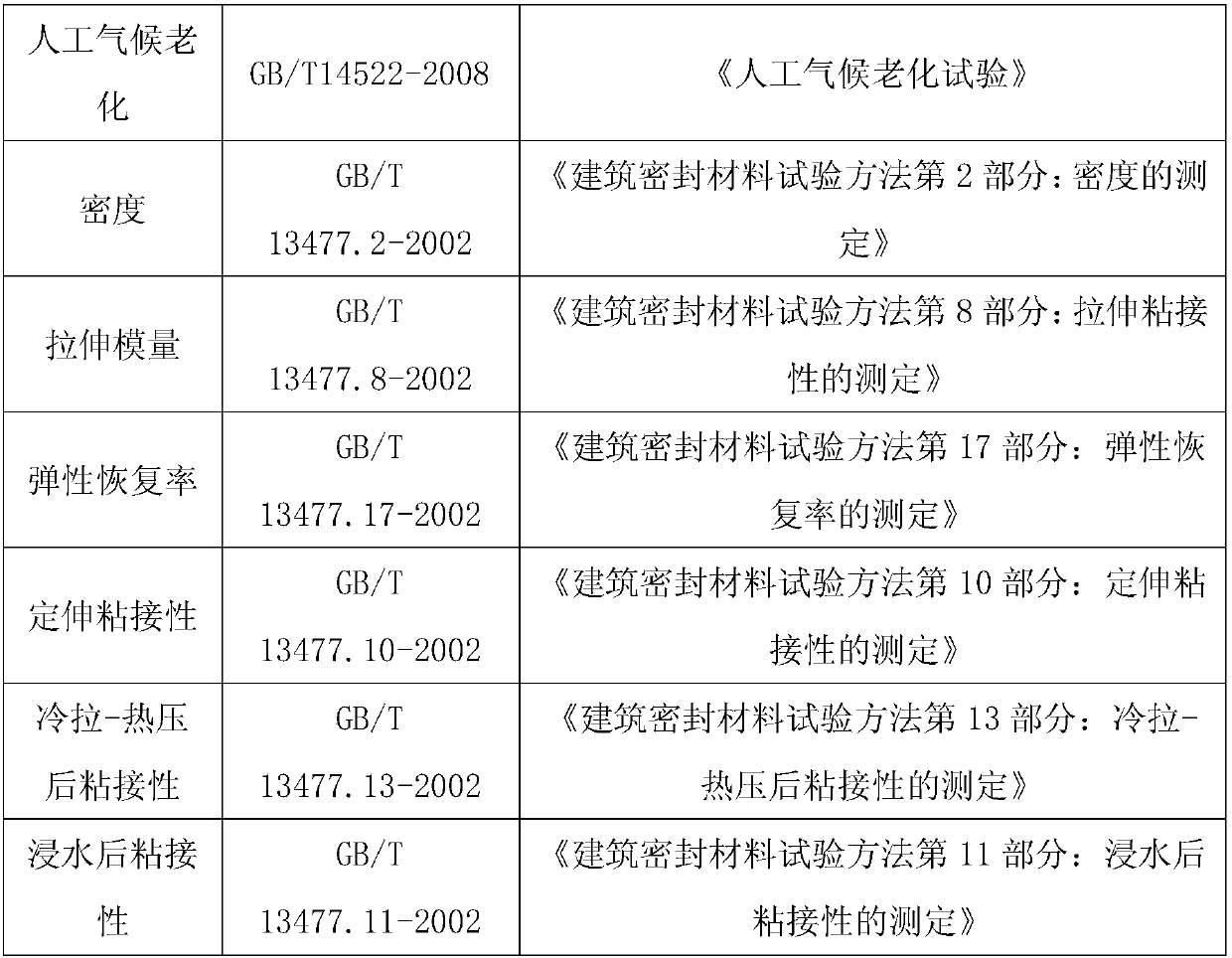

Patents

Literature

376results about How to "Reduce internal friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

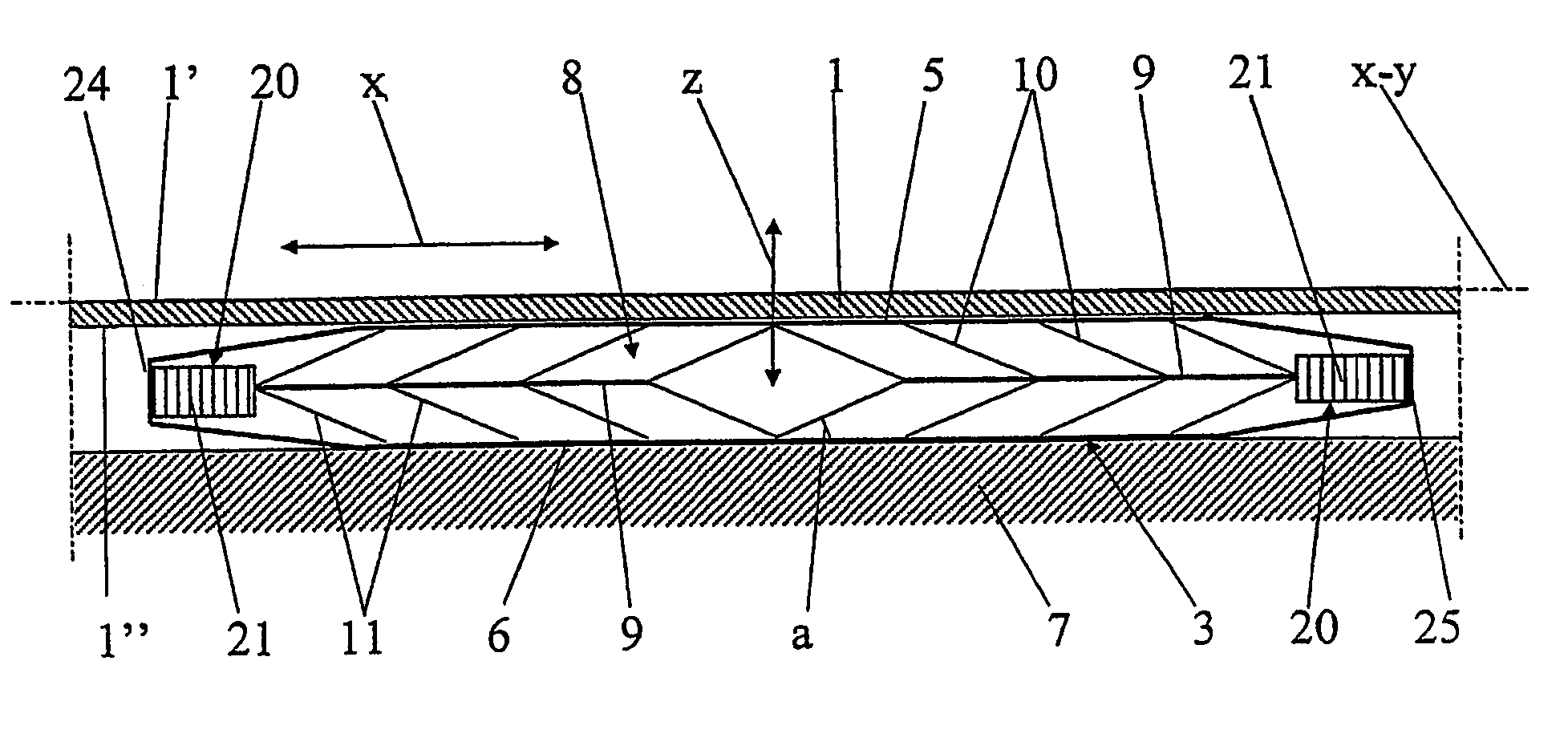

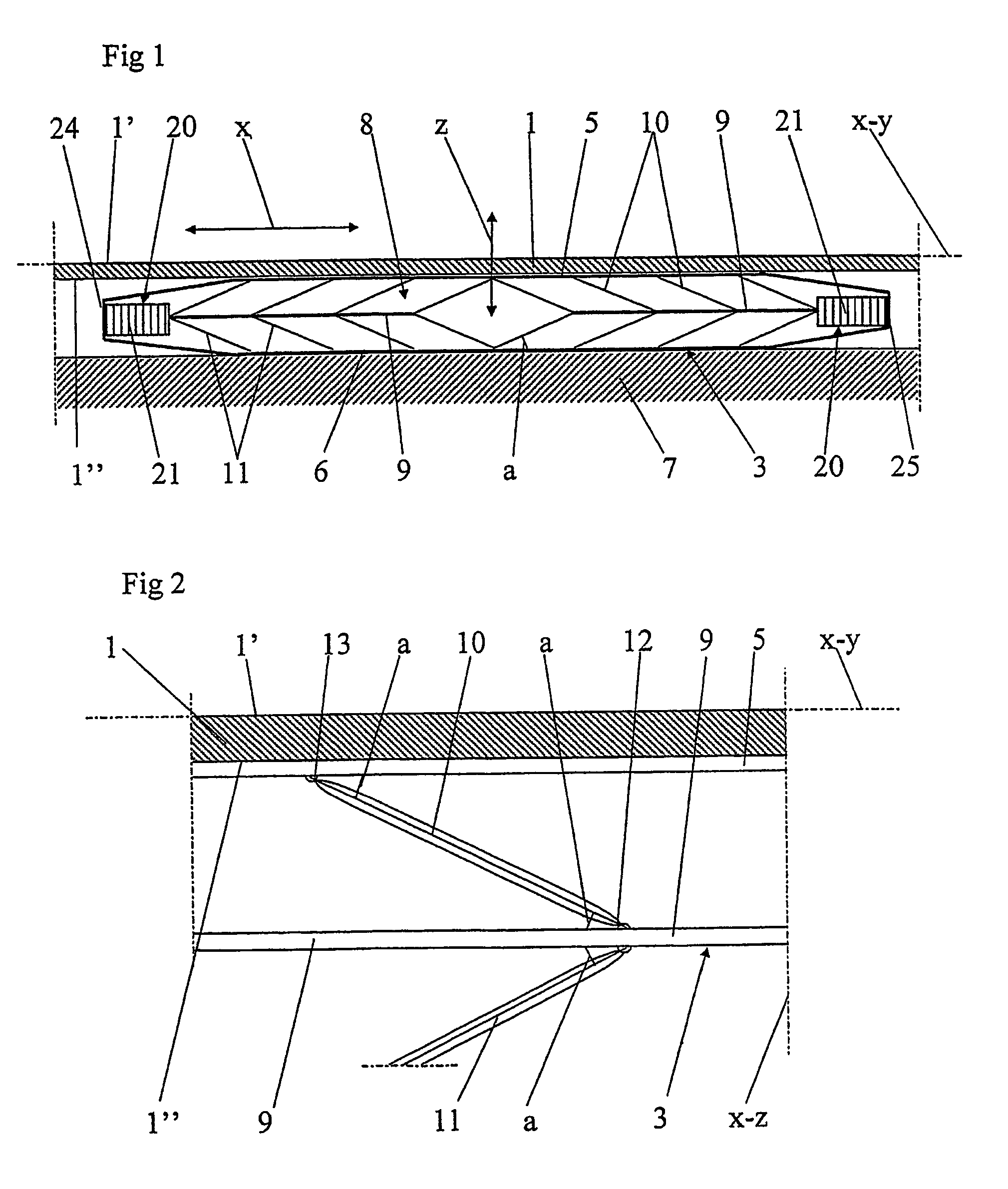

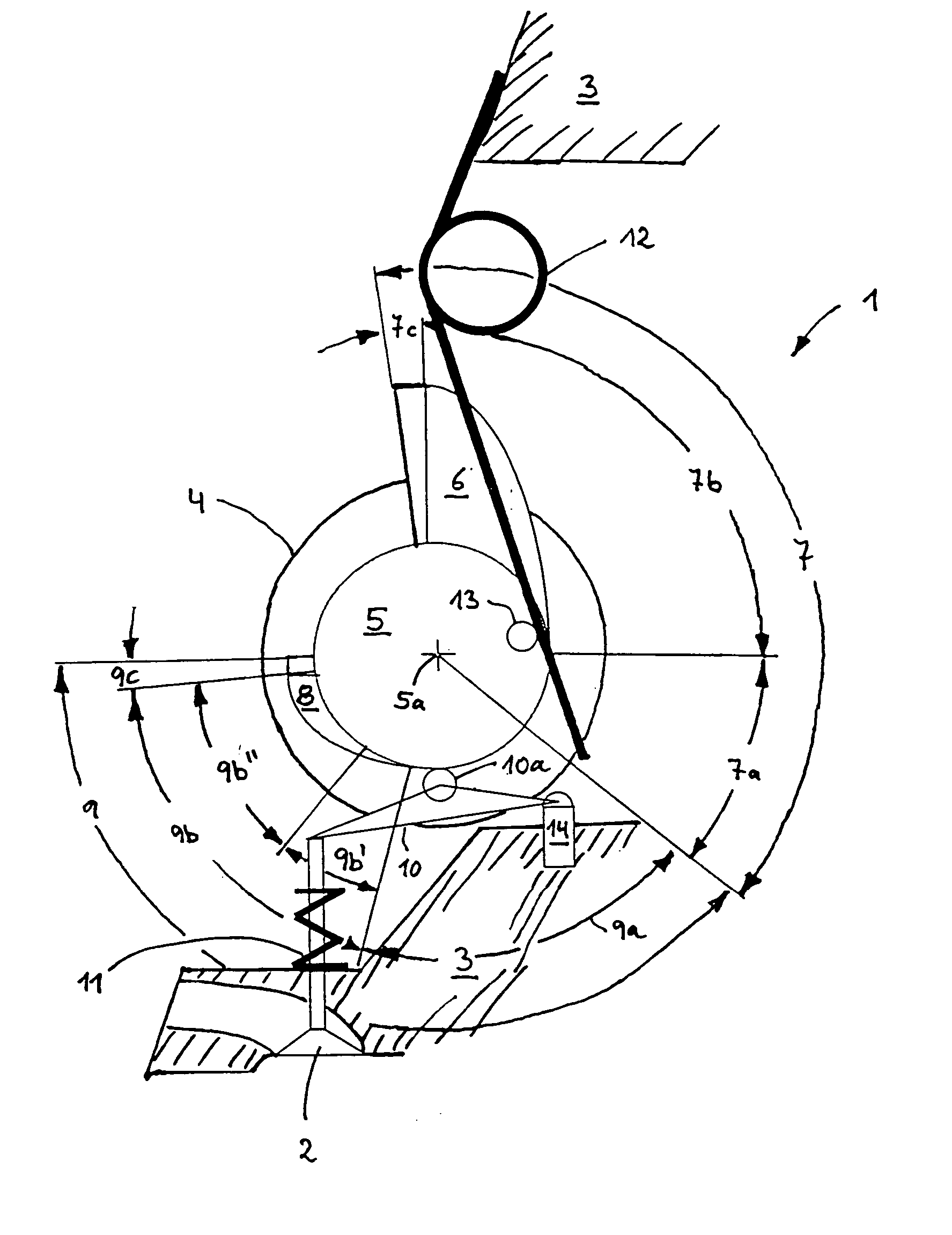

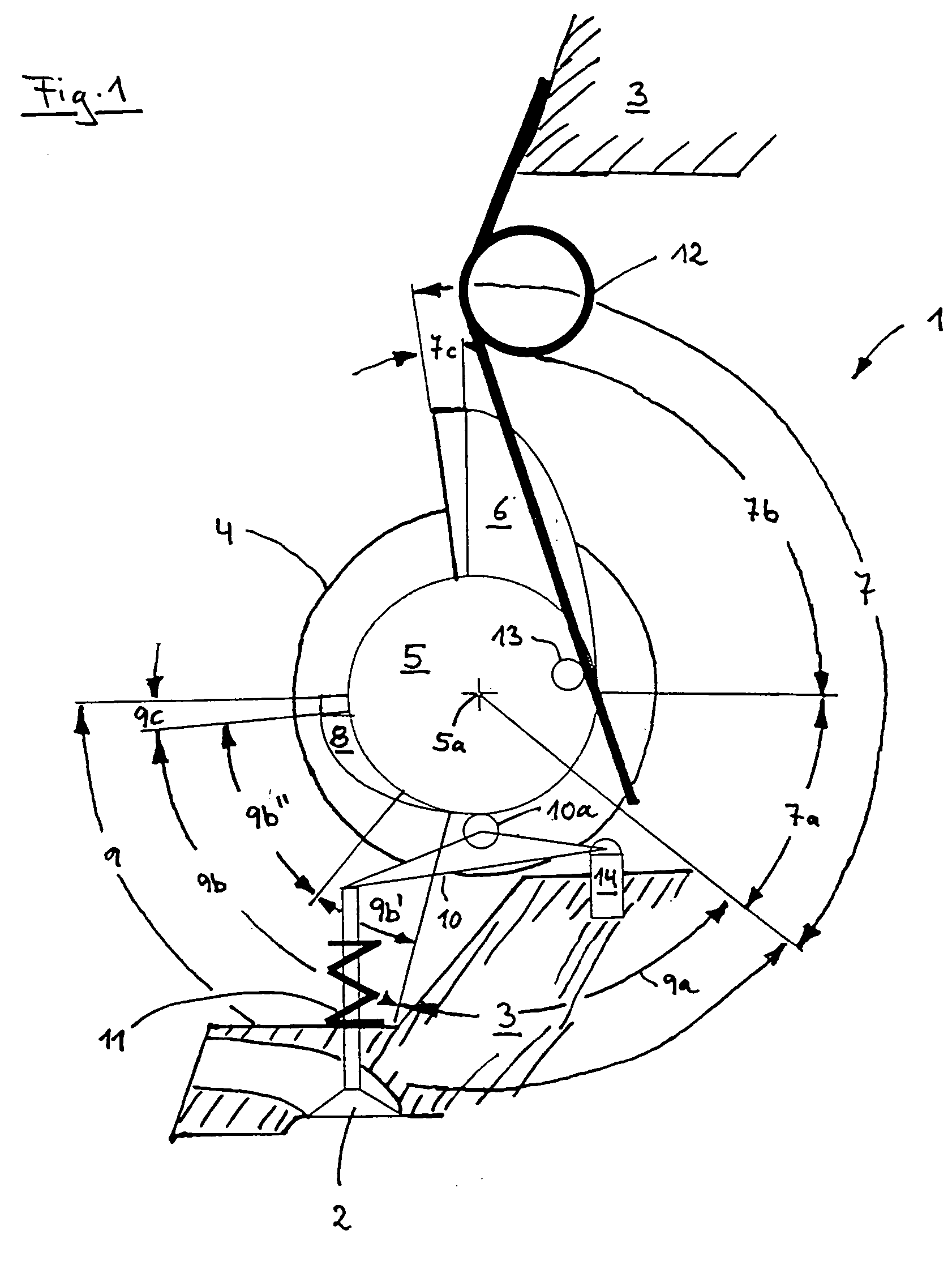

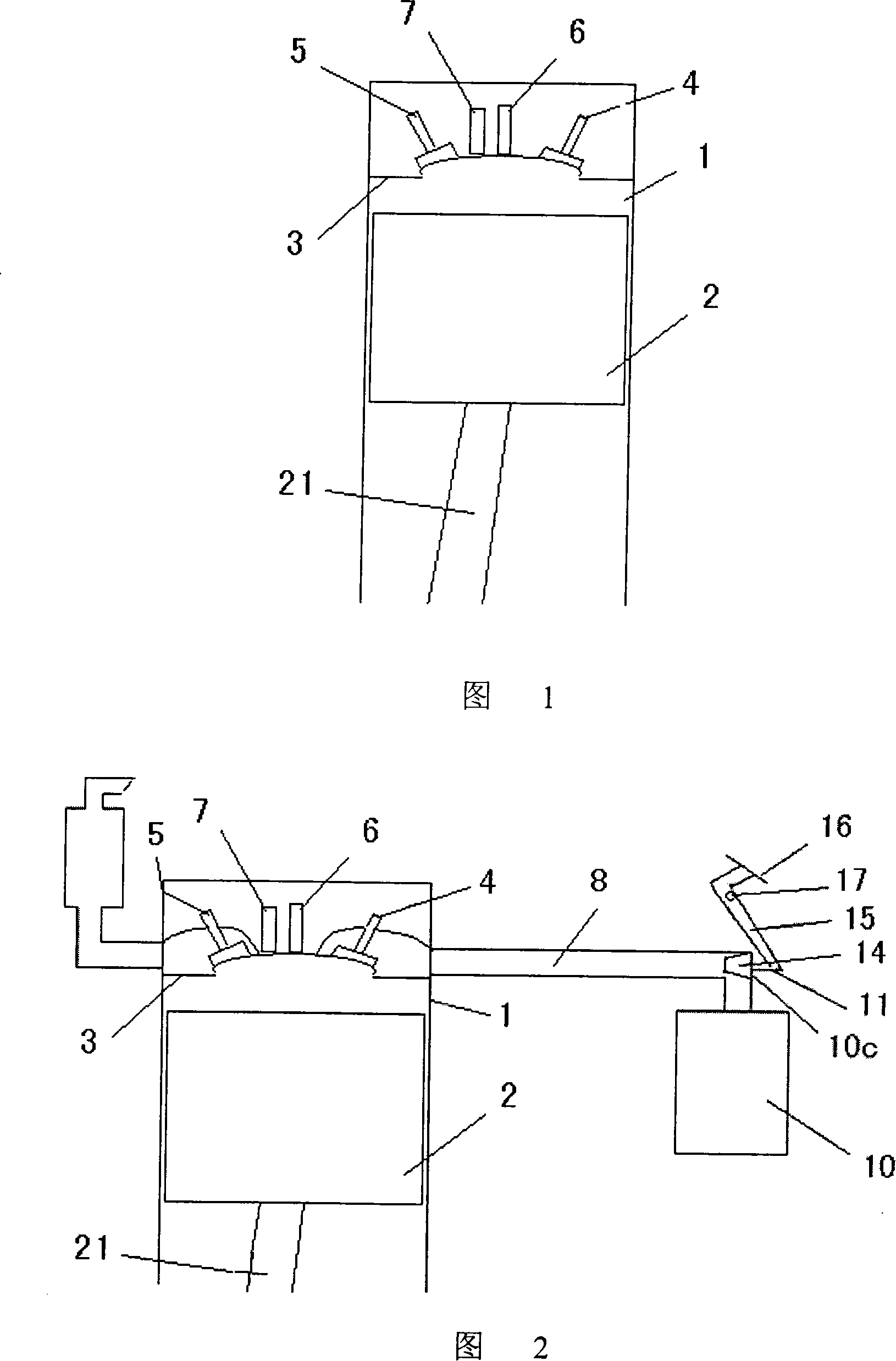

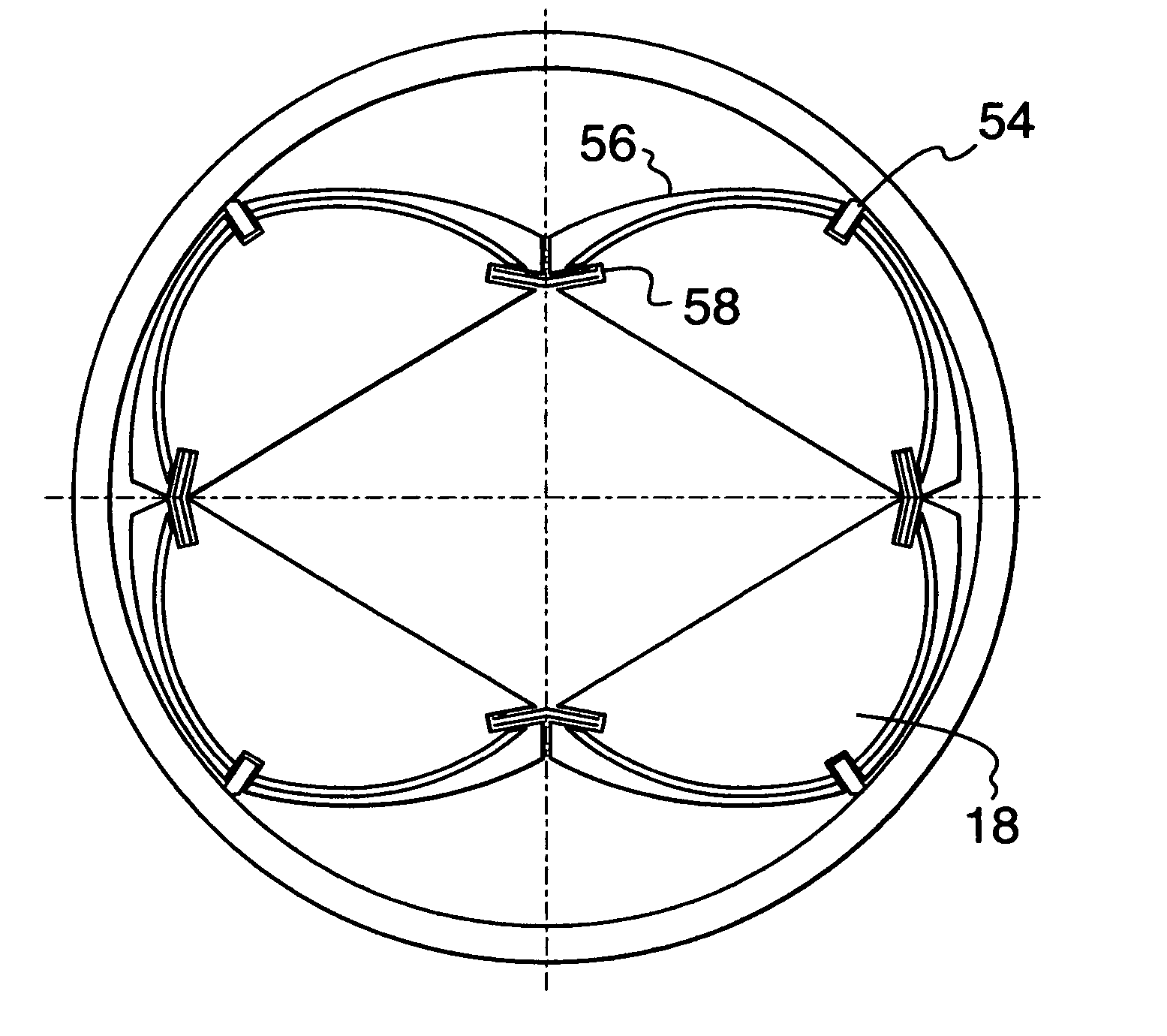

Device for actuating a membrane and a vehicle comprising a device for actuating a membrane

InactiveUS7236602B2Effective movementAvoid short lengthBending wave transducersMechanical vibrations separationEngineeringMechanical engineering

A device is provided for actuating a membrane arranged in an opening to a space, and a vehicle having such a device. The membrane has a first surface and a second opposite surface, and is limited by an edge area. The device includes a first strip to be attached to the second surface of the membrane in the edge area, and a second strip to be attached to a surface of a frame portion extending around the opening. An exchanging member is arranged between and connecting the first strip and the second strip. An actuating member is arranged to transfer a reciprocating primary movement to the exchanging member converting the primary movement to a reciprocating secondary movement, which has a longer length of stroke than the primary movement and acts on the strips to move towards and away from each other.

