Treatment method for improving alloy material strength, toughness, and anti-fatigue life

A technology of alloy material and processing method, which is applied in the processing field of improving the strength, toughness and fatigue life of alloy materials, and achieves the effect of high strength, toughness and fatigue resistance life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

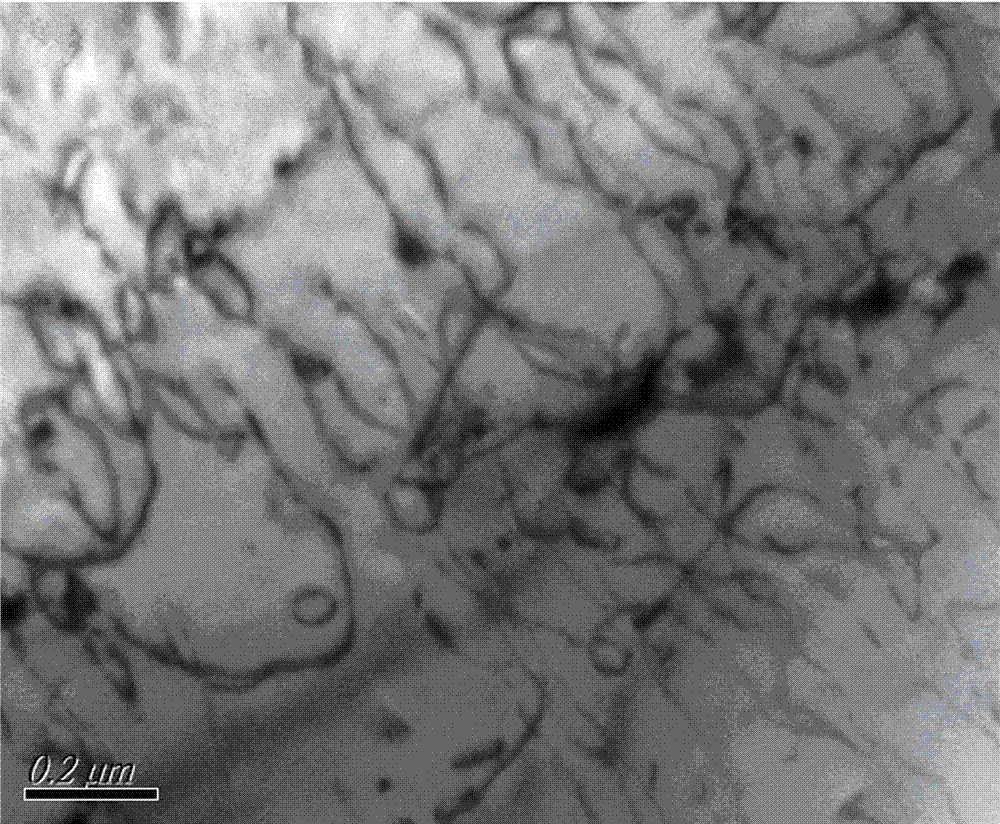

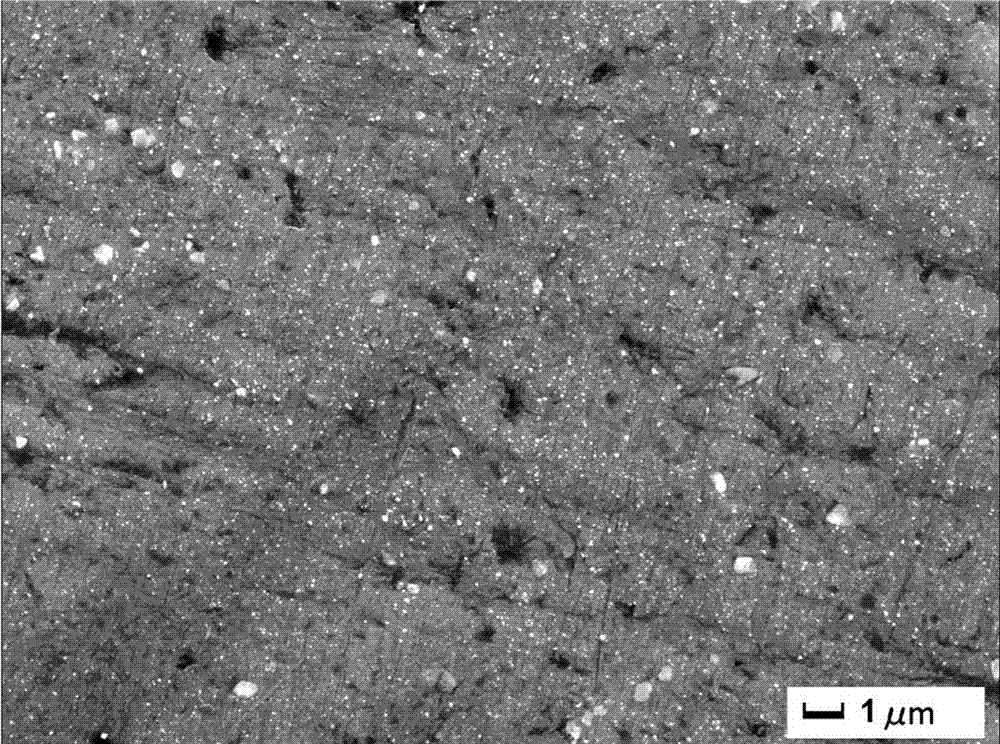

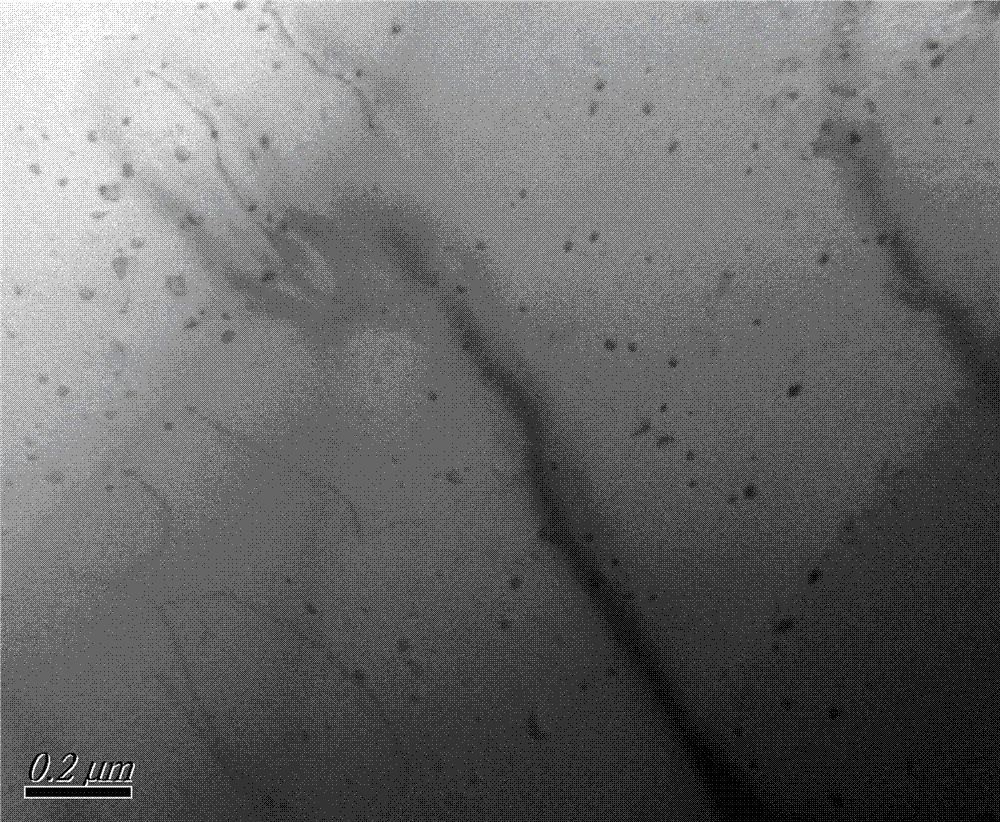

Image

Examples

Embodiment 1

[0035] The 7055 aluminum alloy bar is used as the sample for strengthening treatment. The weight percentage of each component of the aluminum alloy is Zn: 8%, Mg: 2.2%, Cu: 2.2%, Zr: 0.2%, Mn≤0.05%, Fe≤ 0.1%, Si≤0.15%, Ti≤0.06%, Cr≤0.04%, and the balance is Al.

[0036] Solution treatment; the aluminum alloy bar is placed in a heat treatment furnace at 475 o C for 2 hours, then take the aluminum alloy rod out of the heat treatment furnace and allow it to return to room temperature naturally.

[0037] Aging treatment; place the aluminum alloy bar after solid solution treatment in a heat treatment furnace, at 120 o C at a temperature of 24h, and then the aluminum alloy rod is taken out of the heat treatment furnace and allowed to return to room temperature naturally.

[0038] Cryogenic treatment; place the aging-treated aluminum alloy rods in a cryogenic box, start from room temperature, and cool at a rate of 1 o C / min, cooling the aluminum alloy bar to -196 o C for 24 hours...

Embodiment 2

[0043] 6 high-silicon (Si) aluminum alloy rods were used as samples for strengthening treatment. The weight percentages of the components of the aluminum alloy were Si: 20%, Fe: 2.0%, Sr: 0.12%, and the balance was Al.

