Method for preparing complex enzyme preparation and application of complex enzyme preparation to feed

A compound enzyme preparation and feed compound enzyme technology, which is applied in the field of Trichoderma strains to prepare compound enzyme preparations, can solve the problems of low feed utilization rate and achieve the effects of increasing utilization rate, strong adaptability, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

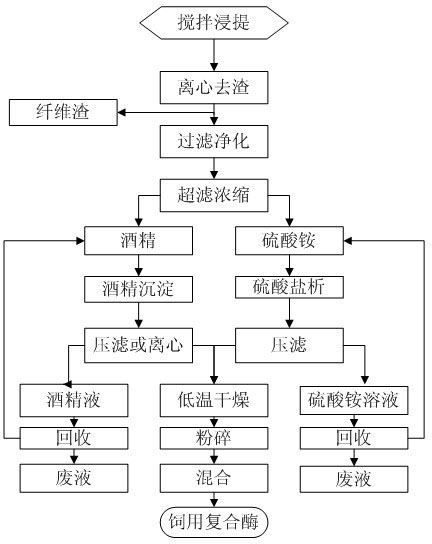

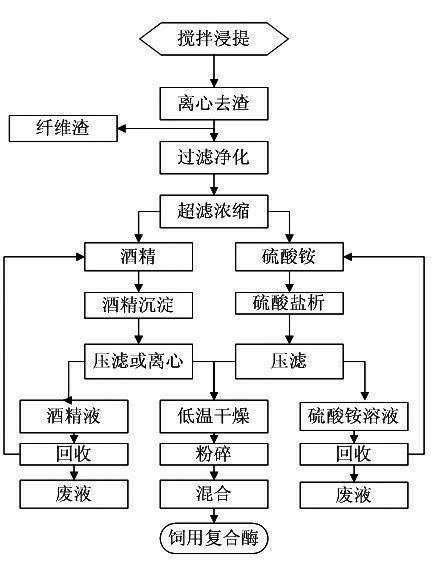

Image

Examples

Embodiment 1

[0049]Trichoderma strain 91-11, the full name is Trichoderma Koningii WJP-02 (Trichoderma Koningii WJP-02), the preservation number is CCTC NO: M2012028, and the breeding method is as follows:

[0050] First prepare the medium: use PDA as the medium to cultivate at 30°C for 4-5 days, then solid-state culture: use straw and bran as the substrate, fill 5g in a 250ml triangular flask, add 15ml of nutrient salt, and sterilize at 0.1MPa for 30min. Inoculate 1ml of the spore suspension (105-106 / ml) of the cellulose-producing strain, and culture at 30°C for 4 days.

[0051] Then take the preserved strain of Trichoderma reesei strain with higher cellulase-producing activity and culture it in solid state under the same conditions, measure the enzyme production ability, and select Trichoderma reesei A3 strain as the starting strain. Then, the spore suspension of the strain cultured on PDA medium for 4-5 days was pre-treated with NIG solution with a final concentration of 2 μg / ml, pH 6.0...

Embodiment 2

[0054] Preparation of enzyme preparation:

[0055] Main equipment: Extraction grains, centrifuges, ultrafilters, salting out tanks, storage tanks, centrifugal settlers, liquid pumps, vacuum dryers, pulverizers, mixers.

[0056] The Trichoderma 91-11 bacterial strain screened out in embodiment 1 carries out slant seed culture with PDA medium, the slant seed suspension that obtains is inoculated in the Erlenmeyer flask that takes stalk and bran as matrix to carry out solid-state culture, obtains enzyme koji ; Quantitative water in the extraction tank, the ratio of enzyme koji to water is 1:7; the pH of the extraction solution is 5.0-5.59, stirring intermittently at room temperature, and extracting for 1.5 hours. The extracted material liquid is centrifuged in batches with a three-legged centrifuge to separate the fiber residue, and the dilute enzyme liquid is put into the storage tank. The centrifuged dilute enzyme solution is pumped into the high level tank, and the liquid is ...

Embodiment 3

[0059] Preparation of enzyme preparation: the Trichoderma 91-11 bacterial strain screened out in embodiment 1 carries out slant seed culture with PDA medium, the slant seed suspension that obtains is inoculated in the Erlenmeyer flask that takes stalk and bran as matrix to carry out solid state. Cultivate to obtain enzyme koji; the quantitative water in the extraction tank, the ratio of enzyme koji to water is 1:7; the pH of the extract is 5.0-5.59, stir intermittently at room temperature, and extract for 1.5 hours. The extracted material liquid is centrifuged in batches with a three-legged centrifuge to separate the fiber residue, and the dilute enzyme liquid is put into the storage tank. The centrifuged dilute enzyme solution is pumped into the high level tank, and the liquid is passed through a tube filter to obtain purified enzyme solution. The purified enzyme solution is concentrated by ultrafiltration. The working temperature is normal temperature, pH 5.0-5.5, the ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com