Flexibly packaged lithium battery evacuation apparatus and use method thereof

A soft-pack lithium battery and evacuation device technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, climate sustainability, etc., can solve the problems of electrolyte overflow and long vacuuming time, so as to reduce overflow, avoid pollution, The effect of reducing the evacuation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Adopt the present invention to carry out evacuation treatment to the soft pack lithium battery that has been filled with electrolyte, the steps are as follows:

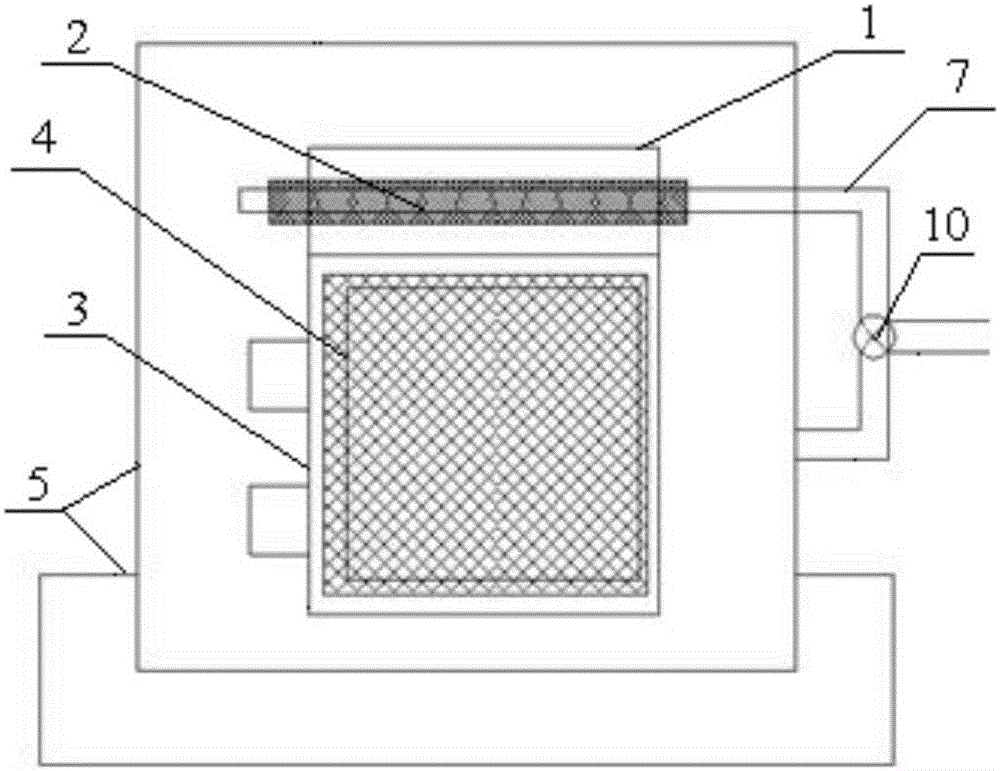

[0030] (1) Fix the soft-packed lithium battery 3 filled with electrolyte in the vacuum chamber 5, clamp and position it through the splint 4, seal the vacuum chamber 5, switch the valve 10, turn on the vacuum pump, and perform the first vacuuming, the vacuum chamber After the vacuum degree inside reaches -0.07MPa, switch the valve 10 and stop vacuuming;

