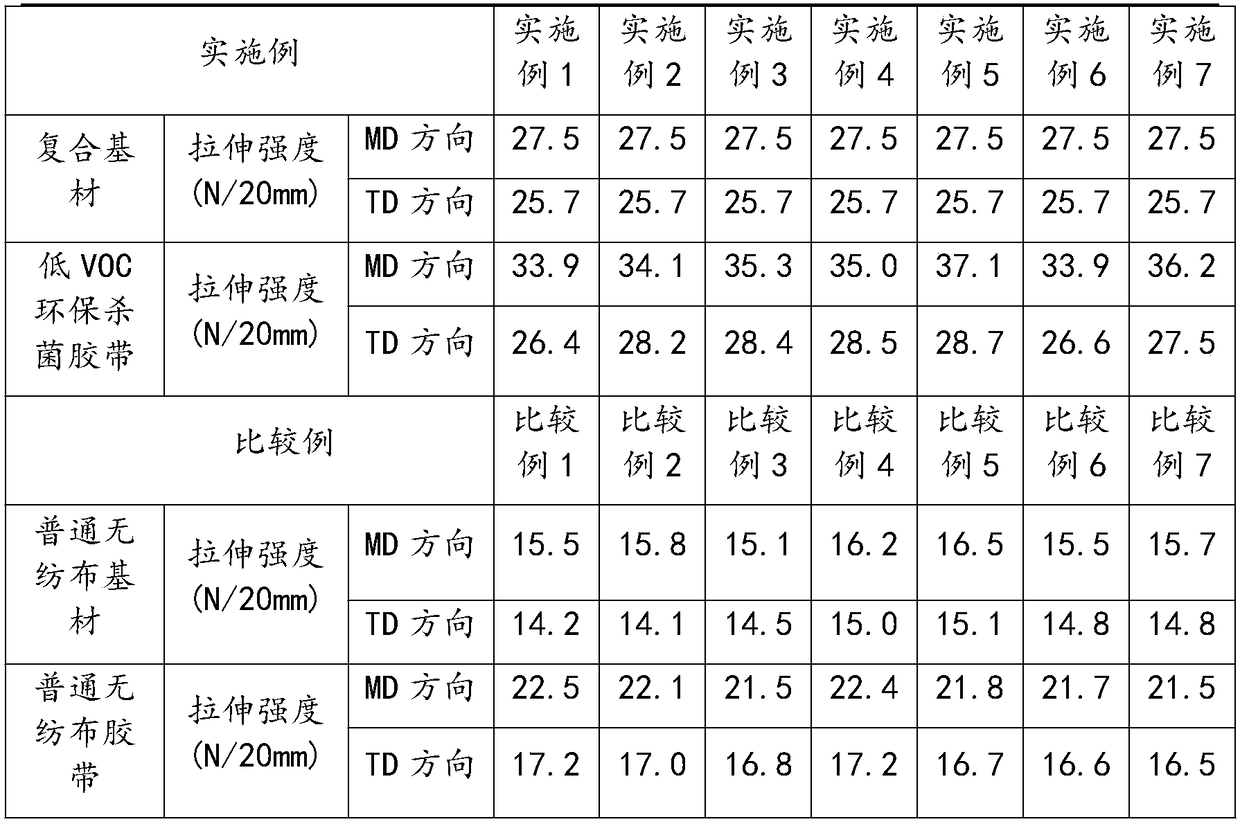

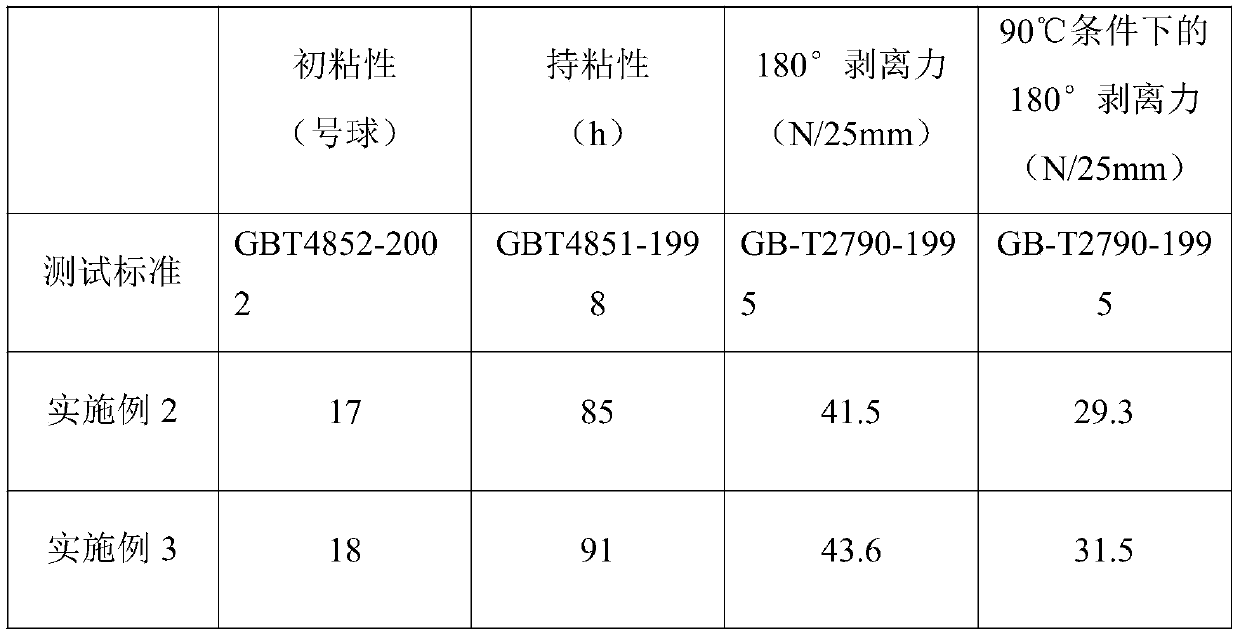

Low-VOC environment-friendly sterilizing adhesive tape

PendingCN108441131AWith softnessImprove fitFilm/foil adhesivesEster polymer adhesivesAdhesiveCompound structure

The invention discloses a low-VOC environment-friendly sterilizing adhesive tape which comprises a base material layer, sterilizing layers, low-VOC adhesive layers and a release type layer, wherein the base material layer is of a double-layer compound structure and comprises a nonwoven fabric layer and a PET membrane layer; the sterilizing layers are respectively covered to the upper surface and the lower surface of the base material layer to form a first sterilizing layer and a second sterilizing layer; the low-VOC adhesive layers are respectively adhered to the other surface of the first sterilizing layer and the other surface of the second sterilizing layer to form a first low-VOC adhesive layer and a second low-VOC adhesive layer; the release type layer is adhered to the other surfaceof the second low-VOC adhesive layer. By means of the compound base material layer, the adhesive tape disclosed by the invention has certain softness and excellent fit and further has certain strength; by means of the design of the sterilizing layers, the adhesive tape not only has a function of inhibiting bacteria and virus breeding, but also has functions of adsorbing VOC gas and decomposing organic pollutant; by means of the low-VOC adhesive layers, VOC organic pollutants are greatly reduced.