Owner:MAGNA DONNELLY

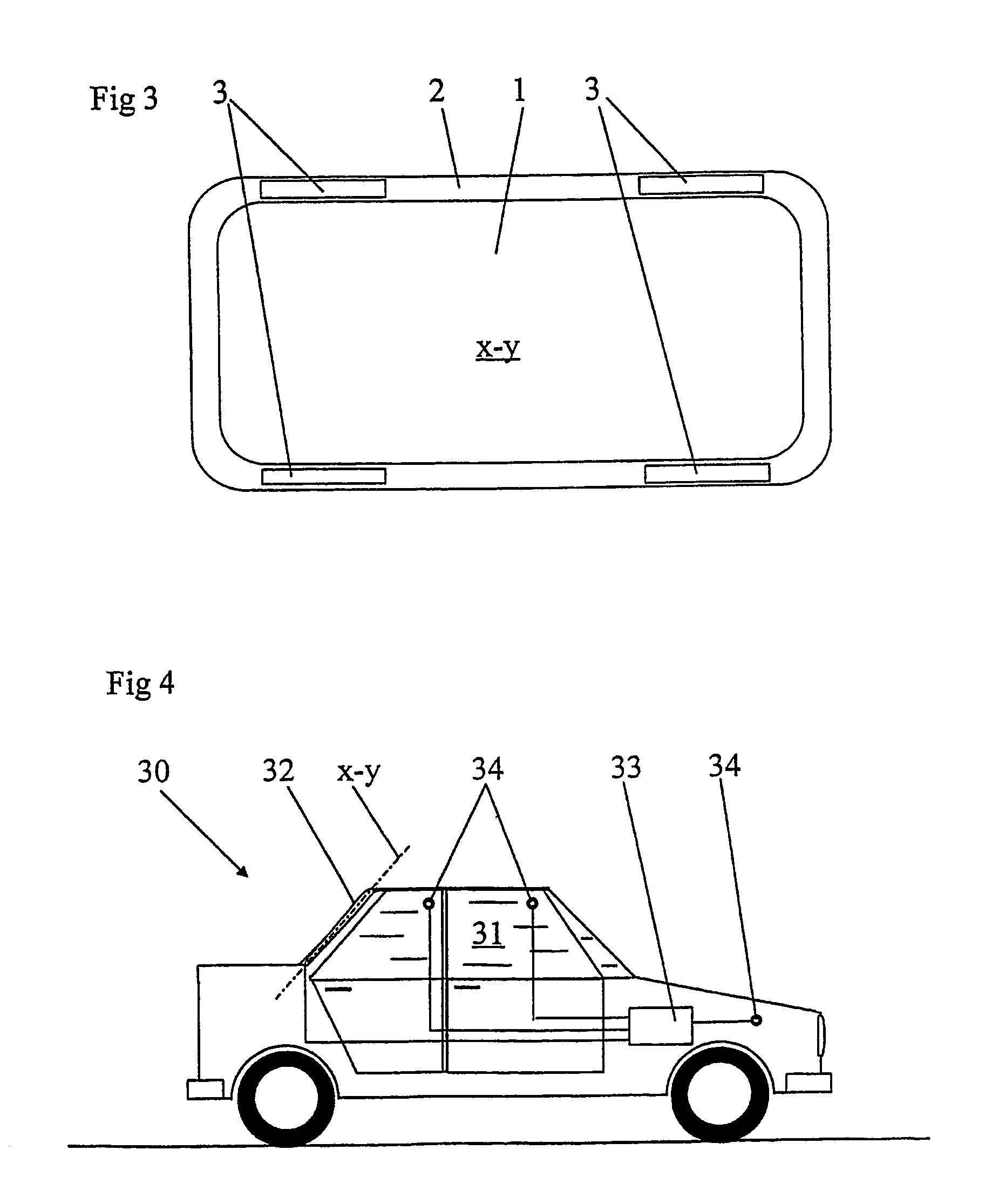

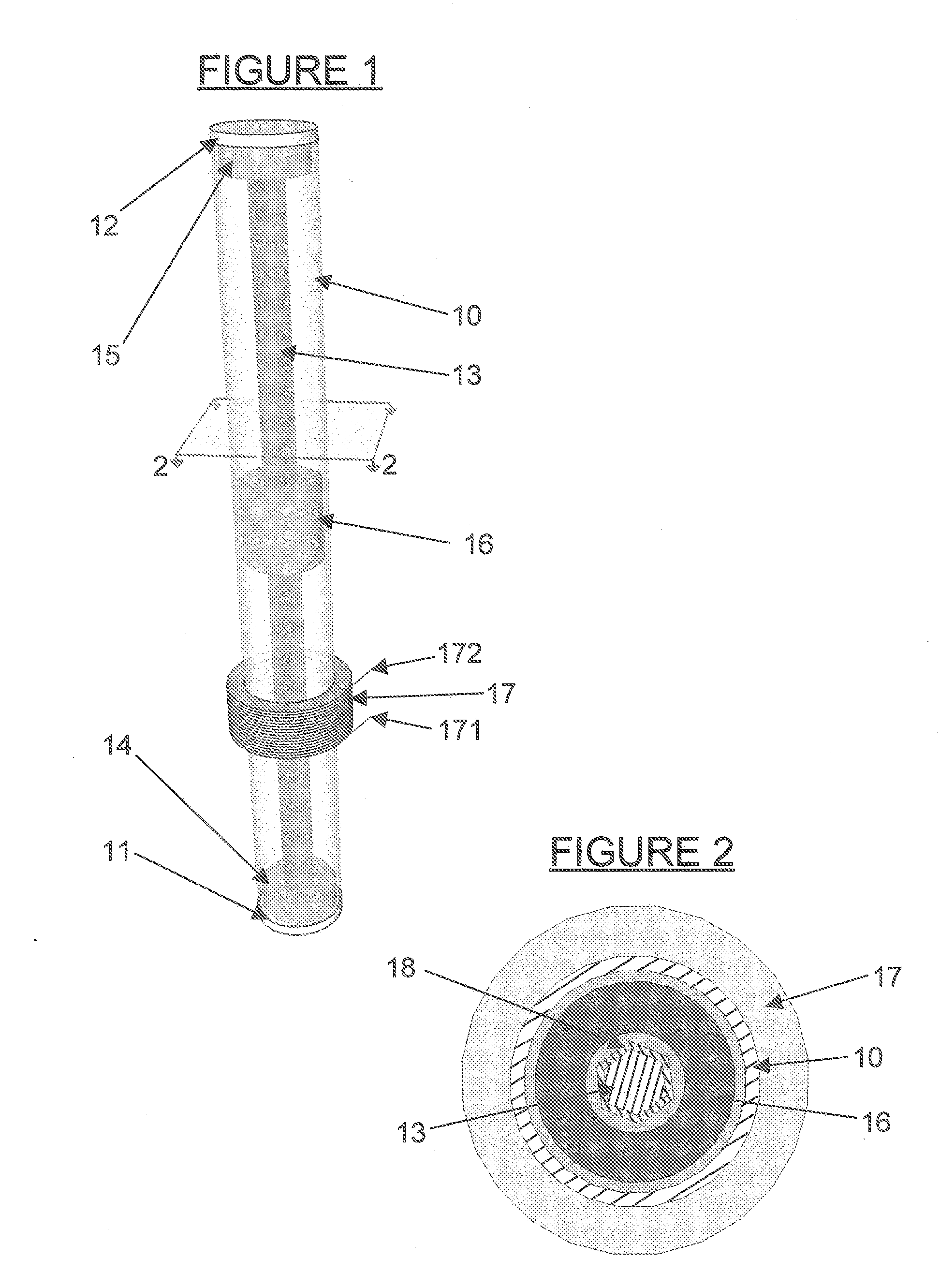

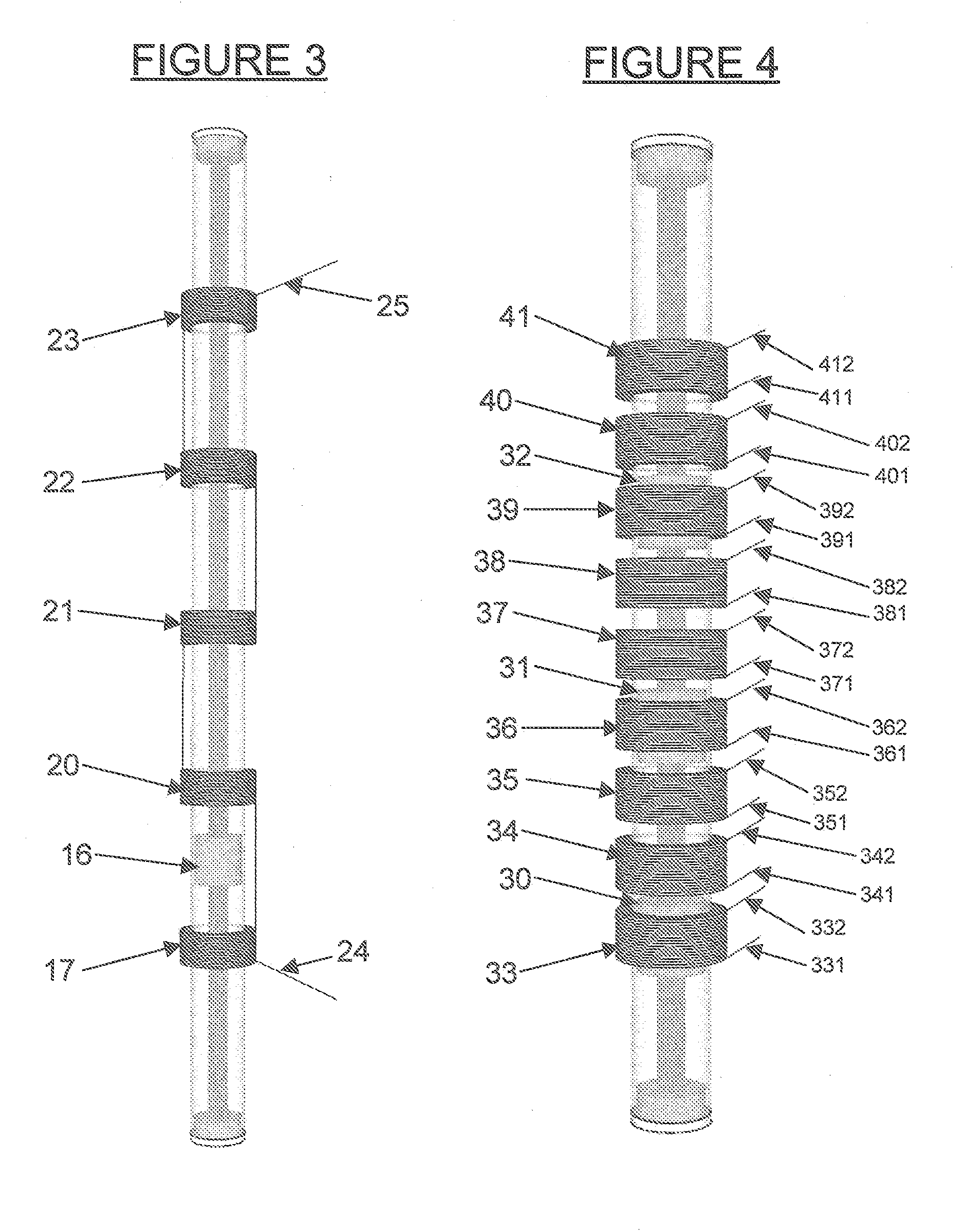

Portable Linear Generator

A portable linear generator for use as a battery charging element inside a portable powered device using multiple permanent magnets arranged linearly with each magnet constrained to repel each nearest magnet, one of the magnets fixed at one or each end of the array, one or more of the magnets free to move along the axis of the array, a guide rod extending through the magnets having a low friction or low friction and diamagnetic surface, and coaxially wound coil or coils of magnet wire arranged to electrically connect outside the device.

Owner:GENNEO

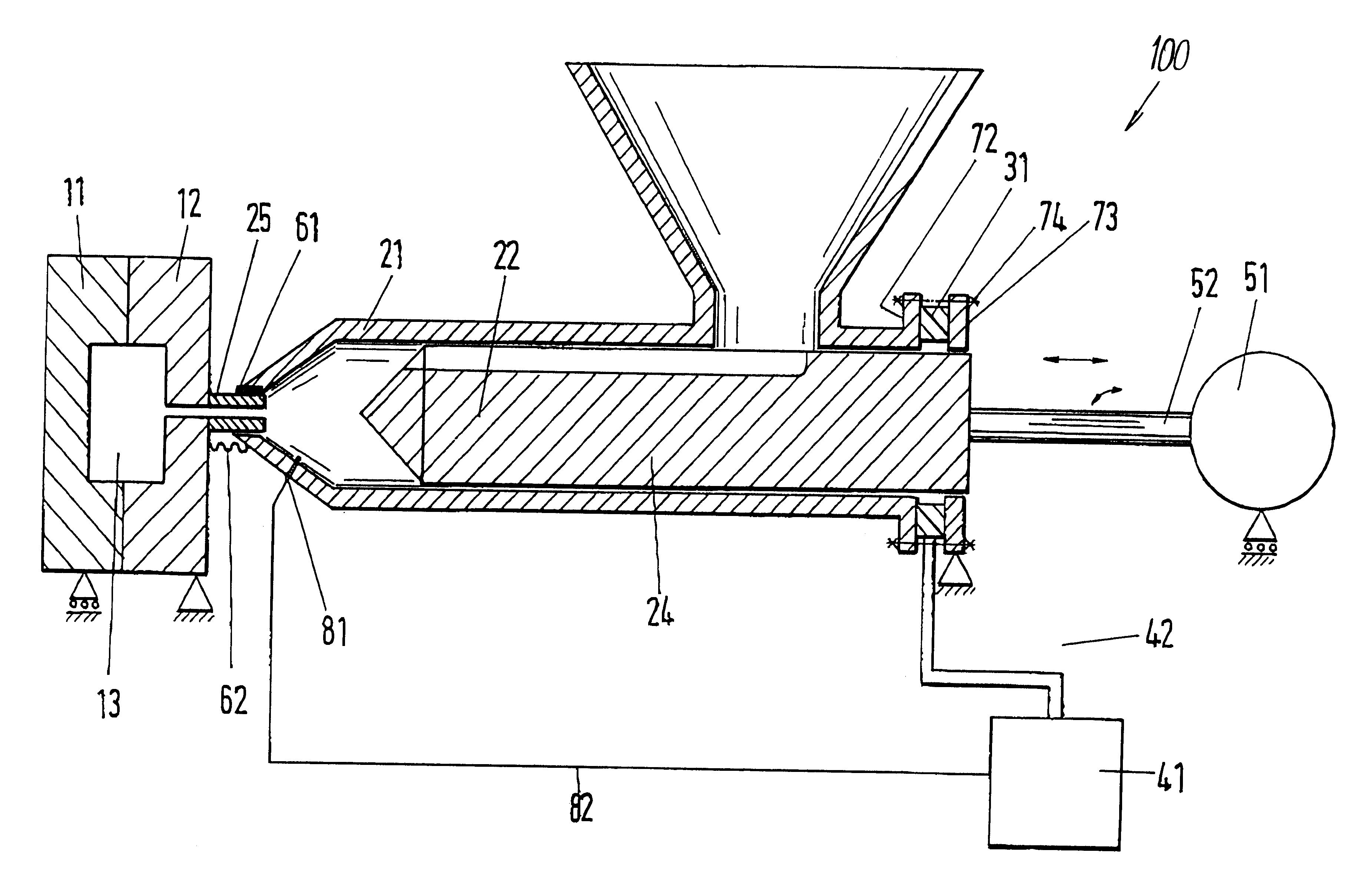

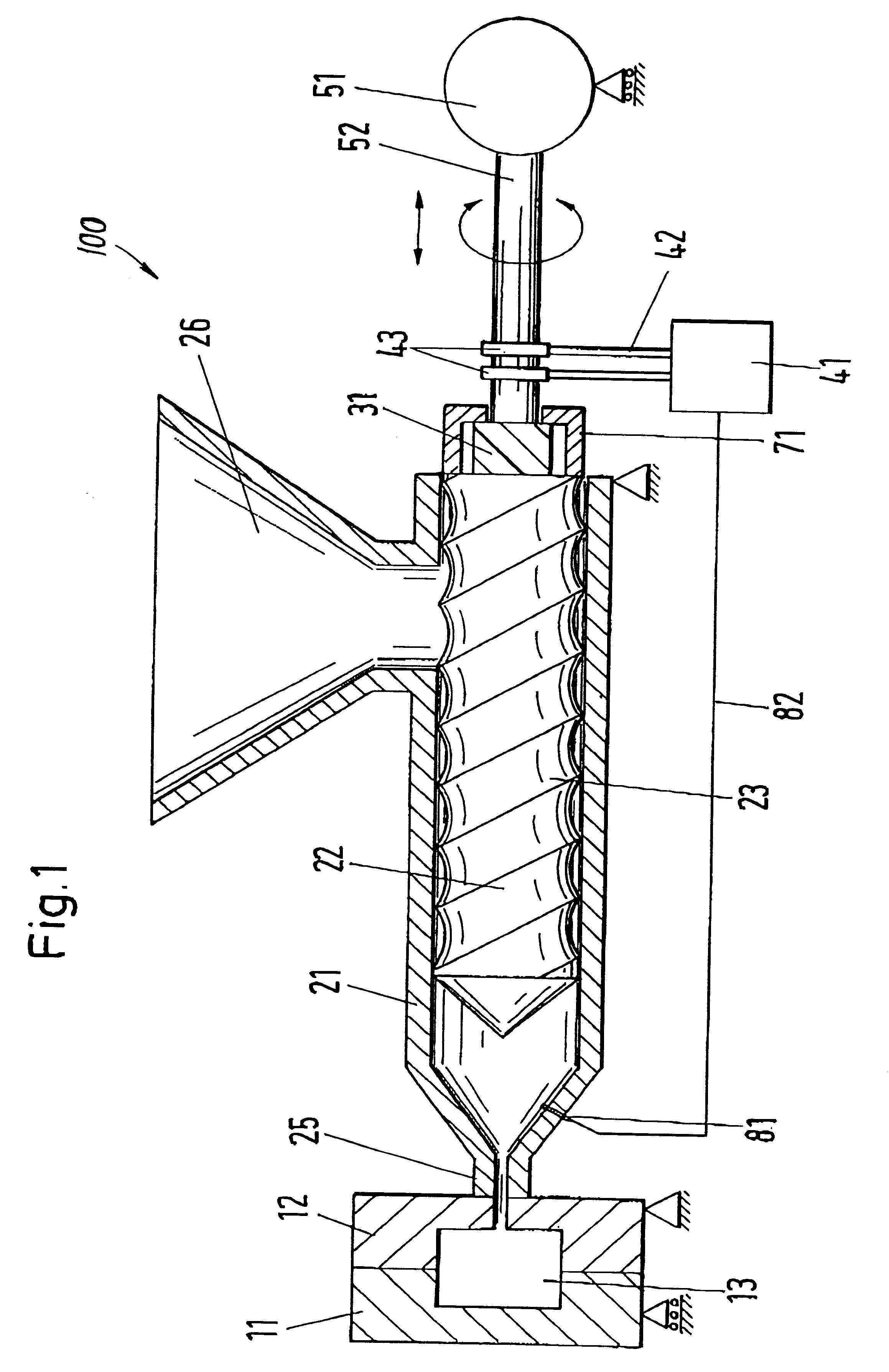

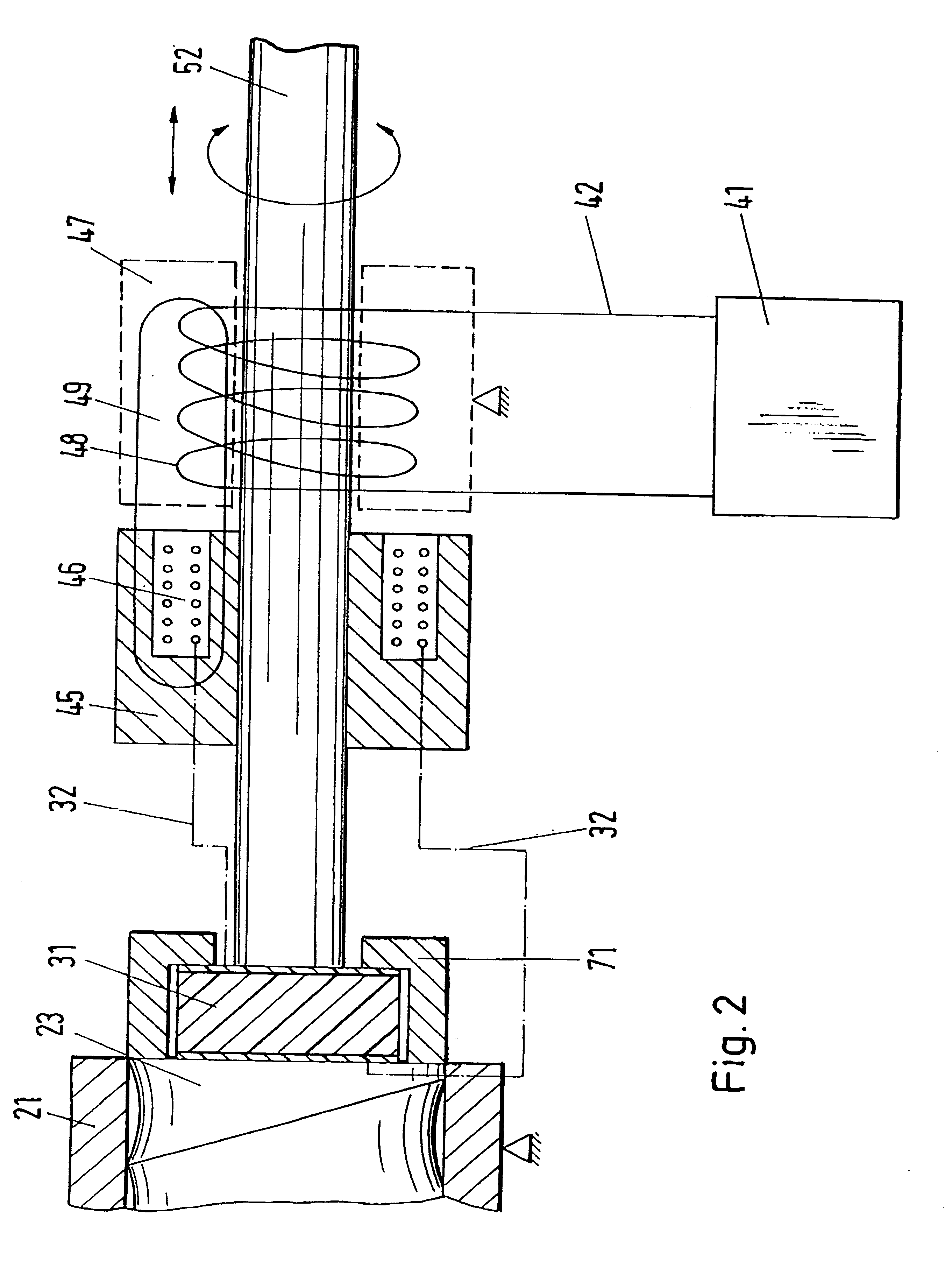

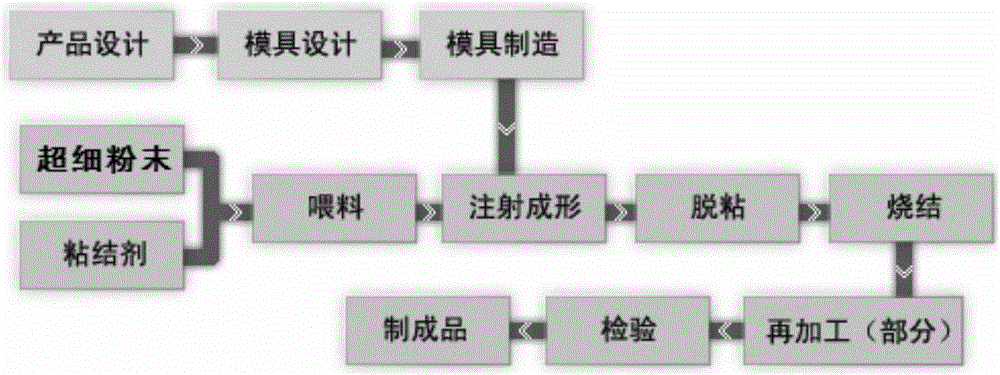

Resonating injection molding machine and process for its operation

InactiveUS6203747B1Reducing internal molecular frictionImprove the mixing effectRotary stirring mixersFrozen sweetsEngineeringInjection moulding

An injection molding machine includes an injection molding cylinder with a material supply at one end and an injection nozzle at the other end and a material conveyance unit attached to a drive and movable in the injection molding cylinder. The injection molding machine also includes a vibration element for inducing a flow of melt within the injection molding cylinder for homogenizing the melt.

Owner:ATECS MANNESMANN GMBH +1

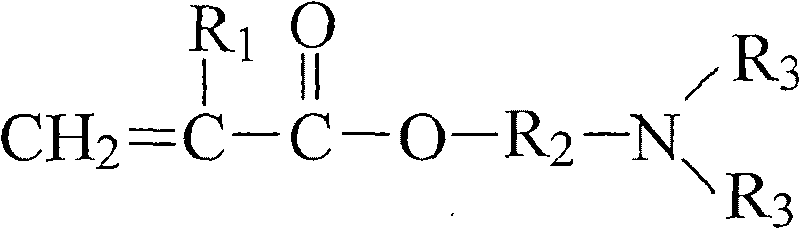

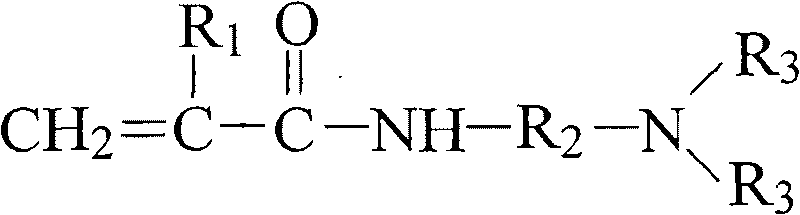

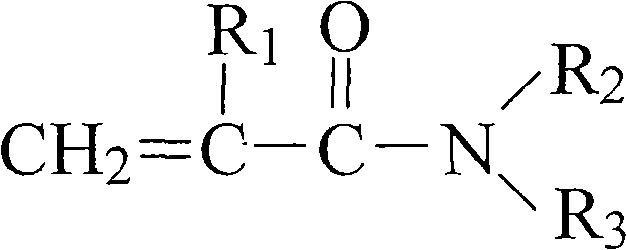

Preparation method of water-soluble polymer dispersion

The invention relates to a preparation method of a water-soluble polymer dispersion. The water-soluble monomer is dispersed in a solution polymerization system containing a dispersant, an initiator and a metal ion scavenger to perform polymerization and obtain the water-soluble polymer dispersion, wherein the dispersant is a composite dispersant system and contains at least one kind of water-insoluble inorganic macroparticles and at least one water-soluble polymer dispersant. The invention utilizes the composite dispersant system in which the water-insoluble inorganic macroparticles are matched with the polymer dispersant to form dispersion coating mechanism so as to reduce the concentration of high molecular polymer in continuous phase and ensure that the rolling friction and rigid impact are mainly adopted between the polymer molecule chain and the macroparticles. Therefore, the viscosity of the dispersion is effectively reduced while the molecular weight of polyacrylamide polymer in the dispersion is not reduced, and the water-soluble polymer dispersion with high concentration, good solubility, uniform dispersion, high efficiency and full water-solubility can be prepared.

Owner:JIANGSU FEYMER TECH

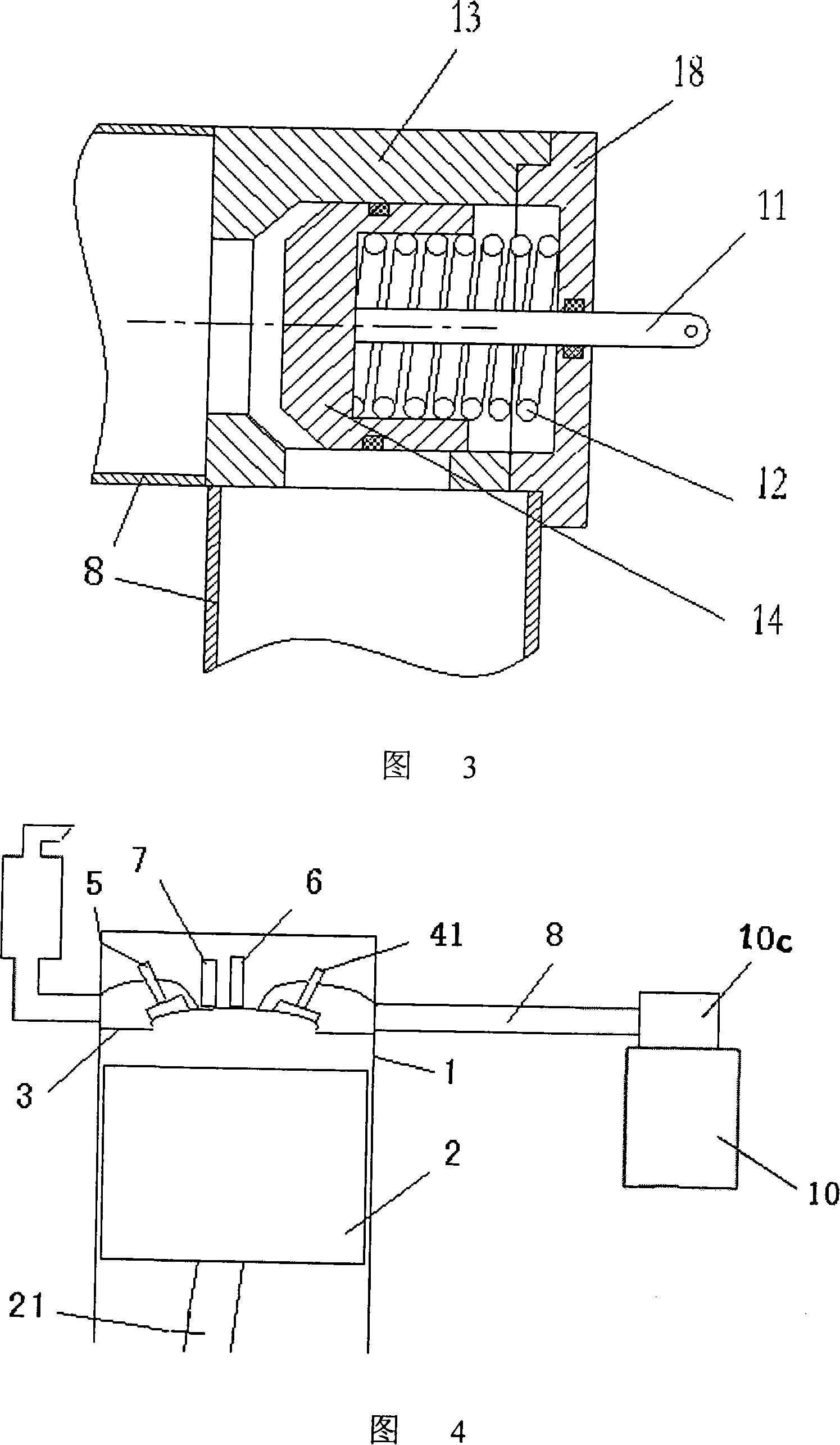

Pivoting actuator system for controlling the stroke of a gas exchange valve in the cylinder head of an internal combustion engine

InactiveUS20060016408A1Reduce power consumptionShorten speedValve drivesMachines/enginesCylinder headExternal combustion engine

Swivel actuator device for lift control of a gas exchange valve in a cylinder head of an internal combustion engine comprising a swivel motor having a shaft on which is provided a first operating element having a control path for opening the gas exchange valve, whereby a second operating element having a second control path provided on the first operating element. Due to the arrangement of the swivel actuator device, less electric power is needed at low rotational speeds and processing of the fuel mixture is improved.

