Oxygen intake type single stroke engine and operation method thereof

An engine and single-stroke technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve problems such as rough work, energy consumption, and serious emission pollution, and achieve the effect of simple structure and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

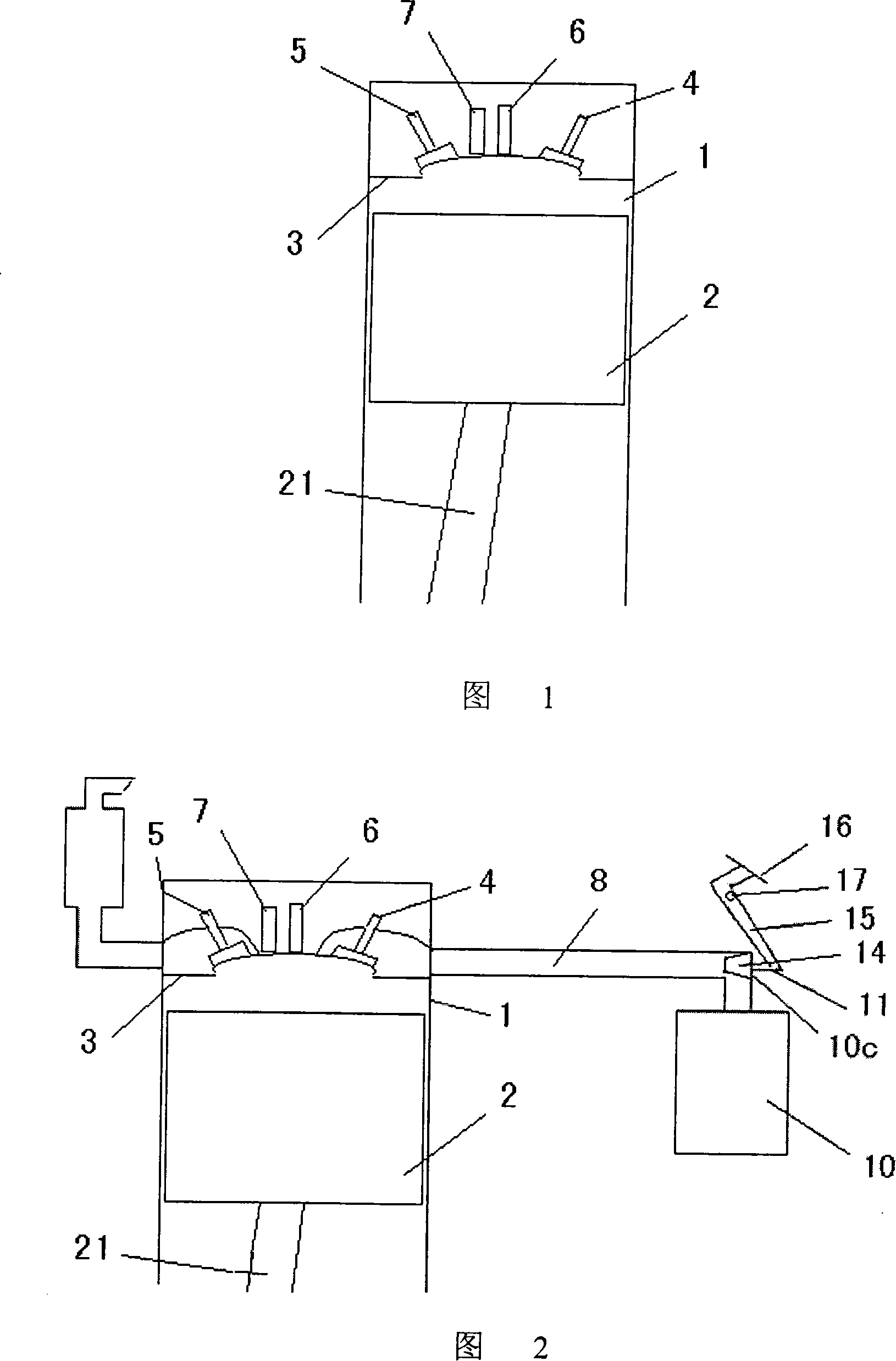

[0038]As shown in Figure 1, it is an existing four-stroke gasoline engine, which includes a cylinder 1, and a piston 2 is arranged in the cylinder 1, which divides the cylinder into two chambers isolated from each other, and is opposite to the piston connecting rod 21 of the piston 2. The end of one of the chambers is provided with a cylinder head 3, which is in a convex shape at the junction with the cylinder, forming an arc-shaped space. When the piston 2 is at the front end (ie, top dead center) closest to the cylinder head 3, The space provided between the end face of the piston 2 and the arc-shaped cylinder head 3 is called a combustion chamber. The cylinder head 3 is provided with an intake valve 4 , an exhaust valve 5 , a fuel injector 6 and a spark plug 7 .