Owner:SHENZHEN NIKTO TAPE NEW MATERIAL CO LTD

Pressure sensitive adhesive with high stripping force and preparation method thereof

ActiveCN110041860AImprove peel forceGood initial adhesionEster polymer adhesivesRosin adhesivesIsooctyl acrylate1-dodecanethiol

The invention discloses a pressure sensitive adhesive with the high stripping force. The pressure sensitive adhesive is prepared from the following raw materials, in parts by weight: 45-55 parts of 2-ethylhexyl acrylate, 4-9 parts of acrylamide, 40-50 parts of butyl acrylate, 7-12 parts of hydroxypropyl acrylate, 3-7 parts of methyl acrylate, 70-90 parts of ethyl acetate and butanone with the massratio being 1 to 1, 1.3-2.2 parts of azodiisobutyronitrile, 0.6-1 part of 1-dodecanethiol and 3-5 parts of tuluene diisocynate. The pressure sensitive adhesive with the high stripping force has the good initial adhesion and persistent adhesion, the 180-degree stripping force is high and can be held at the temperature of 90 DEG C, and the pressure sensitive adhesive can adhere firmly, and has thegood anti-plasticizer property and temperature resistance. No benzene and methylbenzene serves as solvents in the synthesis process of the pressure sensitive adhesive, and the pressure sensitive adhesion is low in toxicity, environmentally friendly, and wide in application range.

Owner:浙江铂淳新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com