Patents

Literature

52results about How to "Meet industrial needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method for improving alloy material strength, toughness, and anti-fatigue life

The invention discloses a treatment method for improving alloy material strength, toughness, and anti-fatigue life. The method comprises solid solution and aging treatments. The method also comprises cryogenic cooling, tempering, and laser impact treatments. The cryogenic cooling treatment comprises the steps that: from room temperature, the alloy is cooled to -196 DEG C with a cooling speed of 1-10 DEG C / min, and the temperature is maintained for 10-40h. According to the tempering treatment, the alloy is heated to 100-150 DEG C, and the temperature is maintained for 2-3h. Laser impact parameters comprise laser impact spot diameter of 1-10mm, pulse energy of 1-10J, laser wavelength of 900-1200nm, repetition rate of 0.1-1HZ, pulse width of 15-40ns, and output laser pulse energy fluctuation no higher than + / -5%. The alloy material is preferably aluminum, magnesium, and titanium alloy. With the method, alloy material tissue can be compact, residue stress is low, and refined grains exist. With the method, yield strength, tensile strength, impact toughness, and anti-fatigue life of the alloy material can be greatly and simultaneously improved.

Owner:CHANGZHOU RUNYUAN WARP KNITTING ENG TECH RES CENT

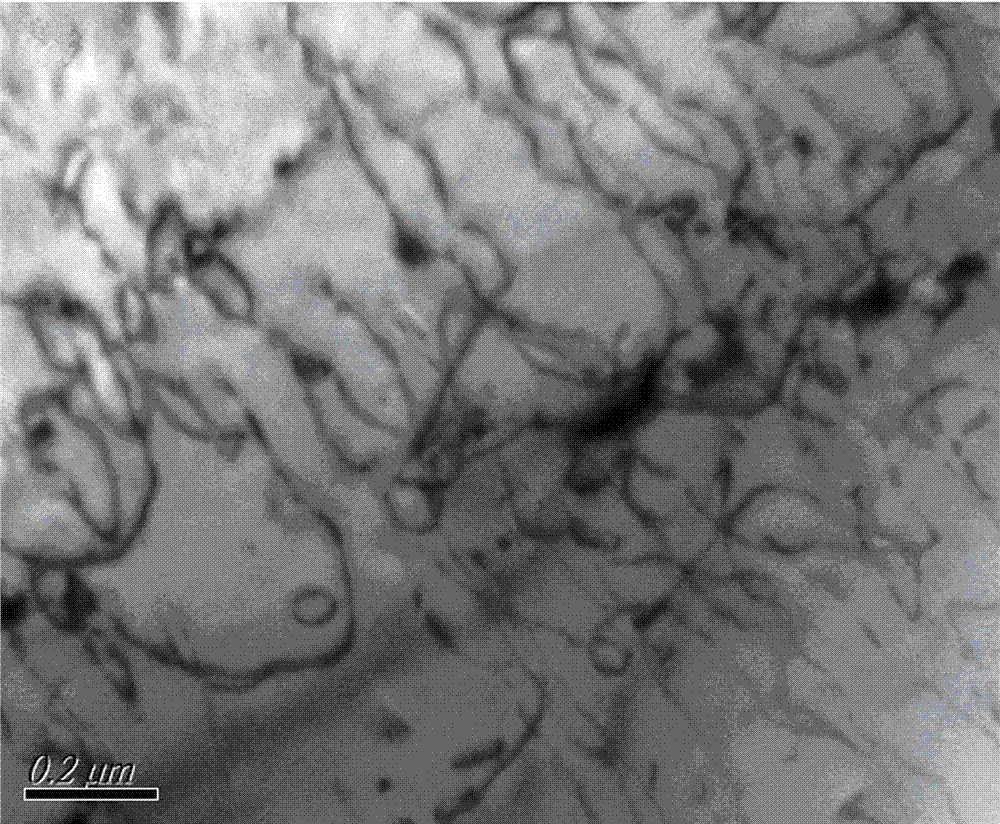

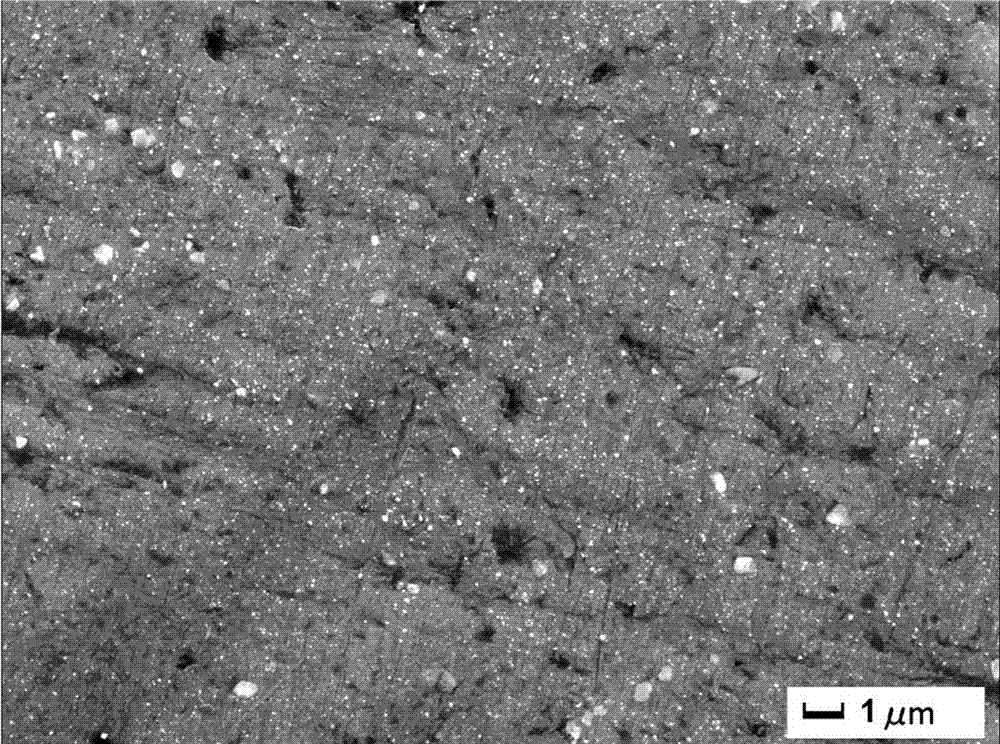

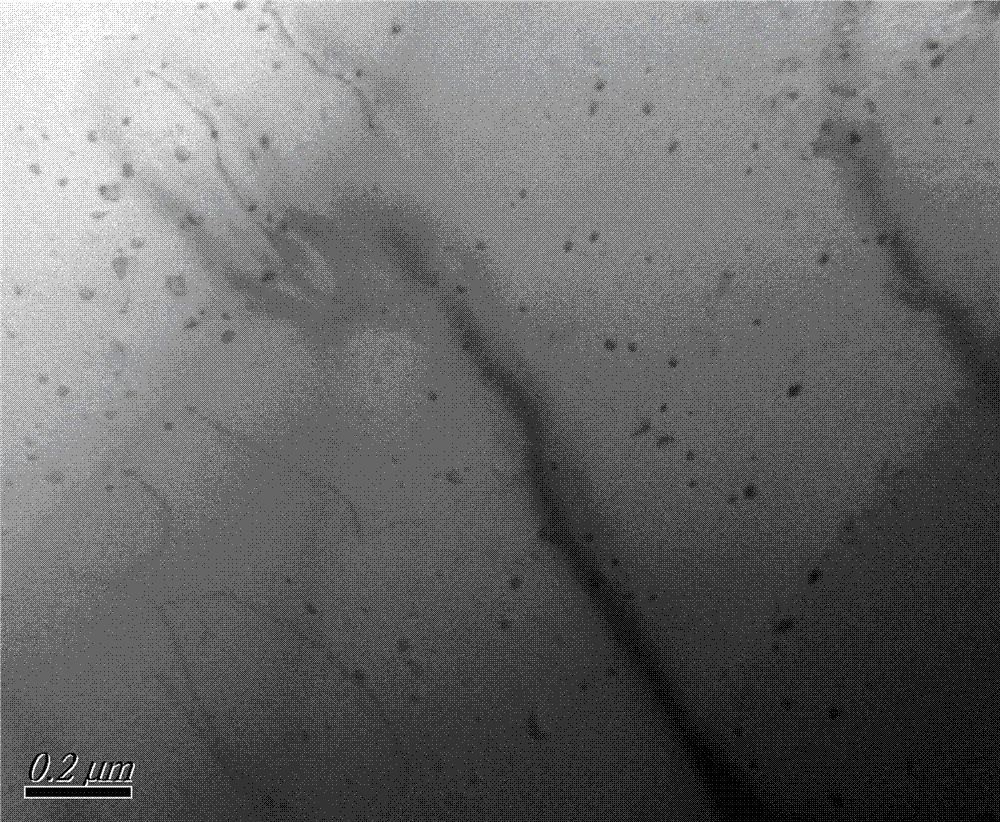

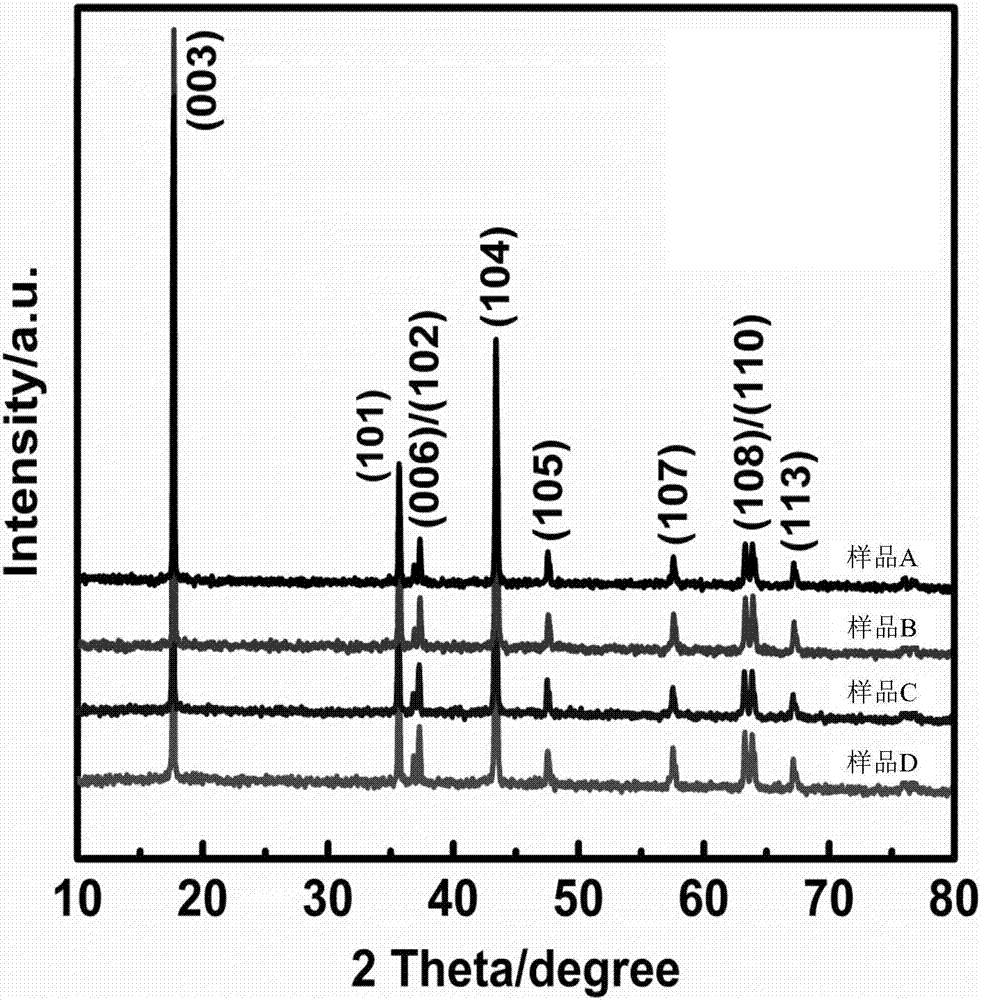

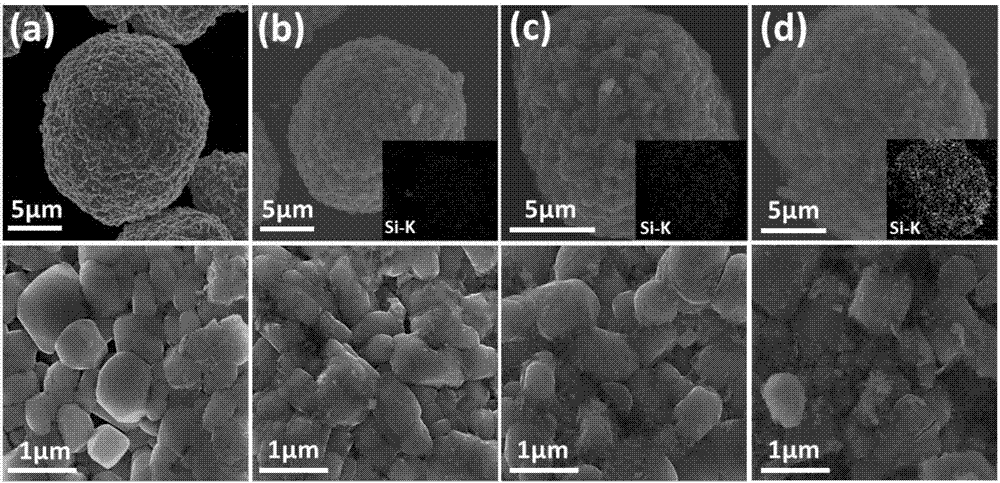

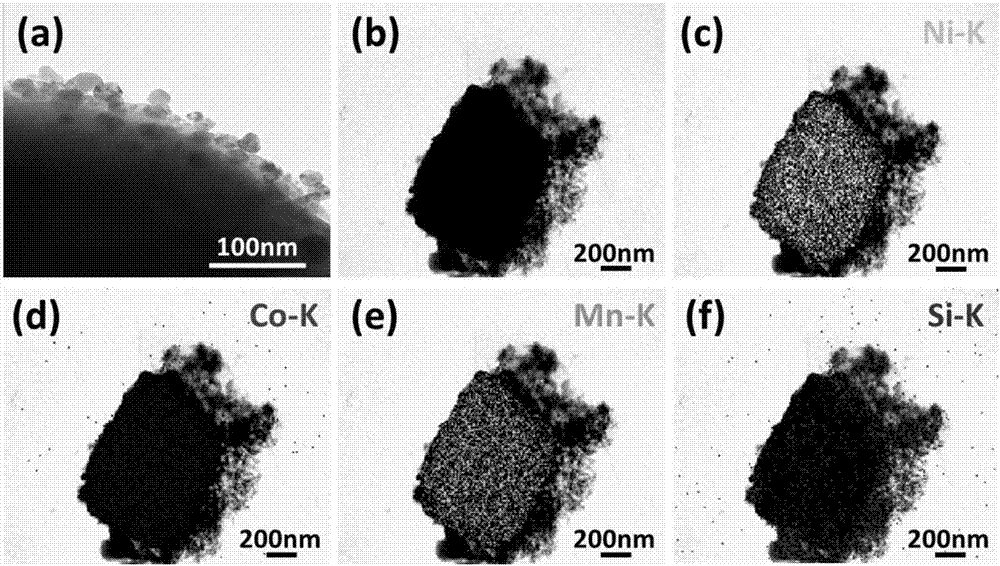

Preparation method of coated lithium ion battery ternary positive electrode material

InactiveCN107240690AMeet industrial needsPromote circulationMaterial nanotechnologyCell electrodesDispersed mediaSodium-ion battery

The invention provides a preparation method of a coated lithium ion battery ternary positive electrode material. The coated lithium ion battery ternary positive electrode material is obtained by dispersing a nanometer oxide in a dispersing medium with ultrasound, mixing with a ternary positive electrode LiNi<x>Co<y>Mn<z>O2 and performing stirring, drying and sintering. The nanometer oxide coated ternary positive electrode material prepared by employing a physical coating method is simple and practical in preparation process and low in cost, production on a large scale can be achieved, and the industrial demand of the lithium ion battery ternary positive electrode material is satisfied; and moreover, the coated material has favorable electrochemical performance such as cycle property, rate performance and capacity and favorable thermal stability, and the performance demand of a lithium ion battery can be satisfied.

