Multi-component scotch tape products

A glue product and multi-component technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of poor sticking effect, non-universal, difficult sticking, etc., and achieve the effect of overcoming warping and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

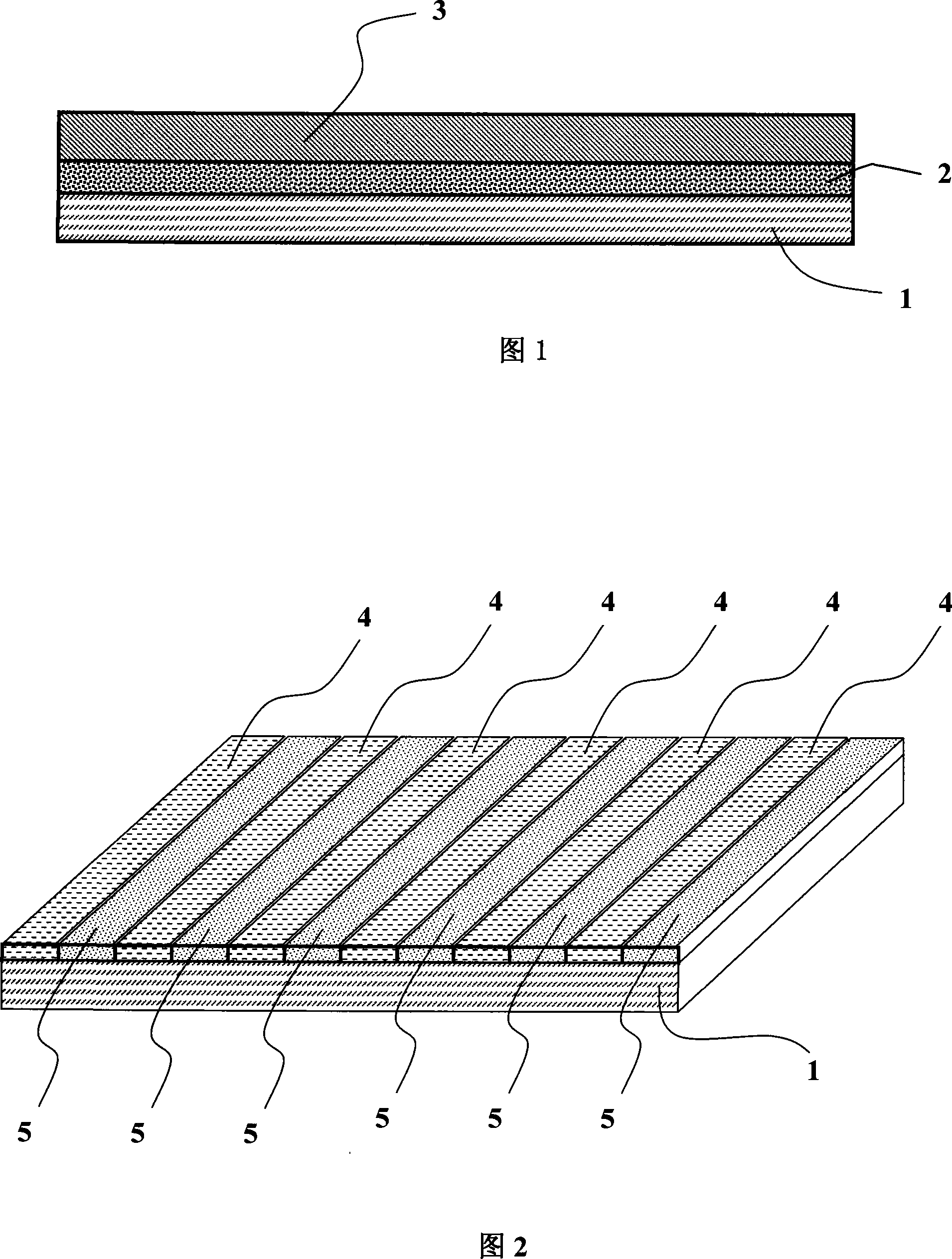

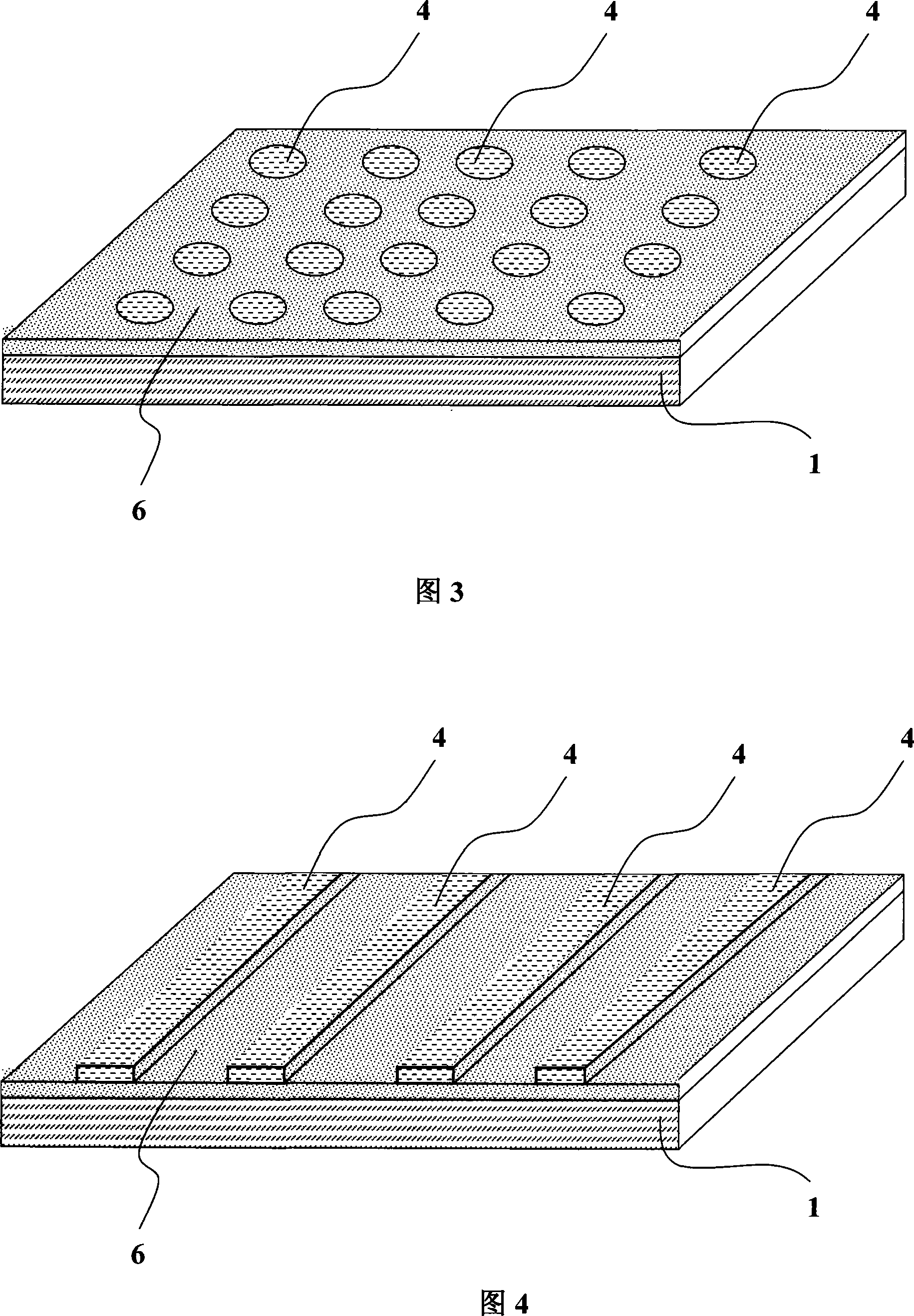

[0034] As shown in Figure 1 and Figure 2, choose a 80g / m 2 1. A roll of copper plate (white) paper with a width of 1050mm is used as the face material layer (1) of the multi-component self-adhesive product of the present invention. Choose a 95g / m2 coated with a layer of silicone oil 2 1. A reel (blue) glassine base paper with a width of 1040mm is used as the release layer (3) of the multi-component self-adhesive product of the present invention. Put the reel of coated paper and the reel of glassine backing paper on the unwinder of the QHTB-1200 self-adhesive coating machine respectively, pass the glassine backing paper around the glue roller and drying tunnel, and then stick it to the coated paper Winding.

[0035] Transform the current glue roller into a groove glue roller. Excavate grooved rings perpendicular to the axial direction one by one with a lathe on the rubberizing roller, with a groove width of 3 mm, a groove depth of 4 mm, and a groove spacing of 3 mm, thereby ...

