Modified hot-melt pressure-sensitive adhesive and preparation method thereof

A hot-melt pressure-sensitive adhesive, modified technology, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problem of incompatibility of peel strength and holding force, unstable quality, Poor fluidity and other problems, to achieve the effect of reducing peel strength, reducing the amount of glue remaining, and reducing the viscosity of the melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

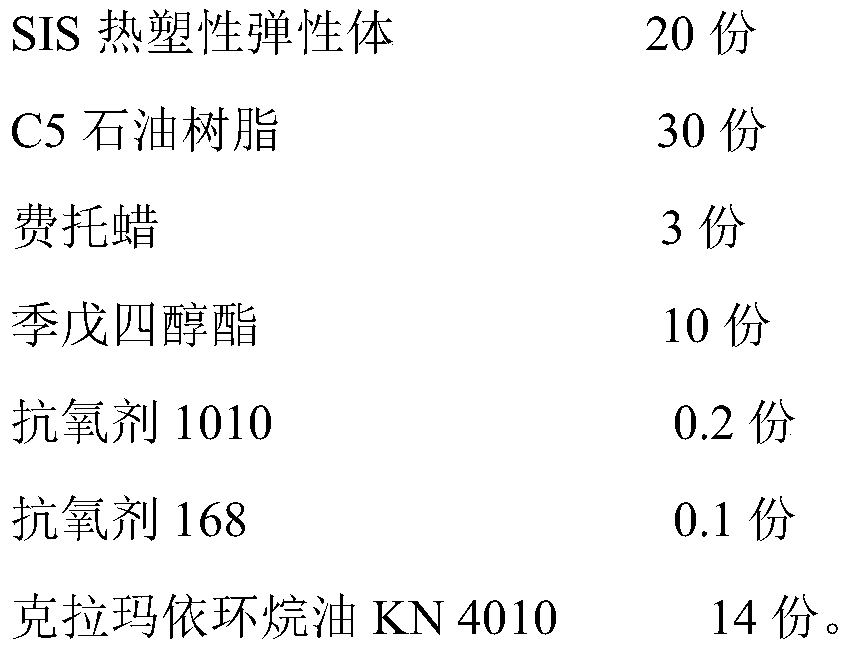

[0041] A modified hot-melt pressure-sensitive adhesive, comprising the following components in parts by weight:

[0042]

[0043] Among them: styrene thermoplastic elastomer is SIS, linear structure, styrene content is 15%, diblock content is 50%.

[0044] The petroleum resin is a C5 petroleum resin with a softening point of 80°C.

[0045] The softening point of pentaerythritol ester is 95°C.

[0046] Fischer-Tropsch wax is a methylene polymer synthesized by a coal-based Fischer-Tropsch polymerization process. It is produced by a cobalt-based catalyst. The molecular weight is about 800. The freezing point of the Fischer-Tropsch wax is 105°C.

[0047] The preparation method of the hot-melt pressure-sensitive adhesive is as follows:

[0048] (1) According to Example 1, weigh styrene thermoplastic elastomer, petroleum resin, Fischer-Tropsch wax, pentaerythritol ester, primary antioxidant, secondary antioxidant, softener.

[0049] (2) Wash and dry a 100ml three-neck flask, p...

