Enhanced rupture-proof shockproof adhesive tape

An enhanced tape technology, applied in the direction of adhesives, film/sheet adhesives, film/sheet release liners, etc., can solve the problems of damage, space occupation, high paper cost, etc., to improve safety, temperature difference The effect of wide range and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

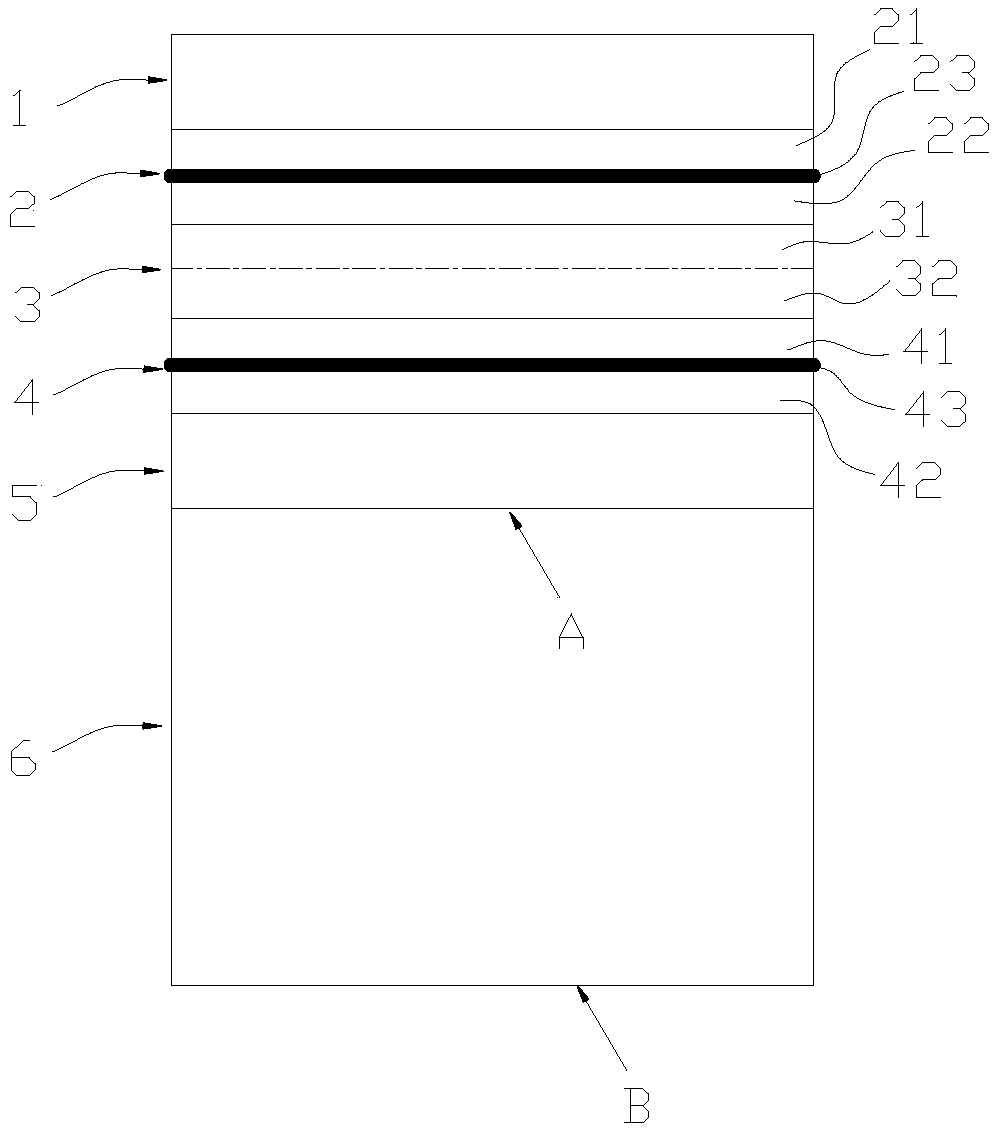

[0030] see figure 1 , the present embodiment discloses a reinforced anti-vibration adhesive tape, comprising a base material layer 3, a first adhesive layer 1, a first anti-vibration layer 2, a second anti-vibration layer 4 and a second adhesive layer 5, the base material layer 3 It is a double-layer composite structure, including one layer of foam layer 31 and one layer of PET film layer 32. Specifically, the thickness of the base material layer 3 is 10um; The second anti-vibration layer 4, the acrylic adhesive with high bonding strength can be used as the adhesive, the thickness of the first anti-vibration layer 2 and the second anti-vibration layer 4 is 10um, and the other side of the first anti-vibration layer 2 is bonded to the first anti-vibration layer. Adhesive layer 1, the other side of the second anti-shock layer 4 adheres to the second adhesive layer 2, the thickness of the first adhesive layer 1 and the second adhesive layer 5 are both 10um. Specifically in this e...

