Low-VOC environment-friendly sterilizing adhesive tape

An environmentally friendly and adhesive tape technology, which is applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., can solve the problems of tape bonding performance reduction, adhesive performance reduction, adhesive performance degradation, etc., to achieve easy Die-cut molding, high initial tack, smooth edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

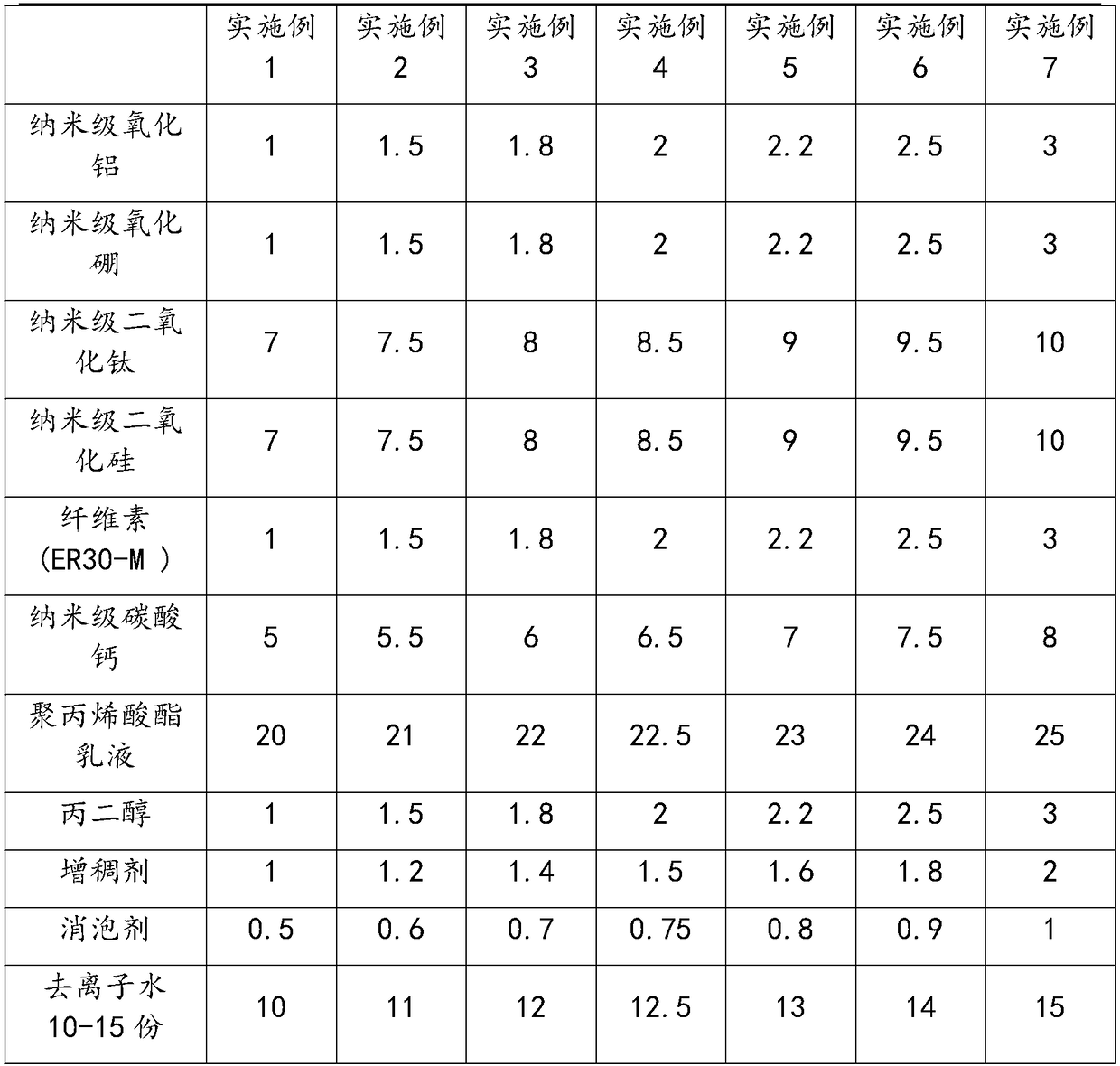

[0038]In the present invention, the preparation method of the bactericidal layer comprises the following steps:

[0039] 1) First mix nano-scale titanium dioxide, nano-scale aluminum oxide, nano-scale boron oxide, nano-scale silicon dioxide, and deionized water according to the formula amount, then stir at 800-1000rpm for 34-45min, and stir evenly Standby, obtain standby mixture 1;

[0040] 2) Stir the polyacrylate emulsion and propylene glycol in the formula amount for 10-20min at 400-600rpm, stir evenly for later use, and obtain the standby mixture 2;

[0041] 3) Then, mix the standby mixture 1 and standby mixture 2, and add a defoamer and stir at 600-800rpm for 10-20min;

[0042] 4) Then, while the stirring speed is constant, add cellulose and nano-scale calcium carbonate in the formula and stir for 8 minutes;

[0043] 5) Finally, add the thickener in the prescribed amount, and stir at 400-600rpm for 10-20min to prepare the bactericidal layer.

[0044] The bactericidal l...

Embodiment 1-7

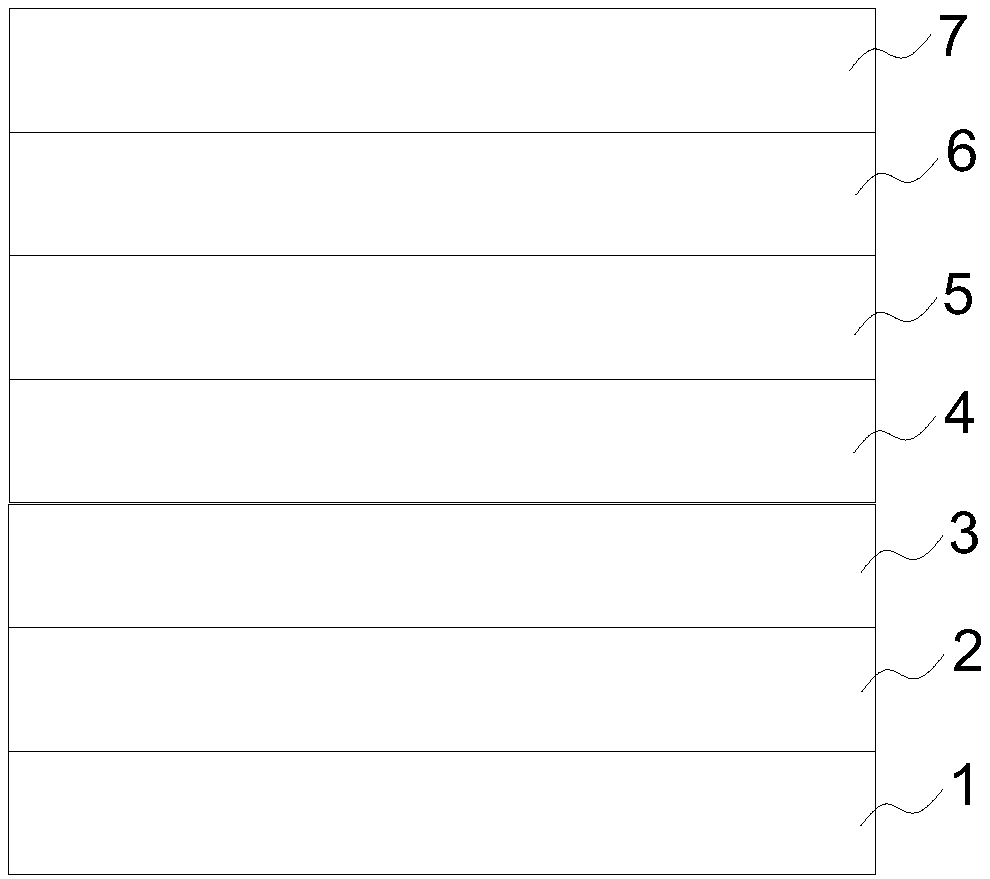

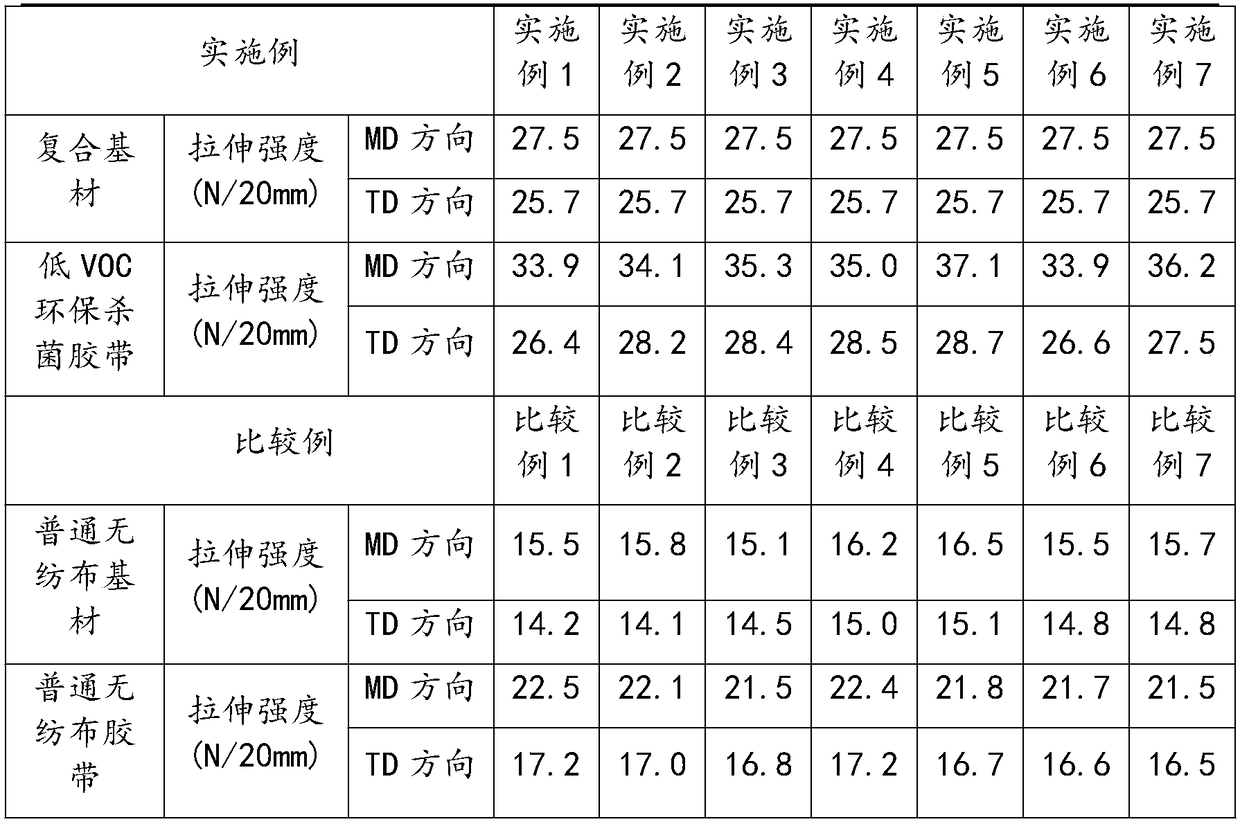

[0066] like figure 1 As shown, a low-VOC environment-friendly sterilization tape structure includes a substrate layer, a low-VOC adhesive layer and a release layer. The substrate layer is a double-layer composite structure, including a layer of non-woven fabric 3 and a layer of PET film Layer 4, the upper and lower surfaces of this substrate layer are coated with the first bactericidal layer 2 and the second bactericidal layer 5 respectively, and the other surface of the first bactericidal layer 2 is coated with the first low-VOC adhesive layer 1, The other surface of the second bactericidal layer 5 is coated with a second low-VOC adhesive layer 6 , and the other surface of the second low-VOC adhesive layer 6 is coated with a double-sided release layer 7 . Wherein, the thickness of the substrate layer is 30 μm; the thicknesses of the first sterilizing layer and the second bactericidal layer are 15 μm respectively; the thicknesses of the first low-VOC adhesive layer and the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com