Owner:BAYERISCHE MOTOREN WERKE AG

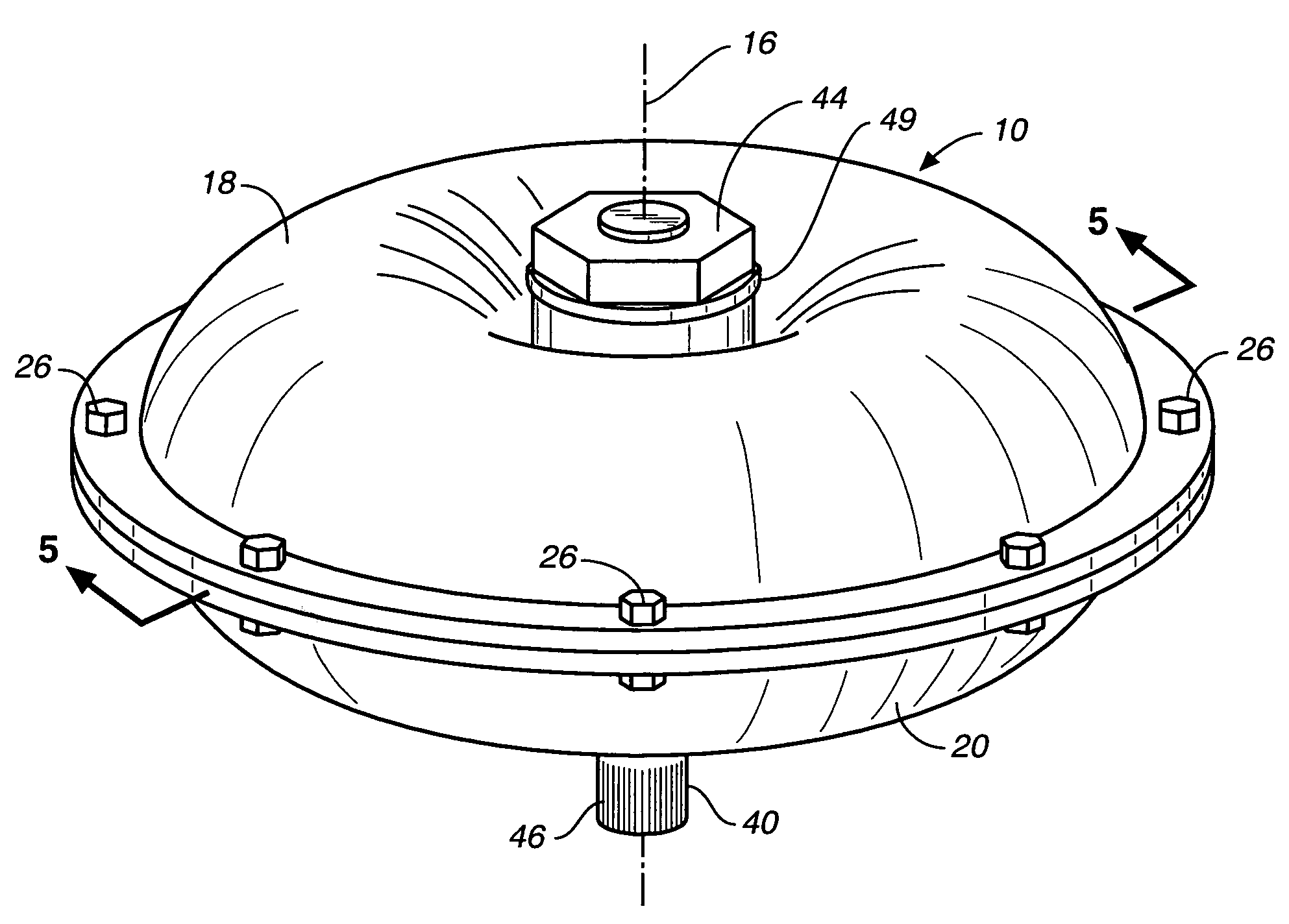

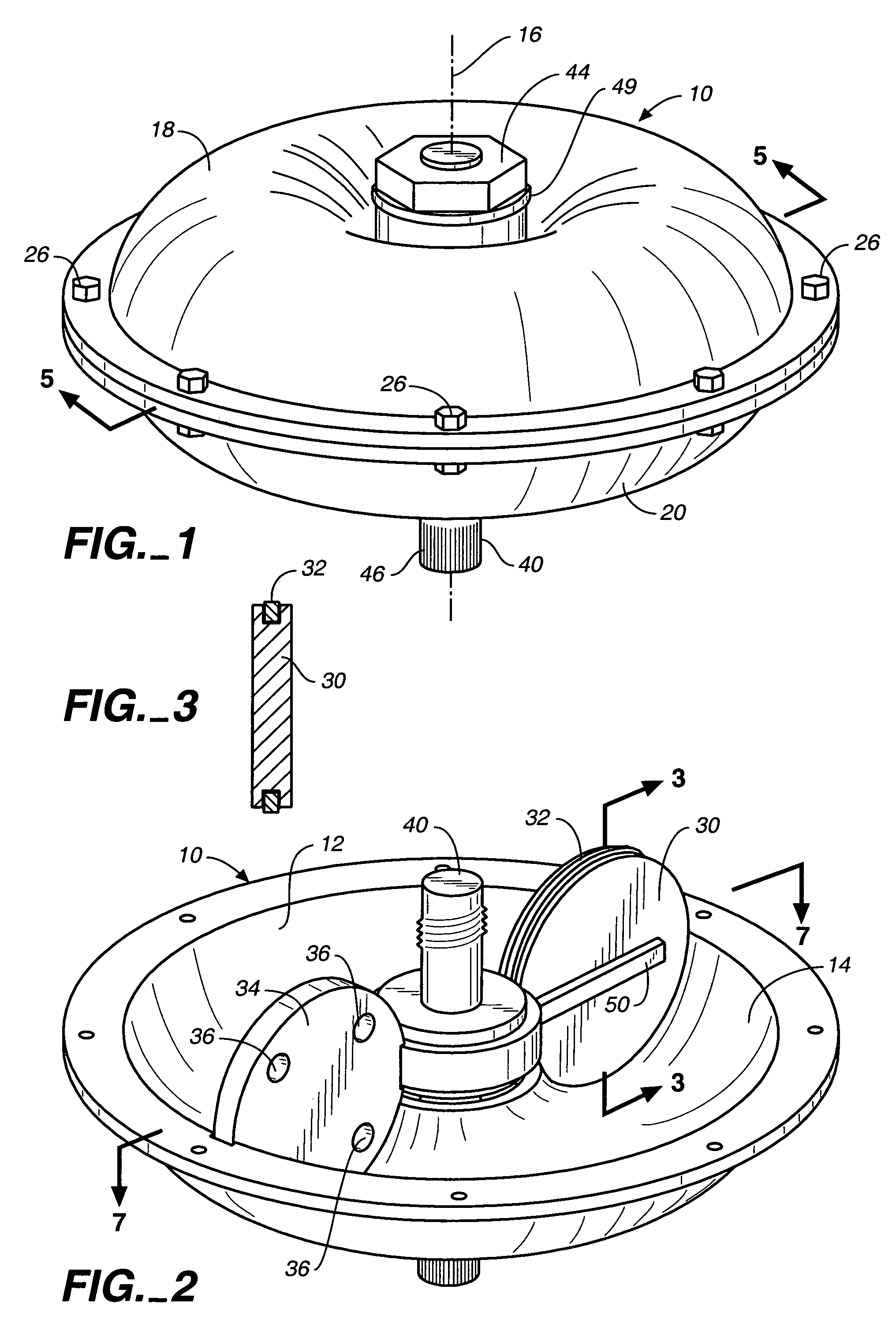

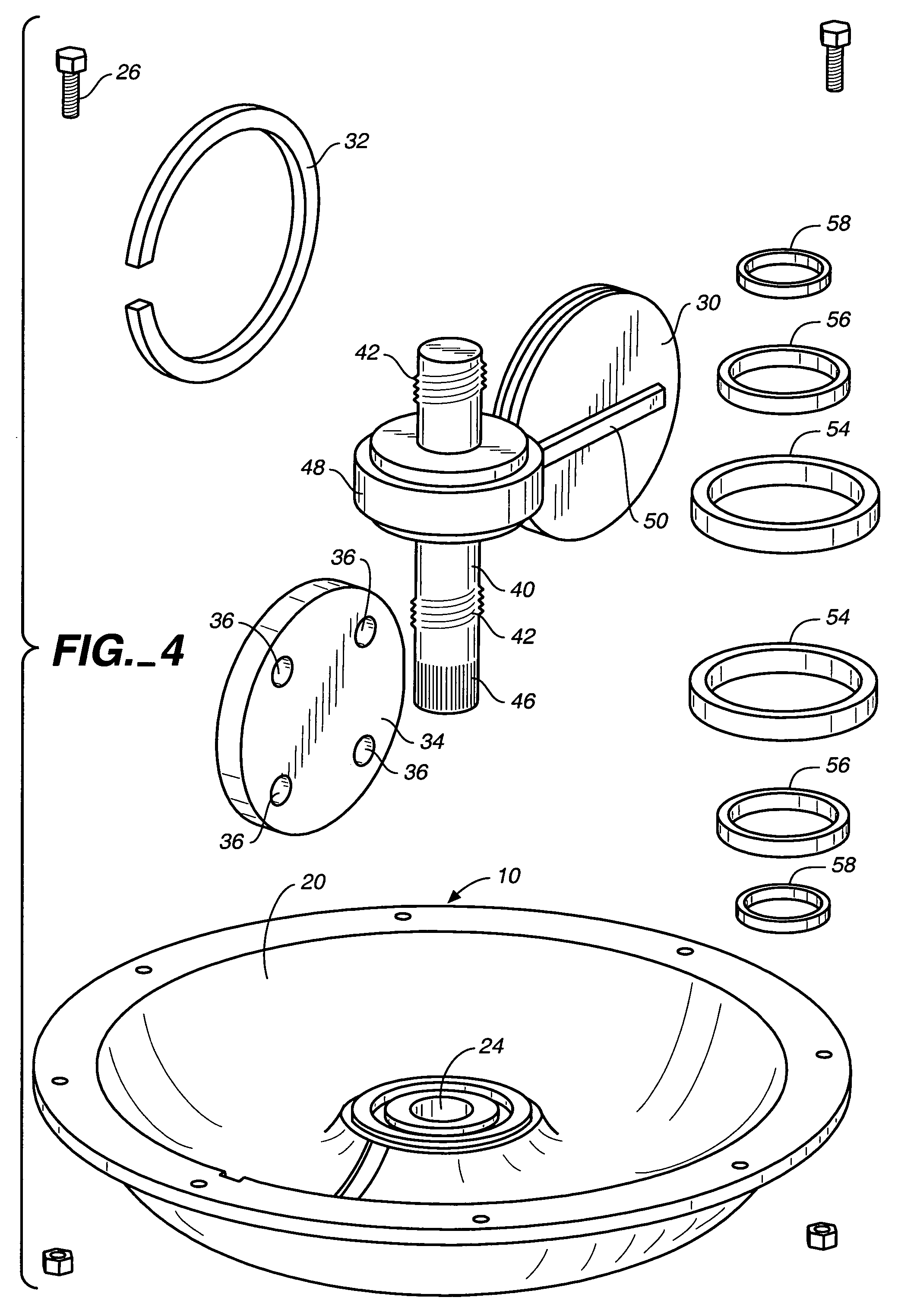

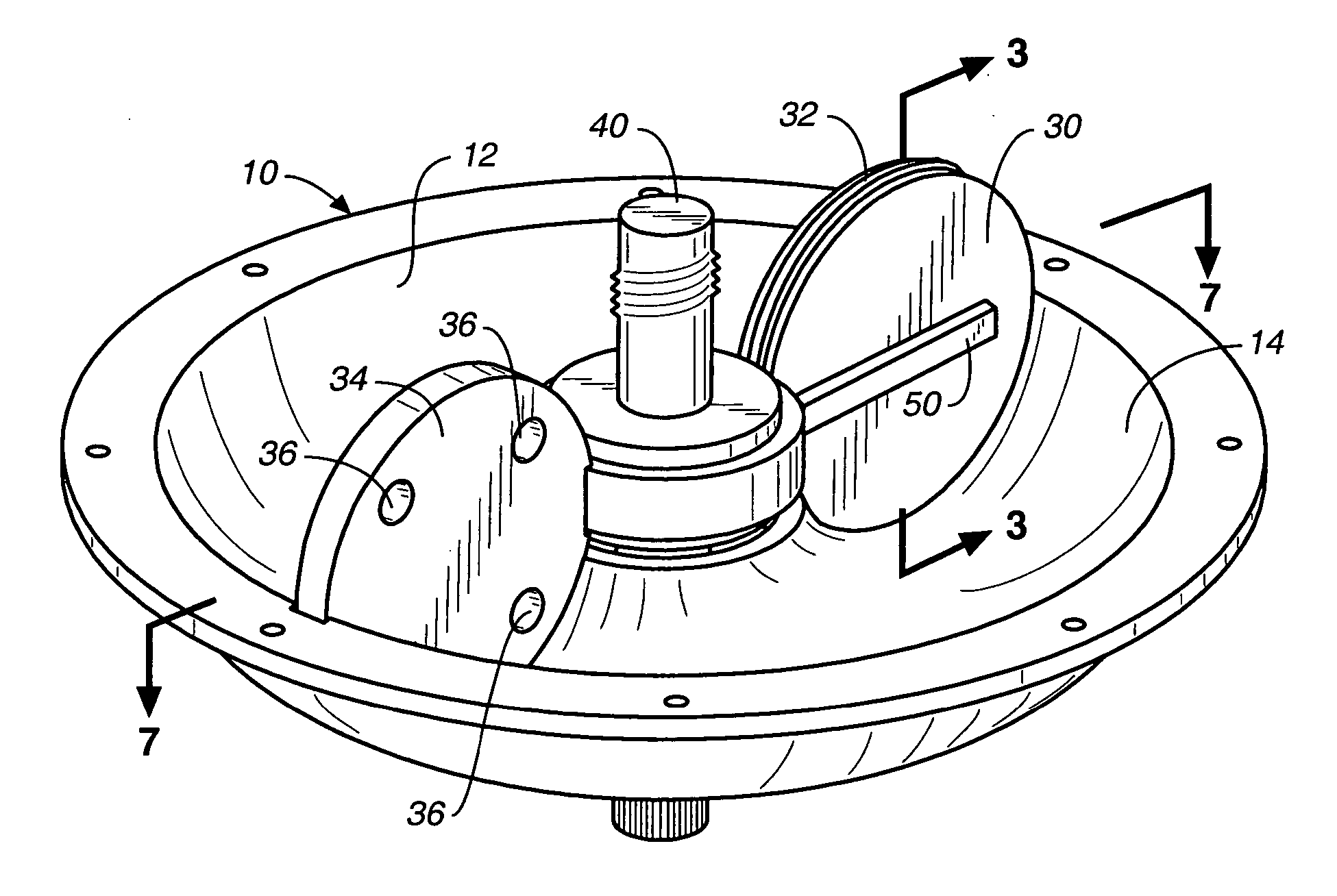

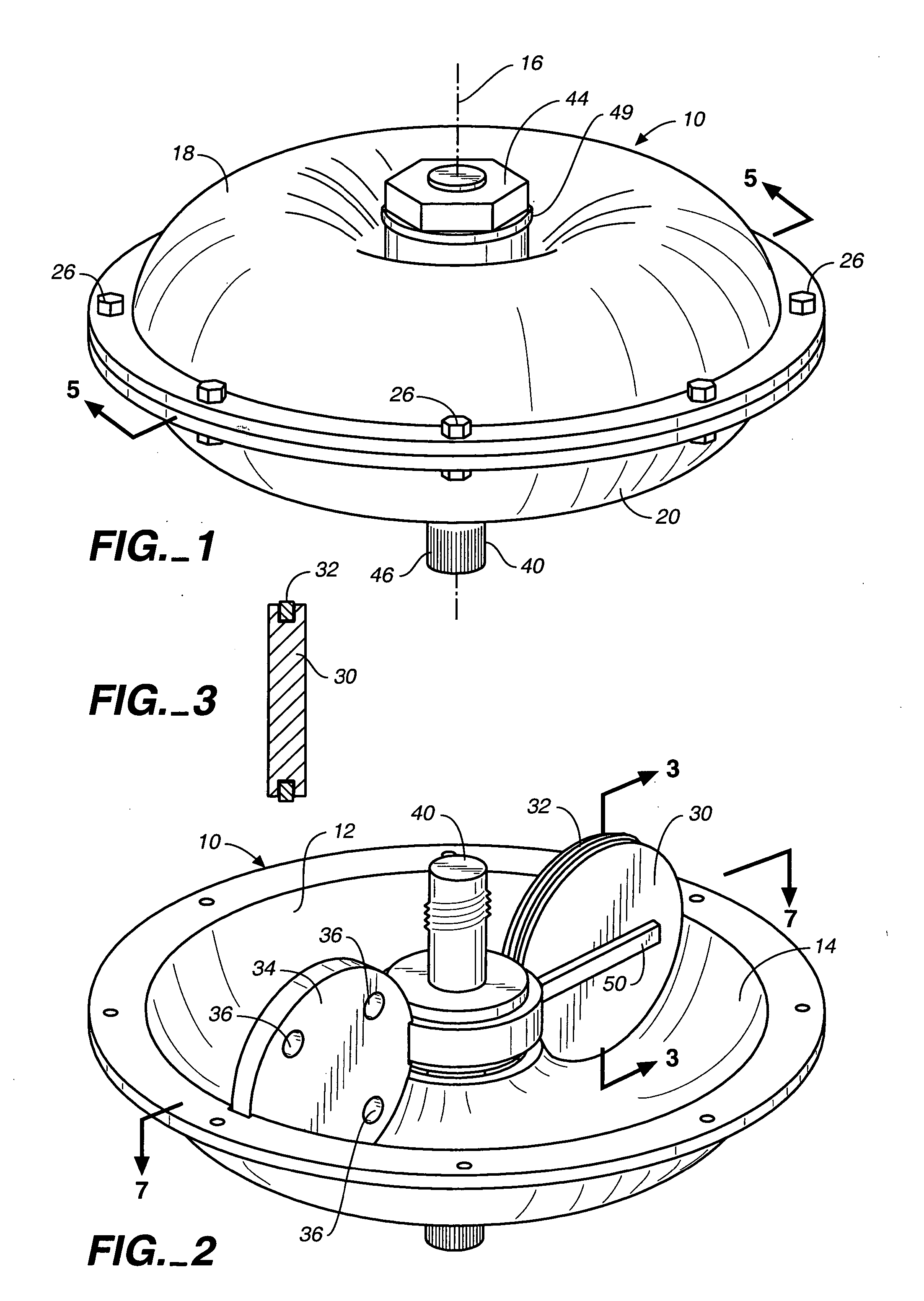

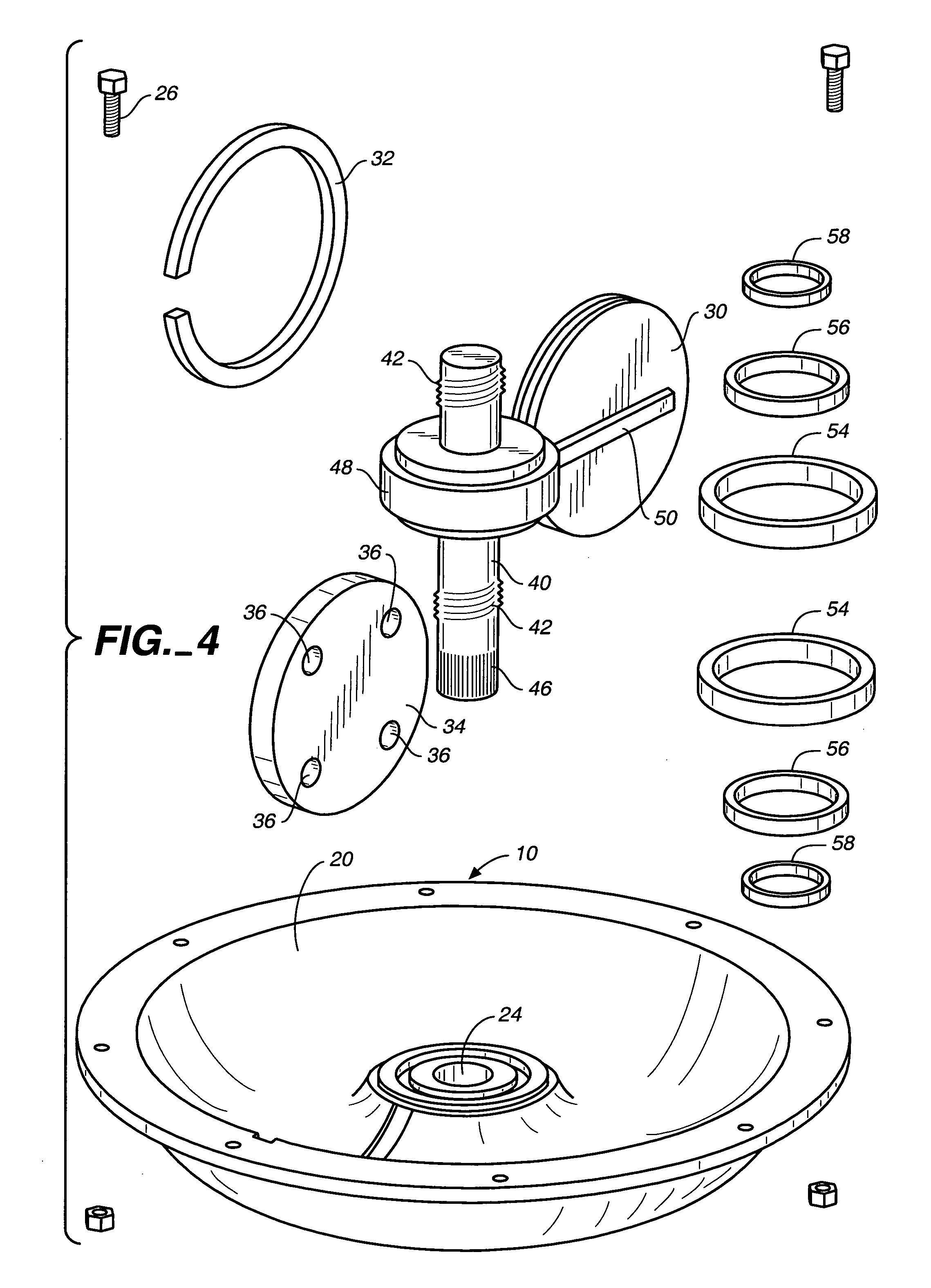

Toroidal rotary damper apparatus

A toroidal rotary damper apparatus includes a housing having a toroidal inner housing surface and a piston moveable in the housing having a curved outer peripheral piston surface in engagement with the inner housing surface. A fluid barrier is attached to the housing and located in the housing interior. A flow control passageway defined by either the piston or the fluid barrier controls passage of damper fluid when there is relative rotational movement between the piston and the housing to dampen the forces causing relative rotational movement.

Owner:MORADIAN NORICK B

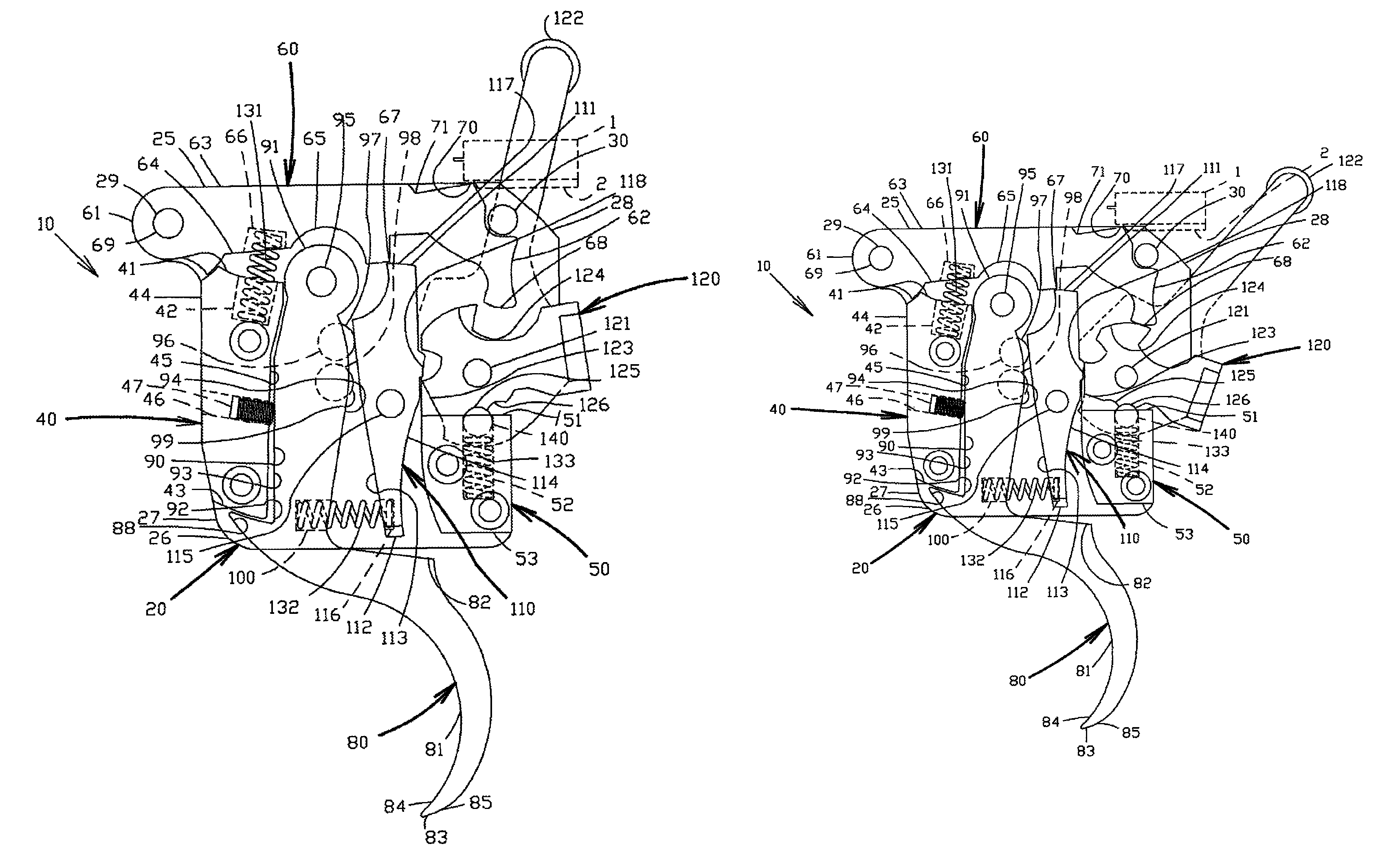

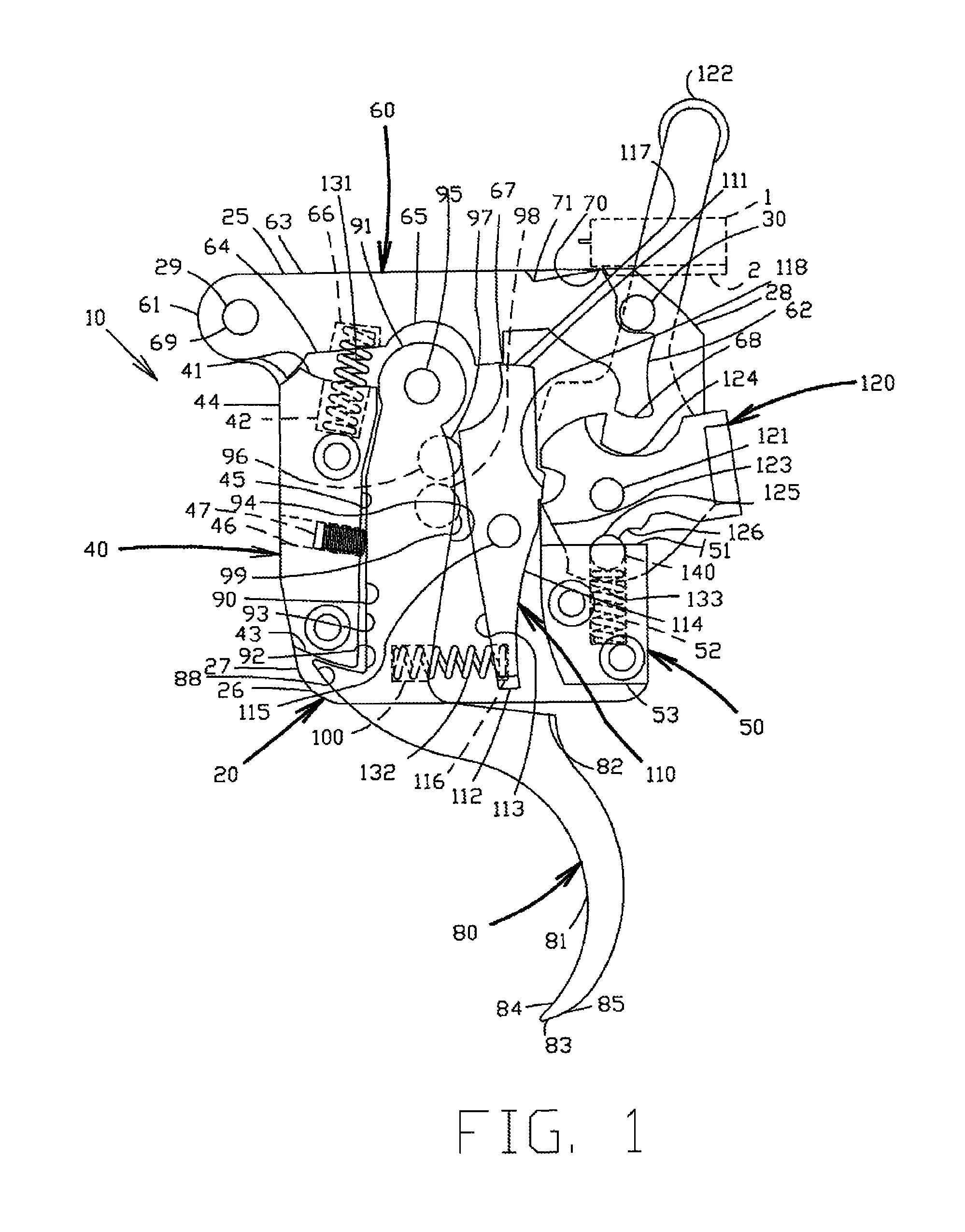

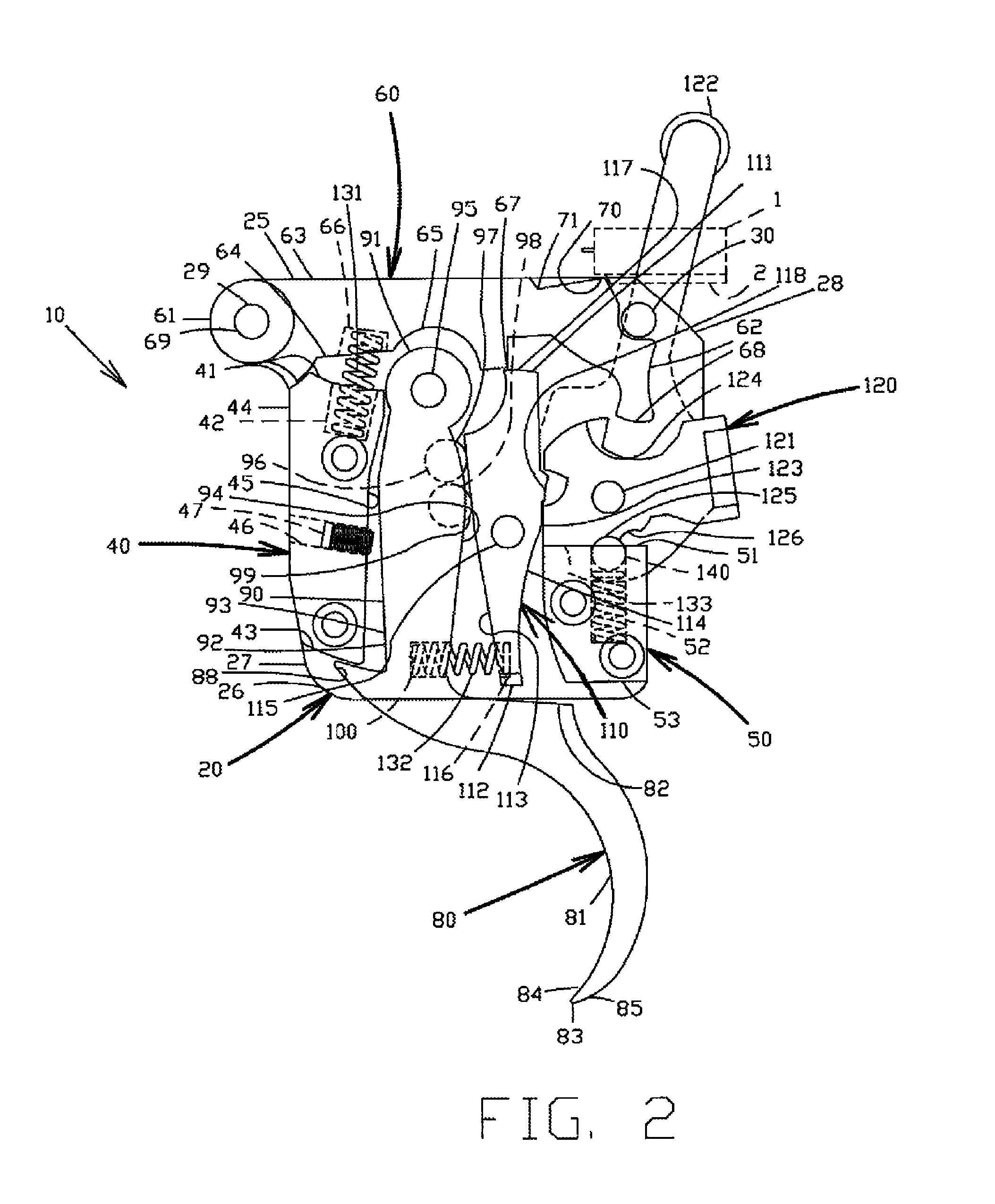

Trigger assembly

InactiveUS8132349B1Reduce internal frictionEasy to adaptSafety arrangementFiring/trigger mechanismsEngineeringMechanical engineering

Owner:HUBER JOHN F

Toroidal rotary damper apparatus

InactiveUS20060096818A1Improve sealingReduce internal frictionLiquid resistance brakesSpringsEngineeringPiston

A toroidal rotary damper apparatus includes a housing having a toroidal inner housing surface and a piston moveable in the housing having a curved outer peripheral piston surface in engagement with the inner housing surface. A fluid barrier is attached to the housing and located in the housing interior. A flow control passageway defined by either the piston or the fluid barrier controls passage of damper fluid when there is relative rotational movement between the piston and the housing to dampen the forces causing relative rotational movement.