Embodiment 2

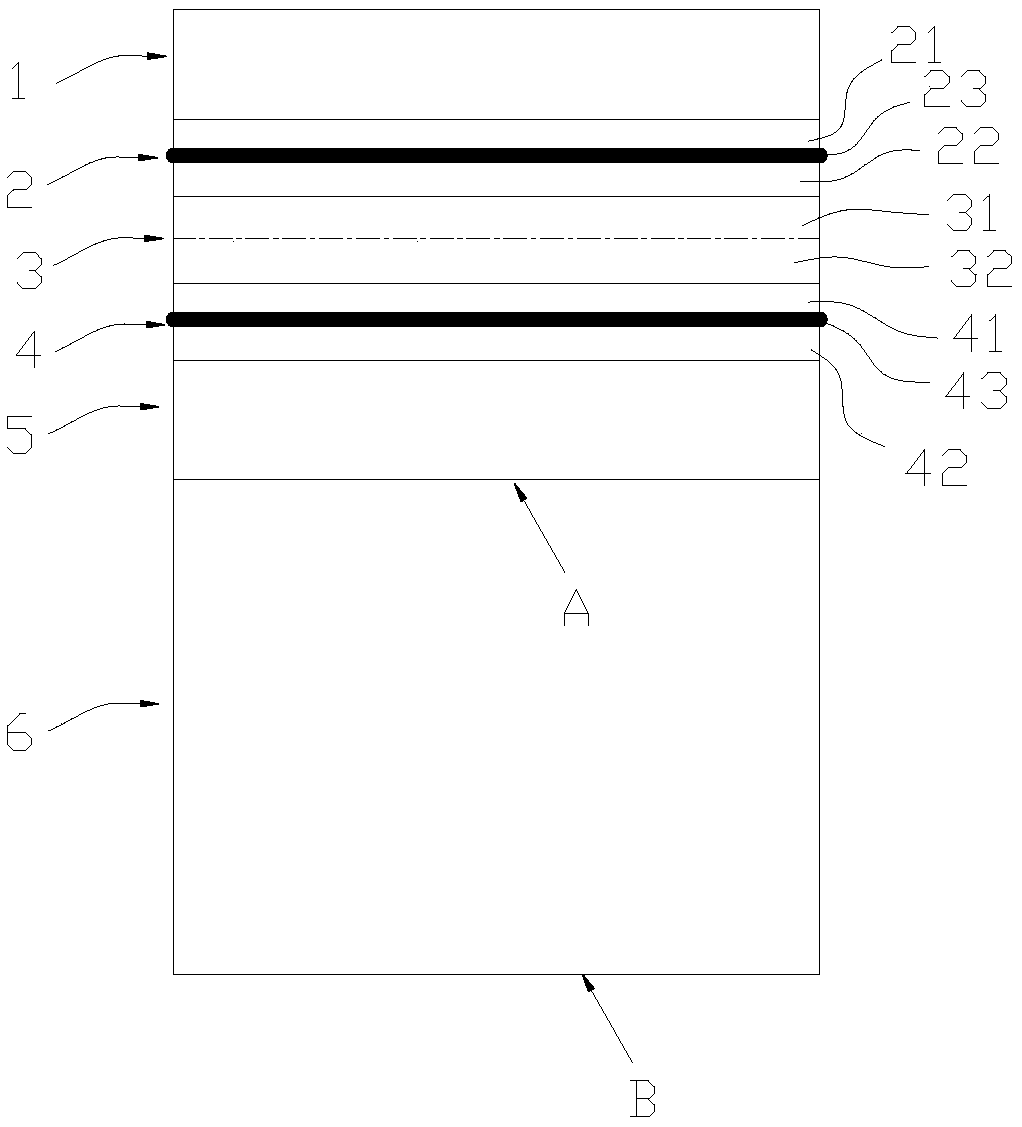

[0037] see figure 2 , the present embodiment is basically the same in structure as the first embodiment, the difference lies in the thickness setting of each layer, the sandwich layer, the first foam material layer 21, the second foam material layer 22, the third foam material layer 41 , the raw material of the fourth foam material layer 42, and the ratio of the release force of the two sides of the double-sided release paper are different. In this embodiment, the thickness of the substrate layer 3 is 25um, the thickness of the first anti-vibration layer 2 and the second anti-vibration layer 4 are both 17.5um, and the thickness of the first adhesive layer 1 and the second adhesive layer 5 is Both are 30um. The thickness of the double-sided release paper 5 is 75um, and the ratio of the release force on both sides is 1:1.5 (inner side: outer side, that is, side A: side B shown in the figure).