Owner:GUANGDONG UNIV OF TECH

Rare earth oxygen-free copper based alloy and production process thereof

The invention discloses a rare earth oxygen-free copper based alloy and a production process thereof. The rare earth oxygen-free copper based alloy is prepared by adding rare earth elements RE, Mn and lithium into copper, wherein the rare earth element RE is at least one of La and Ce; the total addition amount of RE is 0.04-0.08w%; the addition amount of Mn is 0.01-0.02w%; as lithium is an active metal element, the lithium added into the copper is added as a Li-Cu intermediate alloy; and the addition amount of the lithium is 0.05-0.15w%. The production process comprises production steps of washing electrolytic copper, shearing, melting, keeping the temperature and stirring, wherein an additive is added when the temperature of a molten copper liquid is 1260-1350 DEG C in the steps of melting and temperature keeping; the molten copper liquid is covered with a layer of ash wood and is mechanically stirred by using a green tree branch or electromagnetically stirred by using an electromagnetic bar, thereby uniformly mixing the molten liquid; and the mixing and stirring time is 20-30 minutes. The rare earth oxygen-free copper based alloy disclosed by the invention has the characteristics of high antioxidation, high strength and high conductivity at a low temperature.

Owner:黄学志

Method for rapidly breeding hairy roots of vietnamese sophora roots

InactiveCN105494090ASynthetic ability is strong and stableFast growthHorticulture methodsPlant tissue cultureNutrient solutionGenetic stability

The invention provides a method for rapidly breeding hairy roots of vietnamese sophora roots. The method comprises the following steps: (1) seeds of Sophora tonkinensis are disinfected and inoculated to a 1 / 2 MS medium for germination, and aseptic seedlings of Sophora tonkinensis are obtained; (2) R1601 Rhizobium rhizogenes is used for inducing rooting of aseptic cotyledons of Sophora tonkinensis; (3) division of hairy roots obtained in the step (2) is carried out, and the divided hairy roots are placed in a nutrient solution for rapid breeding and cultivation, and the breeding multiple reaches 39-55 times. The hairy roots of vietnamese sophora roots have the characteristics of fast growth speed, good genetic stability, and good and stable synthesis capability; partial metabolites are released to the medium, and the hairy roots can be used as alternative resources of industrial vietnamese sophora roots in large scale production.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