Owner:MORADIAN NORICK B

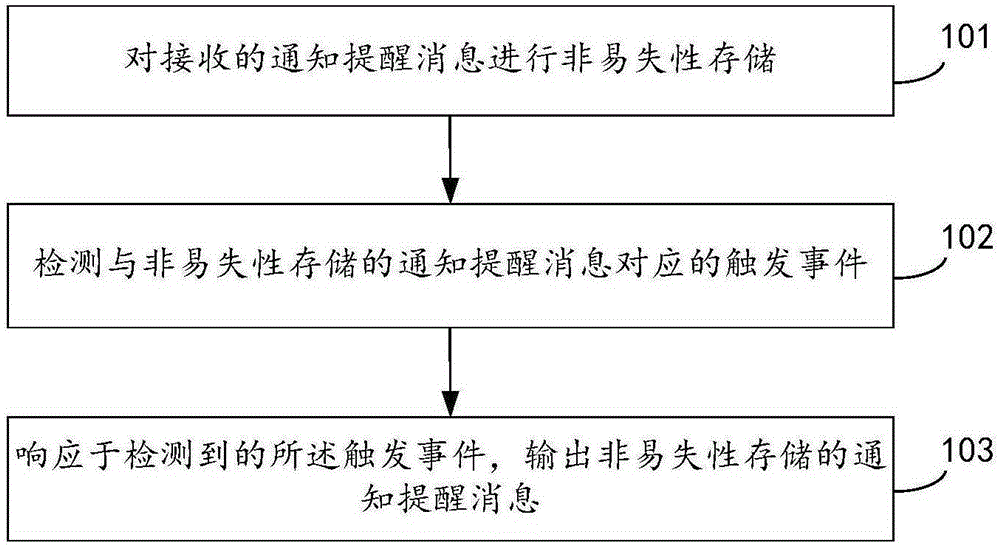

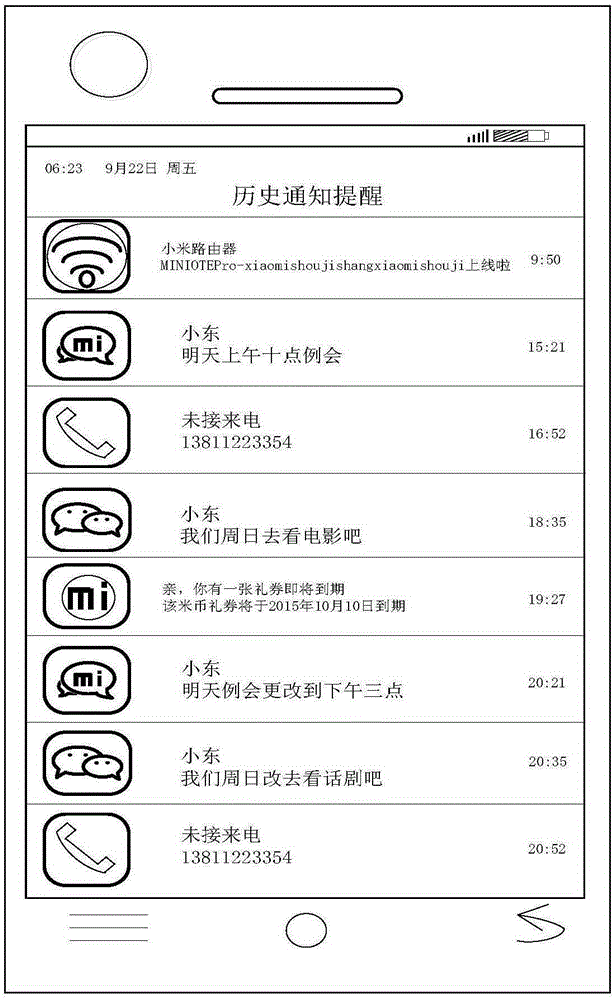

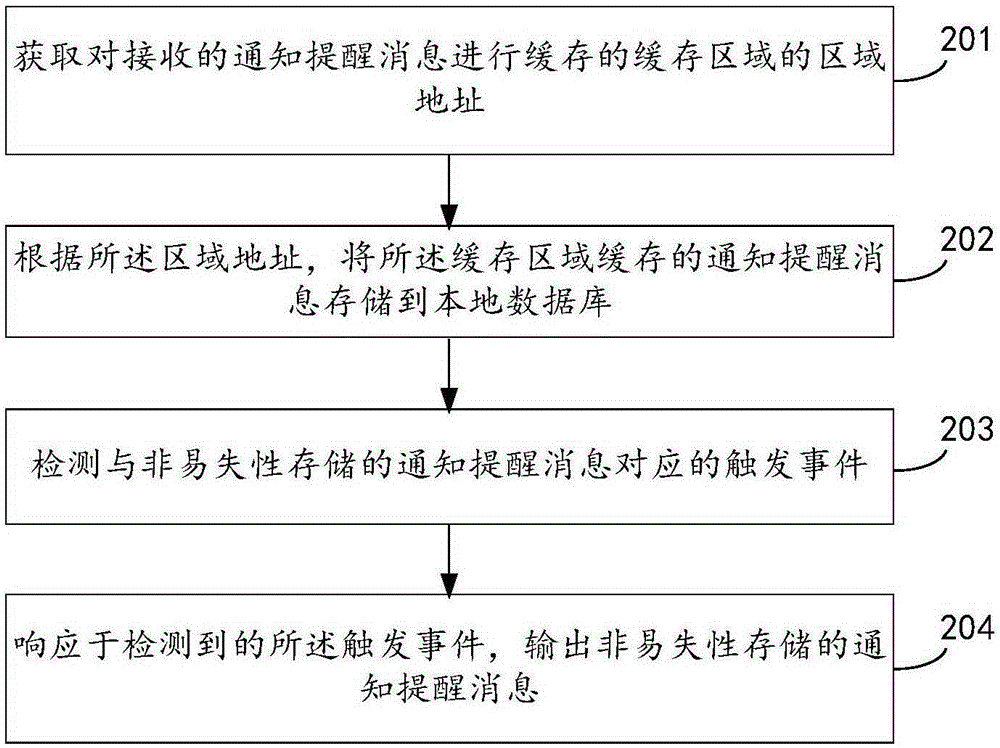

Processing method and apparatus of notification prompting message, and terminal

InactiveCN105225096AImprove experienceIncrease flexibilityOffice automationUser needsReal-time computing

The invention relates to a processing method and apparatus of a notification prompting message, and a terminal. The method comprises the following steps: performing nonvolatile storage on a received notification prompting message; detecting a trigger event corresponding to the notification prompting message stored in a nonvolatile mode; and outputting the notification prompting message stored in a nonvolatile mode in response to the detected trigger event. By using the method, apparatus and terminal provided by the embodiments of the invention, a historical notification prompting message received by a terminal can be output at any time in response to a user need, even if a notification prompt in a notification column is deleted, a historical notification prompt received by the terminal can be output again in response to the user need, and a user can check the historical notification prompt repeatedly so that the flexibility in processing the notification prompt and user experience can be improved.

Owner:XIAOMI INC

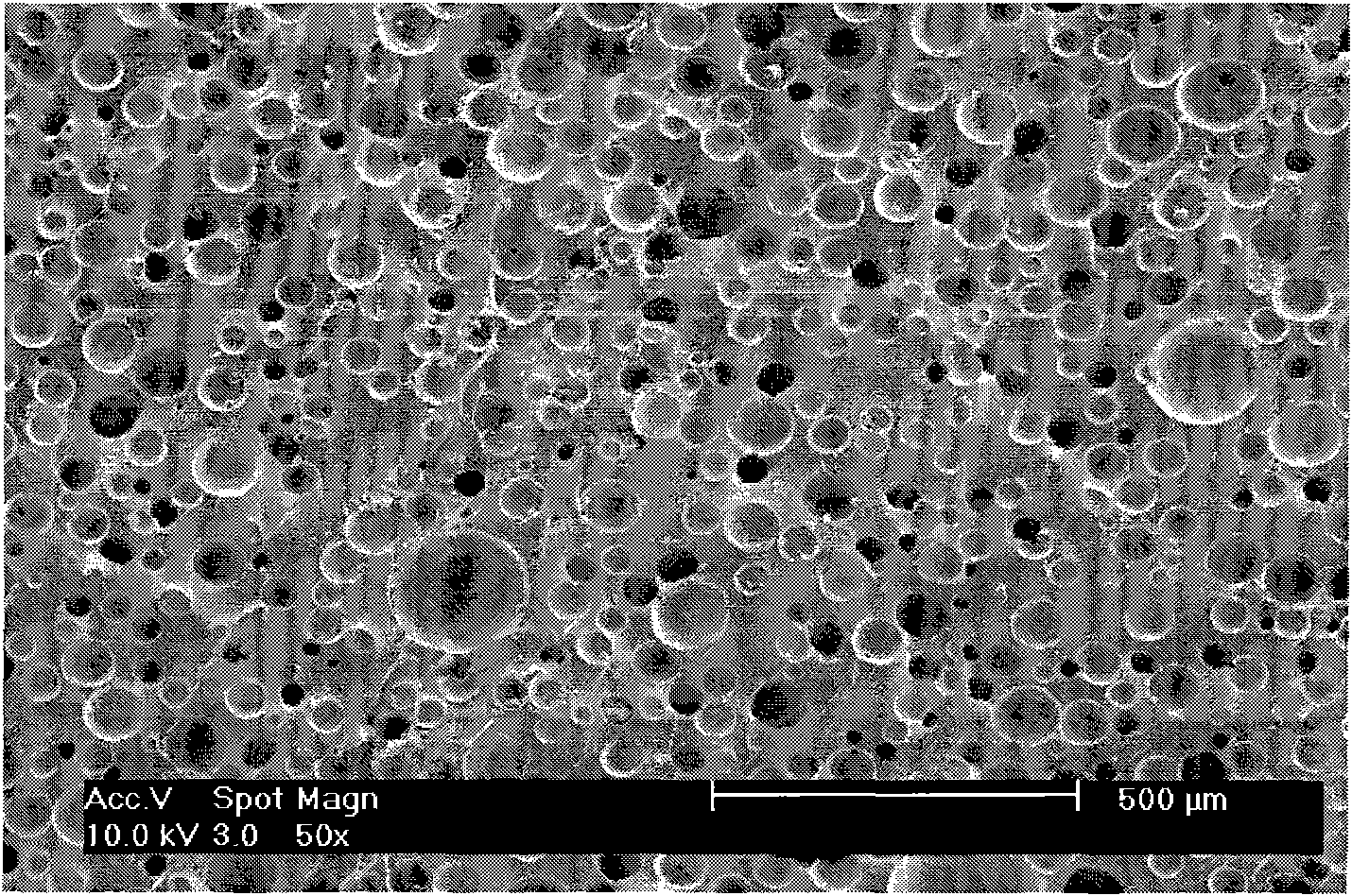

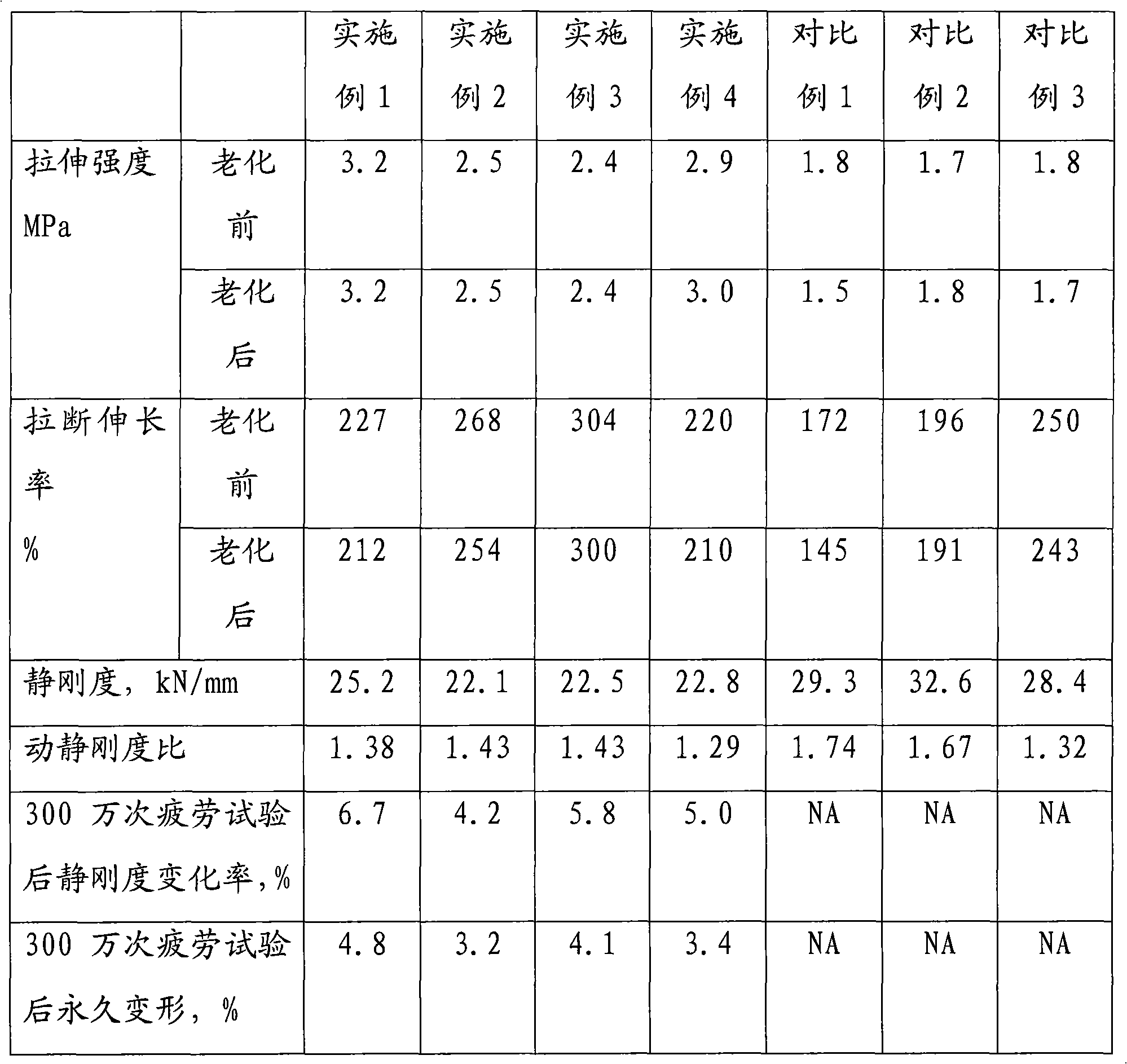

Low-lag microcellular rubber material for oscillation reduction of high-speed railway fastener and preparation method thereof

ActiveCN101817957AImprove mechanical propertiesImprove fatigue resistanceRail fastenersRubber materialVulcanization

The invention discloses a low-lag microcellular rubber material for oscillation reduction of a high-speed railway fastener and a preparation method thereof. The material comprises the following components in part by mass: 100 parts of base rubber, 40 to 80 parts of nano reinforcing filler, 8 to 16 parts of surface modifier, 5 to 15 parts of plasticizer, 1 to 2 parts of age resister, 2 to 4 parts of chemical foaming agent and 10 to 20 parts of curing agent and vulcanizing aid. The preparation method comprises the following steps of: performing banburying on an EPDM, the nano reinforcing filler and the surface modifier under the conditions of high temperature and high shear; adding the chemical foaming agent, the age resister, the plasticizer, the curing agent and the vulcanizing aid, and performing normal banburying on the mixture at room temperature; performing presulfurization on the mixture for 15 minutes at the temperature of 120 DEG C under the vulcanization pressure of 10MPa; foaming and vulcanizing the mixture for 20 minutes at the temperature of 170 DEG C and under the pressure of 10MPa to obtain the microcellular rubber material; and putting the microcellular rubber material in an oven at the temperature of 150 DEG C and then vulcanizing the microcellular rubber material for 2 hours to obtain the product. The product has the advantages of weakened dynamic lag phenomena, lower dynamic-static stiffness ratio, higher mechanical property and fatigue resistance.