Embodiment 2

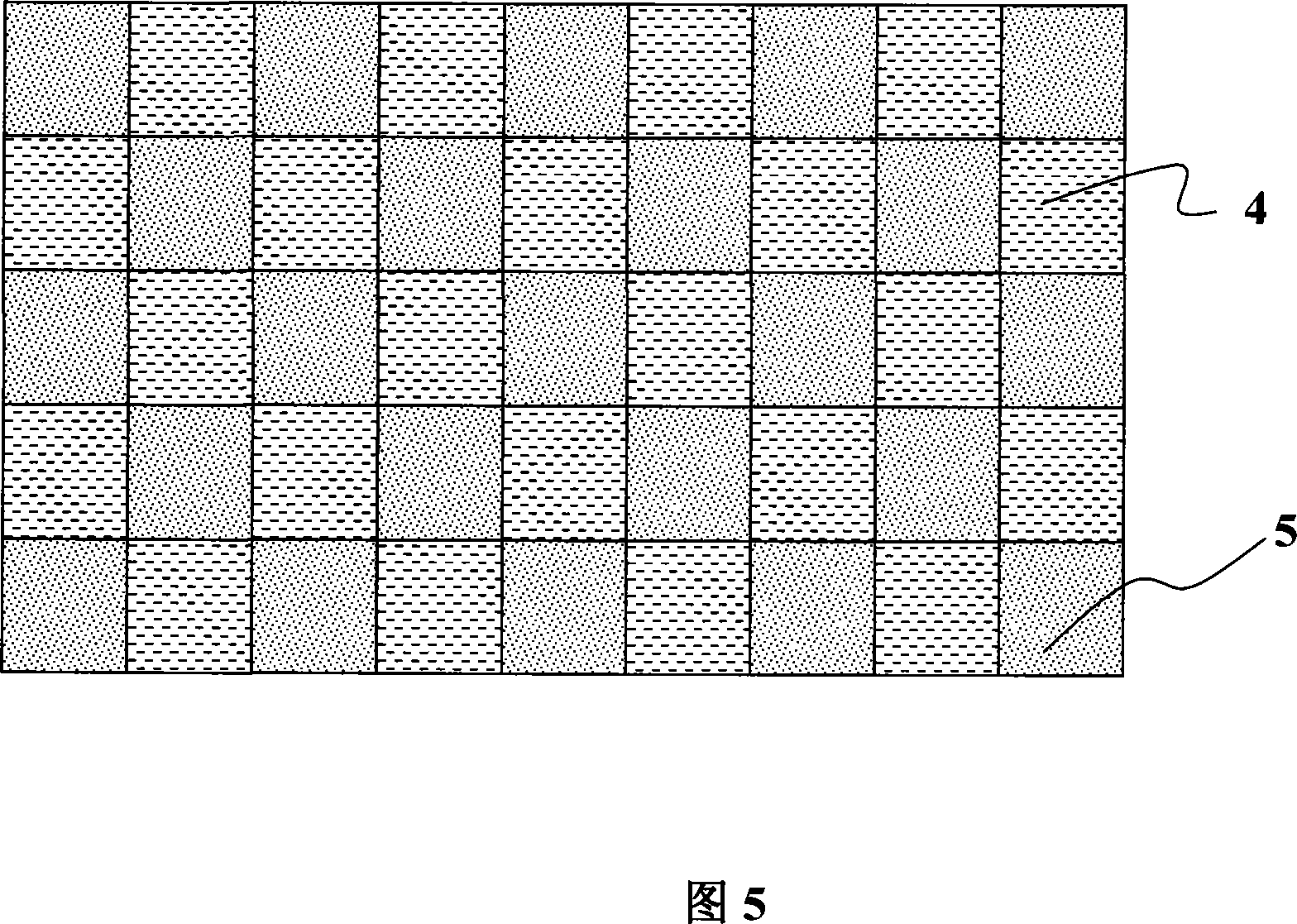

[0038] As shown in Figure 1 and Figure 4, choose a 80g / m 2 1. A roll of copper plate (white) paper with a width of 1050mm is used as the face material layer (1) of the multi-component self-adhesive product of the present invention. Choose a 95g / m2 coated with a layer of silicone oil 2 1. A reel (blue) glassine base paper with a width of 1040mm is used as the release layer (3) of the multi-component self-adhesive product of the present invention. Put the reel of coated paper and the reel of glassine backing paper on the unwinder of the QHTB-1200 self-adhesive coating machine respectively, pass the glassine backing paper around the glue roller and drying tunnel, and then stick it to the coated paper Winding.

[0039] Excavate grooved rings perpendicular to the axial direction one by one on the rubberizing roller, with a groove width of 3mm, a groove depth of 4mm, and a groove spacing of 3mm to make a grooved rubberizing roller.

[0040] First use a grooved glue roller to coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com