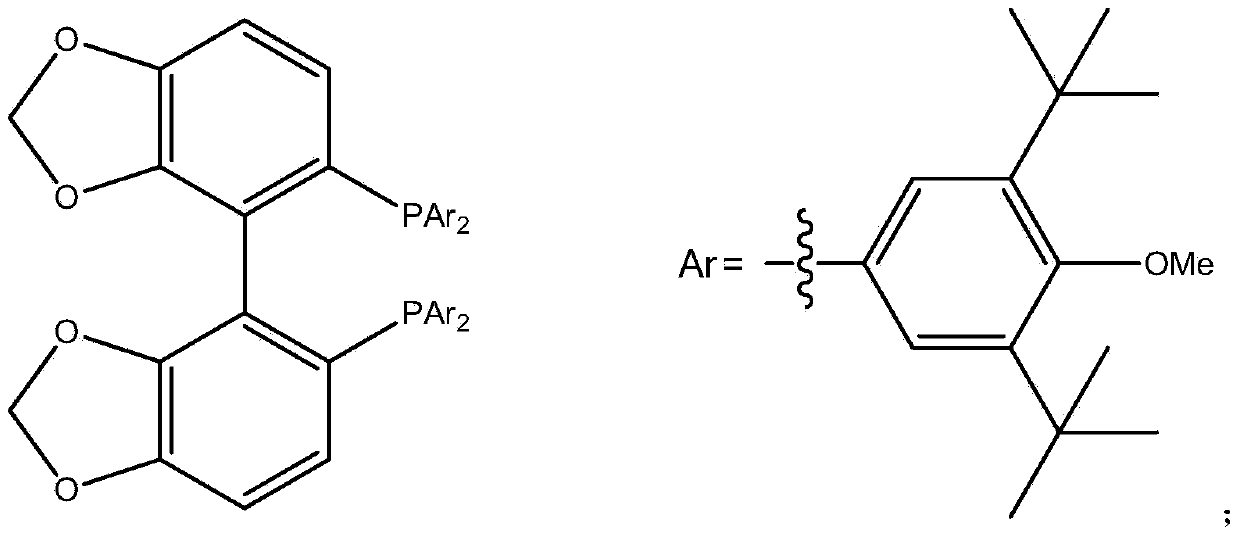

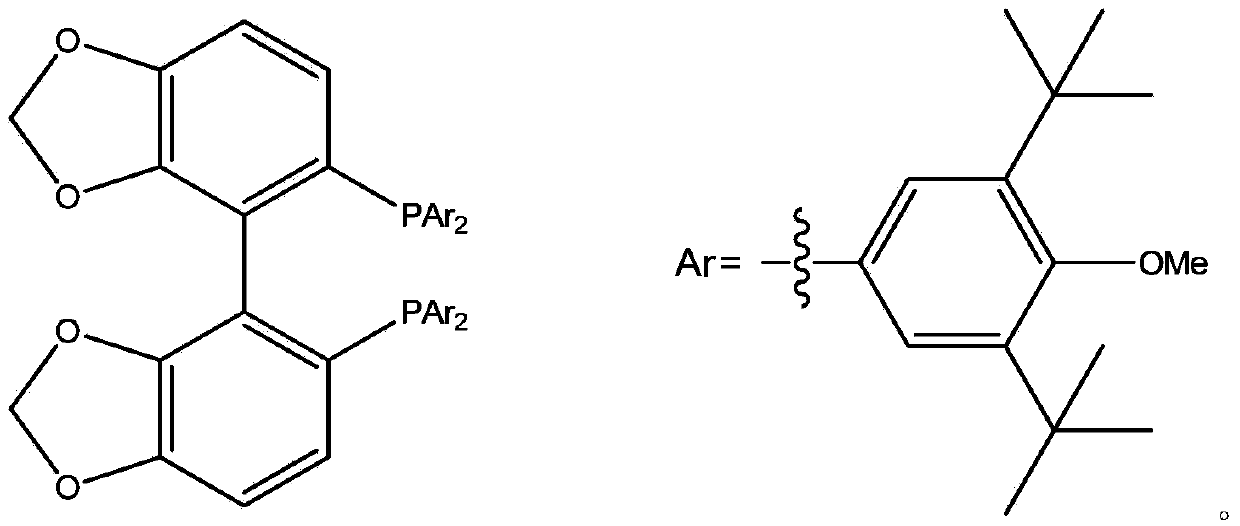

Method for purifying electronic grade octamethylcyclotetrasiloxane

ActiveCN103788124AMeet industrial needsSimple methodSilicon organic compoundsDistillationPhysical chemistry