Owner:BEIJING UNIV OF CHEM TECH +1

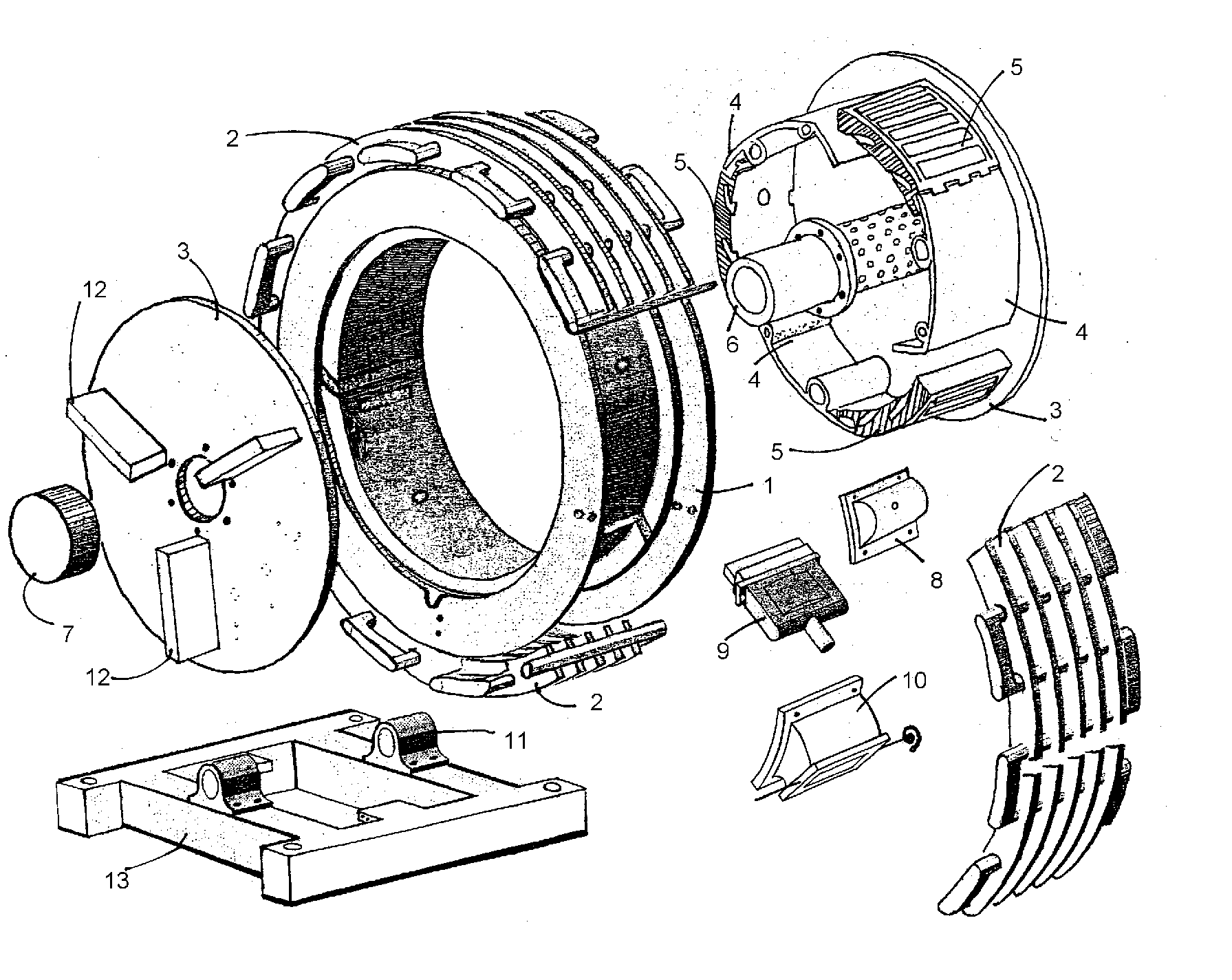

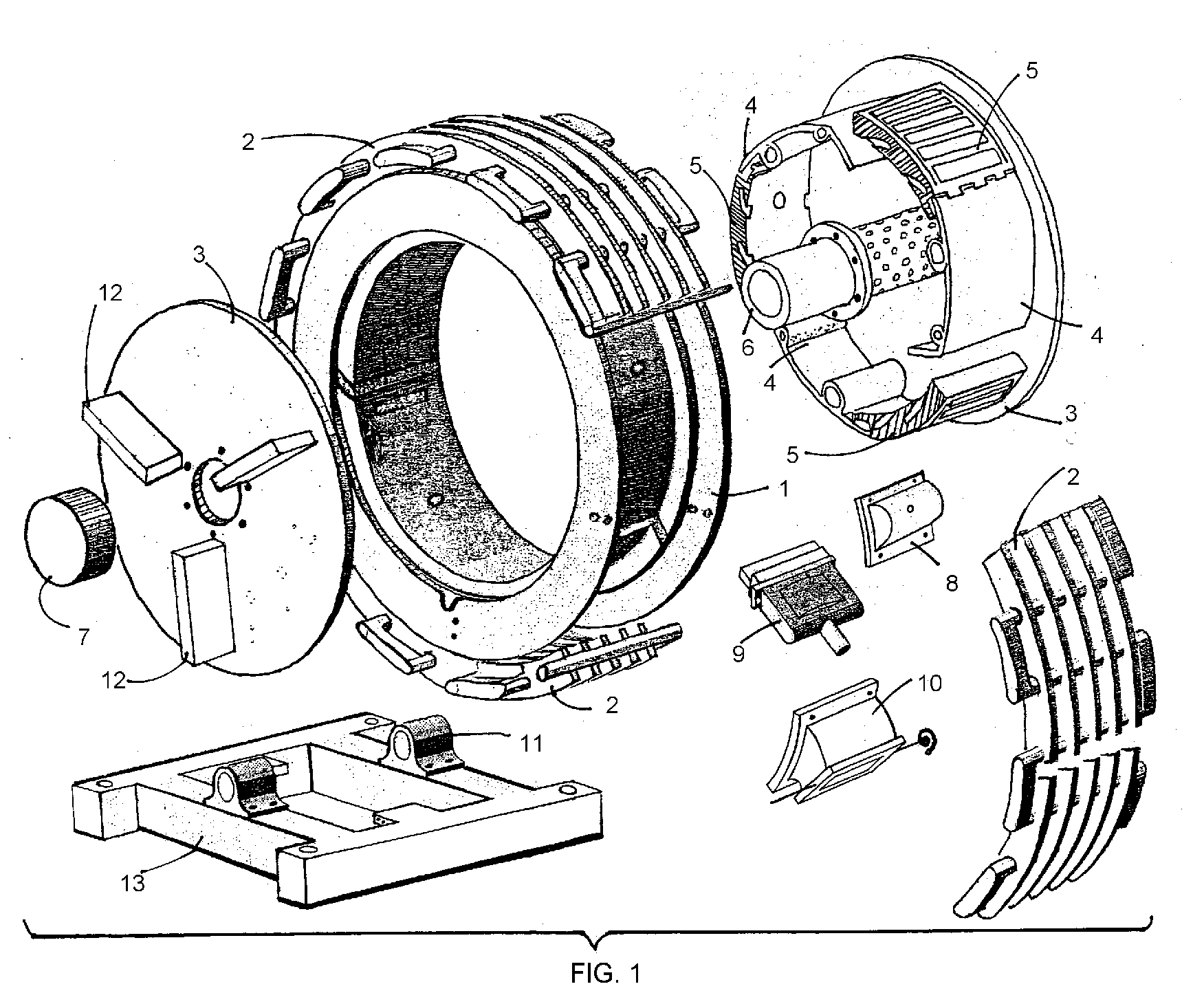

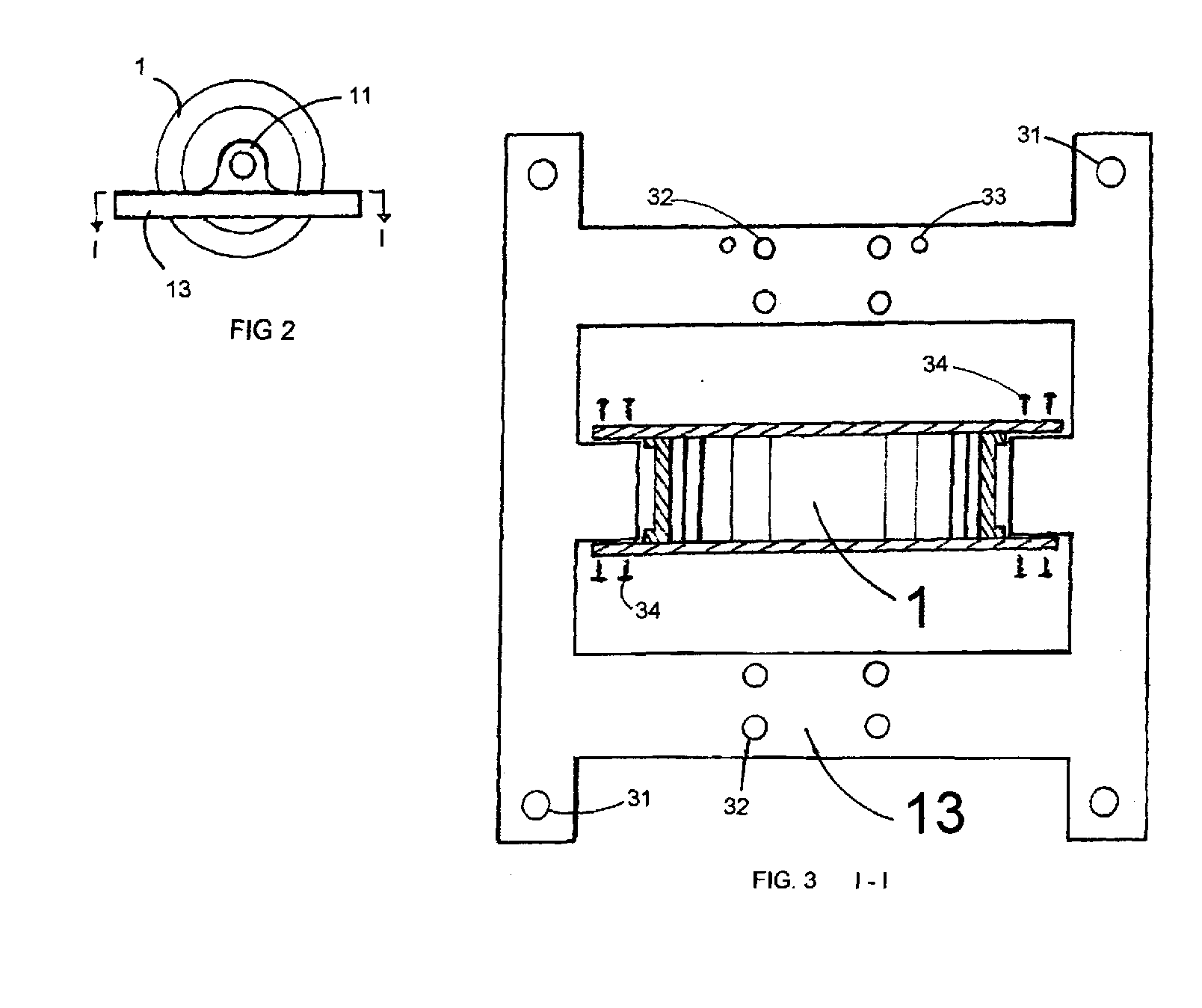

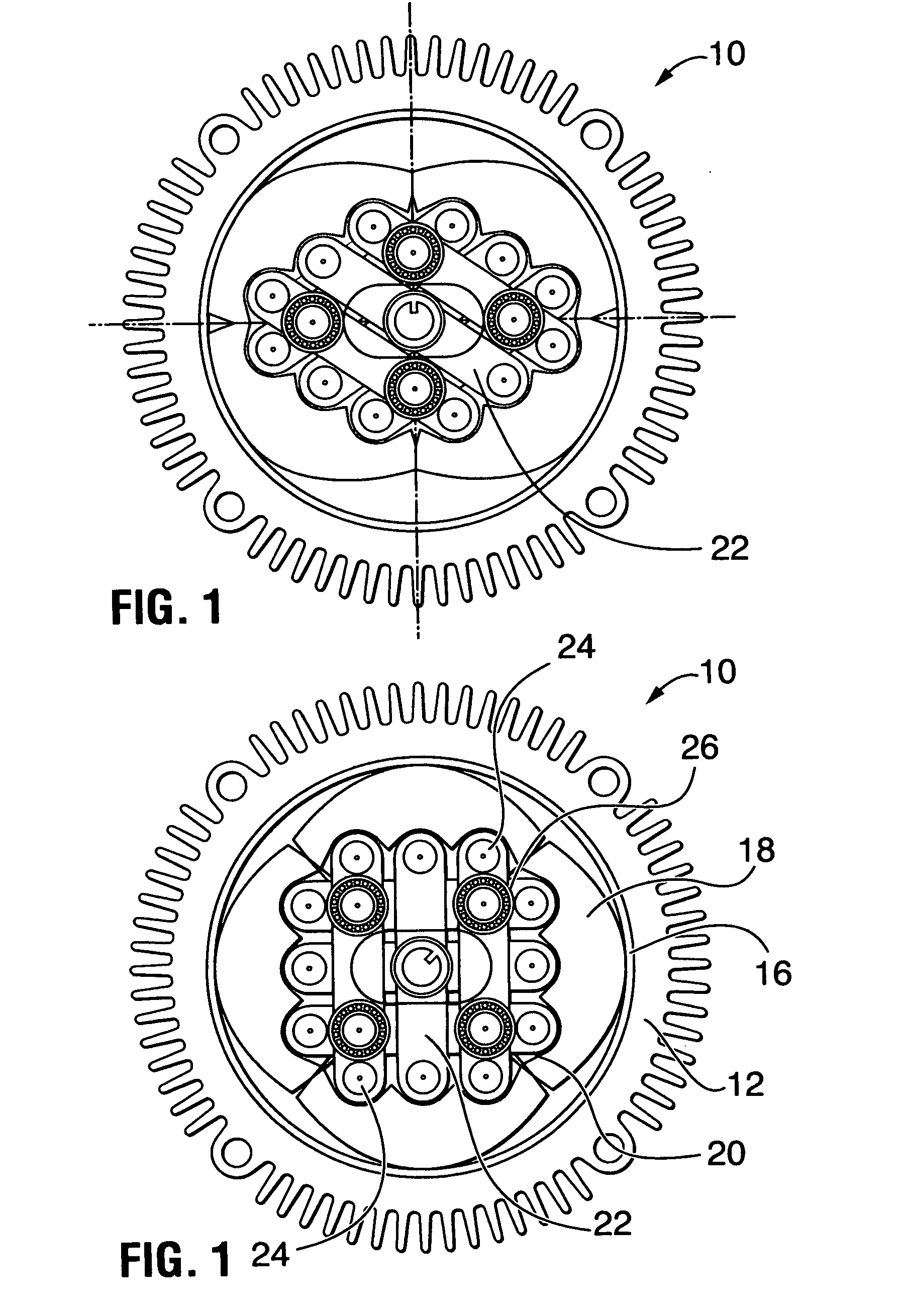

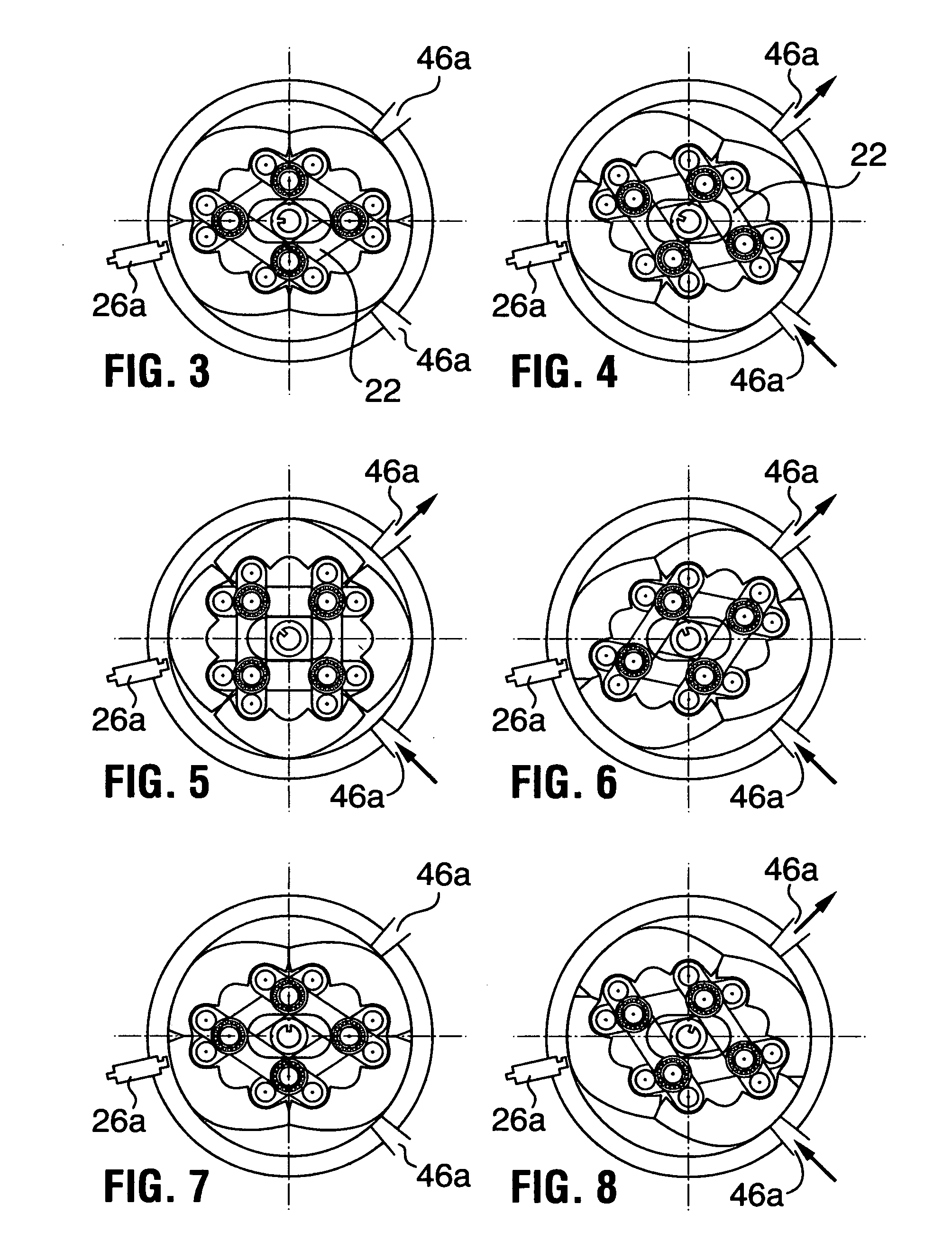

Modular Rotary Engine

InactiveUS20070084434A1Low reciprocating massReduce distanceInternal combustion piston enginesOscillating piston enginesExternal energyEngineering

An internal combustion rotary engine, self cooled, totally concentric and symmetric, dynamically variable compression ratio, capable of developing multiple Otto cycles in each rotation, by means using modules, composed mainly by a solenoid gate valve and three chambers operating at the rotor periphery, producing at low RPM, torsion of value near close at theoretical limit. High power / weight ratio, which increases substantially when number of modules increase, without drive shaft length increase; plus reduced internal friction, is a truly saver fuel machine; with volumetric asymmetry ratio between expansion and compression chambers, and that compression chambers working at beginning of the cycle at normal atmospheric pressure, it gives a fast rise pressure peak, because of the almost wedged form of that chambers. Proper for many types of combustion and class of fuels, including hydrogen, liquefied propane gas and efficient use of air compressed as external energy supply. Excels in aircraft use.

Owner:LEON ENRIQUE HALUY

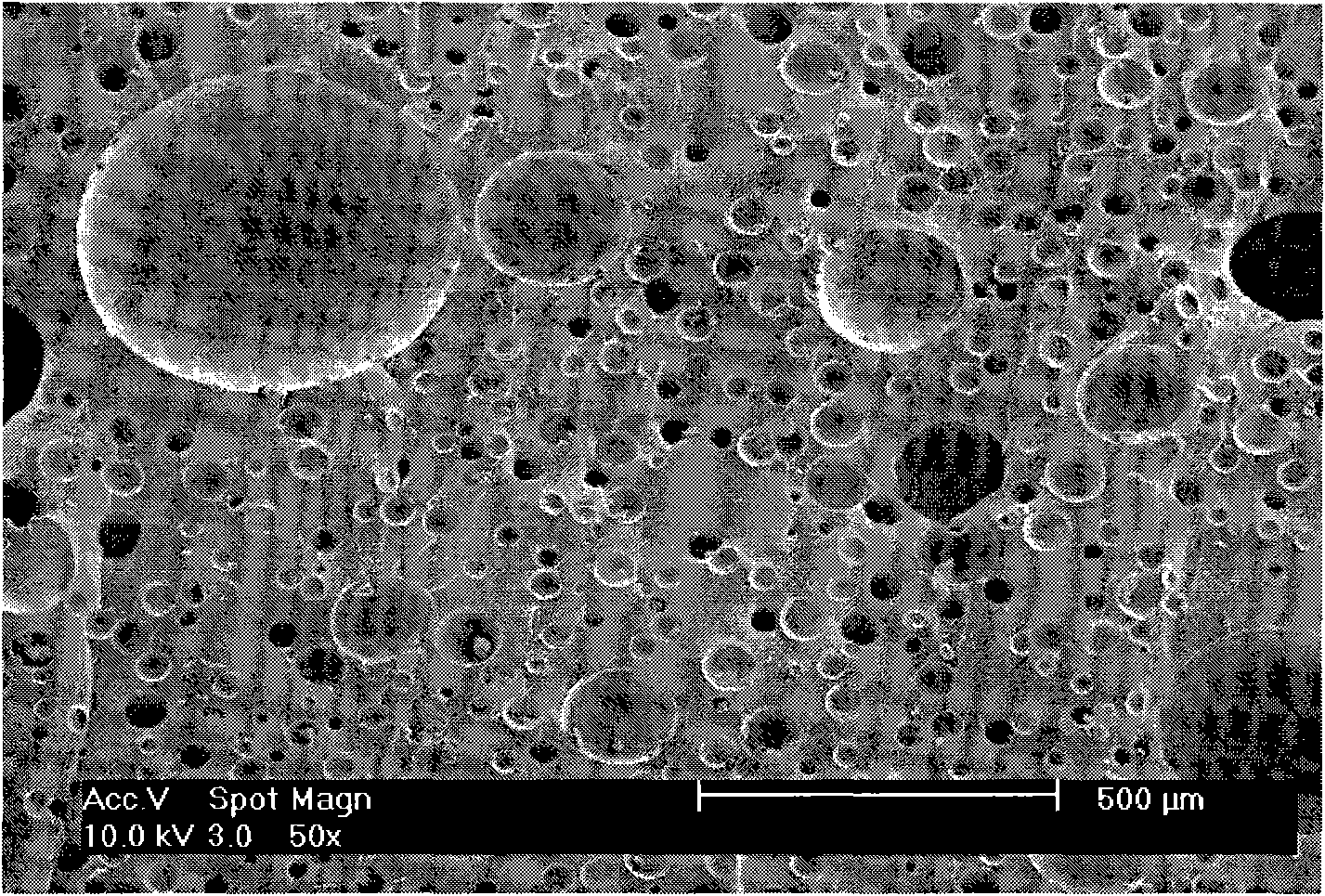

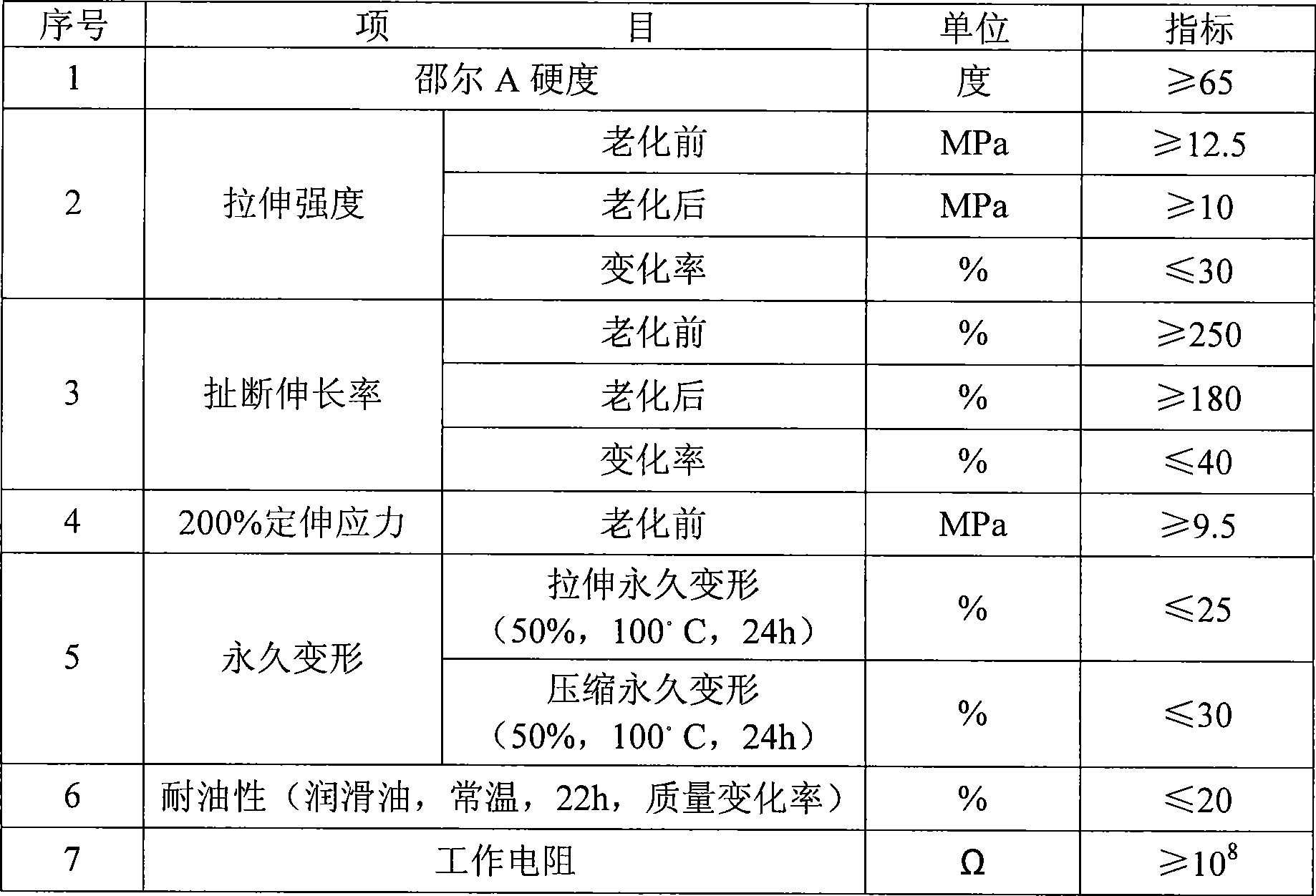

Rubber backing plate of passenger dedicated line

InactiveCN101381485AImprove dispersion uniformityDynamic Hysteresis ReducedRail fastenersEngineeringStearic acid

The invention relates to a technology for laying train rails, in particular to a passenger special line rubber tie plate. According to the technical proposal provided by the invention, the rubber tie plate comprises 100 portions of styrene-butadiene rubber, 4 to 8 portions of zinc oxide, 0.5 to 1.5 portions of stearic acid, 0.8 to 1.5 portions of accelerant TMTD, 0.5 to 1.5 portions of accelerant CZ, 0.5 to 1.5 portions of accelerant DTDM, 1.0 to 3.0 portions of coupling agent Si69, 30 to 50 portions of semi-reinforcing carbon black, 50 to 70 portions of nano kaolin, 10 to 20 portions of nano calcium carbonate, 1 to 1.5 portions of antiaging agent 4010NA, 1 to 2 portions of antiaging agent RD, 0.5 to 1.5 portions of micro-crystalline wax and 0.3 to 1.5 portions of sulfur; and the unit is weight portion. The rubber tie plate makes the performance of the rubber tie plate reach the technical requirements of the passenger special line rubber tie plate by using high-performance novel materials, namely the nano kaolin and the nano calcium carbonate in the compositions, and has high insulativity, high ageing resistance and low ratio of dynamic stiffness to static stiffness of products.

Owner:WUXI TIEHUA RUBBER

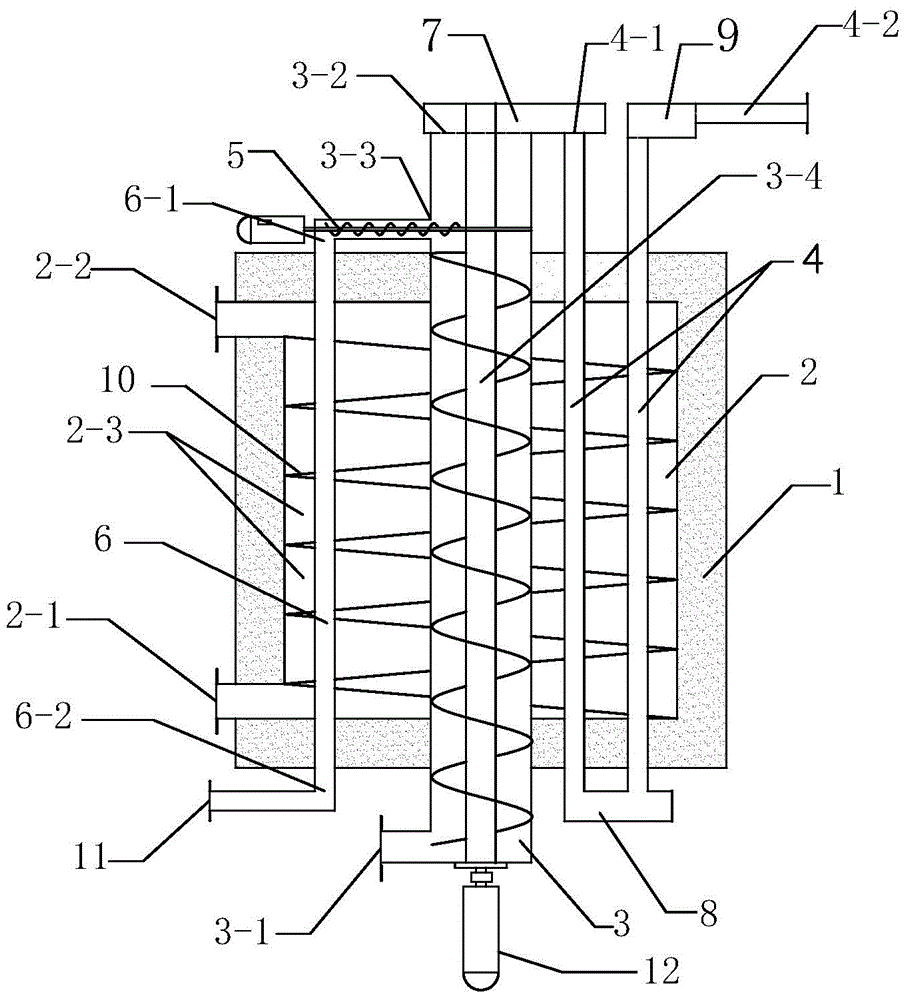

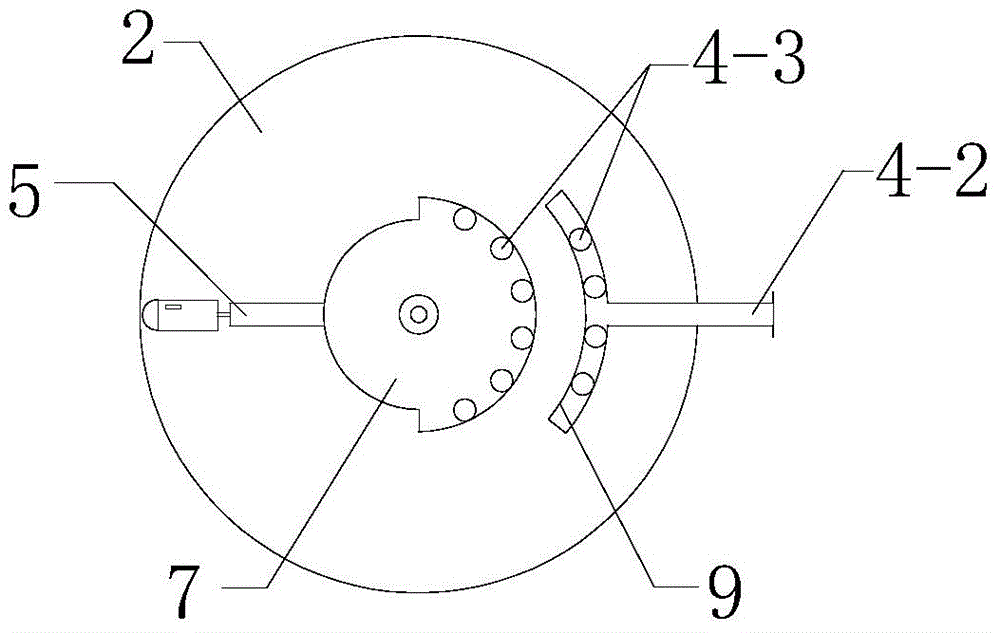

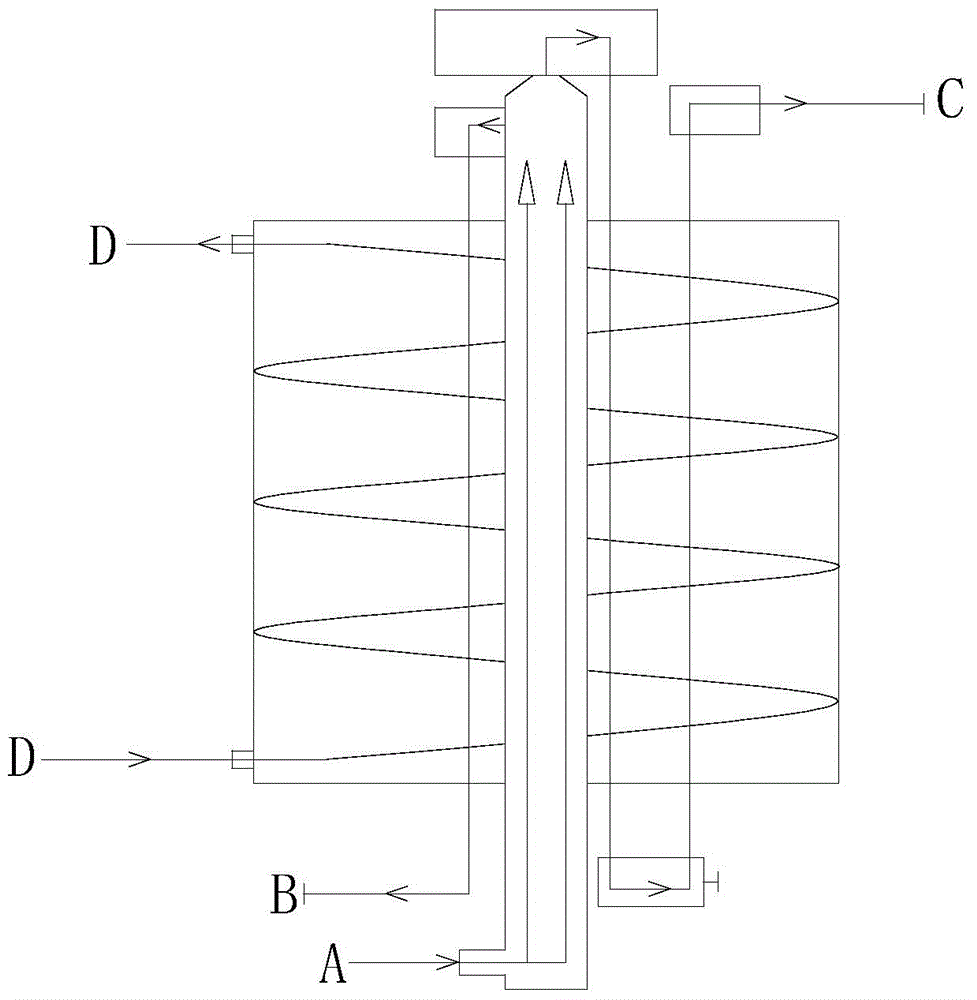

Continuous and overall biomass pyrolysis furnace

ActiveCN104099111AImprove heat utilizationReduce internal frictionBiofuelsIndirect heating destructive distillationThermal insulationFlue gas

The invention provides a continuous and overall biomass pyrolysis furnace which comprises a thermal insulation casing and a flue gas heat supply cavity, wherein a pyrolysis chamber is formed in the flue gas heat supply cavity. The biomass pyrolysis furnace is characterized in that a pyrolysis gas tar pyrolysis chamber and a semicoke calcination chamber are further formed in the flue gas heat supply cavity; the pyrolysis chamber, the pyrolysis gas tar pyrolysis chamber and the semicoke calcination chamber are vertically arranged in the flue gas heat supply cavity and penetrate through a spiral hot air channel, and upper ends and lower ends of the pyrolysis chamber, the pyrolysis gas tar pyrolysis chamber and the semicoke calcination chamber extend out of the flue gas heat supply cavity; and a material inlet is formed in the lower end of the pyrolysis chamber, a pyrolysis gas outlet and a semicoke outlet are formed in the upper end, the pyrolysis gas outlet in the upper end of the pyrolysis chamber is communicated with a pyrolysis gas inlet in the pyrolysis gas tar pyrolysis chamber, and the semicoke outlet is communicated with a semicoke inlet in the semicoke calcination chamber through a horizontal auger. According to the continuous and overall biomass pyrolysis furnace, three processes including pyrolysis, tar pyrolysis and semicoke calcination are implemented in a segmented manner in the same flue gas heat supply cavity, the whole reaction process is controlled effectively, the quality of charcoal and gas is improved, and the conversion efficiency is increased.

