Non-oriented electrical steel for variable frequency motor and production method thereof

A technology of grain-oriented electrical steel and variable frequency motor, applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of complex process procedures, low magnetic induction of low iron loss silicon steel, low production efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

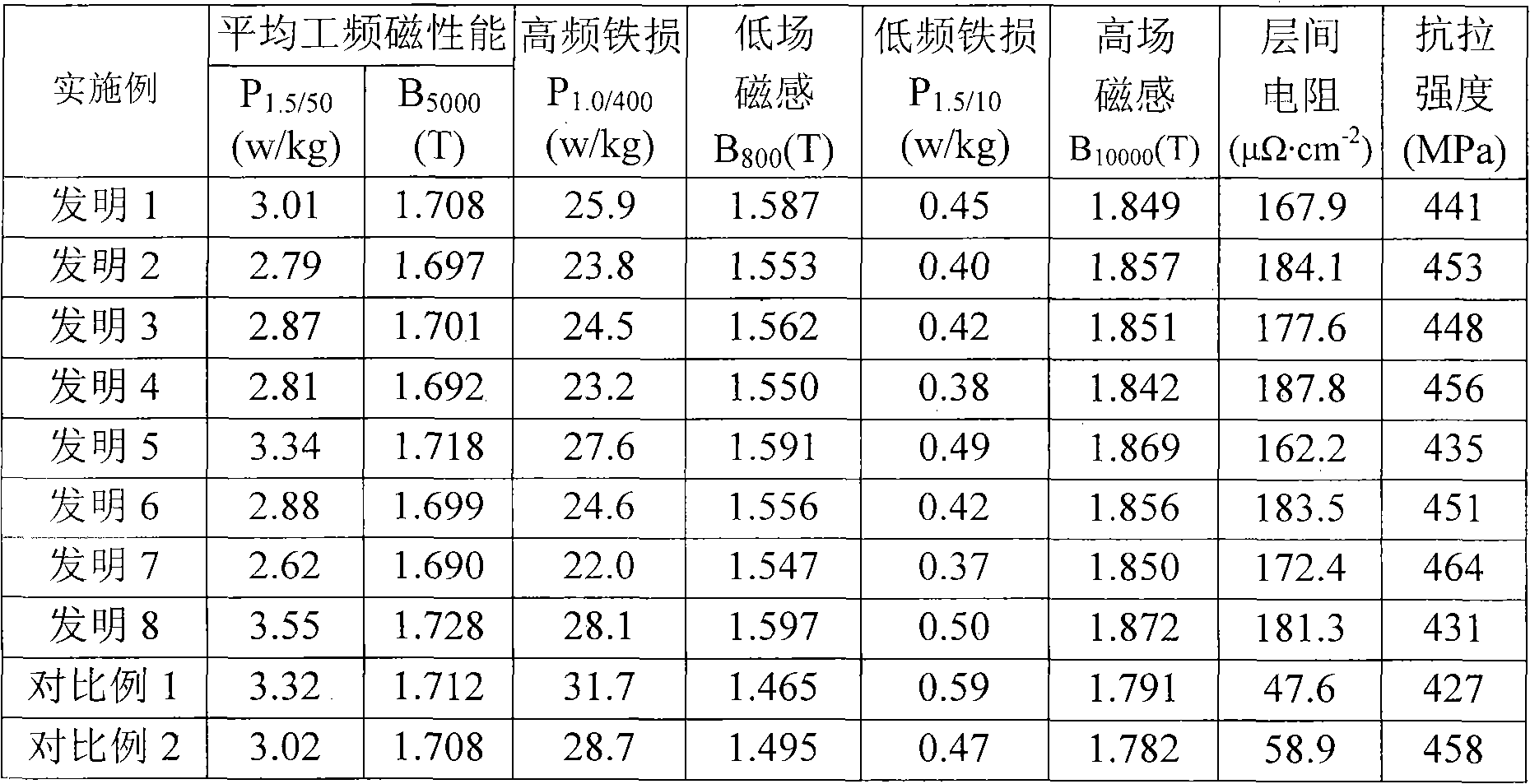

Examples

Embodiment Construction

[0053] A detailed description is given below:

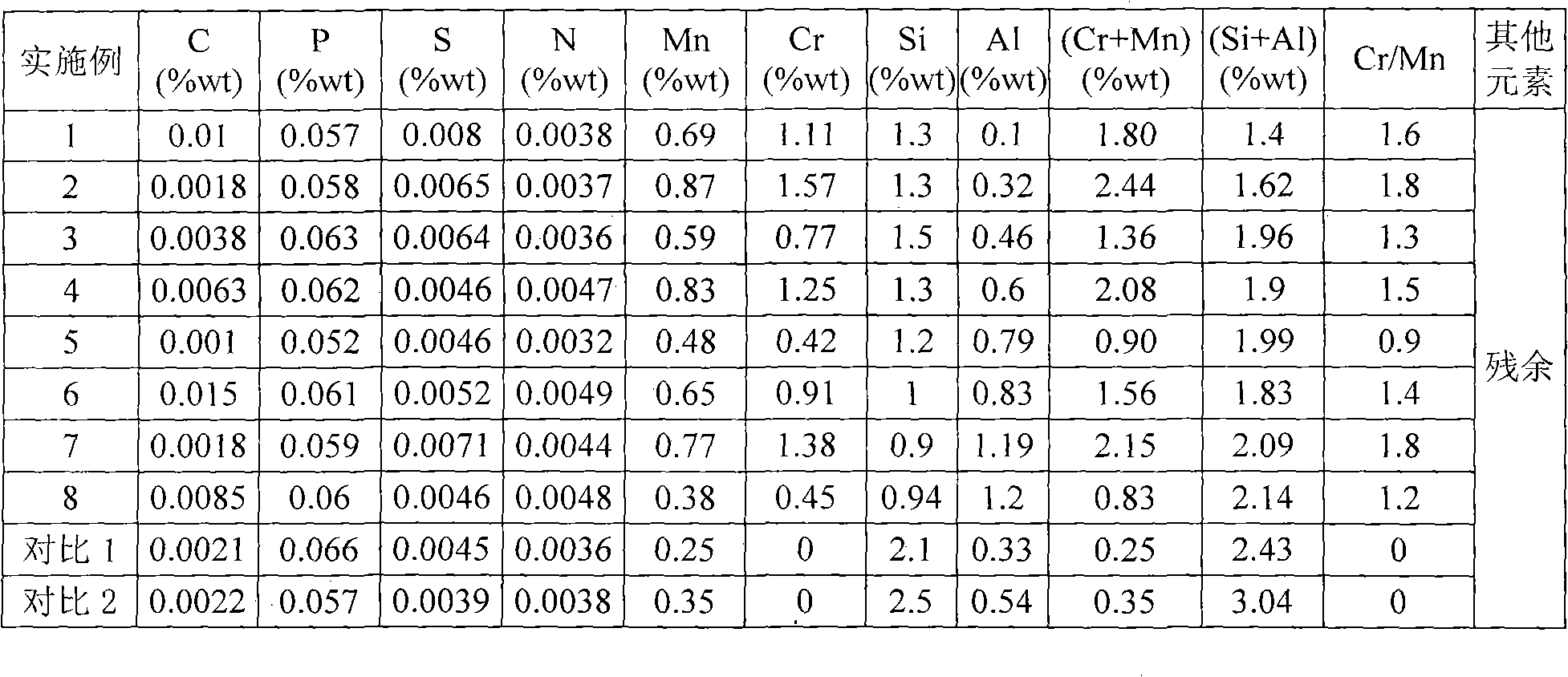

[0054] The smelting composition of each embodiment is shown in Table 1:

[0055] Table 1

[0056]

[0057] 2. According to the composition design in Table 1, carry out smelting and rolling, according to the process steps:

[0058] 1) The smelting process of clean steel is used for smelting and continuous casting into billets;

[0059] 2) Heat the continuous casting billet to 950-1300°C, and control its time in the furnace: 1.5-3 hours;

