Equal channel angular extrusion device of ultrasonic vibration female die

A technology of equal angular extrusion and ultrasonic vibration, applied in the direction of vibrating fluid, metal extrusion die, etc., can solve the problem that the scale of ultra-fine-grained materials is difficult to reach below 200nm, and the extruded parts are prone to cracks or scratches. Problems such as poor distribution of the plastic deformation zone of the sample structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below through examples.

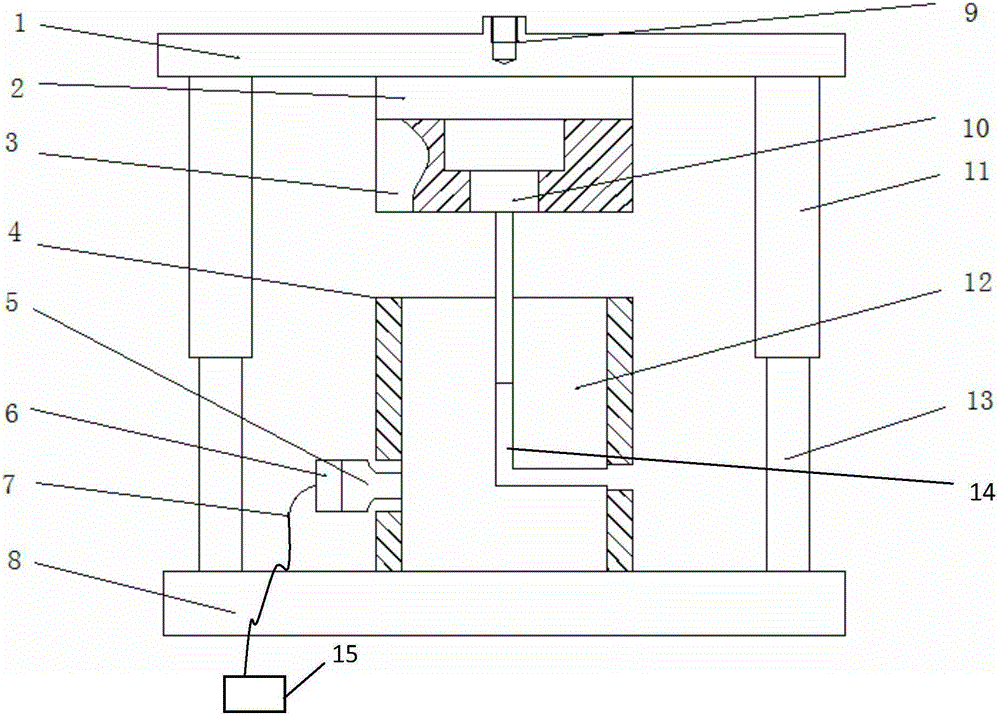

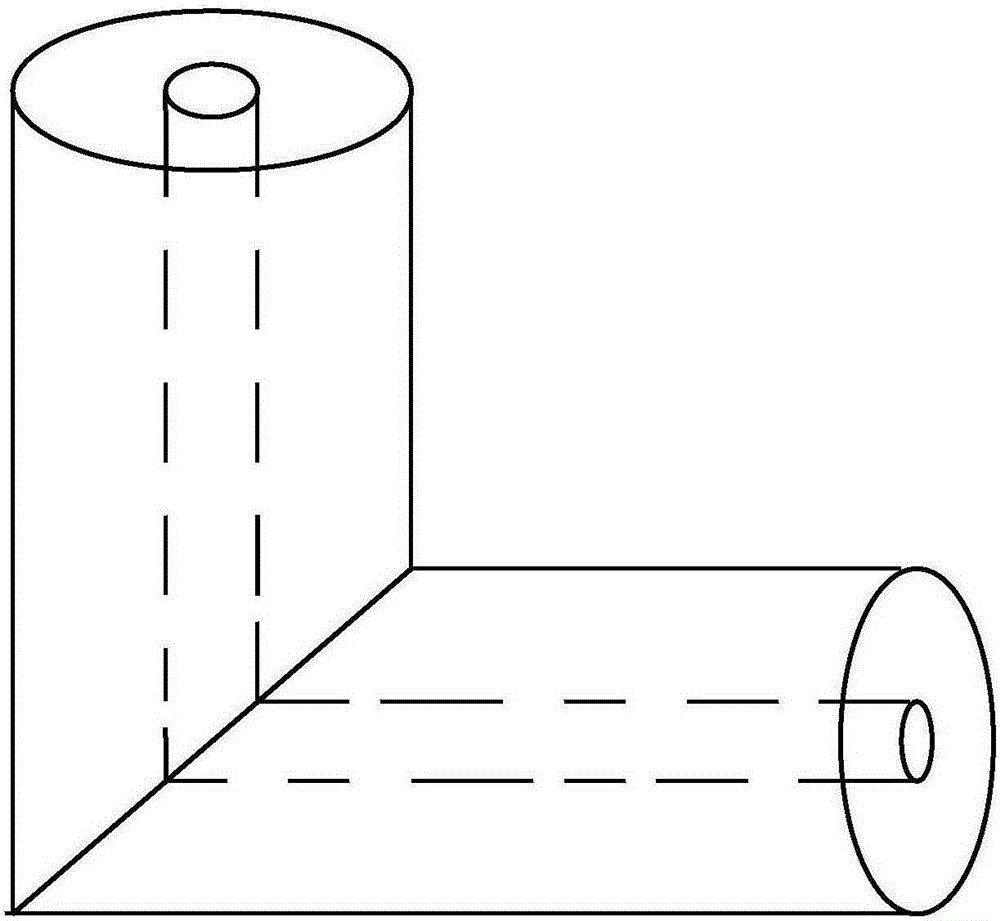

[0026] like figure 1 As shown, the equal angular extrusion device of the ultrasonic vibrating die according to the present invention includes an upper template 1, a cushion block 2, a retaining ring 3, a stress ring 4, an ultrasonic amplifier 5, an ultrasonic transducer 6, a cable 7, Lower template 8, hydraulic plunger 9, punch 10, guide sleeve 11, die 12 and guide post 13. The specific structure and connection relationship are: the upper formwork 1 and the lower formwork 8 make relative movement, the threaded hole at the upper end of the upper formwork 1 is connected with the hydraulic plunger 9 on the hydraulic press, the upper end of the spacer 2 is connected with the upper formwork 1, and the lower end of the spacer 2 Connect with the punch 10, the punch 10 is fixed in the retaining ring 3, the upper end of the retaining ring 3 is fixedly connected with the pad 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com