[0038]There is a thickness difference of 5um between the first foam material layer...

Embodiment 3

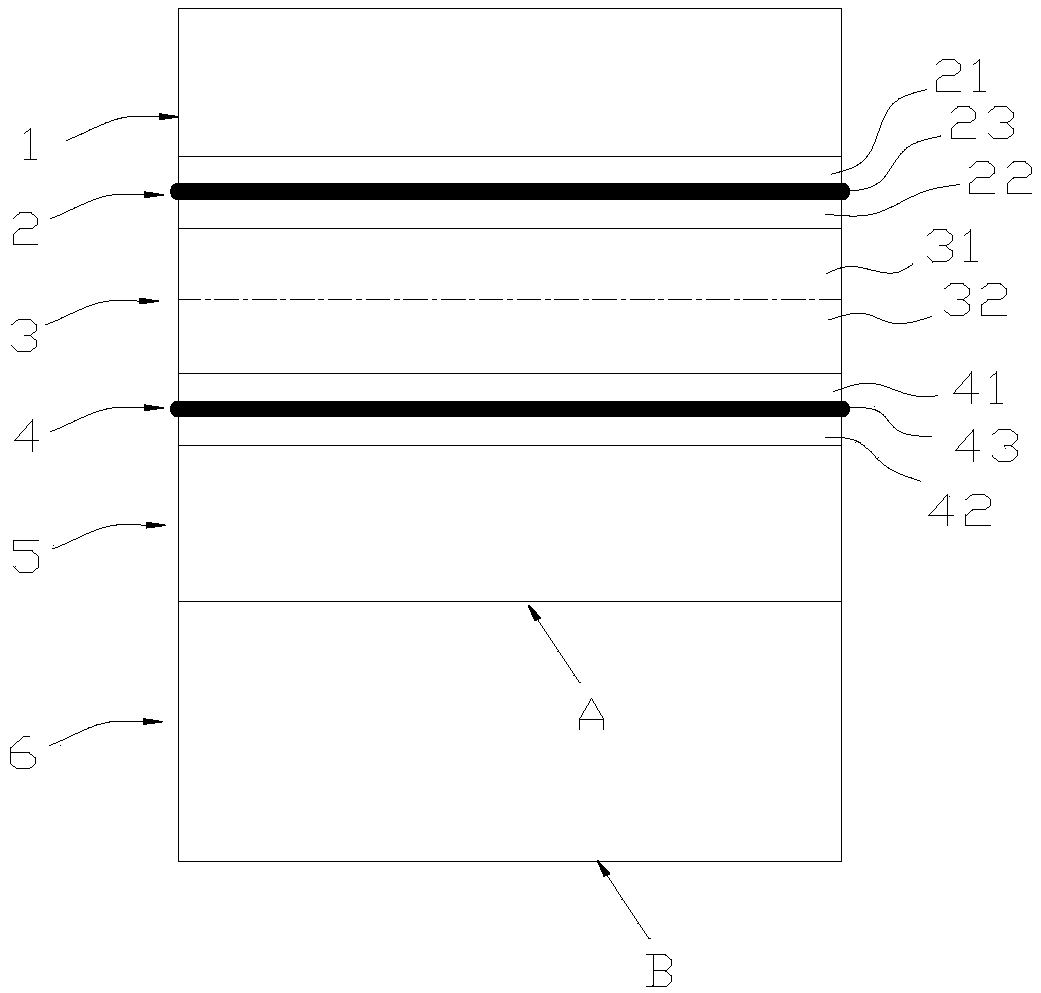

[0044] see image 3 , the present embodiment is basically the same in structure as the first and second embodiments, the difference is that the thickness of each layer is set, the sandwich layer, the first foam material layer 21, the second foam material layer 22, the third foam material layer The raw materials of the layer 41, the fourth foam material layer 42, and the release force ratio of the two sides of the double-sided release paper are different.

[0045] Specifically, the thickness of the substrate layer 3 is 50um, the thickness of the first anti-vibration layer 2 and the second anti-vibration layer 4 are both 25um, and the thickness of the first adhesive layer 1 and the second adhesive layer 5 are both 50um , The thickness of the double-sided release paper 5 is 100um, and the release force ratio of both sides is 1:2 (inside: outside, that is, side A: side B shown in the figure).

[0046] Preferably, there is a thickness difference of 10um between the first foam mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com