Ultrasonic-based medium-high carbon steel fine blanking forming device

An ultrasonic, medium and high carbon technology is applied in the field of medium and high carbon steel fine blanking forming devices to achieve the effect of improving forming efficiency and high forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The ultrasonic-based medium-high carbon steel fine-blanking forming device of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

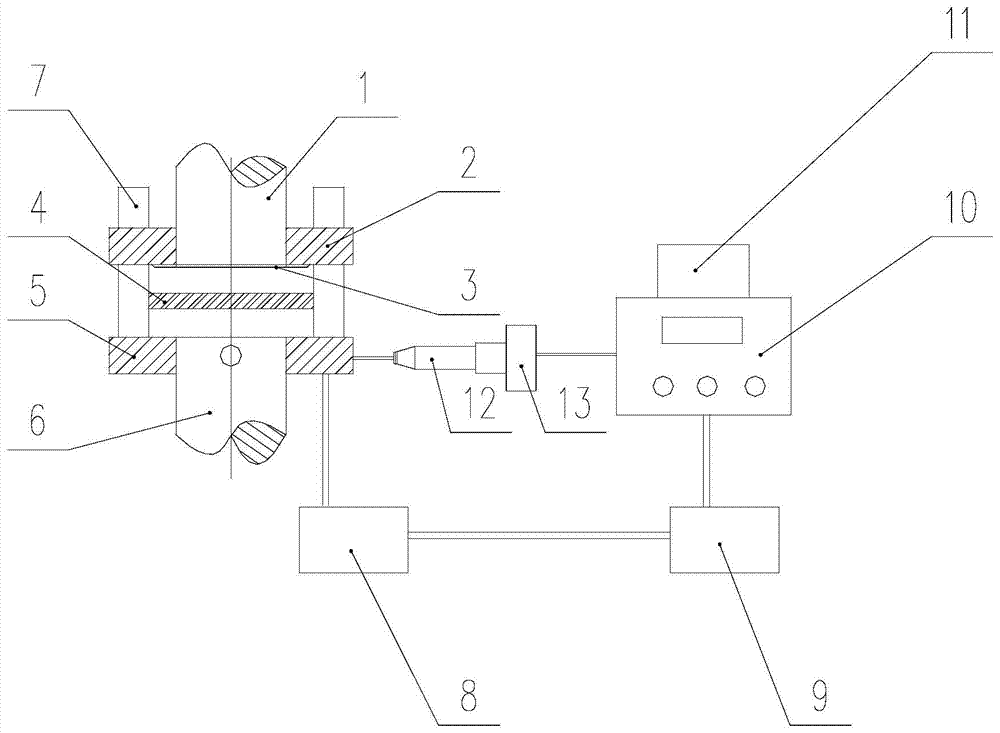

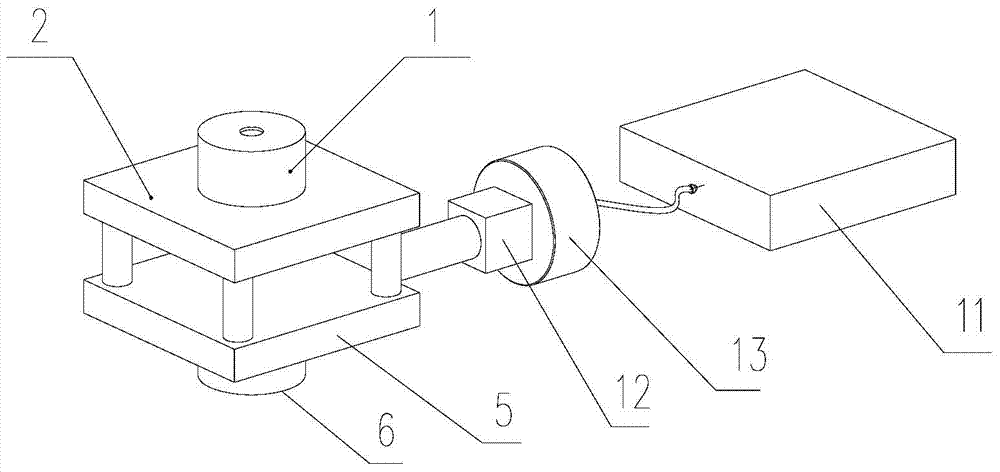

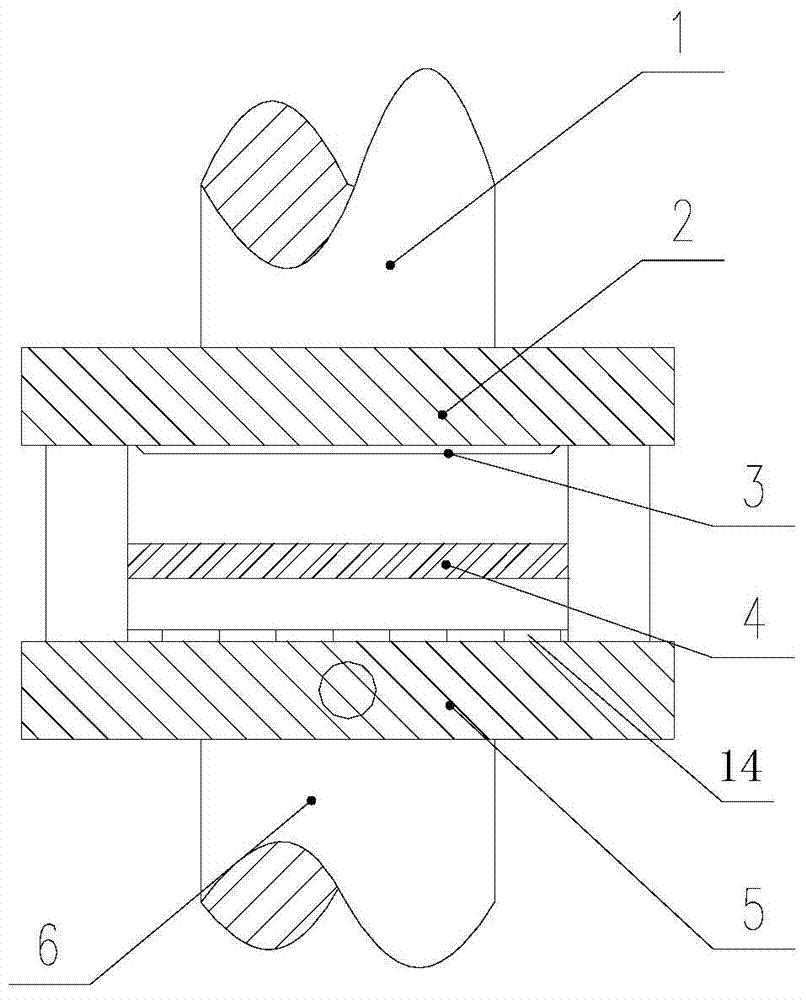

[0031] The medium and high carbon steel fine blanking forming device based on ultrasonic wave of the present invention, its working principle is as follows figure 1 and Figure 4 As shown, it includes an ultrasonic generating system, a fine blanking die system and a temperature feedback adjustment system. The ultrasonic generating system is connected with the die 5 of the fine blanking die through a horn 12, and the horn 12 is converted by ultrasonic waves. The device 13 is connected with the ultrasonic generator 10, and the fine blanking die system includes a die 5, a punch 1, an anti-jack block 6, a blank holder ring 2, a V-shaped ring gear 3 and a hydraulic device; wherein, the die 5 and The punch 1 is connected through the hydraulic rod 7 of the hydraulic devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com