Owner:武汉海德天物新材料有限公司

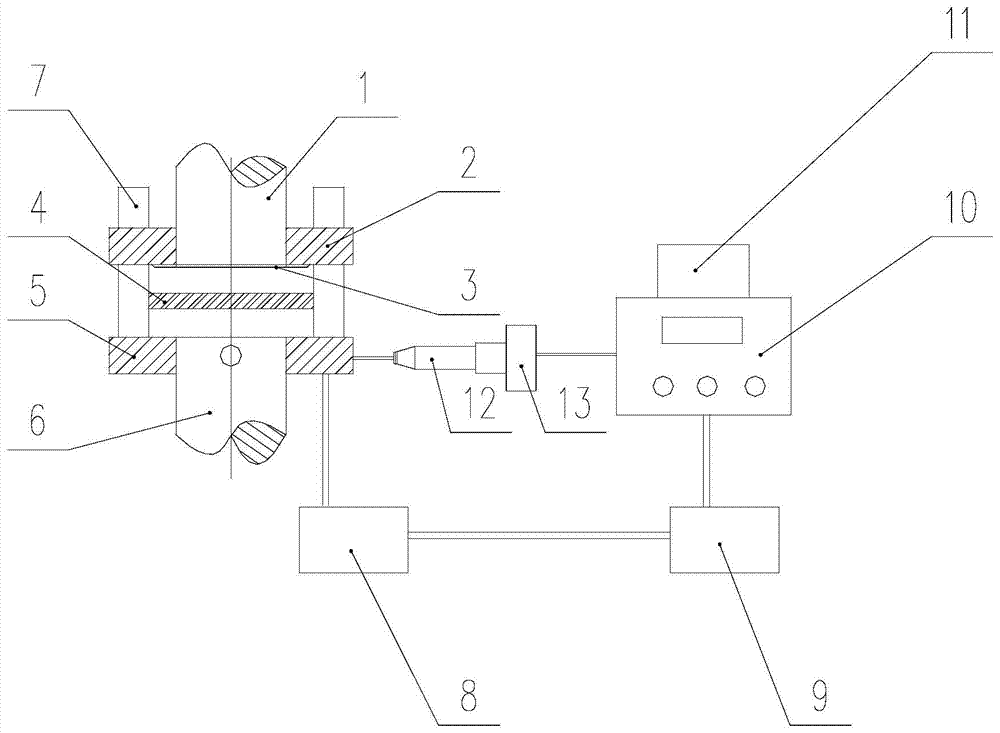

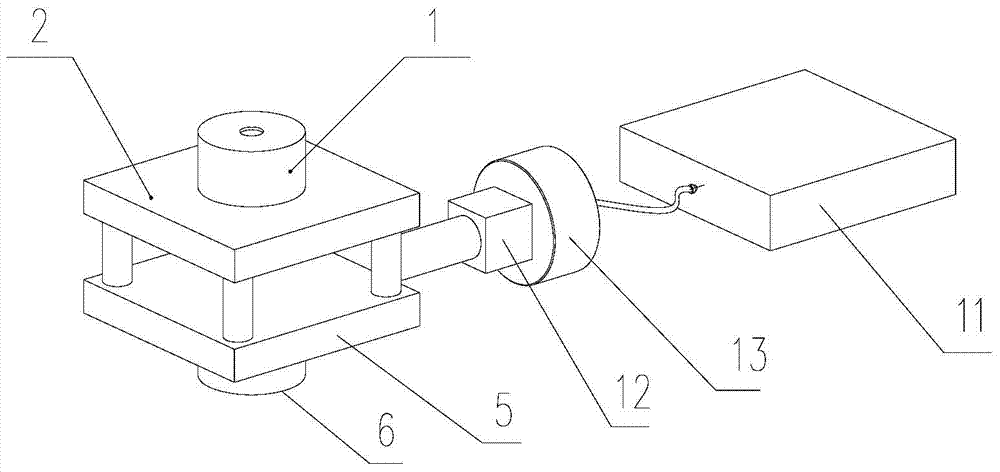

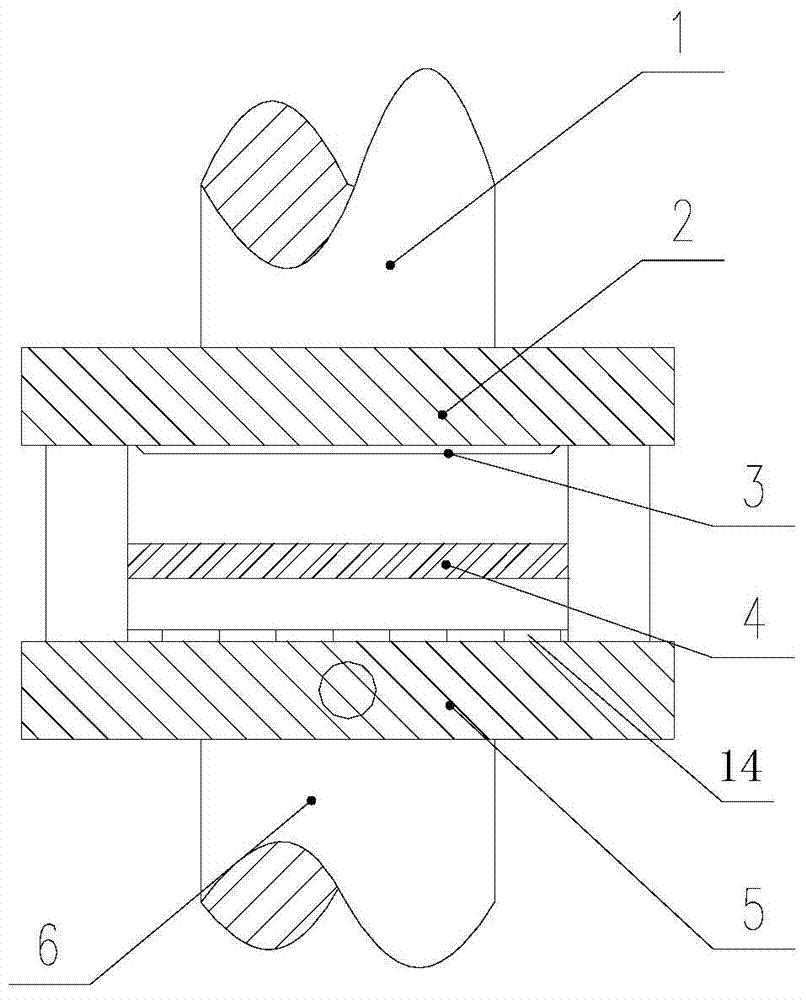

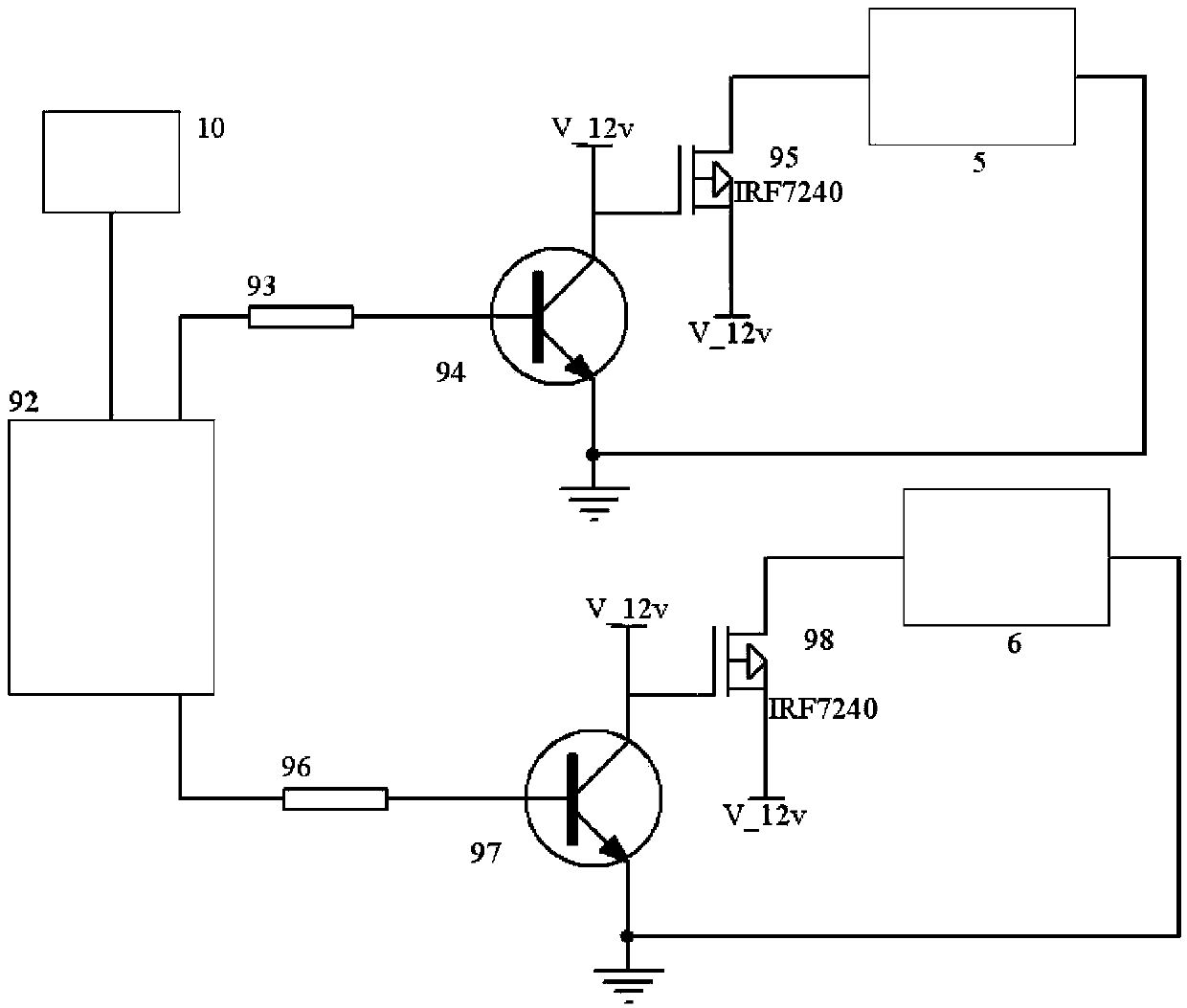

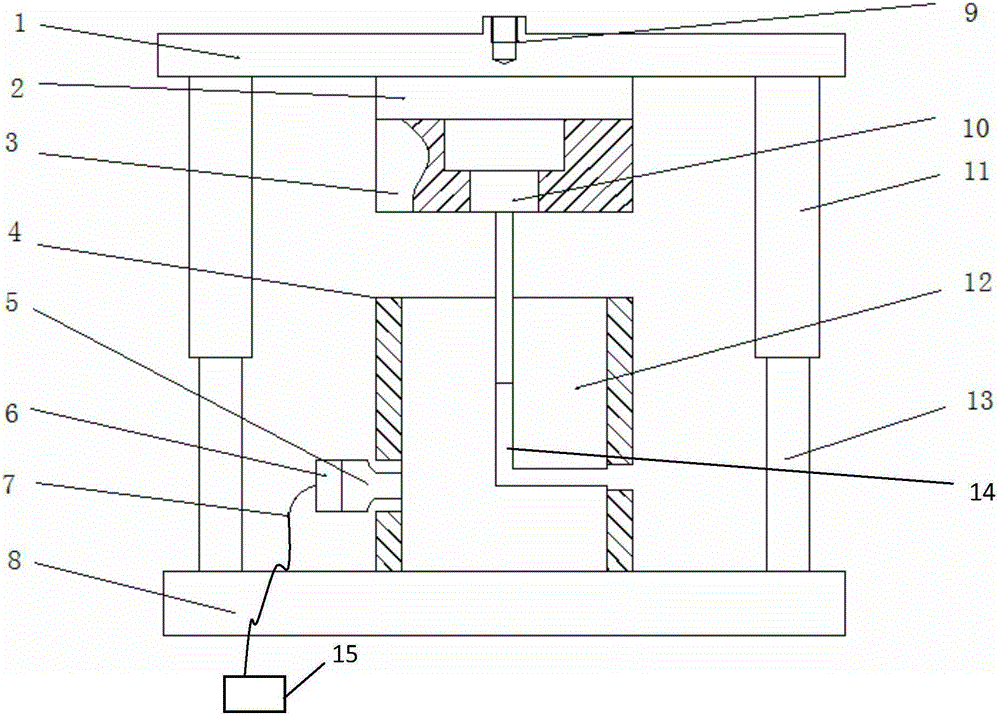

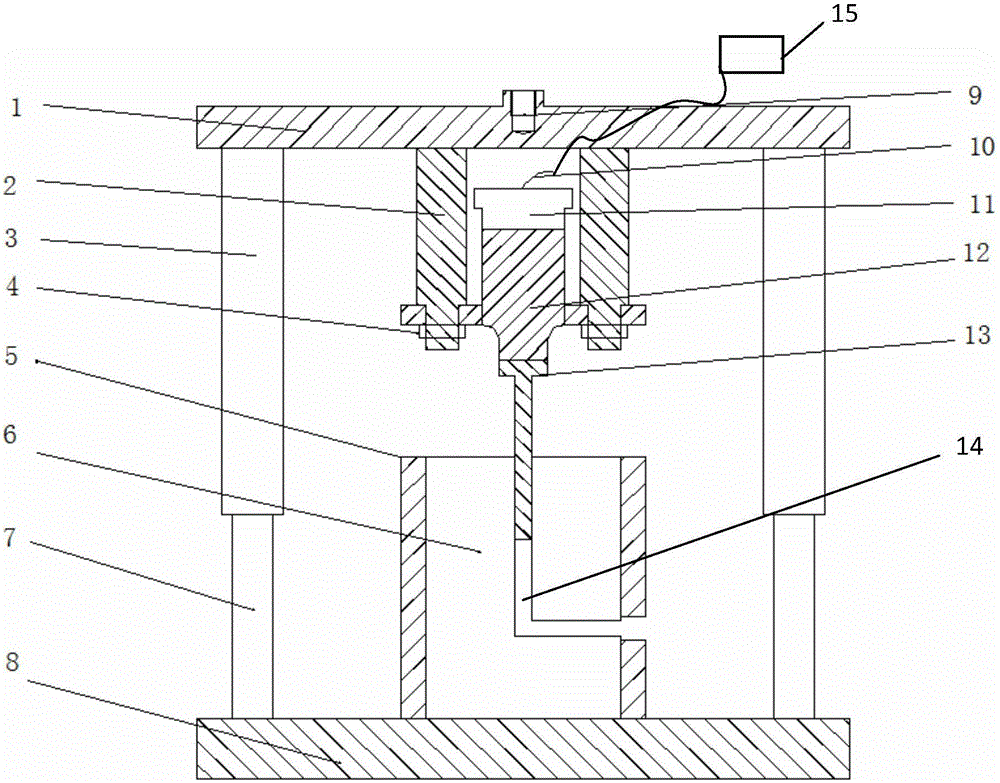

Ultrasonic-based medium-high carbon steel fine blanking forming device

The invention discloses an ultrasonic-wave-based medium-high carbon steel fine blanking forming device. According to the ultrasonic-wave-based medium-high carbon steel fine blanking forming device, on one hand, an ultrasonic generation system is added, dislocation density of materials is increased and internal frictional force of the materials is reduced during a forming process due to the fact that ultrasonic waves are transmitted to a die and blank, and the resistance to deformation of a to-be-machined machine part is remarkably reduced under a coupling function of alternating stress fields generated through the ultrasonic waves and stress fields generated through elasticoplastic deformation and on the other hand, a temperature feedback adjusting system is added and a centralized control mode through a microcomputer control system is adopted to keep a best vibrational frequency of the ultrasonic waves during a fine blanking process and improve the forming efficiency and accuracy. The ultrasonic-wave-based medium-high carbon steel fine blanking forming device has the advantages of being high in machining and forming accuracy and low in noise, enabling the service life of a stamping device to be long and being applicable for fine blanking and forming of various medium-high carbon steel materials.

Owner:SHANDONG UNIV OF SCI & TECH

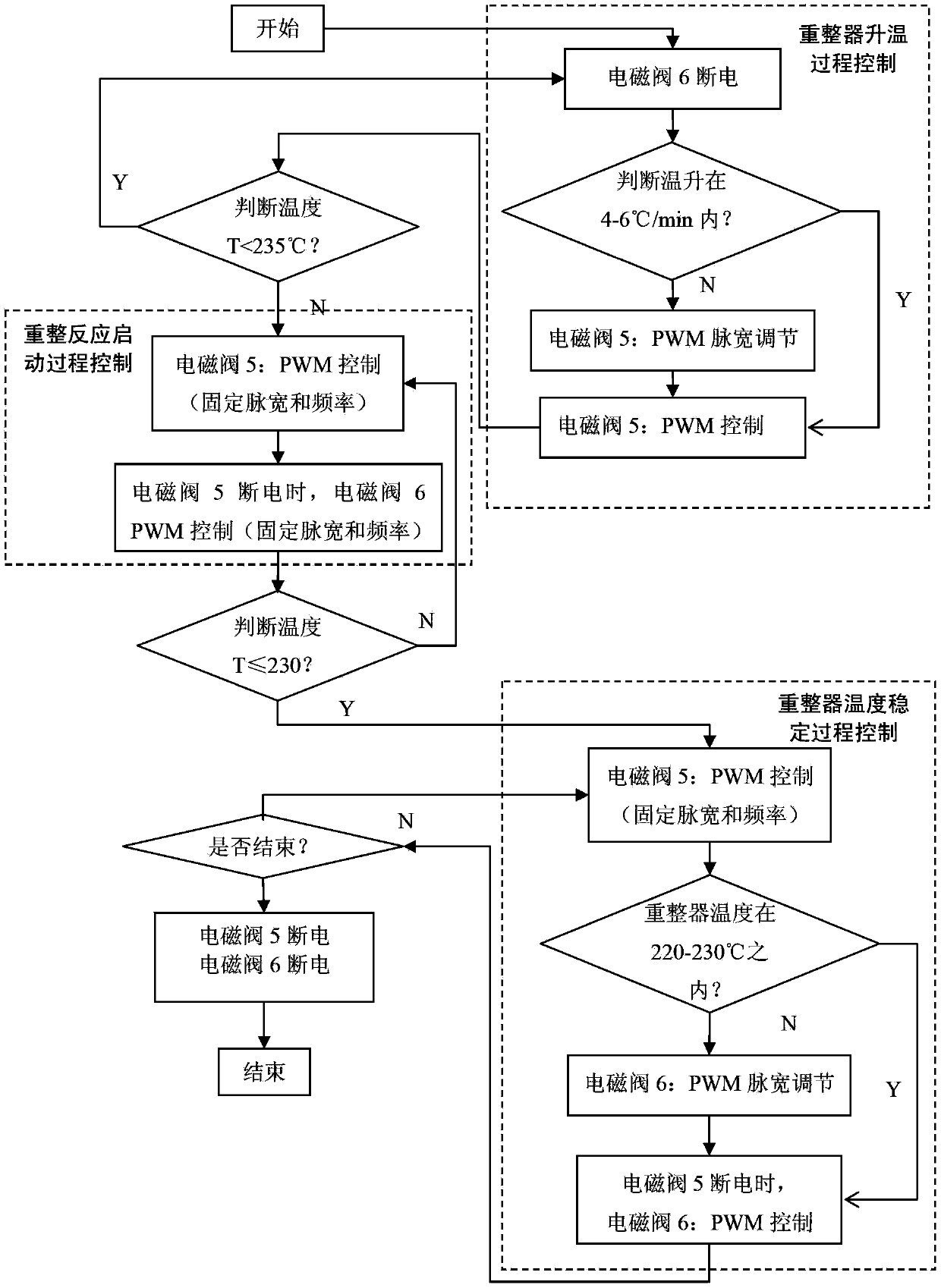

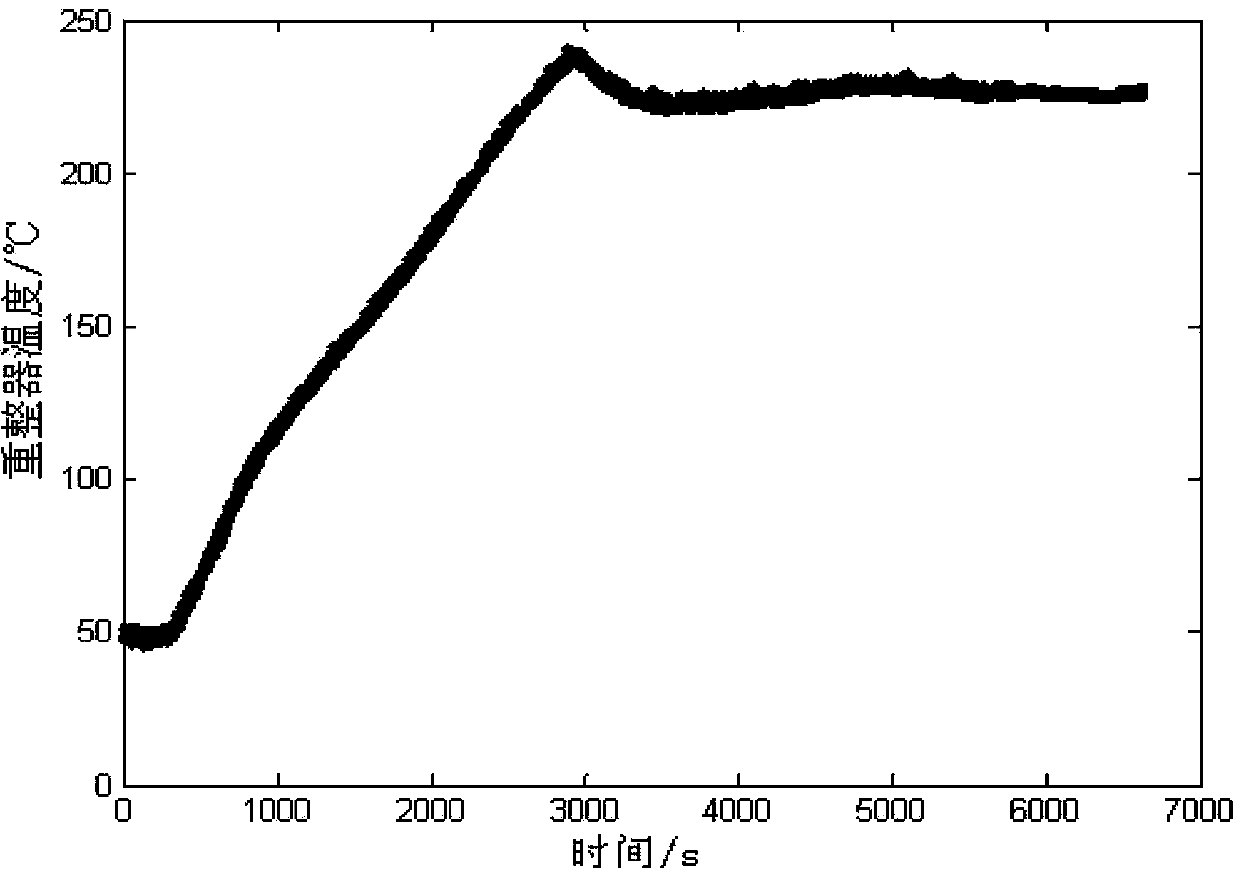

Fuel feeding device of high temperature liquid fuel cell or cell stack

ActiveCN103887540ALow costBroaden your optionsReactant parameters controlFuel cell controlSystem integrationFuel cells

The invention relates to a fuel feeding subsystem of a high temperature liquid fuel cell system. The high temperature liquid fuel cell system comprises a fuel tank, a fuel feeding subsystem, a fuel reformer consisting of a fuel combustion chamber and a fuel reforming chamber, a gas feeding subsystem consisting of a gas pump and a gas pipe, and a fuel cell stack. The fuel feeding subsystem comprises a liquid pump and a flow control part which are located between a material outlet of the fuel tank and a material inlet of the fuel reformer, and are orderly connected through a liquid pipe; the fuel feeding subsystem also comprises a controller for controlling the start and stop of fuel feeding and the flow of the fuel feeding; the controller controls the start and stop of fuel feeding subsystem according to a temperature signal sent by a temperature sensor disposed inside the fuel reformer; the controller controls the flow of the liquid fuel flowing into the fuel reformer according to the temperature signal. The fuel feeding subsystem reduces the high requirements for liquid pump flow by the system, and more facilitates system integration.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Cement-water glass grouting material

The invention discloses a kind of cement-water glass grouting material, and belongs to the technical field of strengthening of soft stratum in underground engineering and anti-seepage water-plugging grouting. The material comprises two uniformly mixed components of a liquid A and a liquid B, wherein the A liquid is water glass with a modulus in a range of 2.6-3.2 and a baume degree of 20-45 Be', and the liquid B is cement slurry which includes cement, a retarder, a stabilizer and a water reducing agent, wherein the mixing amount of the retarder is 0.5-3% of the cement mass, the mixing amount of the stabilizer is 0.1-0.5% of the cement mass, and the mixing amount of the water reducing agent is 0.1-1% of the cement mass. When the material is used, the A liquid and the B liquid are uniformlymixed according to a volume ratio of 0.8:1-1.2:1 for obtaining the cement-water glass grouting material. The material has the advantages of good stability of slurry, good water retaining property, good fluidity, controllable coagulation time, high strength of stone body, good durability, and good water dissolution resistance and erosion resistance.

Owner:建发合诚工程咨询股份有限公司 +1

Foaming agent for shield machine

InactiveCN106190136AImprove work performanceReduce wearBuilding constructionsOrganic fertilisersAlpha-olefinMaterials science

The invention belongs to the technical field of foaming agents, and particularly relates to a foaming agent for a shield machine. In order to solve the problems that various properties including the uniformity, the stability, the lubricating properties, the permeability and the like of foams of a domestic foaming agent at current cannot completely meet requirements for foams in shield tunneling, and the adaptability of the foaming agent has certain limit, the invention provides the foaming agent for the shield machine, and the foaming agent is prepared from sodium dodecylsulfate, sodium alcohol ether sulphate, sodium alpha-olefin sulfonate, modified polyethoxylated silicone, and water in a certain proportion. According to the foaming agent disclosed by the invention, the working performance of soil is improved, so that the soil forms plastic deformation to provide uniform and controllable support pressure, and a working surface is stable; leakage is reduced, the sealing properties of the working surface are strengthened, internal frictional force is reduced, abrasion of the soil on cutter heads, conveyors and conveyer belts is reduced, and the energy consumption is reduced; the viscosity of a soil mass is reduced, and generation of plugging is avoided; and the foaming agent has the effect of restraining dust during construction of rock and soil tunnels and mines.

Owner:天津盾构科技发展有限公司

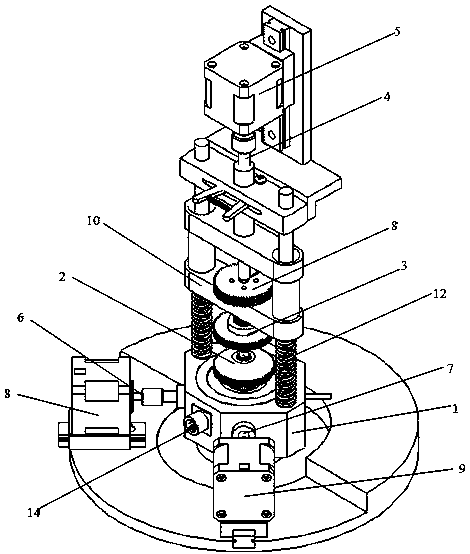

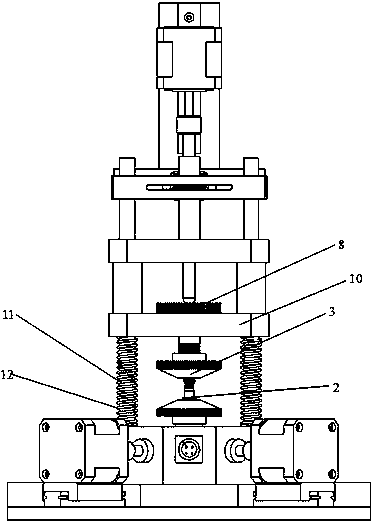

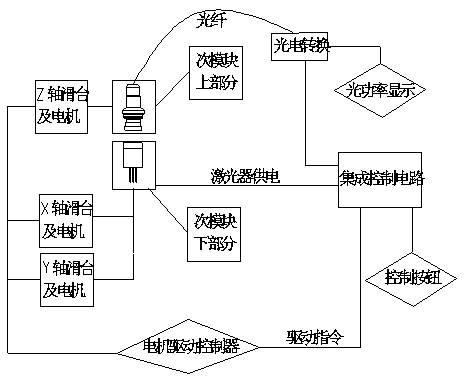

Photo-communication secondary module automatic coupling device and coupling method

InactiveCN103543505AReduce human production costsReduce internal frictionCoupling light guidesEngineeringLaser diode

The invention discloses a photo-communication secondary module automatic coupling device and method. An X axis, a Y axis and a Z axis which can move in the three three-dimensional directions are set so that during coupling working, the relative positions of an element in an upper clamp and an element in a lower clamp can be automatically corrected accurately, the X axis, the Y axis and the Z axis move in the direction in which light power becomes higher, finally after light power reaches the maximum value, laser welding is carried out on an optical fiber standard connector mechanism tube core and a laser diode, a photo-communication secondary module is formed, and accordingly quick, efficient and accurate automatic coupling working is achieved.

Owner:JIANGSU ALLRAY

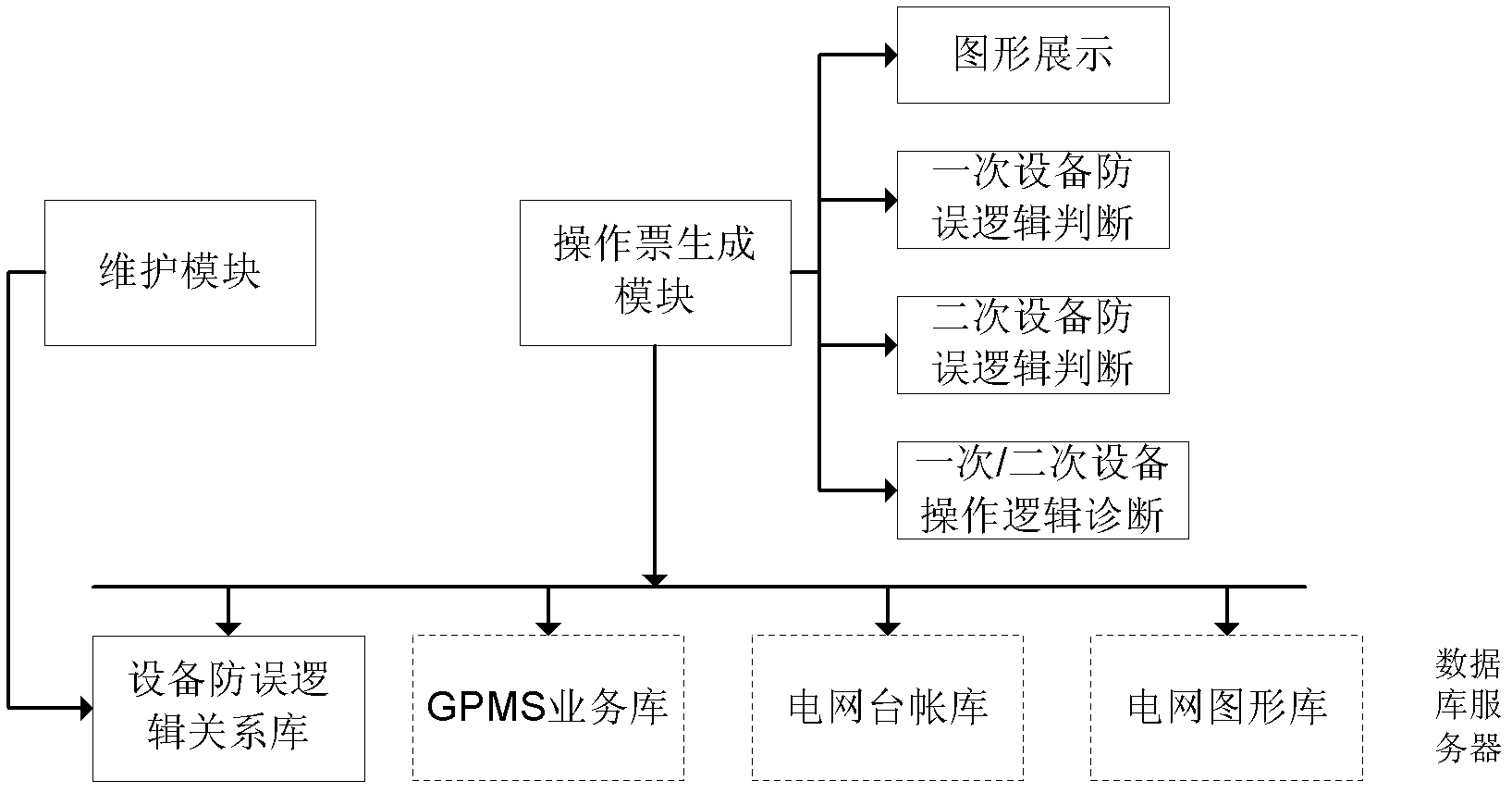

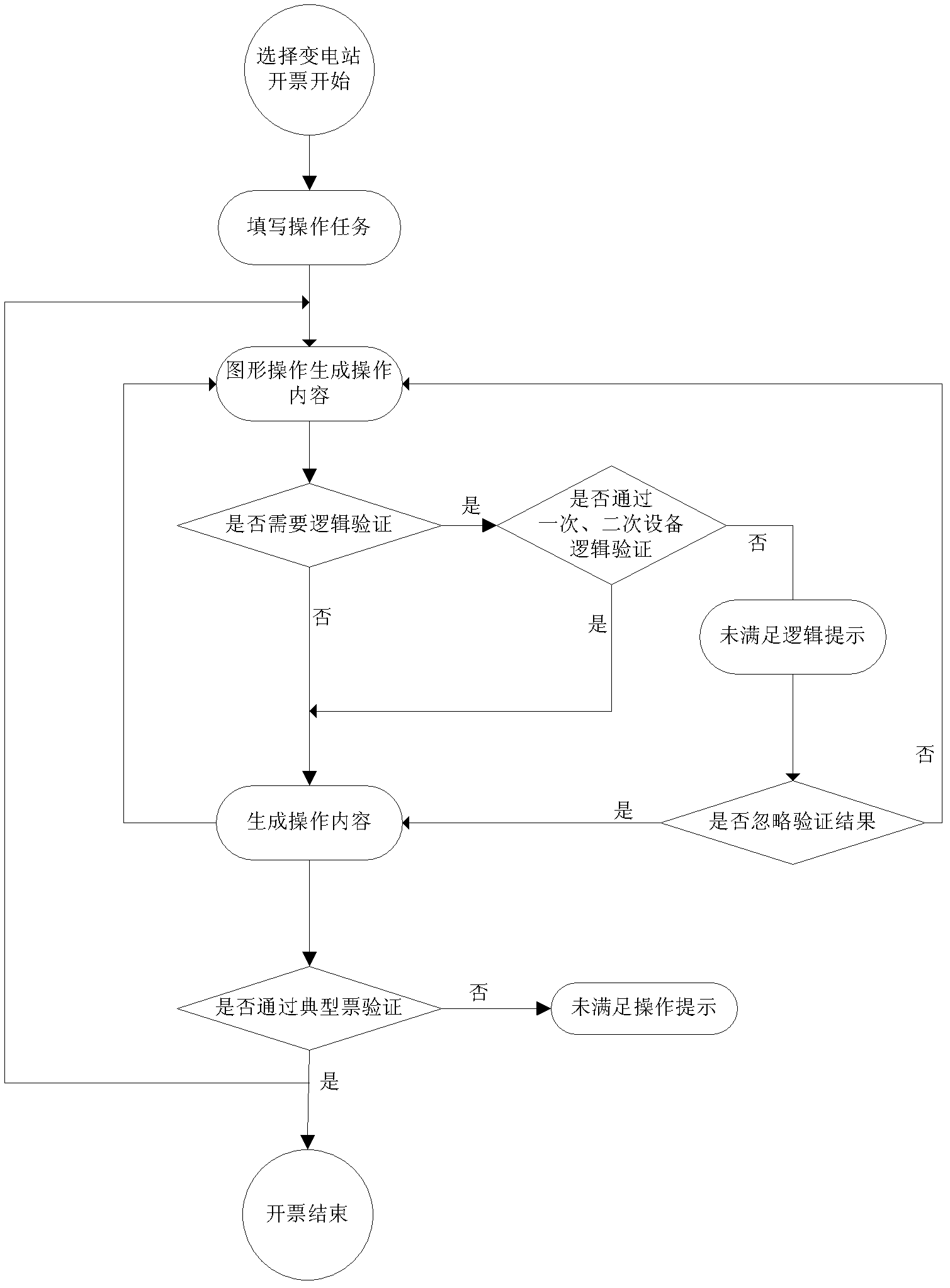

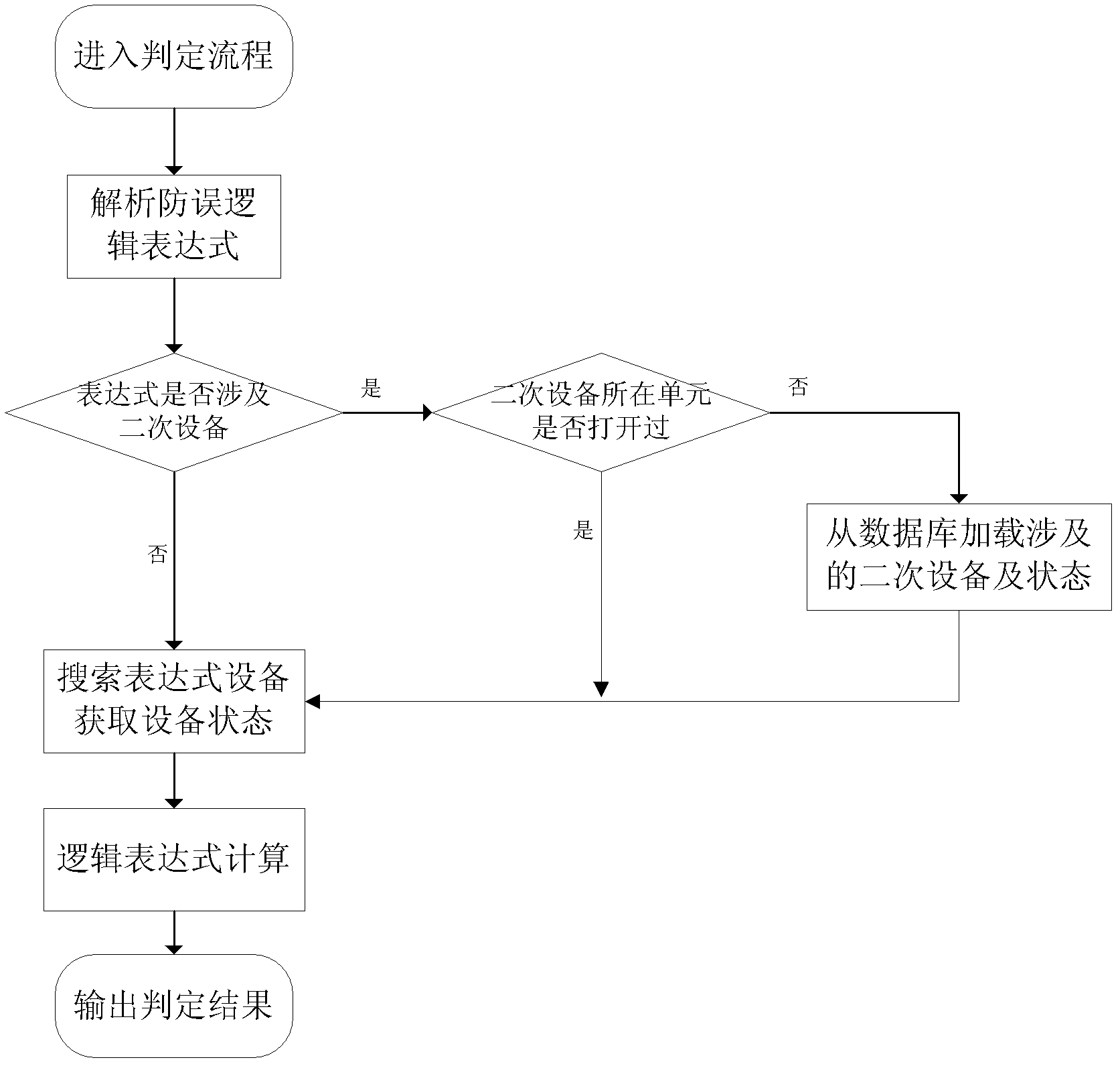

Intelligentized diagnostic system of substation-operation operation tickets

ActiveCN102591223AImprove securityImprove reliabilityProgramme control in sequence/logic controllersDatabase serverDevice status

The invention discloses an intelligentized diagnostic system of substation-operation operation tickets, which is mainly formed by a maintenance module and an operation ticket generating module, wherein the operation ticket generating module is in communication connection with a database server, and the maintenance module is connected with a device anti-operation logic base in the database server. The device anti-operation logic base comprises a primary device anti-operation logic base, a secondary device anti-operation logic base and a primary / secondary device operation logic base. The operation ticket generating module comprises a picture display unit, a primary device anti-operation logic judgment unit, a secondary device anti-operation logic judgment unit and a primary / secondary device operation logic diagnosis unit. The intelligentized diagnostic system has the advantages that secondary device anti-operation logic added in an operation ticket system has a prompt locking effect on operation of important pressing boards in secondary switching operation and operation of secondary pressing boards related to a primary device state, and accidents of pressing board throwing leakage or throwing errors in an operation process can be effectively avoided.