Embodiment 2

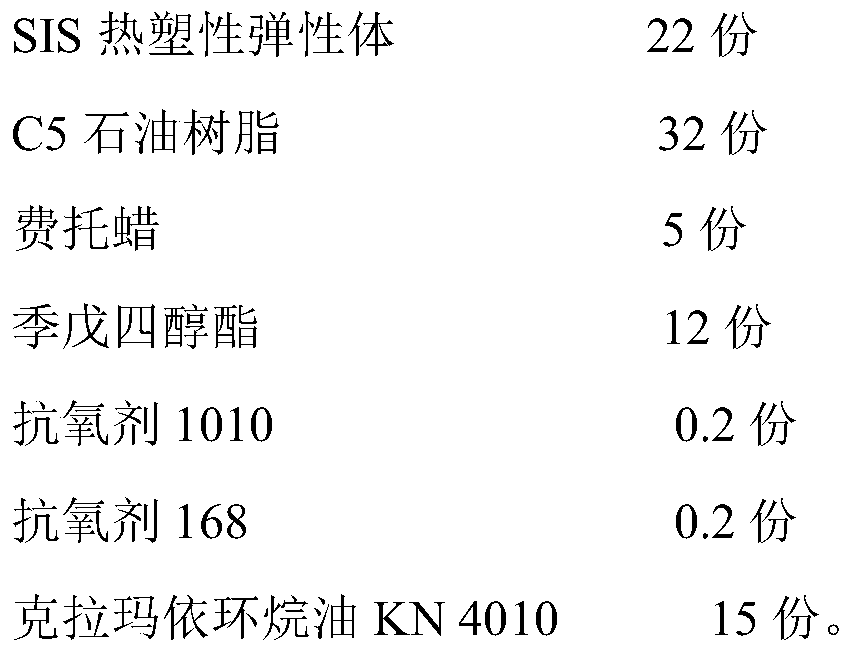

[0054] A modified hot-melt pressure-sensitive adhesive, comprising the following components in parts by weight:

[0055]

[0056] Among them: styrene thermoplastic elastomer is SIS, linear structure, styrene content is 18%, and diblock content is 60%.

[0057] The petroleum resin is a C5 petroleum resin with a softening point of 89°C.

[0058] The softening point of pentaerythritol ester is 100°C.

[0059] Fischer-Tropsch wax is a methylene polymer synthesized by a coal-based Fischer-Tropsch polymerization process. It is produced by a cobalt-based catalyst. The molecular weight is about 700. The freezing point of the Fischer-Tropsch wax is 105°C.

[0060] The preparation method of the hot-melt pressure-sensitive adhesive is as follows:

[0061] (1) According to Example 2, styrene-based thermoplastic elastomer, petroleum resin, Fischer-Tropsch wax, pentaerythritol ester, primary antioxidant, secondary antioxidant, and softener were weighed.

[0062] (2) Wash and dry a 100...

Embodiment 3

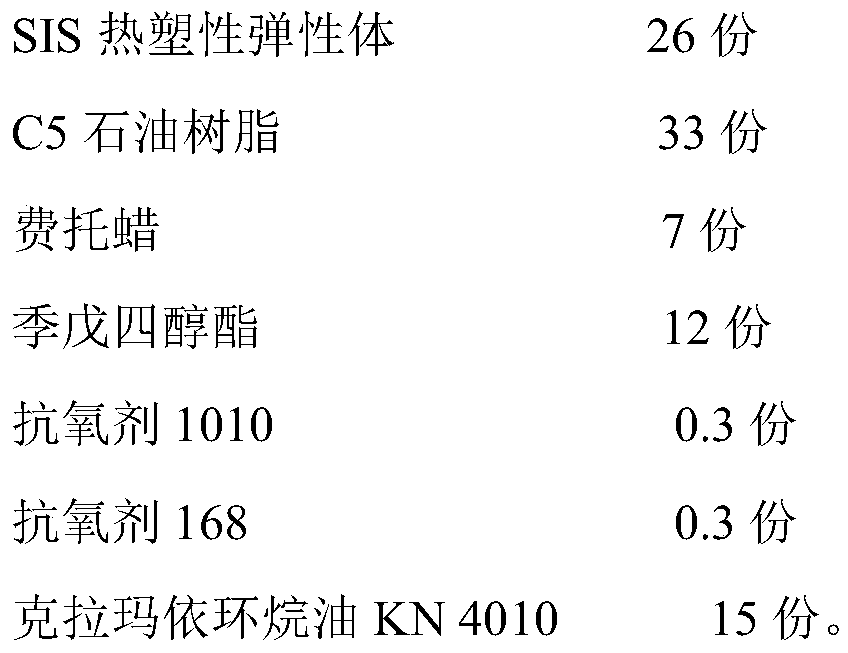

[0067] A modified hot-melt pressure-sensitive adhesive, comprising the following components in parts by weight:

[0068]

[0069] Among them: styrene thermoplastic elastomer is SIS, linear structure, styrene content is 20%, diblock content is 60%.

[0070] The petroleum resin is a C5 petroleum resin with a softening point of 92°C.

[0071] The softening point of pentaerythritol ester is 105°C.

[0072] Fischer-Tropsch wax is a methylene polymer synthesized by a coal-based Fischer-Tropsch polymerization process. It is produced by a cobalt-based catalyst. The molecular weight is about 800. The freezing point of the Fischer-Tropsch wax is 105°C.

[0073] The preparation method of the hot-melt pressure-sensitive adhesive is as follows:

[0074] (1) According to Example 3, styrene-based thermoplastic elastomer, petroleum resin, Fischer-Tropsch wax, pentaerythritol ester, primary antioxidant, secondary antioxidant, and softener were weighed.

[0075] (2) Wash and dry a 100ml t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com