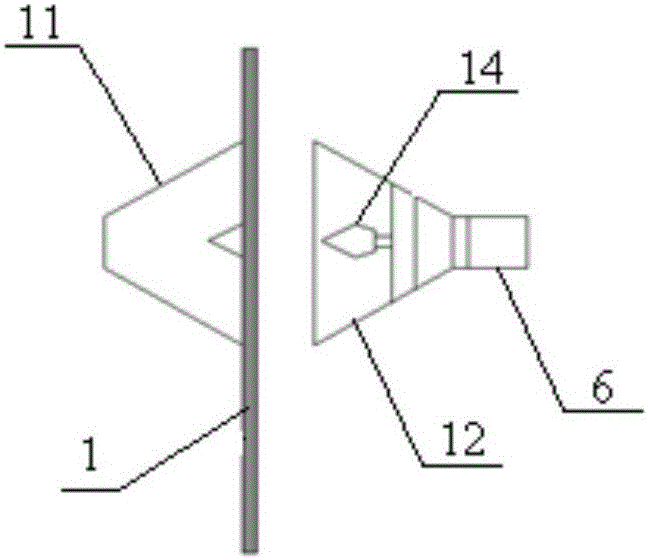

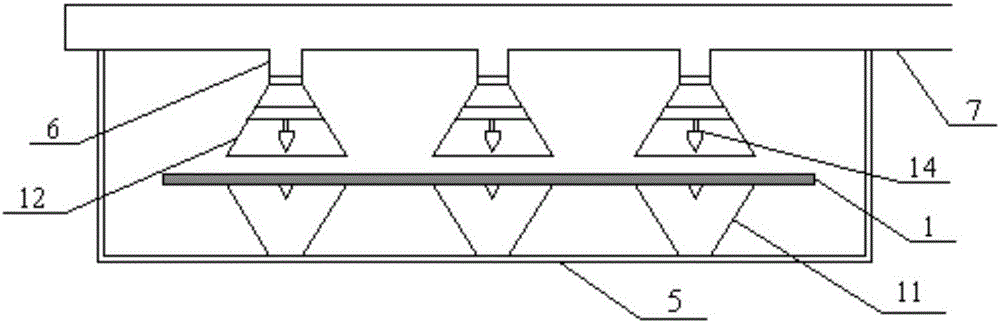

[0031] (2) Fix the battery airbag 1 by fixing the suction cup 11 and driving the suction cup 12, then drive the bayonet 14 to pierce the battery airbag 1, and start exhausting, the exhausting time is 30s, and one combined suction cup is set;

[0032] (3) After the exhaust is completed, switch the valve 10 and carry out the second vacuuming. After the vacuum degree reaches -0.093MPa, maintain it for 20s to fully exhaust the gas inside the soft-pack lithium batt...

Embodiment 2

[0035] Adopt the present invention to carry out evacuation treatment to the soft pack lithium battery that has been filled with electrolyte, the steps are as follows:

[0036] (1) Fix the soft-packed lithium battery 3 filled with electrolyte in the vacuum chamber 5, clamp and position it through the splint 4, seal the vacuum chamber 5, switch the valve 10, turn on the vacuum pump, and perform the first vacuuming, the vacuum chamber After the vacuum inside reaches -0.08MPa, switch the valve 10 and stop vacuuming;

[0037] (2) Fix the battery airbag 1 by fixing the suction cup 11 and driving the suction cup 12, then drive the bayonet 14 to pierce the battery airbag 1, and start exhausting, the exhausting time is 20s, and the combined suction cups are set to 3;

[0038] (3) After the exhaust is completed, switch the valve 10 and carry out the second vacuuming. After the vacuum degree reaches -0.094MPa, maintain it for 12 seconds to fully exhaust the gas inside the soft-pack lithi...

Embodiment 3

[0041] Adopt the present invention to carry out evacuation treatment to the soft pack lithium battery that has been filled with electrolyte, the steps are as follows:

[0042] (1) Fix the soft-packed lithium battery 3 filled with electrolyte in the vacuum chamber 5, clamp and position it through the splint 4, seal the vacuum chamber 5, switch the valve 10, turn on the vacuum pump, and perform the first vacuuming, the vacuum chamber After the vacuum inside reaches -0.09MPa, switch valve 10 and stop vacuuming;

[0043] (2) Fix the battery airbag 1 by fixing the suction cup 11 and driving the suction cup 12, then drive the bayonet 14 to pierce the battery airbag 1, and start to exhaust, the exhaust time is 10s, and the number of combined suction cups is set to 6;

[0044] (3) After the exhaust is completed, switch the valve 10 and carry out the second vacuuming. After the vacuum degree reaches -0.095MPa, keep it for 5s to fully exhaust the gas inside the soft-pack lithium battery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com