Owner:STATE GRID CORP OF CHINA +1

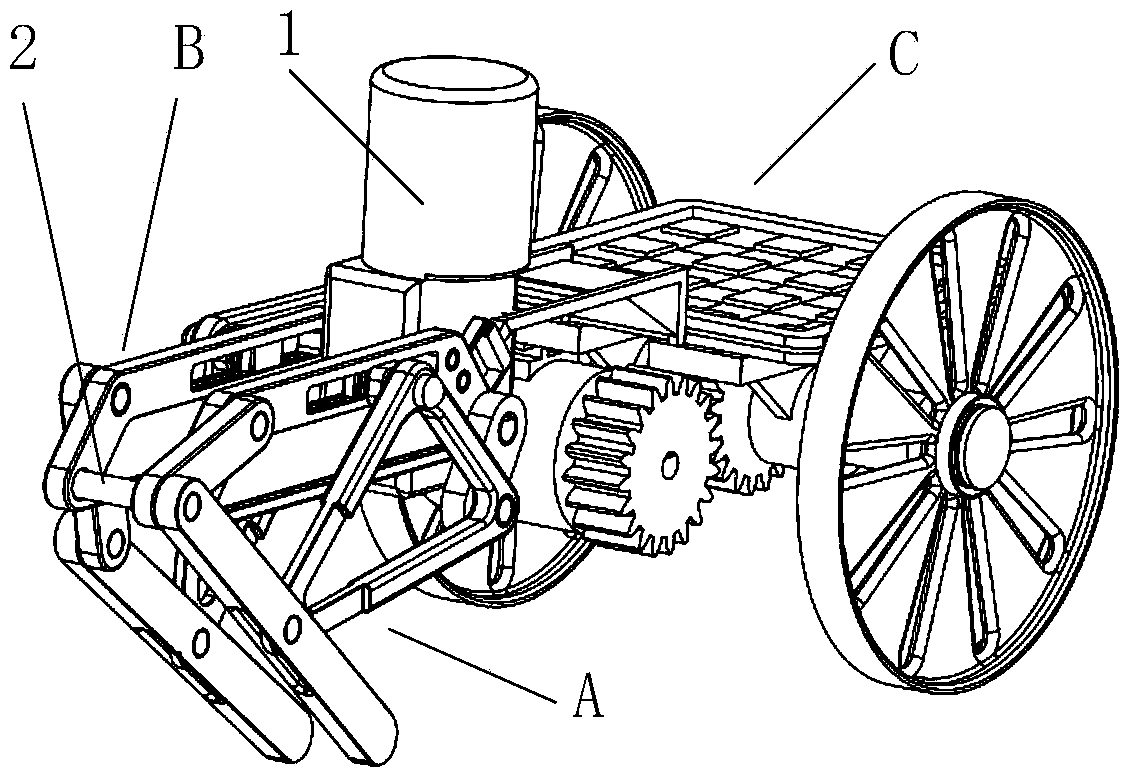

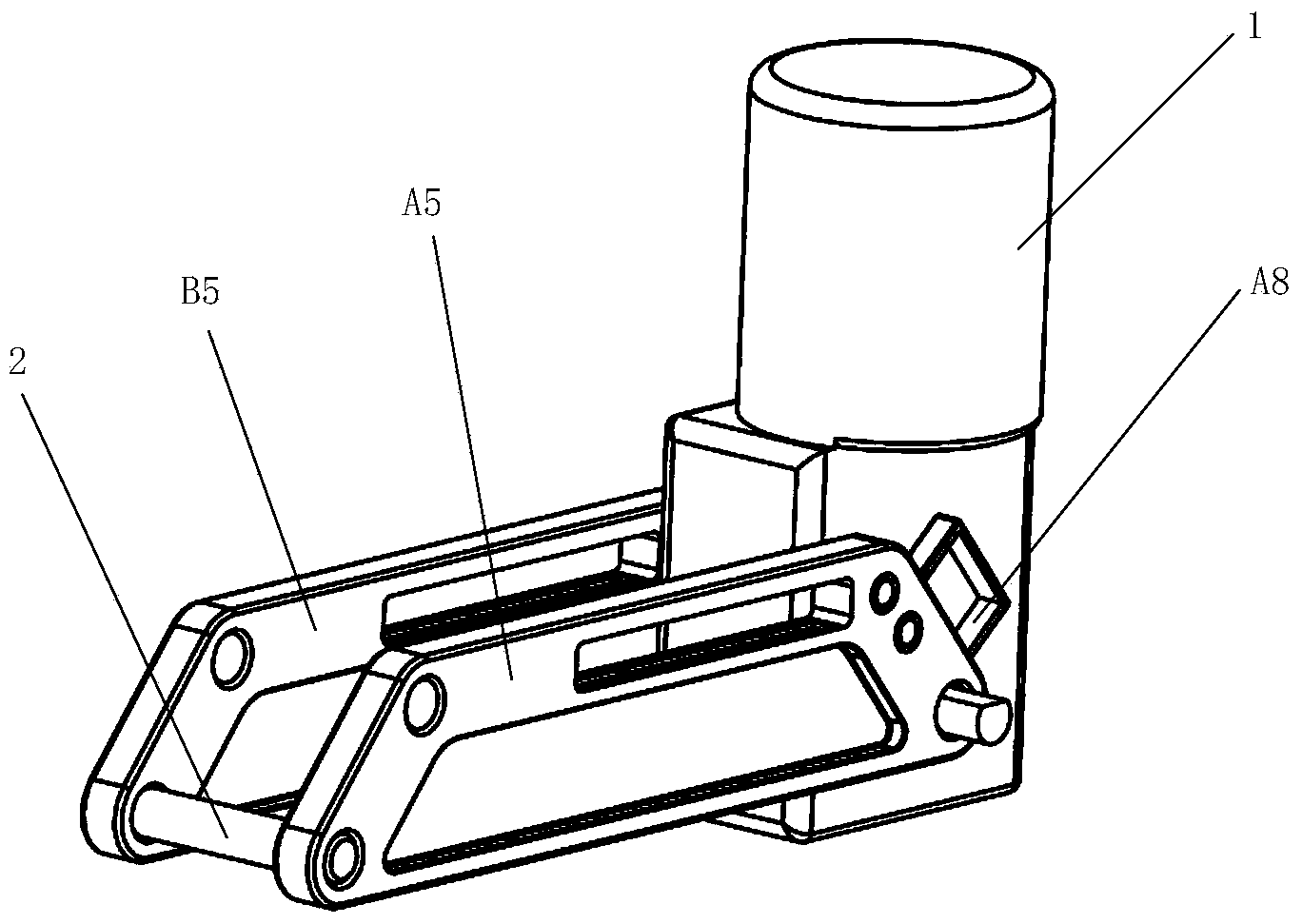

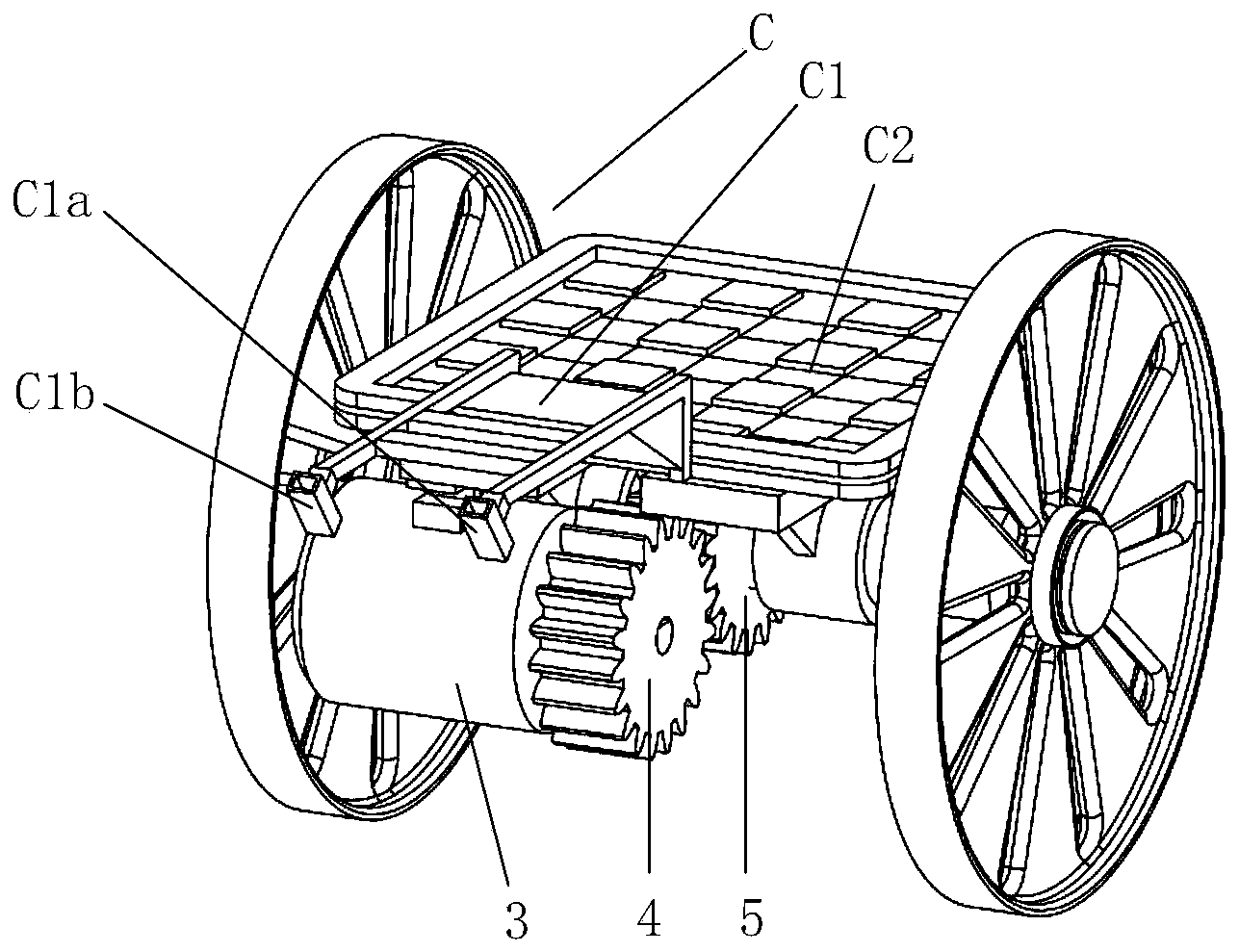

Wheel and leg composite carrying robot

ActiveCN103818492AOptimize motion trajectoryReduce internal frictionVehiclesEngineeringRobot locomotion

A wheel and leg composite carrying robot comprises a left side leg (A), a right side leg (B) and a trailer (C), wherein a clamping groove of a left first connecting rod (A1) of the left side leg (A) is matched and fixed with one output shaft of a double-output shaft motor (1), a clamping groove of a right first connecting rod (B1) of the right side leg (B) is matched and fixed with the other output shaft of the double-output shaft motor (1), a left rack (A5) of the left side leg (A) is fixedly connected with a right rack (B5) of the right side leg (B) through a connecting shaft (2), a left clamping sleeve (C1a) and a right clamping sleeve (C1b) of a connecting frame (C1) of the trailer (C) is respectively and fixedly connected with a left clamping ring (A8) and a right clamping ring (B8), and the double-output shaft motor (1) drives for the complete cycle for realizing motion of the robot. The wheel and leg composite carrying robot is simple in leg structure and is easy to process and assemble; a sliding pair is adopted at the joint, so that the foot end track is optimized, synergic movement of wheels and legs is realized, and the internal friction is reduced. The robot can be used in the fields of planet detection, cargo transportation, military reconnaissance and the like.

Owner:BEIJING JIAOTONG UNIV

Oxygen intake type single stroke engine and operation method thereof

InactiveCN101109344ADischarge fullyBurn fullyInternal combustion piston enginesNon-fuel substance addition to fuelHigh concentrationExhaust valve

An oxygen-entering type single-stroke engine is provided. Wherein, on an air-intake port of an air-intake valve of a cylinder, one end of a compressed oxygen intake pipe is connected, another end of the intake pipe is connected with an oxygen storage tank and an adjustable air valve; the air intaker, an air exhaust valve, an oil injection nozzle and the devices of switches on a spark plug match each other: a piston moves from the lower stop to the upper stop, the air exhaust valve opens to the upper stop, the exhaust valve closes, the air intake valve opens instantaneously, oxygen enters, meanwhile the oil injection nozzle opens, the air intake valve and the oil injection nozzle close instantaneously before ignition; the engine ignites, the piston moves to the lower stop. The invention additionally provides the operation way for the oxygen-entering type single-stroke engine. The oxygen-entering type single-stroke engine provided in the invention realizes a single-stroke no-compression high-efficiency operation mode by inputting oxygen of high concentration in the air intake valve. The device supplying oxygen of high concentration is only a set of oxygen tank and a hi-concentration oxygen delivery pipeline, and is of very simple structure. The engine combines and improves the functions of prior engines, is of high operation efficiency, full combustion and low energy consumption.

Owner:郑杰

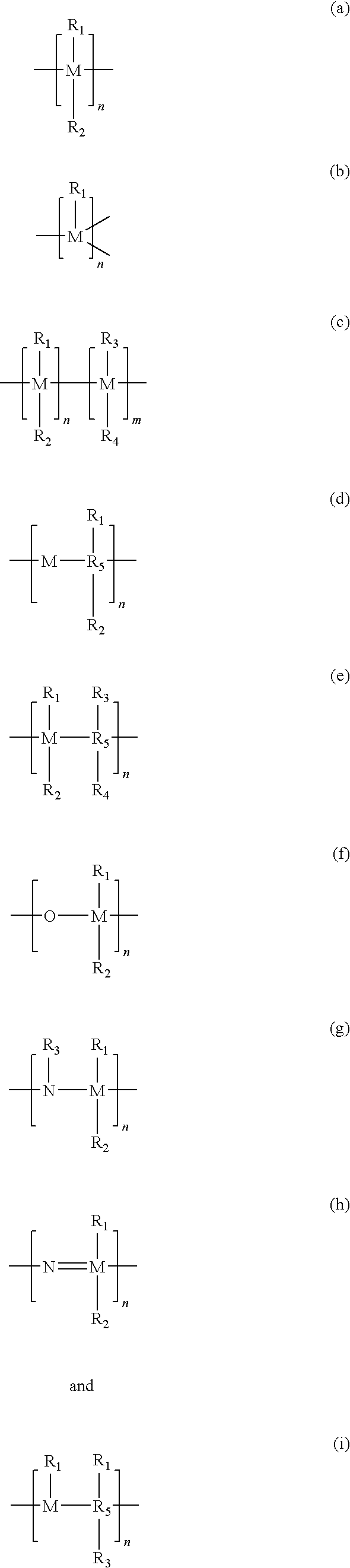

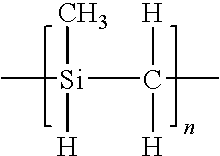

Powder metallurgical compositions containing organometallic lubricants

InactiveUS7604678B2Good physical propertiesReduce internal frictionTransportation and packagingMetal-working apparatusMetal powderLubricant

The present invention relates to improved metallurgical powder compositions, methods for the preparation of those compositions, and methods for using those compositions to make compacted parts. The metallurgical powder compositions comprise a base metal powder, such as an iron-based or nickel-based powder, to which is added or blended an organometallic lubricant. Organometallic lubricants are monomers or polymers having a metal-carbon bond or metalloid-carbon bond on the polymer backbone, which degrade into physical property enhancing compounds upon heating. The metallurgical powder compositions can also comprise small amounts of other commonly used alloying powders, binding agents, and lubricants.

Owner:HOGANAS AB

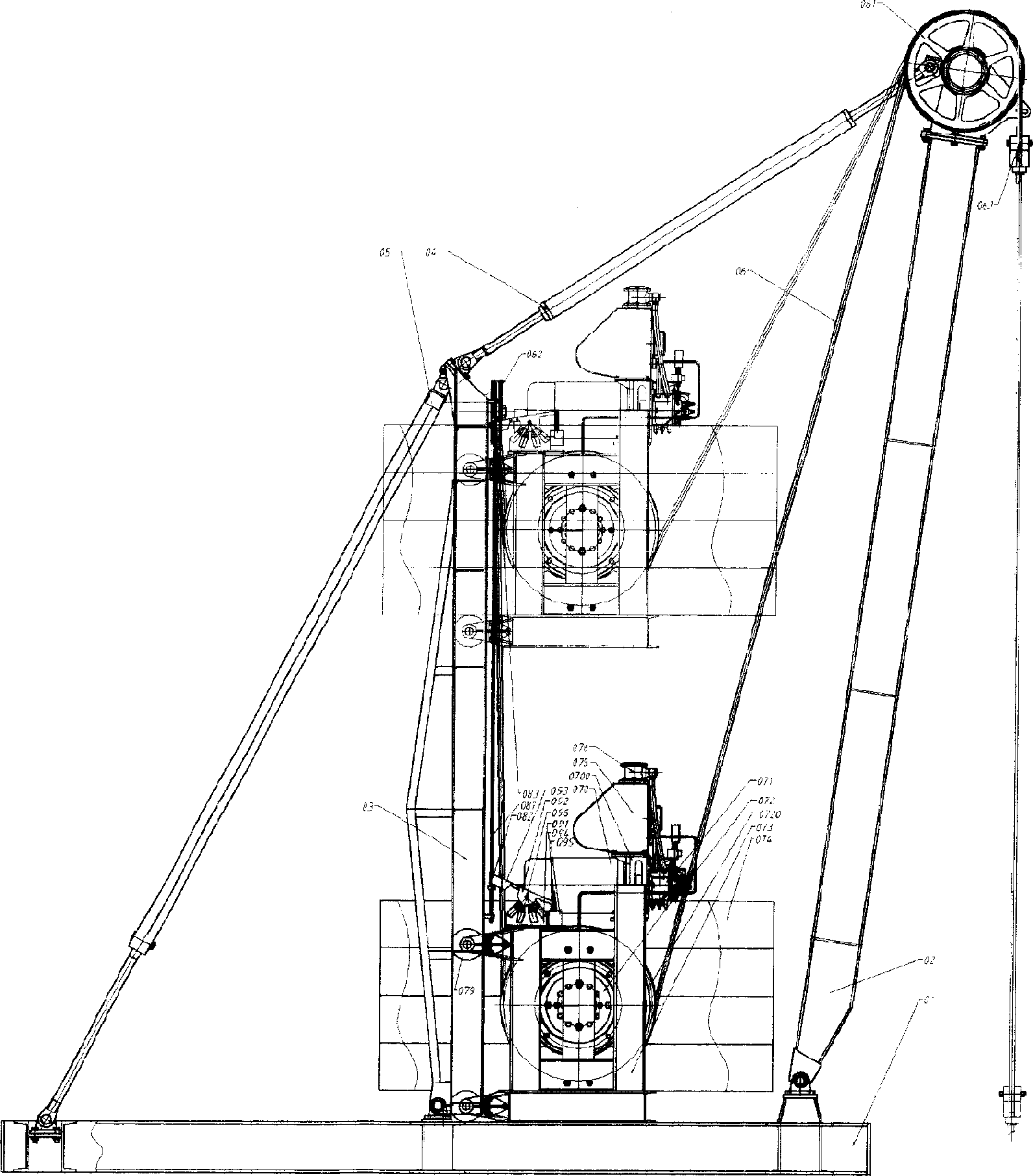

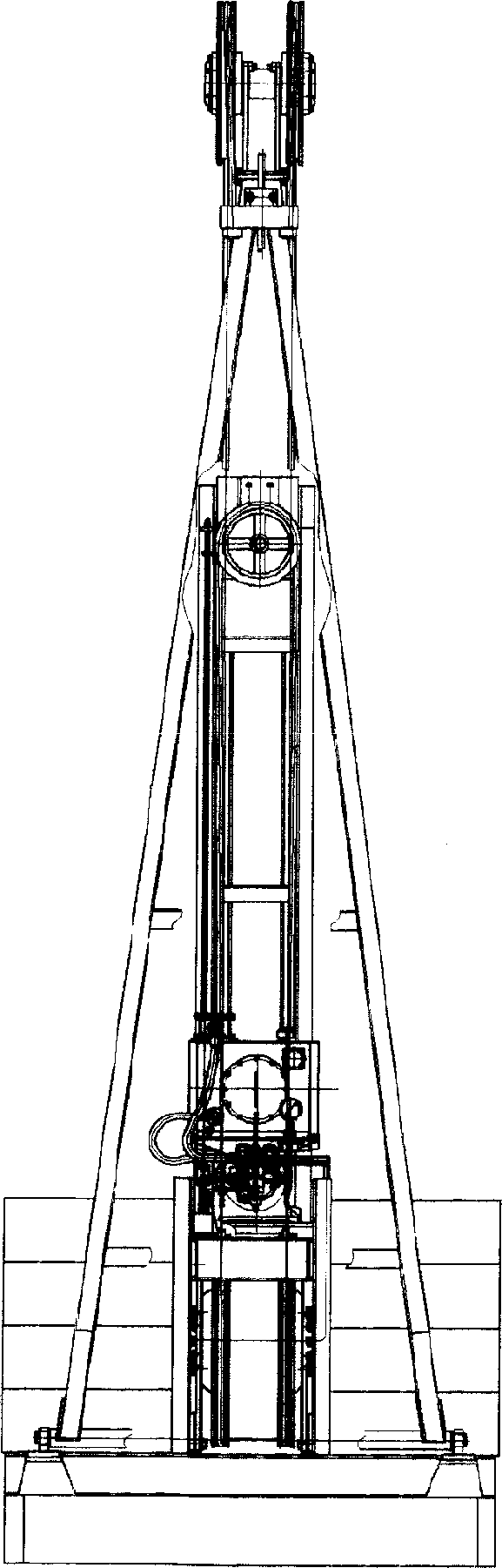

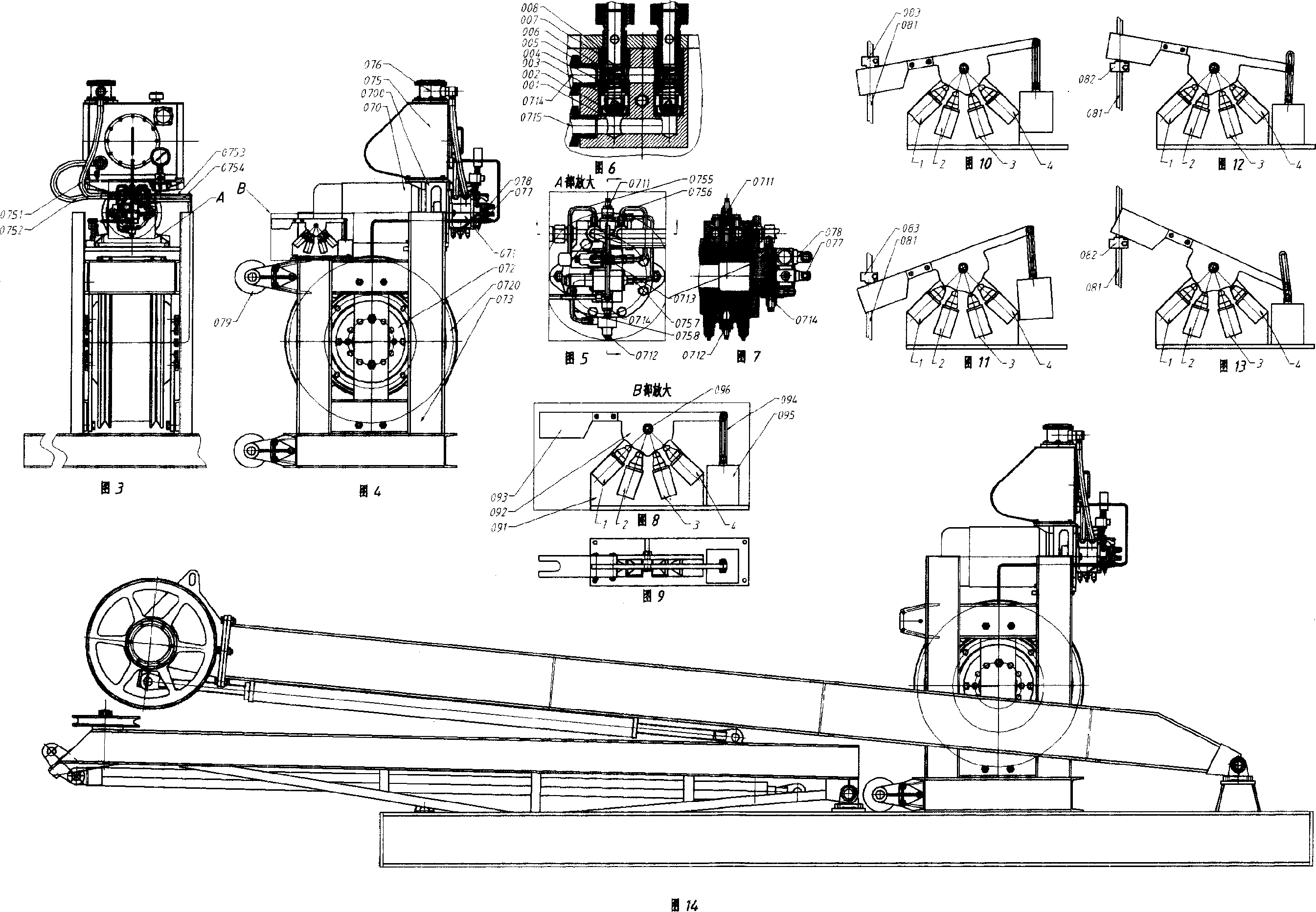

Reciprocating petroleum beam-pumping unit with hydraulic transmission

A hydraulic transmission petroleum mining pumping unit, it compose of foundation, front bracket, rear bracket, up pull-rod and diagonal pull-rod that are connected by hinge, hydraulic transmission assembly is set between front and rear bracket which compose of slide-block type variable and reversing gear hydraulic pump of combinational flat valve, slide-block type plate transmission low-speed torque hydraulic motor, oil-box and accessories group of pipe line, that is the transmission system operates opening pump motor to volume velocity modulation and reversing loop, and combine by hydraulic transmission wheel connecting with transmission pieces of mining pump, control by machined, electric and hydraulic adjustable system to work continuously and reciprocally with the needful stroke and stroke time.

