Seat filled with particulate matters

A technology of particles and seats, which is applied in the field of seats, can solve problems such as decomposition, uneven distribution of particles, and inability to adjust the amount of particles, so as to avoid the effect of escaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

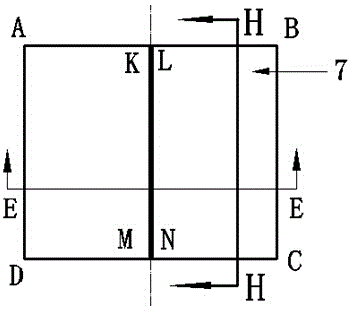

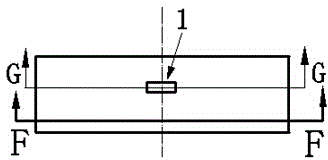

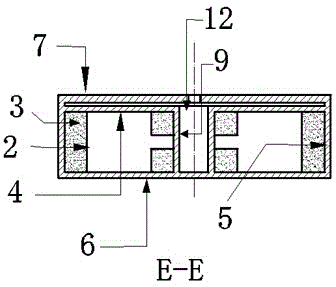

[0048] refer to Figure 1 to Figure 6 , the plane ABCD is the seating surface 7, and the seating surface 7 is set above the upper bottom surface 4, and is composed of the butt joint of the plane AKMD and the plane LBCN. The plane AKMD and the plane LBCN form the middle seam KLNM through the fixed combination with the upper bottom surface 4 and the outer ring 5. The middle part of the upper bottom surface 4 is provided with a central hole 12. Between the upper bottom surface 4 and the lower bottom surface 6 are arranged a peripheral ring 5 , a connecting block 2 , an isolation ring 9 , a material regulating port 1 and a material pipe 10 . The material properties of the seating surface 7, the upper bottom surface 4, the lower bottom surface 6, the peripheral ring 5, the connecting block 2, the isolation ring 9, and the material pipe 10 are all soft.

[0049] The cushion core of the seat is composed of the upper bottom surface 4, the peripheral ring 5, the connecting blo...

Embodiment 2

[0061] refer to Figure 7 to Figure 12 As shown, the plane A1B1C1D1 is the seating surface 7, and the seating surface 7 is arranged above the upper bottom surface 4, and is composed of the docking of the plane A1K1M1D1 and the plane L1B1C1N1. Plane A1K1M1D1 and plane L1B1C1N1 form the central seam K1L1N1M1 through the fixed combination with the upper bottom surface 4 and the outer ring 5.

[0062] Magnetic strips 11 are provided on both sides of the middle seam K1L1N1M1 of the seating surface 7, and the magnetic strips 11 are fixedly combined on both sides of the middle seam K1L1N1M1 in a manner of opposite sex attraction. A central hole 12 is provided in the middle of the upper bottom surface 4 . Both ends of the magnetic strip 11 are located within the range corresponding to the central hole 12 . Between the upper bottom surface 4 and the lower bottom surface 6 are arranged a peripheral ring 5 , a connecting block 2 , an isolation ring 9 , a material regulating por...

Embodiment 3

[0074] refer to Figure 13 to Figure 18 As shown, the plane A2B2C2D2 is the seating surface 7, and the seating surface 7 is arranged above the upper bottom surface 4, and is formed by docking the plane A2K2M2D2 and the plane L2B2C2N2. Plane A2K2M2D2 and plane L2B2C2N2 form the central raft U2T2Y2V2 through the fixed combination of K2U2 and L2T2, V2M2 and Y2N2.

[0075] A central hole 12 is provided in the middle of the upper bottom surface 4 . Between the upper bottom surface 4 and the lower bottom surface 6 are arranged a peripheral ring 5 , a connecting block 2 , an isolation ring 9 , a material regulating port 1 and a material pipe 10 . The material properties of the seating surface 7, the upper bottom surface 4, the lower bottom surface 6, the peripheral ring 5, the connecting block 2, the isolation ring 9, and the material pipe 10 are all soft.

[0076] The cushion core of the seat is composed of the upper bottom surface 4, the peripheral ring 5, the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com