High-performance left and right paste hot melt adhesive and preparation method thereof

A high-performance, hot-melt adhesive technology, applied in adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve problems that affect consumer experience, adult diapers are large, and smell heavy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also provides a preparation method of high-performance left and right pasting hot melt adhesive, comprising the following steps:

[0059] S1: Confirm that the bottom valve of the reactor is closed, turn on steam heating, turn on the stirring paddle, and add plasticizer, poly-α-methylstyrene resin and antioxidant;

[0060] S2: Raise the temperature of the reactor in S1 to 150-165°C, and add the formulated polymer; after the polymer is added, stir for 15 minutes, then add styrene-butadiene rubber, and wait until the material is no longer increased after the addition Use a scraper to scrape off the polymer and styrene-butadiene rubber on the tank wall of the reaction kettle and the stirring paddle, and continue to stir. After stirring for 45 minutes, take a sample to see if the sample is completely melted. If there are still particles, continue to stir and record the extended stirring. time until the polymer and styrene-butadiene rubber melt;

[0061...

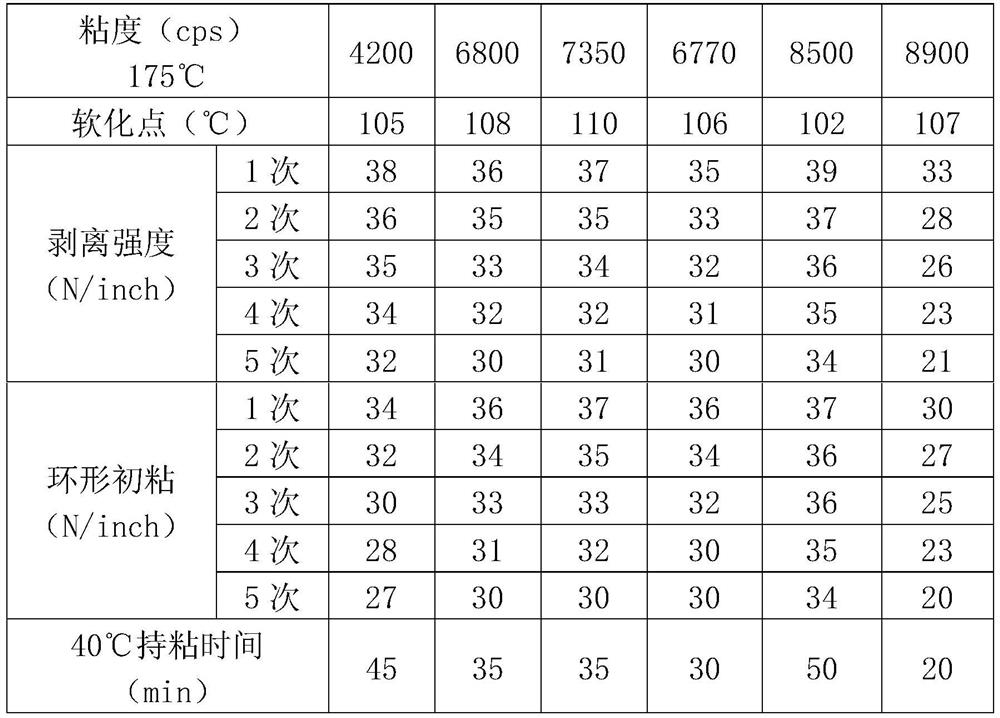

Embodiment 1-5 and comparative example 1

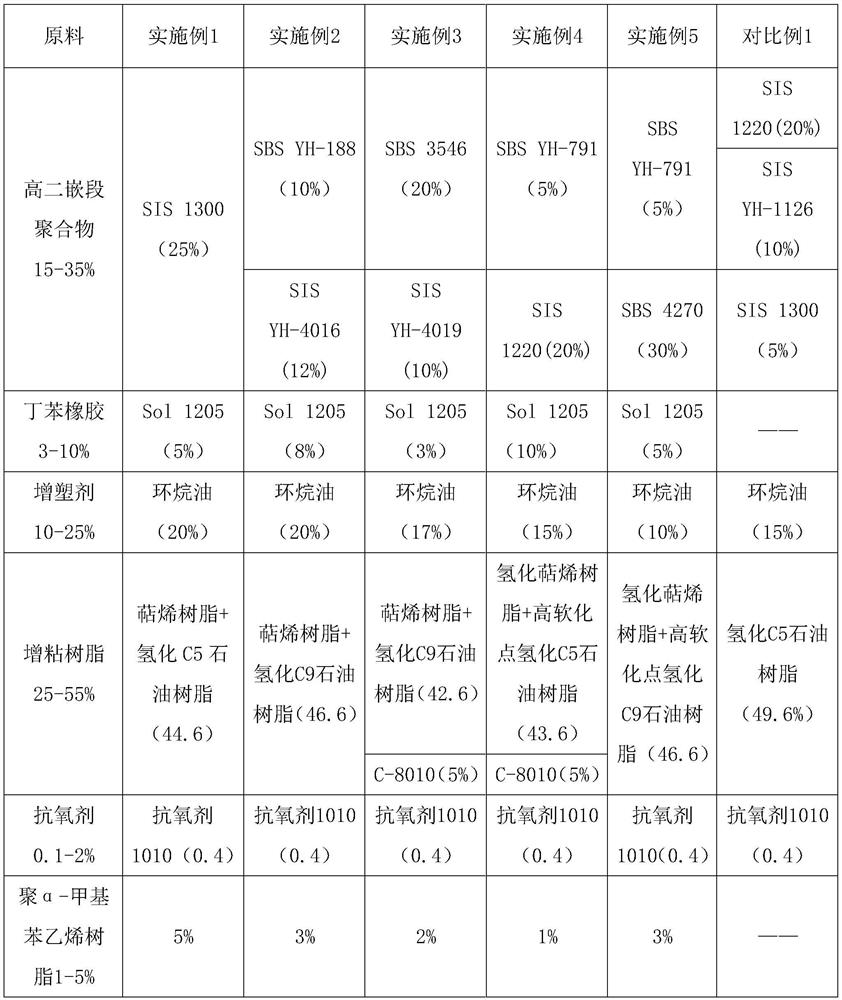

[0070] The raw materials were weighed according to the proportioning in Table 1 respectively, and the products were prepared according to the steps in Examples 1-5, see Table 1 for details:

[0071] Table 1 embodiment 1-5 and comparative example 1 raw material ratio table

[0072]

[0073] Wherein, unless otherwise specified in Table 1, in order to reflect the comparability of test results, the raw materials used are the same.

[0074] It should be noted that the ratio of terpene resin to hydrogenated C9 petroleum resin in the above formula is 1:8; the ratio of terpene resin to hydrogenated C5 petroleum resin is 1:8.

[0075] The softening point of high softening point hydrogenated C5 petroleum resin is 110-130°C; the softening point of high softening point hydrogenated C9 petroleum resin is 110-130°C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com