Pressure sensitive adhesive with high stripping force and preparation method thereof

A pressure-sensitive adhesive, high-peeling technology, applied in the direction of adhesives, adhesive types, rosin adhesives, etc., can solve the problem of poor plasticizer resistance and temperature resistance of pressure-sensitive adhesives, peeling force and adhesion of pressure-sensitive adhesives Insufficient height, insufficient bonding strength, etc., to achieve good plasticizer resistance, high 180° peeling force, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A pressure-sensitive adhesive with high peeling force, made of the following raw materials in parts by weight: 45-55 parts of isooctyl acrylate, 4-9 parts of acrylamide, 40-50 parts of butyl acrylate, 7 parts by weight of hydroxypropyl acrylate ~12 parts, 3~7 parts of methyl acrylate, 70~90 parts of ethyl acetate and butanone with a mass ratio of 1:1, 1.3~2.2 parts of azobisisobutyronitrile, 0.6~1 part of dodecanethiol, 3-5 parts of toluene diisocyanate.

[0037] Preferably, first use isooctyl acrylate as a soft monomer, acrylamide as a functional hard monomer, azobisisobutyronitrile as an initiator, ethyl acetate and methyl ethyl ketone with a mass ratio of 1:1 as a solvent, ten Dithiol is used as a molecular weight regulator, prepolymerized to obtain an acrylamide prepolymer; butyl acrylate is used as a soft monomer, hydroxypropyl acrylate is used as a functional hard monomer, and azobisisobutyronitrile is used as an initiator. Ethyl acetate and methyl ethyl ketone at ...

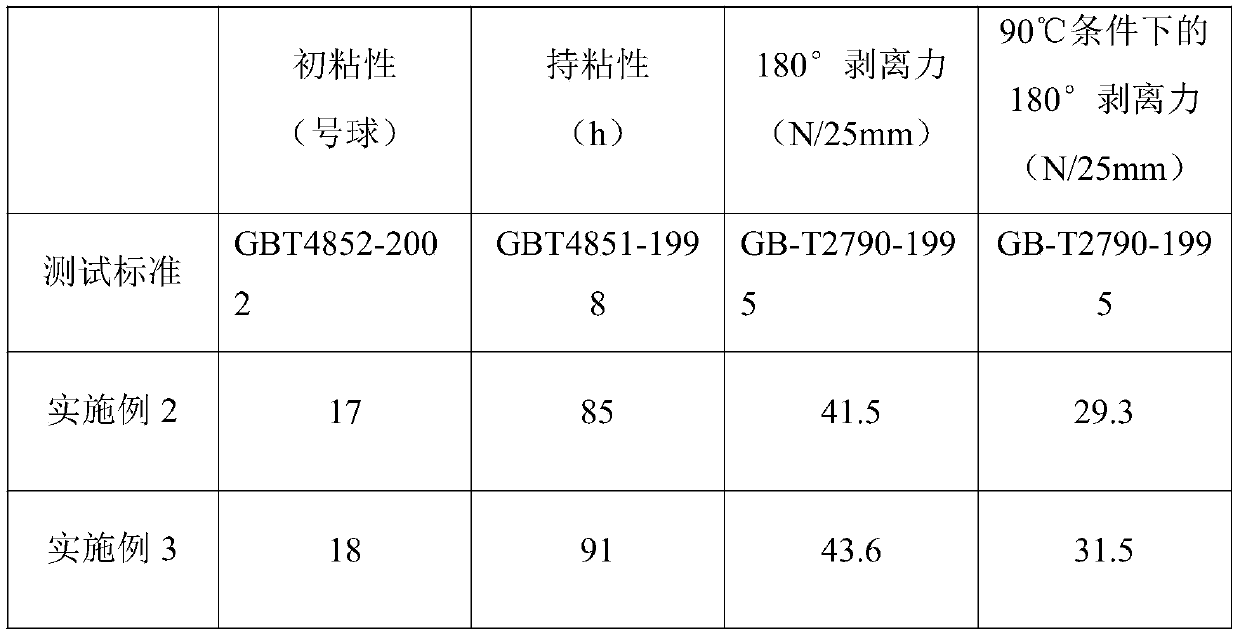

Embodiment 2

[0053] A pressure-sensitive adhesive with high peeling force, made of raw materials including the following parts by weight: 45 parts of isooctyl acrylate, 4 parts of acrylamide, 40 parts of butyl acrylate, 7 parts of hydroxypropyl acrylate, 3 parts of methyl acrylate 70 parts, 70 parts of ethyl acetate and butanone with a mass ratio of 1:1, 1.3 parts of azobisisobutyronitrile, 0.6 parts of dodecanethiol, and 3 parts of toluene diisocyanate.

[0054] In this example, isooctyl acrylate is used as a soft monomer, acrylamide is used as a functional hard monomer, azobisisobutyronitrile is used as an initiator, and ethyl acetate and butanone with a mass ratio of 1:1 are Solvent, dodecyl mercaptan as molecular weight regulator, pre-polymerized to obtain acrylamide prepolymer; butyl acrylate as soft monomer, hydroxypropyl acrylate as functional hard monomer, azobisisobutyronitrile as initiator agent, ethyl acetate and butanone with a mass ratio of 1:1 are solvents, and dodecanethiol ...

Embodiment 3

[0070] A pressure-sensitive adhesive with high peeling force, made of the following raw materials by weight: 55 parts of isooctyl acrylate, 9 parts of acrylamide, 50 parts of butyl acrylate, 12 parts of hydroxypropyl acrylate, 7 parts of methyl acrylate 90 parts, 90 parts of ethyl acetate and butanone with a mass ratio of 1:1, 2.2 parts of azobisisobutyronitrile, 1 part of dodecanethiol, and 5 parts of toluene diisocyanate.

[0071] In this example, isooctyl acrylate is used as a soft monomer, acrylamide is used as a functional hard monomer, azobisisobutyronitrile is used as an initiator, and ethyl acetate and butanone with a mass ratio of 1:1 are Solvent, dodecyl mercaptan as molecular weight regulator, pre-polymerized to obtain acrylamide prepolymer; butyl acrylate as soft monomer, hydroxypropyl acrylate as functional hard monomer, azobisisobutyronitrile as initiator agent, ethyl acetate and butanone with a mass ratio of 1:1 are solvents, and dodecanethiol is a molecular wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com