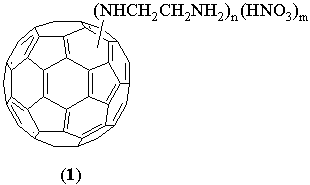

Fullerene ethylenediamine nitrate as well as preparation method and application thereof

A technology of fullerene ethylenediamine nitrate and fullerene ethylenediamine, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, can solve problems such as entanglements, and achieve high yield, The preparation method is simple and convenient, and the effect of easy separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

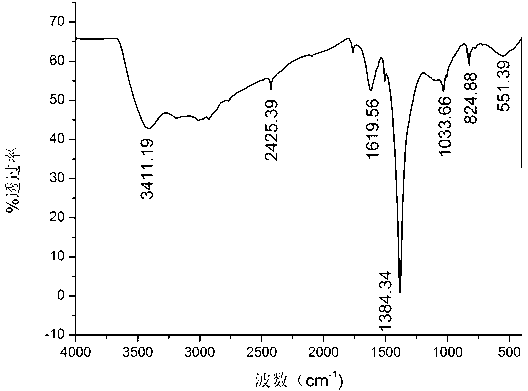

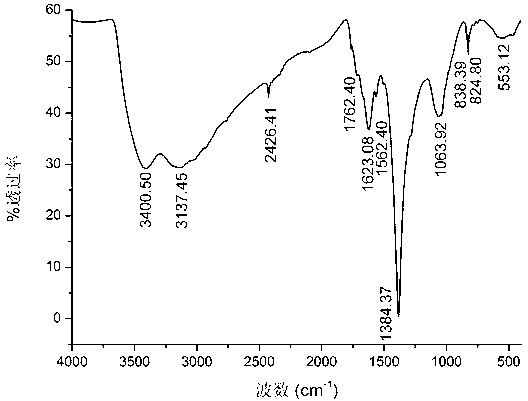

[0023] First weigh 0.30g of C60, add 200mL of ethylenediamine into a 250mL three-neck round bottom flask, and under nitrogen protection, react at 80°C for 4 days until the color of the solution turns yellowish brown, then stop the reaction. Excess ethylenediamine solution was removed by rotary evaporation at 55° C. to obtain a large amount of tan viscous material. Dissolve the viscous matter with 8ml of distilled water, and then add 100 mL of acetone, a large number of brown flocculent precipitates precipitate out, filter under reduced pressure, collect the precipitate, and vacuum-dry at 45°C to obtain brown fullerene ethylenediamine. The reaction equation is shown in Formula (2). Then weigh 1.00 g of fullerene ethylenediamine and 16 ml of nitric acid with a concentration of 1 mol / L, control the temperature to 40° C., and stir for 0.5 h. The reaction liquid was evaporated under reduced pressure to remove water and nitric acid to obtain a brown solid, which was dried under vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com