Twist-woven glass fiber adhesive tape and preparation method thereof

A glass fiber tape and glass fiber technology, applied in the direction of fabrics, textiles, adhesives, etc., can solve the problems of insufficient transparency of twisted glass fiber tape, inability to unwind and unwrap, and tape falling off, etc., to achieve beautiful appearance and good effect of the tape , Improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Formula: twisted glass fiber gauze 25%, film 5%, solvent release agent 1%, coating primer 24%, coating surface adhesive 45%;

[0041] Preparation method: PET film with 3% of the total mass of the tape is passed through a coating machine, one side is coated with 1% solvent release agent, and the other side of the film is coated with 24% primer through a coating machine; 25% twisted glass fiber gauze and film are firmly combined, and then coated with 45% surface glue on the twisted glass fiber, and then rewinding and cutting can be started to make twisted glass fiber tape.

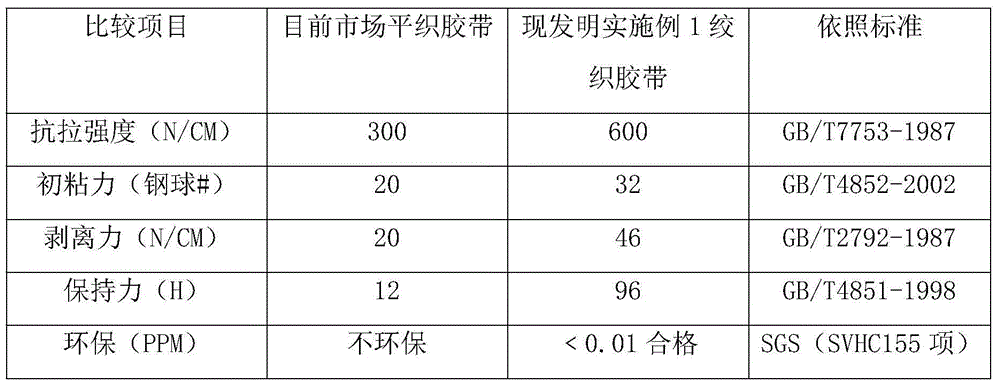

[0042] Effect: From the beginning of weaving to the whole process of cutting and packaging, the strand-woven glass fiber tape will not appear like the traditional flat-woven glass fiber tape: yarn shifting, twisting, messy, etc. Instead, the surface of the tape is intuitive and the grid pattern is clear; the process flow is simplified, the production efficiency is improved, and the production cost is ...

Embodiment 2

[0045] Formula: twisted glass fiber gauze 40%, film 6%, solvent release agent 0.5%, coating primer 28%, coating surface adhesive 25.5%;

[0046] Preparation method: PET film with 3% of the total mass of the tape is passed through a coating machine, one side is coated with 0.5% solvent release agent, and the other side of the film is coated with 28% primer through a coating machine; 40% twisted glass fiber gauze and film are firmly combined, and then coated with 25.5% top glue on the twisted glass fiber, and then rewinding and cutting can be started to make twisted glass fiber tape.

Embodiment 3

[0048]Formula: twisted glass fiber gauze 45%, film 3%, solvent release agent 0.6%, coating primer 22%, coating surface glue 29.4%; preparation method: PET film with 3% of the total mass of the tape, by coating Layer machine, one side is coated with 0.6% solvent release agent, and the other side of the film is coated with 22% primer by the coating machine; 45% twisted glass fiber gauze and film are firmly combined by pressing rollers , and then coat 29.4% surface glue on the strand-woven glass fiber, and then you can start rewinding and cutting to make strand-woven glass fiber tape.

[0049] The components used in the present invention are all commercially available products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com