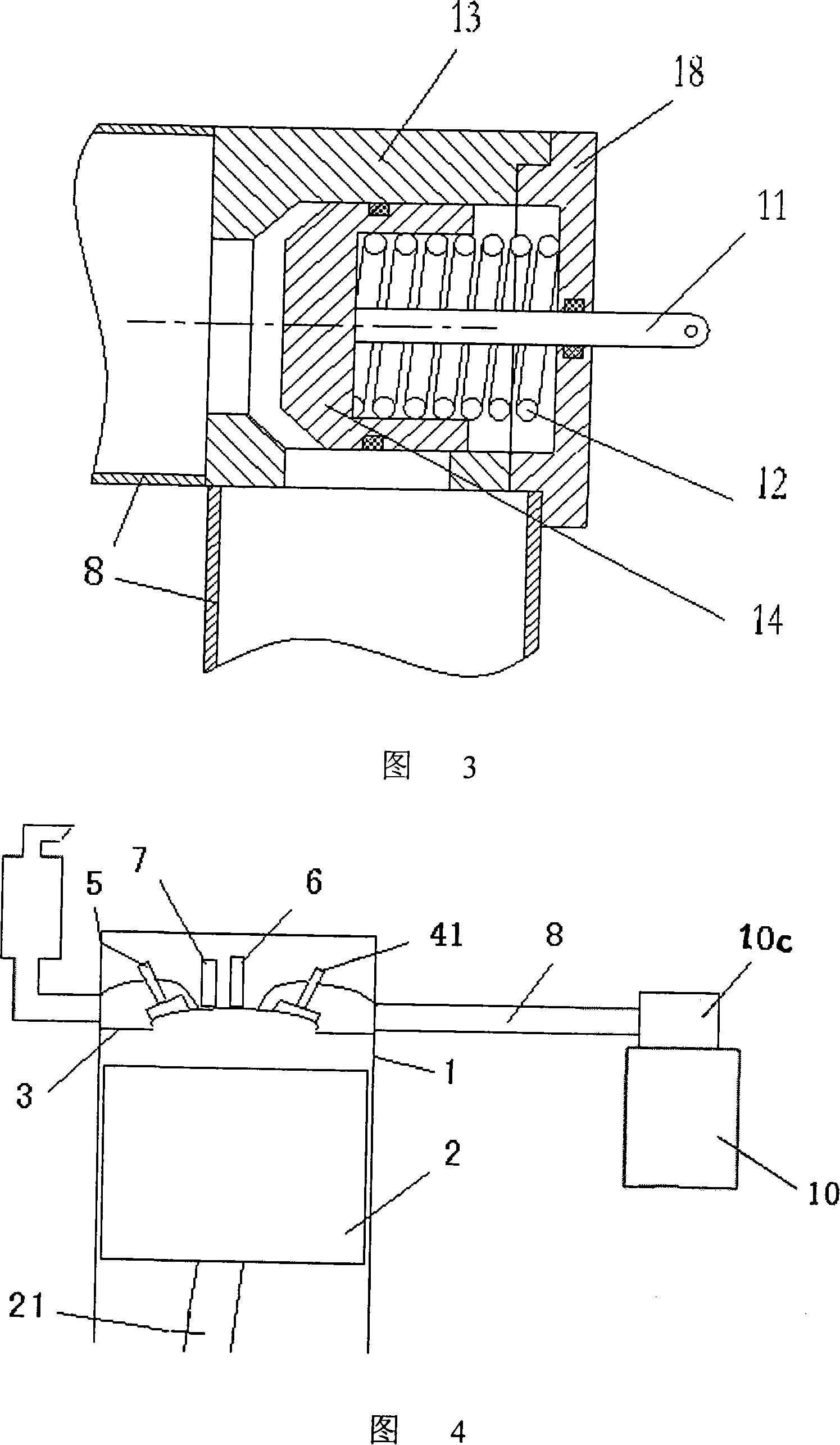

[0039] The oxygen-intake type single-stroke engine provided by the present invention is improved on the basis of the existing four-stroke gasoline engine shown in Figure 1, that is, the aforementioned intake valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com