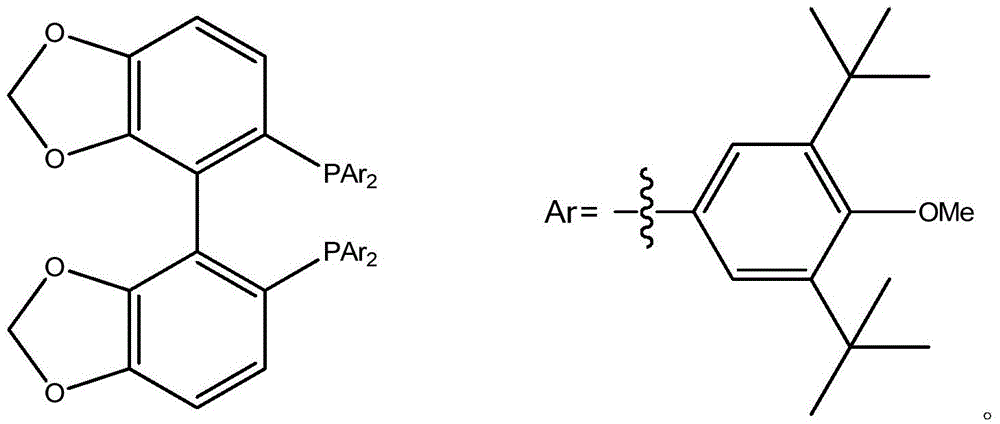

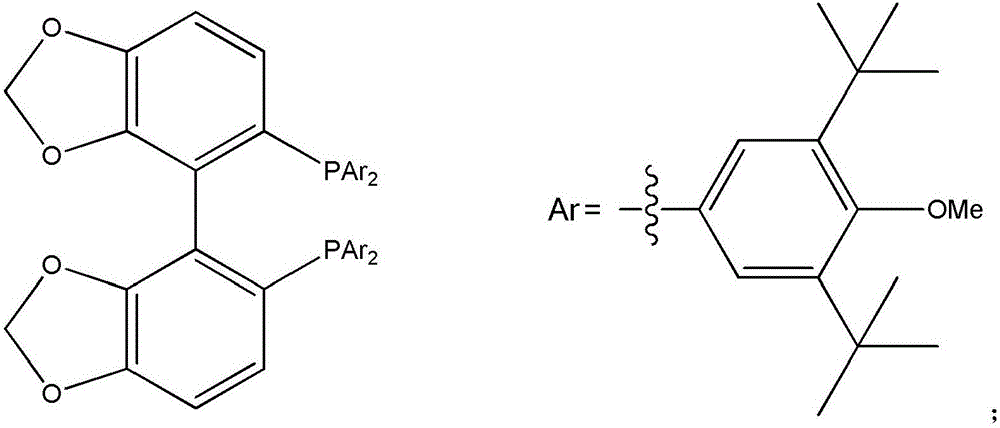

The invention relates to a method for purifying electronic grade octamethylcyclotetrasiloxane in a rectifying manner. The method comprises the following steps: (1) adding 99% of the octamethylcyclotetrasiloxane into a rectifying tower, and removing little residual hexamethylcyclotrisiloxane (D3 for short) from the top of the tower at 90-96 DEG C under the pressure of 0.02-0.03MPa; (2) enabling the octamethylcyclotetrasiloxane without the D3 to flow out of the tower and enter a reaction kettle of a de-heavy rectifying tower, adding 0.01%-0.1% by weight of a special efficient metal complex ligand, heating to 90-100 DEG C, reacting for 1-10 hours, and performing reduced pressure distillation. The de-heavy rectifying tower is arranged in a superclean room, the reduced pressure operation is adopted in the tower, the pressure of the tower is 0.005-0.01Mpa, the temperature of the top of the tower is 100-110 DEG C, more than 99.99% by weight of the octamethylcyclotetrasiloxane is received, and residues at the bottom of the tower are high-boiling-point impurities; the reaction kettle and the inner wall of the de-heavy rectifying tower and a pipeline receiving container are all wrapped with polytetrafluoroethylene, and fillers of the de-heavy rectifying tower are wrapped with the polytetrafluoroethylene.