[0044] Solution treatment; the aluminum alloy bar is placed in a heat treatment furnace at 540 o C at a temperature of 4 h, and then the aluminum alloy rod is taken out of the heat treatment furnace, and allowed to return to room temperature naturally.

[0045] Aging treatment; place the aluminum alloy bar after solid solution treatment in a heat treatment furnace at 150 o C for 12 hours, then take the aluminum alloy rod out of the heat treatment furnace and allow it to return to room temperature naturally.

[0046] Cryogenic treatment; place the aging-treated aluminum alloy rods in a cryogenic box, start from room temperature, and cool at a rate of 5 o C / min, cooling the aluminum alloy bar to -196 o C for 12 hours at ultra-low temperature, and then the alu...

Embodiment 3

[0051] Use ZK61 magnesium alloy rods as samples for strengthening treatment. The weight percentage of the magnesium alloy components is Al≤0.05%, Zn: 5.0~6.0%, Mn≤0.1%, Zr: 0.3~0.9%, Si≤0.05 %, Fe≤0.05%, Cu≤0.05%, Ni≤0.005%, others: 0.31%, and the balance is Mg.

[0052] Solution treatment; the magnesium alloy bar is placed in a heat treatment furnace at 400 o C at a temperature of 3 h, and then the magnesium alloy rod is taken out from the heat treatment furnace, and allowed to return to room temperature naturally.

[0053] Aging treatment; the magnesium alloy bar after solid solution treatment is placed in a heat treatment furnace, at 100 o C for 12 hours, and then the magnesium alloy rod was taken out of the heat treatment furnace to allow it to return to room temperature naturally.

[0054] Cryogenic treatment: place the aging-treated magnesium alloy rods in a cryogenic box, start from room temperature, and cool at a rate of 1 o C / min, cooling the magnesium alloy bar to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com