Adhesive for alkali resistant acrylate glass fiber mesh cloth shaping, and preparation method thereof

An acrylic glass fiber mesh and adhesive technology, applied in the direction of adhesive type, graft polymer adhesive, adhesive, etc. Excellent alkaline effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The reaction preparation method in the above-mentioned adhesive comprises the following steps:

[0026] A. Preparation of seed emulsion: add deionized water and part of the emulsifier to form an emulsifier solution with a mass percent concentration of 0.10% to 0.14% in the stirring state of the polymerization kettle, and add nano-silica in the formed emulsifier solution Stir the aqueous sol for 10-30 minutes, then add the initiator solution prepared by the initiator with a mass percentage concentration of 0.80%-1.64%, and then keep warm for 15-30 minutes to obtain the seed emulsion;

[0027] B. Pre-emulsification of shell-layer mixed monomers: mix any one of acrylic acid and its ester monomers or methacrylic acid and its ester monomers with styrene monomers to form shell-layer mixed monomers, and shell The layer mixing monomer is divided into 6-8 parts by mass on average; the emulsifier, buffer and molecular weight regulator are evenly mixed and divided into 6-8 parts b...

Embodiment 1

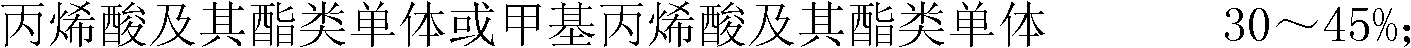

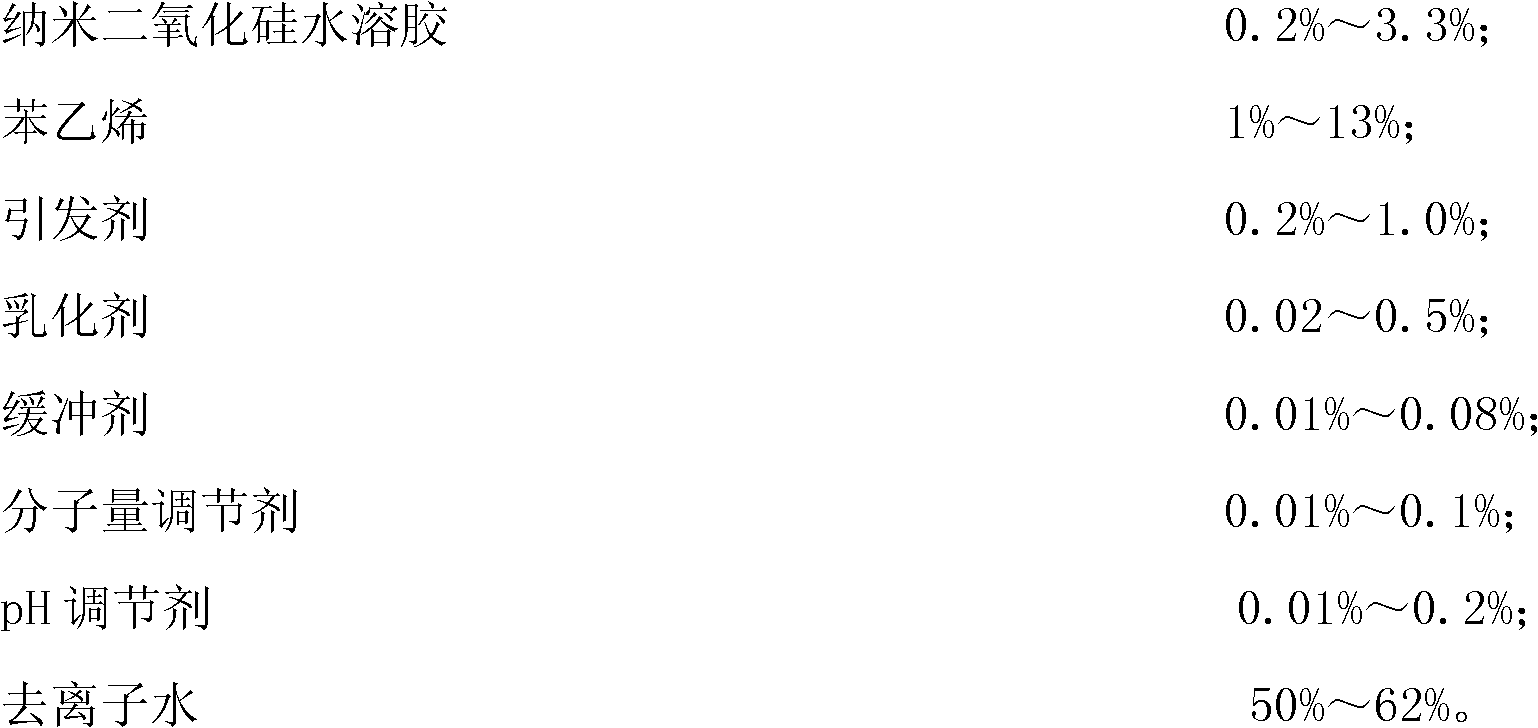

[0034] This embodiment provides an alkali-resistant acrylate glass fiber grid cloth setting adhesive, the formulation of which is as follows (each component is by mass):

[0035] 54 parts by mass of (meth)acrylic acid and its ester monomers (including 42 parts by mass of butyl acrylate, 1 part by mass of acrylic acid, and 11 parts by mass of methyl methacrylate), 11.68 parts by mass of styrene monomer, nano-silica 8.8 parts by mass of hydrosol, 2.0 parts by mass of initiator (potassium persulfate), 1.34 parts by mass of emulsifier (sodium diisooctyl sulfonate), 0.32 parts by mass of buffer (sodium bicarbonate), molecular weight regulator ( dodecylmercaptan) 3.06 parts by mass, pH adjuster (ammonia water) 0.8 parts by mass, deionized water 100 parts by mass.

[0036] The preparation method of above-mentioned adhesive comprises the following steps:

[0037] A, the preparation of seed emulsion: add the deionized water of 47 mass parts and the emulsifier (sodium diisooctyl sulfon...

Embodiment 2

[0041] This embodiment provides an alkali-resistant acrylate glass fiber grid cloth setting adhesive, the formulation of which is as follows (each component is by mass):

[0042] 28.8 parts by mass of (meth)acrylic acid and its ester monomers (including 21 parts by mass of butyl acrylate, 1 part by mass of acrylic acid, and 6.8 parts by mass of methyl methacrylate), 21.68 parts by mass of styrene monomer, nano-silica 8.8 parts by mass of hydrosol, 2.0 parts by mass of initiator, 1.34 parts by mass of emulsifier (sodium diisooctyl sulfonate), 0.32 parts by mass of buffer (ammonium bicarbonate), molecular weight regulator (dodecyl sulfide) Alcohol) 3.06 parts by mass, pH adjuster (ammonia water) 0.8 parts by mass, deionized water 95.2 parts by mass.

[0043] The preparation method of above-mentioned adhesive comprises the following steps:

[0044] A, the preparation of seed emulsion: add the deionized water of 38.2 mass parts and the emulsifier (sodium diisooctyl sulfonate succ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com