Owner:SHANGHAI AIMO JINSHAN PHARM CO LTD

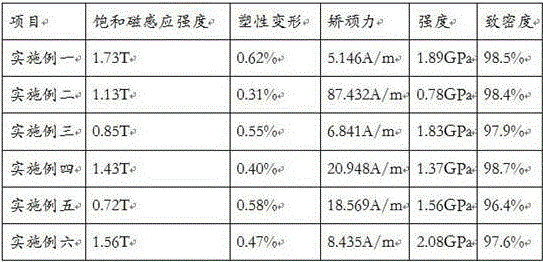

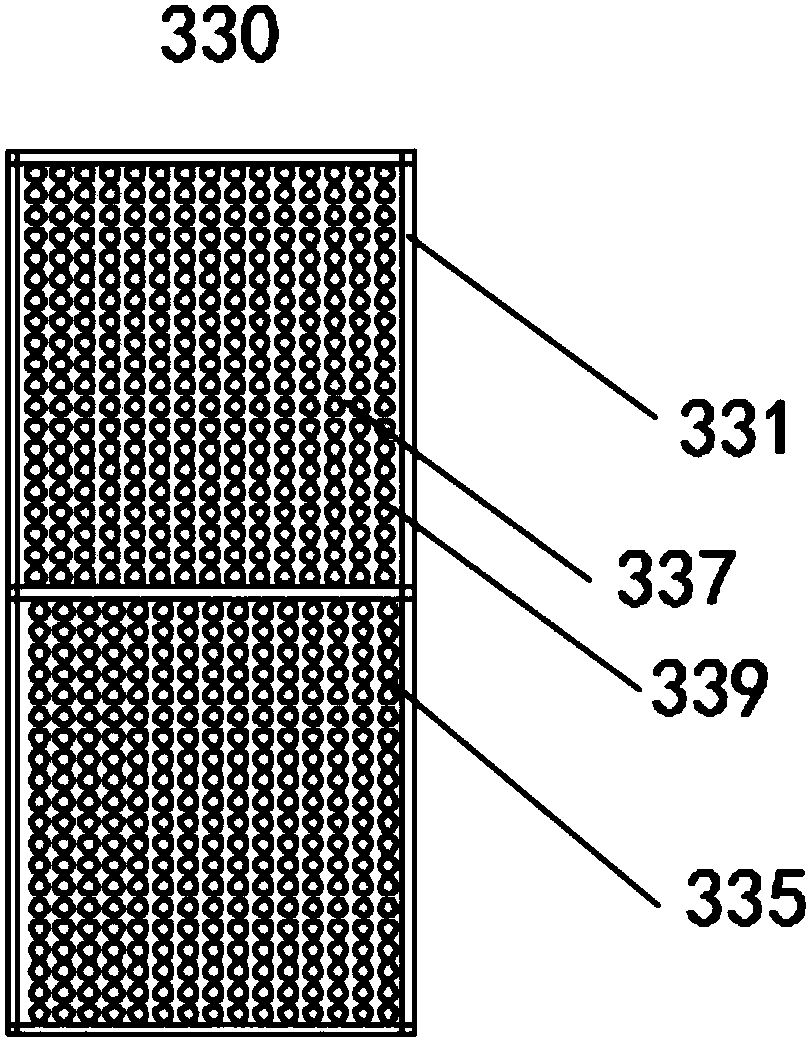

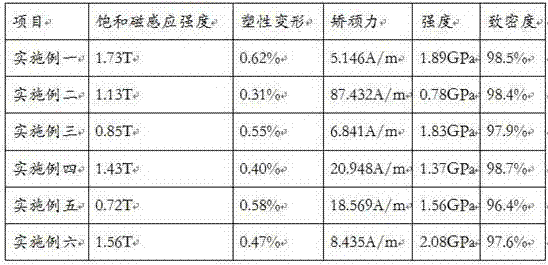

Fe-based amorphous alloy composite

ActiveCN106282848AImprove plasticityFacilitate forkingTransportation and packagingMetal-working apparatusRare-earth elementPowder metallurgy

The invention discloses a Fe-based amorphous alloy composite. The composition of the Fe-based amorphous alloy composite is FeaAlbGacY(3-d)VdInxCoyBzSir, wherein a, b, c, d, x, y, z, and r represent atomic percent, a is larger than or equal to 70 and smaller than or equal to 76, b is larger than or equal to 3 and smaller than or equal to 5, c is 0 or 2, d is larger than or equal to 0 and smaller than or equal to 3, x is larger than or equal to 0 and smaller than or equal to 1.86, Co is larger than or equal to 8 and smaller than or equal to 10, z is 4 or 8, and r is larger than or equal to 0 and smaller than or equal to 3. The Fe-based amorphous alloy composite has excellent high plasticity and soft magnetic properties and has the saturation induction density Bs up to 1.73T, the bulk amorphous alloy composite prepared with a powder metallurgy method has the compactness up to 98.7% and strength up to 2.08 GPa, has good mechanical properties and can meet the industrial requirement, meanwhile, the Fe-based amorphous alloy composite contains no expensive rare earth elements, the demand for the only more expensive indium is very low, so that the production cost is not high, the process is not complex, and commercial production is easy to implement.