[0060] 3) Rough rolling is carried out, the outlet temperature is controlled to be 800-1050°C, and the cumulative reduction rate is controlled to be 90-95%;

[0061] 4) Carry out finish rolling, control the cumulative reduction ratio of the first 4 passes to 80-95%, and control the rolling temperature at 700-900°C;

[0062] 5) Carry out coiling, and its coiling temperature is controlled at 600~800 ℃;

[0063] 6) naturally cool to room temperature;

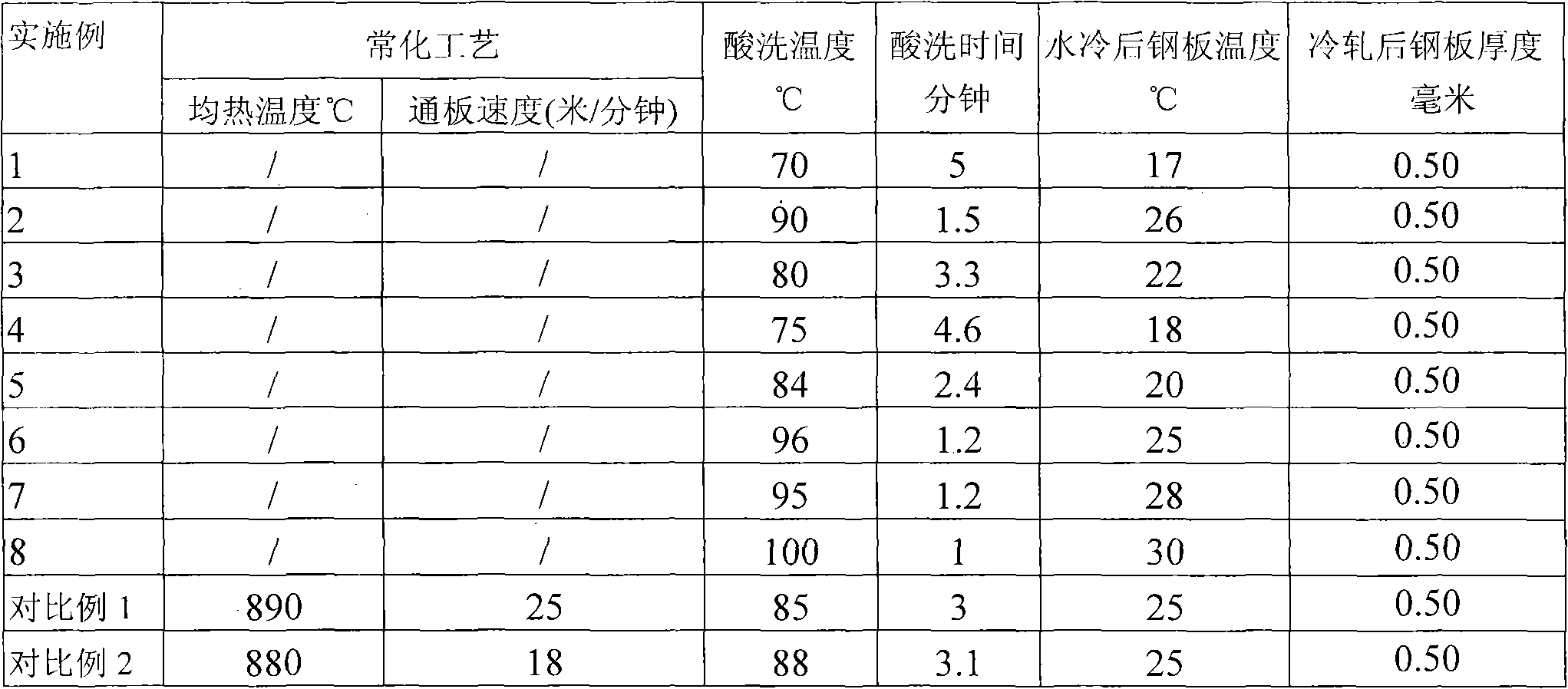

[0064] 7) Pickling, the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com