Owner:彭利

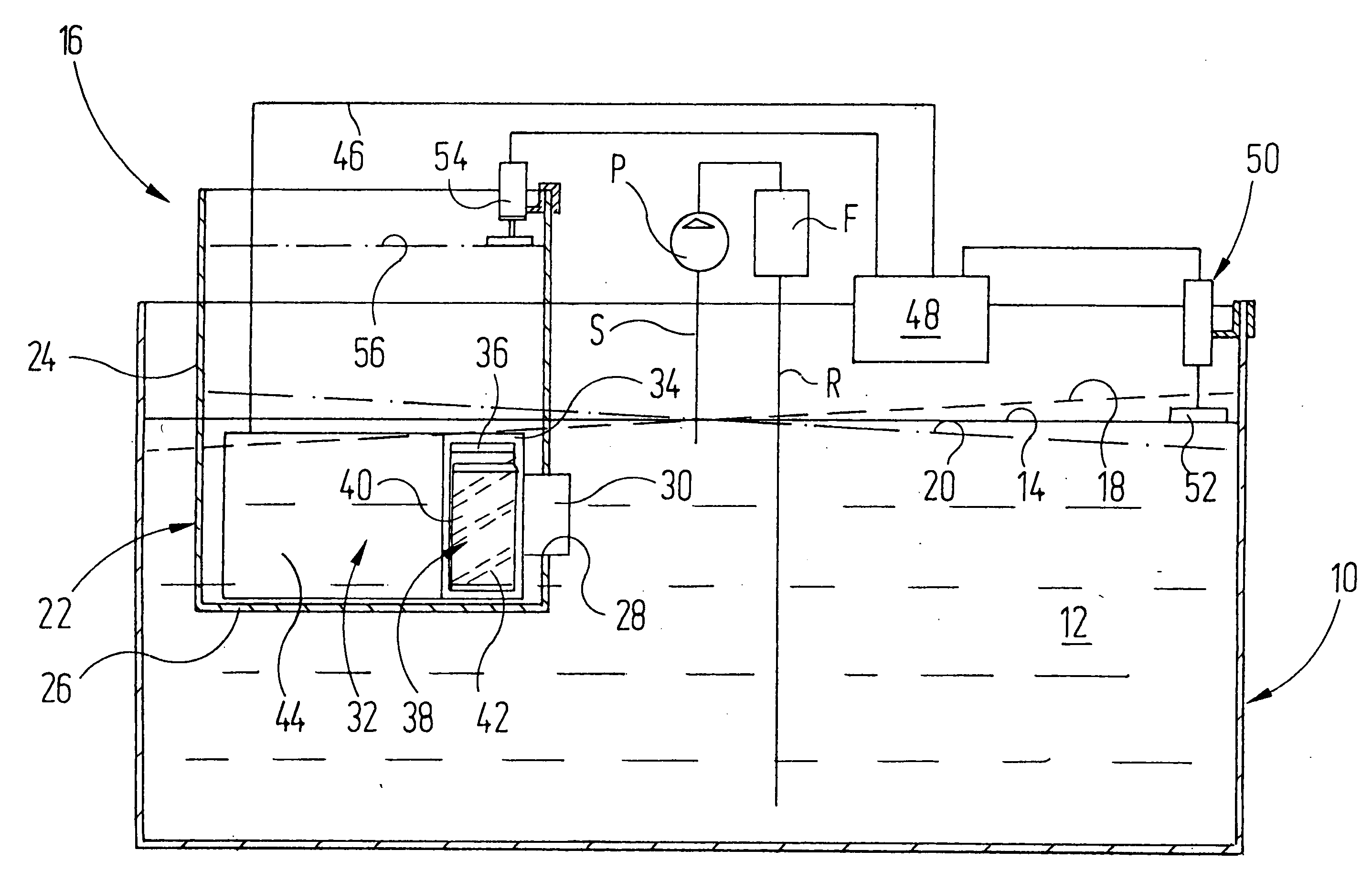

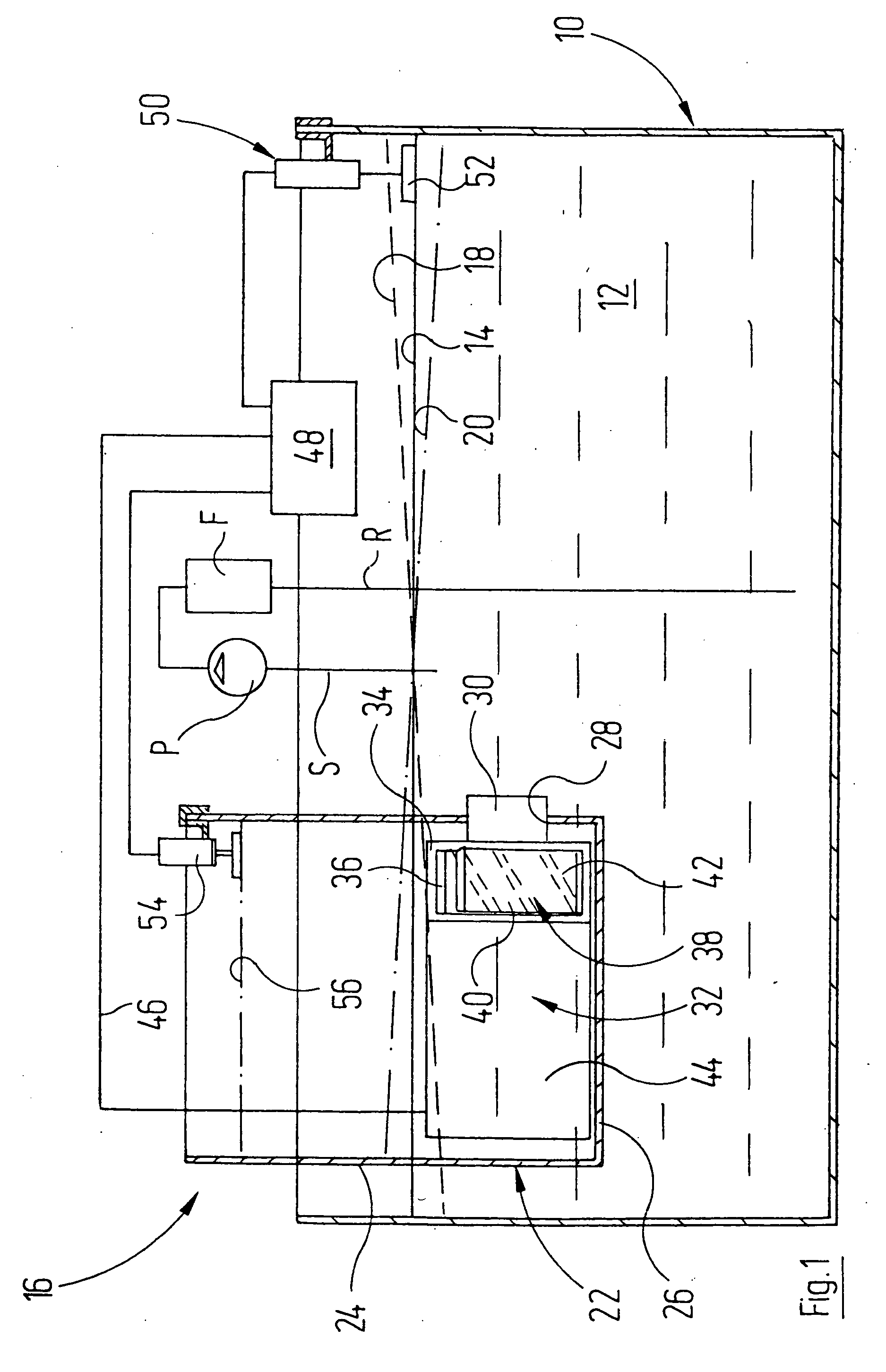

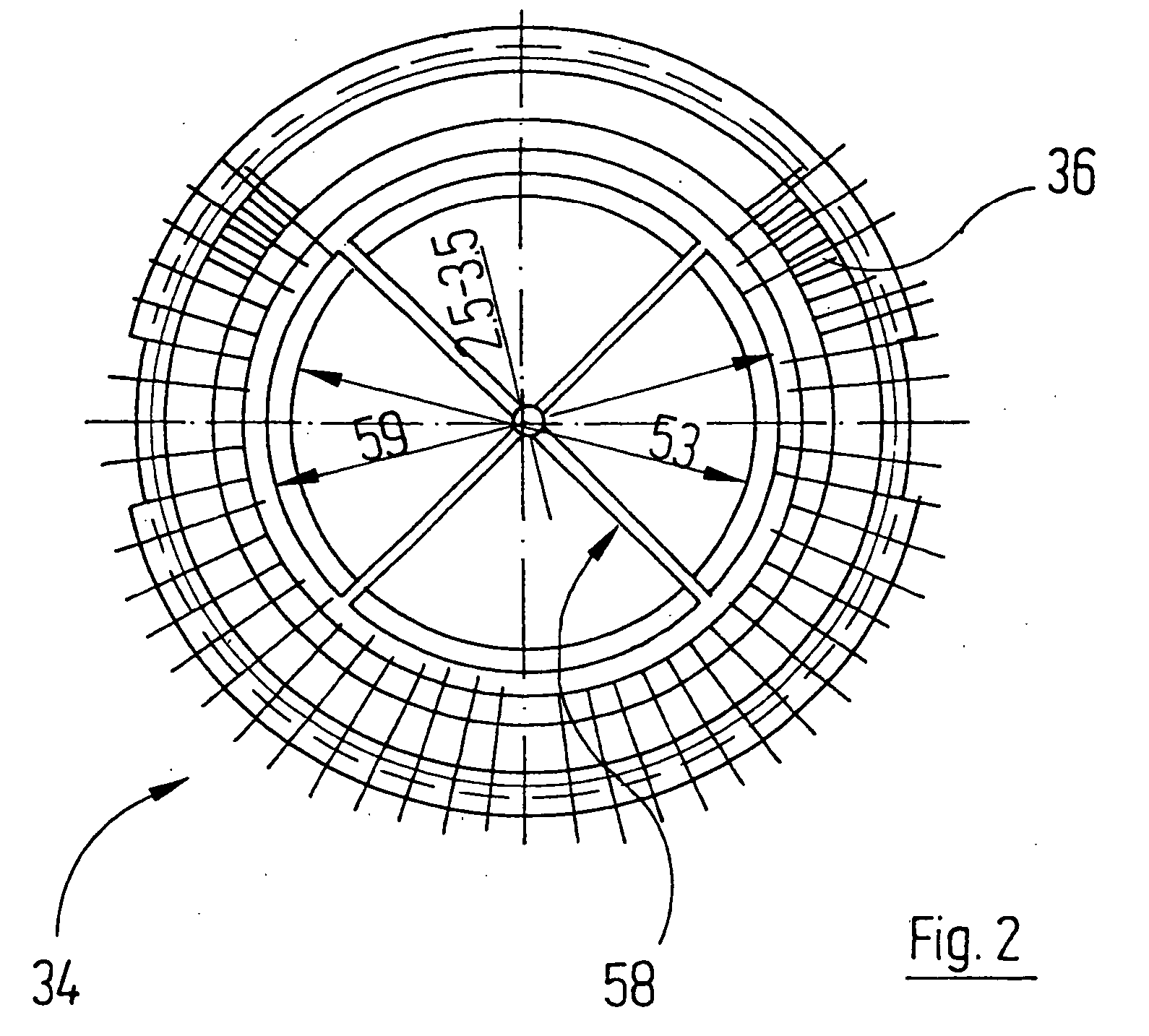

Method and device for generating waves in an aquarium

InactiveUS20050263090A1Reduce internal frictionPotential energyBathsDouchesEnvironmental engineeringMechanical load

In order to generate waves in a volume of water (12) of an aquarium, it is proposed that a storage container (22) which extends beyond the surface of the volume of water (12) should be provided in the aquarium (10). Using a pump (32), water is periodically pumped from the water container (10) into the storage container (22) and returned from the storage container (23) into the aquarium (10). The energy delivered to the water during this leads to fluctuations in the position of the free surface (14) of the volume of water (12) and in-phase operation of the pump (32) provides stronger surface displacements in the aquarium (10), which are comparable with a wave in open water and which expose the plants and living beings in the aquarium to an alternating mechanical load.

Owner:TUNZE AQUARIENTECHN

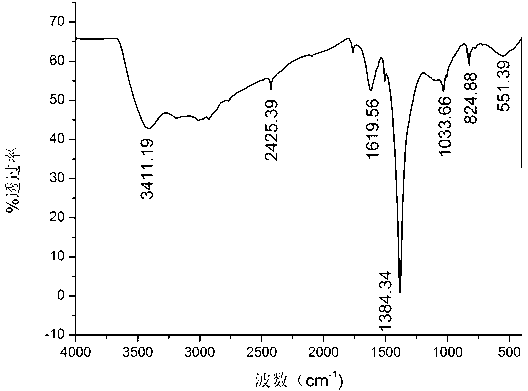

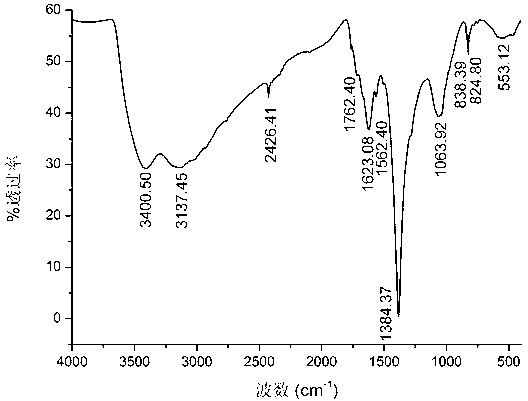

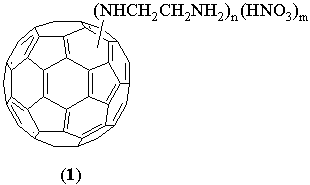

Fullerene ethylenediamine nitrate as well as preparation method and application thereof

InactiveCN103274949AEasy to prepareEasy to separate and purifyOrganic compound preparationAmino compound preparationEthylenediamineNitrate

The invention discloses a fullerene ethylenediamine nitrate as well as a preparation method and an application thereof. Firstly, fullerene C60 and ethylenediamine are taken as raw materials, fullerene ethylenediamine is prepared by the aid of a nucleophilic addition principle, and the fullerene ethylenediamine reacts with nitric acid so that the fullerene ethylenediamine nitrate is obtained. The fullerene ethylenediamine nitrate has the advantages of oxidant ammonium nitrate (AN), can avoid disadvantages of hygroscopicity, and crystal transformation of AN, and can be used as an oxidant to be applied in a novel solid rocket propellant or explosive.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Equal channel angular extrusion device of ultrasonic vibration female die

InactiveCN105170681AIncrease the dislocation densityReduce internal frictionExtrusion diesMechanical vibrations separationEngineeringUltrasound

The invention provides an equal channel angular extrusion device of an ultrasonic vibration female die. The equal channel angular extrusion device is composed of an upper template and a lower template. A threaded hole in the upper end of the upper template is connected with a hydraulic plunger on a hydraulic machine. The upper end of a cushion block is connected with the upper template. The lower end of the cushion block is connected with a male die. The male die is fixed in a blocking ring. The upper end of the blocking ring is fixedly connected with the cushion block. The upper end of a guide sleeve is fixedly connected with the upper template. The lower end of the guide sleeve is connected with the upper end of a guide column. The lower end of the guide column is fixedly connected with the lower template. The lower end of the female die is fixed to the lower template. The side face of the female die is fixed through a split stress ring. An ultrasonic vibration device is fixedly connected to the side face of the female die. High-strength ultrasonic waves are input into the female die, high-frequency periodic vibration displacement is generated on the surface of the female die, grain uniformizing and refining of an extrusion piece are improved, and the problems that an equal channel angular extrusion die is nonuniform in grain refining, and cracks exist on the extrusion piece are solved effectively.

Owner:GUANGXI UNIV

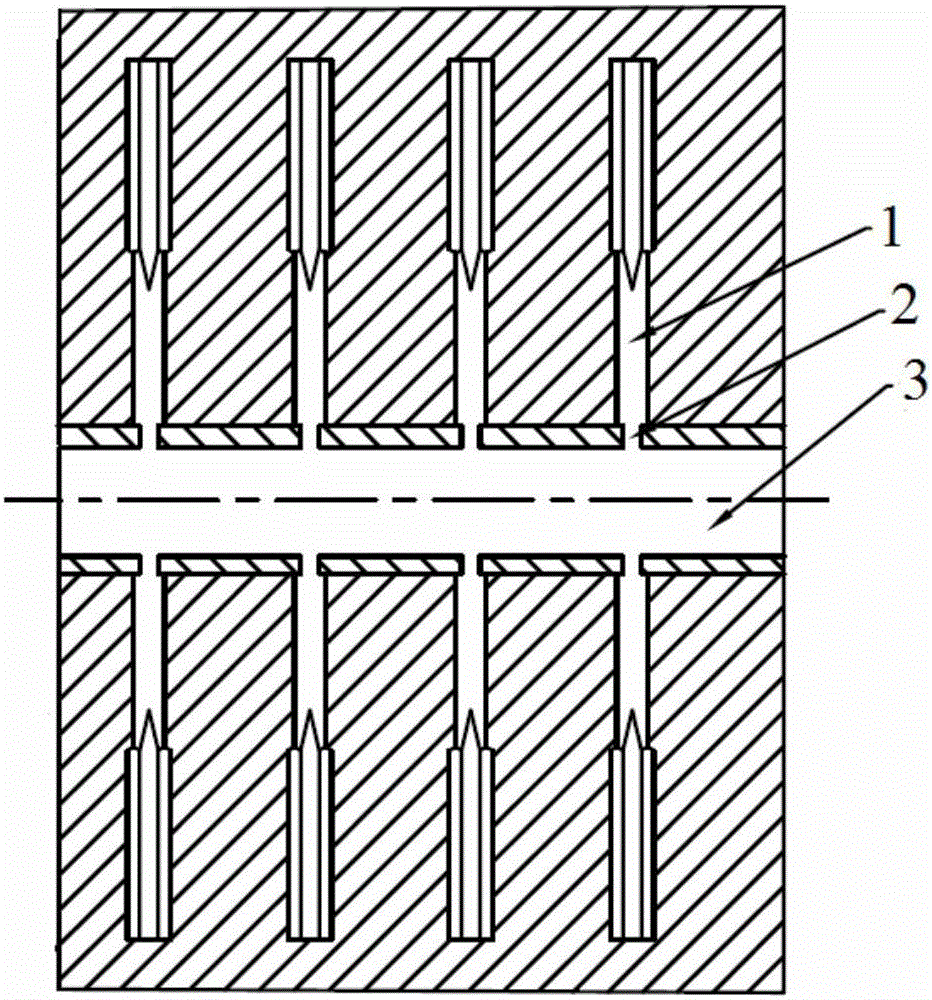

Preparation method for superfine hard alloy cutter blank with preformed cutter groove

ActiveCN106312074AHigh strengthImprove adhesionNon-macromolecular adhesive additivesTransportation and packagingMolten stateAdhesive

The invention provides a preparation method for a superfine hard alloy cutter blank with a preformed cutter groove. The preparation method is characterized by comprising the following steps: step 1, performing wet mixing and ball milling on superfine WC, superfine Co, superfine VC and Cr3C2, and then performing uniform mixing to obtain a superfine mixture of which all the components are uniform; step 2, adding an adhesive into a vacuum kneading machine, performing kneading till the superfine mixture and the adhesive are uniformly mixed, pelletizing the superfine mixture doped with the adhesive, heating the pelletized material in an injection molding machine till the pelletized material enters a molten state, injecting the molten material into a mold cavity by an injection molding mode, and dissolving and removing the adhesive in a superfine hard alloy soft blank in water; and step 3, performing sintering at 1340-1420 DEG C in a low-pressure sintering furnace, and performing argon gas pressurization at 1-10 MPa to prepare the superfine hard alloy cutter blank with the preformed cutter groove. When the superfine hard alloy cutter blank with the preformed cutter groove is produced by adopting the preparation method provided by the invention, the grinding amount during cutter production can be greatly reduced, the cutter production efficiency can be greatly improved, and the waste of tungsten resources can be reduced.

Owner:SUZHOU SAITERUI PRECISION MACHINERY PARTS CO LTD

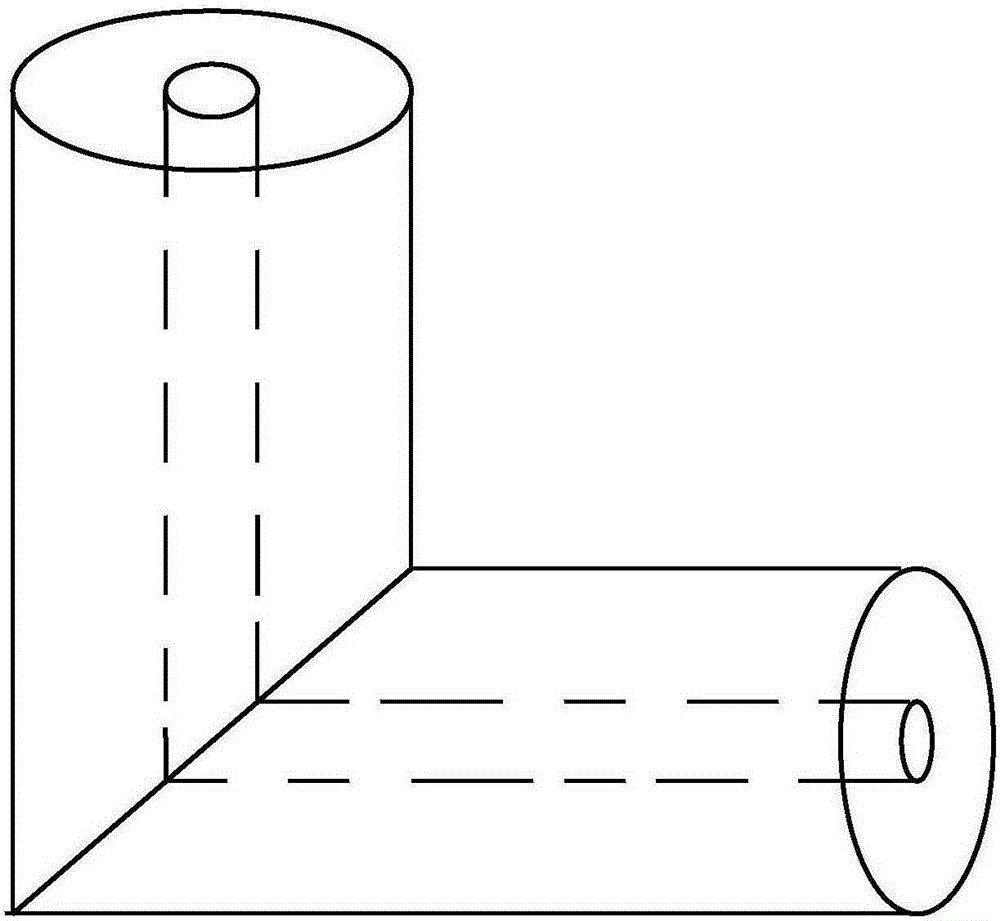

Equal channel angular pressing device of ultrasonic vibration male die

InactiveCN105080992AIncrease the dislocation densityReduce internal frictionExtrusion diesHydraulic ramHigh intensity

Provided is an equal channel angular pressing device of an ultrasonic vibration male die. The upper ends of pressure columns of the device are fixed to an upper die plate. A threaded hole in the upper end of the upper die plate is connected with a hydraulic plunger on a hydraulic machine. The upper ends of guide sleeves are fixedly connected with the upper die plate. The lower ends of the guide sleeves are connected with guide columns. The lower ends of the guide columns are fixedly connected with a lower die plate. The side face of a female die is fixed through a stress ring. An ultrasonic vibration device is fixedly connected between the upper end of the male die and the upper die plate. According to the device, high-intensity ultrasonic waves are input into the male die, high-frequency periodic vibration displacement is generated on the surface of the male die, uniformity of extruded elements is improved, crystal particles are refined, and the problems that according to an equal channel angular pressing die, the crystal particles are not uniform in refining and the extruded elements have cracks are solved.

Owner:GUANGXI UNIV

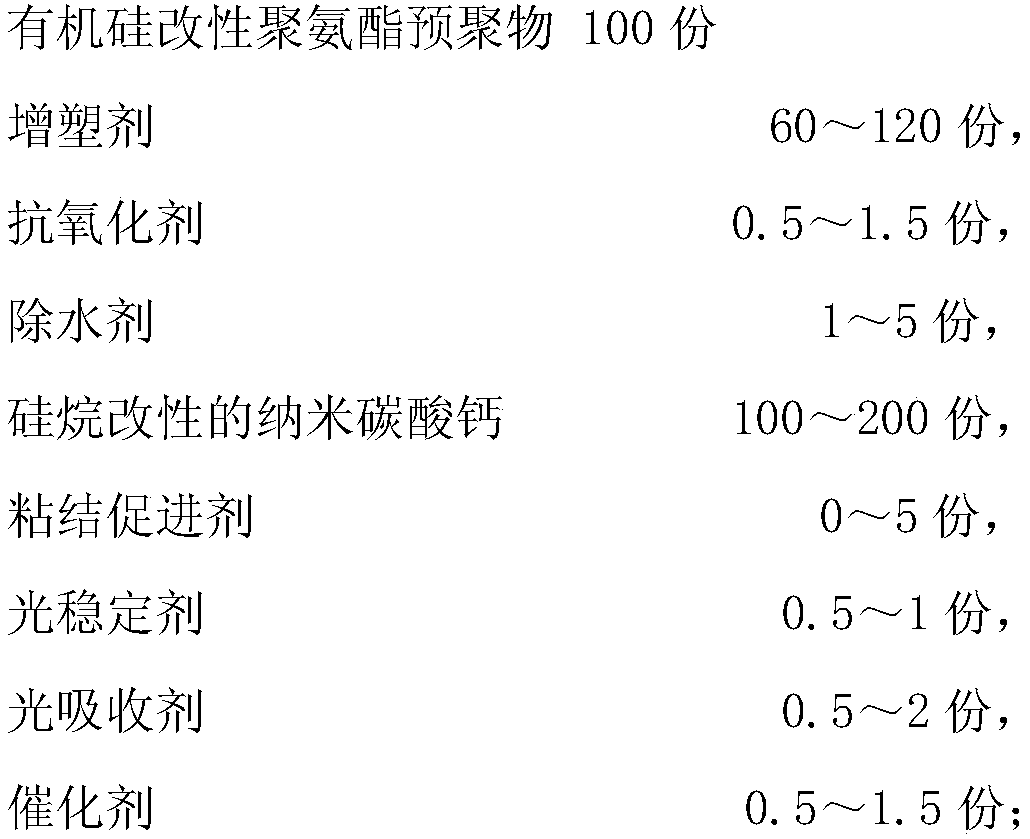

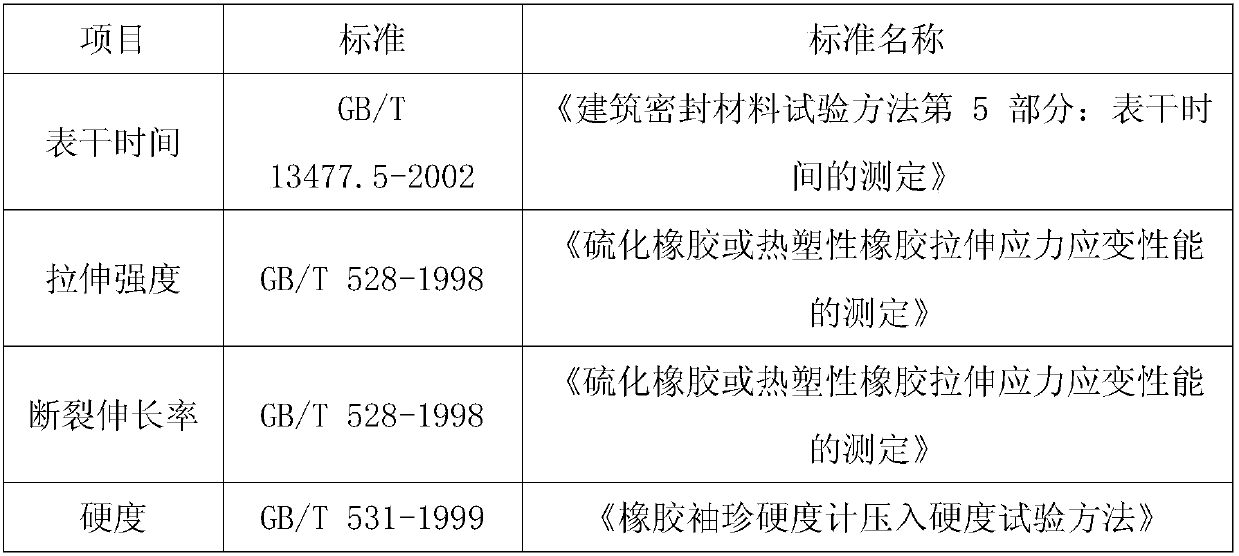

Low-modulus polyurethane sealant with high elasticity recovery rate and preparation method thereof

ActiveCN108018018AEasy to separateReduced mechanical propertiesNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSilanesRecovery performance

The invention discloses a low-modulus polyurethane sealant with a high elasticity recovery rate and a preparation method thereof. The low-modulus polyurethane sealant with the high elasticity recoveryrate is prepared from an organosilicone-modified polyurethane prepolymer and silane-modified nano calcium carbonate. The low-modulus organosilicone-modified polyurethane sealant has favorable elasticity recovery performance, and meanwhile, has certain hydrophobic performance, excellent water resistance and good stability.

Owner:JIANGSU SOBUTE NEW MATERIALS

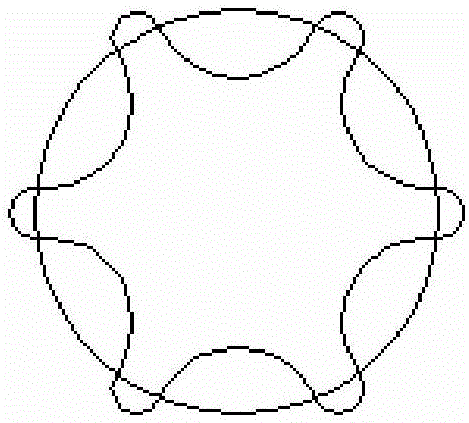

Ballanced rotary internal combustion engine or cycling volume machine

InactiveUS20050000483A1Simplified and effectiveEfficient combustionInternal combustion piston enginesEngine of arcuate-engagement typeCombustion chamberEngineering

A balanced rotary cycling machine suitable for use as an internal combustion engine, compressed gas or steam engine, compressor or pump is disclosed herein. The rotor assembly consists of four articulating pistons where the opposite pistons are inter-linked with each other by pivoted rods comprising a parallelogram mechanism and therefore eliminating a need for pivots between pistons. The rotor assembly rotates inside or outside of a circular or non-circular stator depending on the configuration chosen. A variety of mechanisms for shape deformation of four piston assembly during its rotating cycle is also disclosed herein, as well as detailed descriptions of preferred embodiments, including a four cycle internal combustion engine with circular stator, marine engine with polymer parts and a four cycle automobile rotary engine with conventional oil pan. In addition, a method of operation of external rotary combustion engine, employing a high-pressure compressor and an external combustion chamber, is disclosed. This invention also teaches a novel lubrication system for rotary engine providing low emissions. The engine has few moving parts, simplified circular or semi-circular stator shape and utilizes simple and effective sealing techniques. It is fully balanced, has very low friction and heat losses and can employ a pre-designed configuration of the combustion chamber for a desired compression ratio and power output.

Owner:OKULOV PAUL D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com