Owner:南通巨升非晶科技股份有限公司

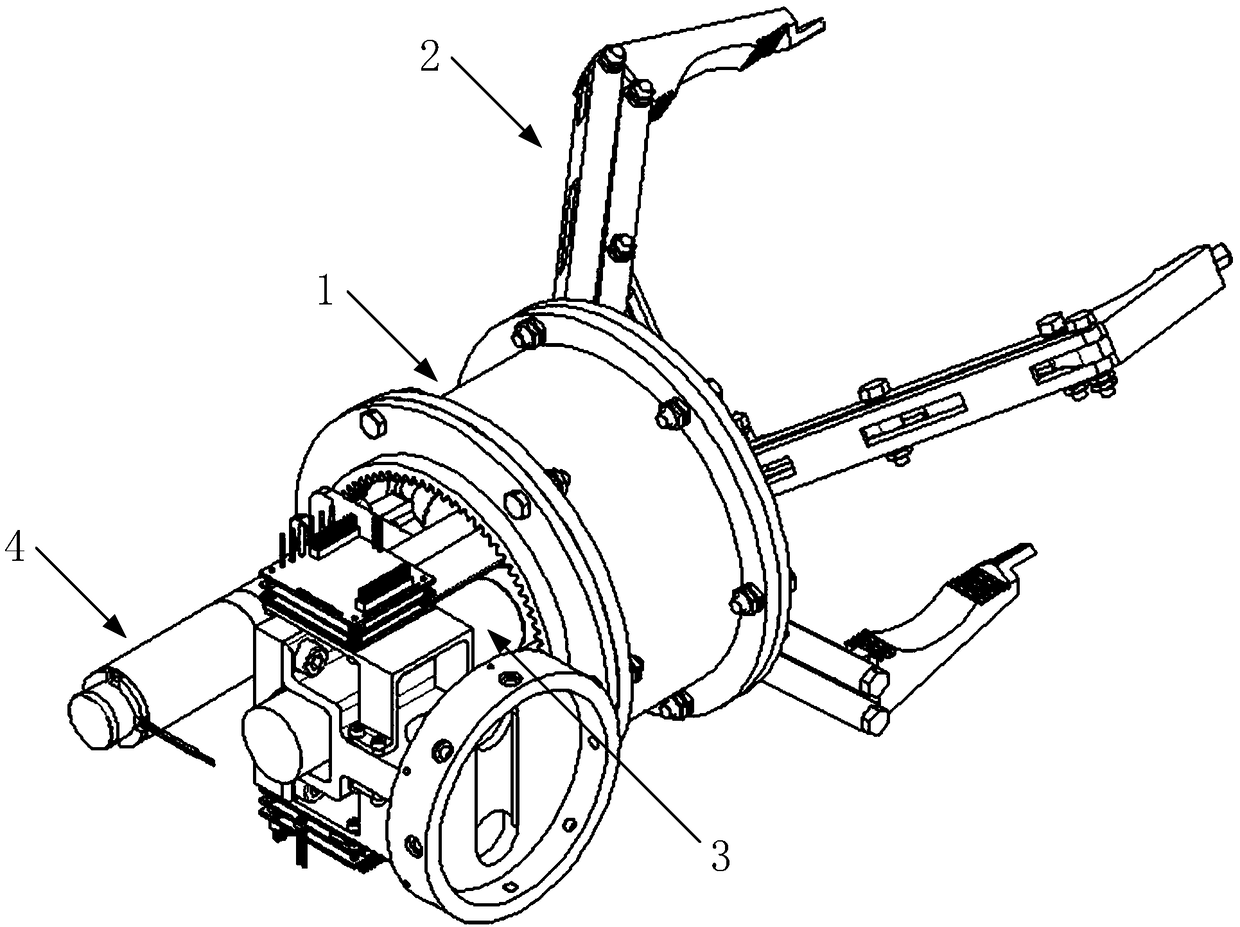

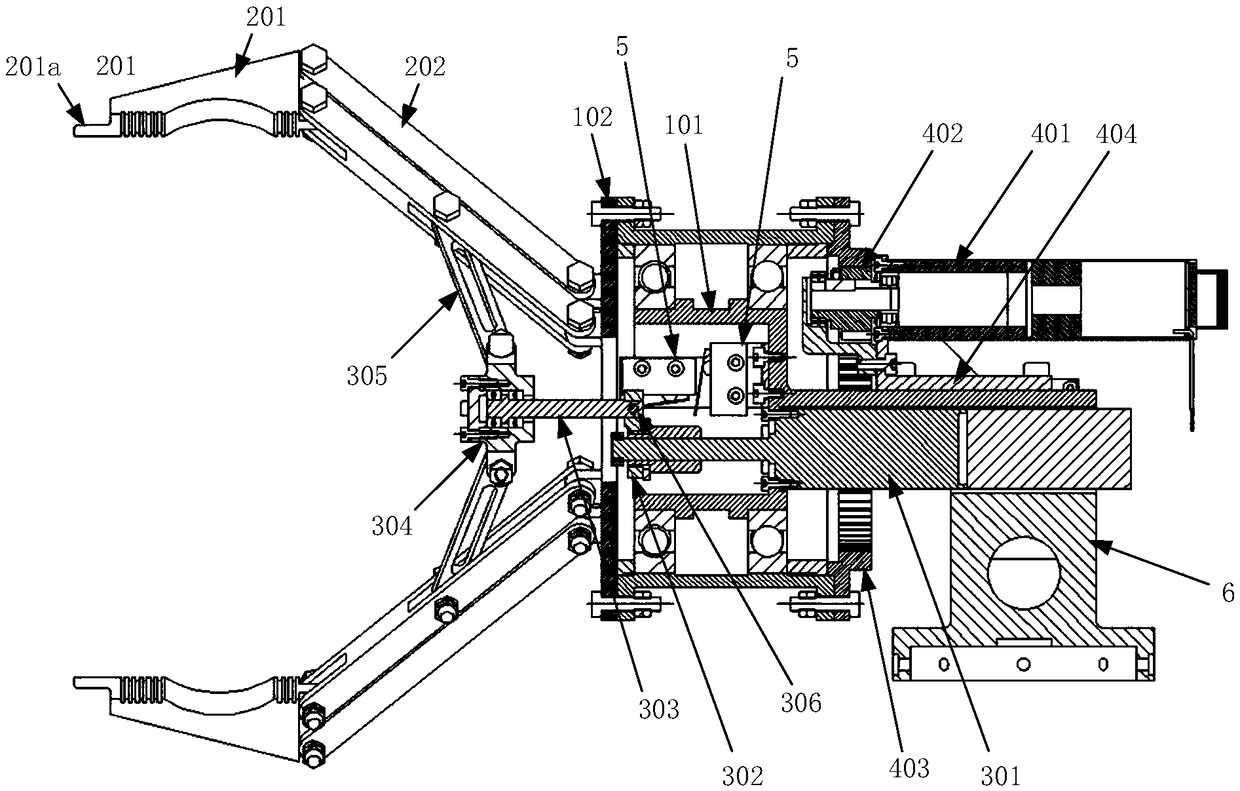

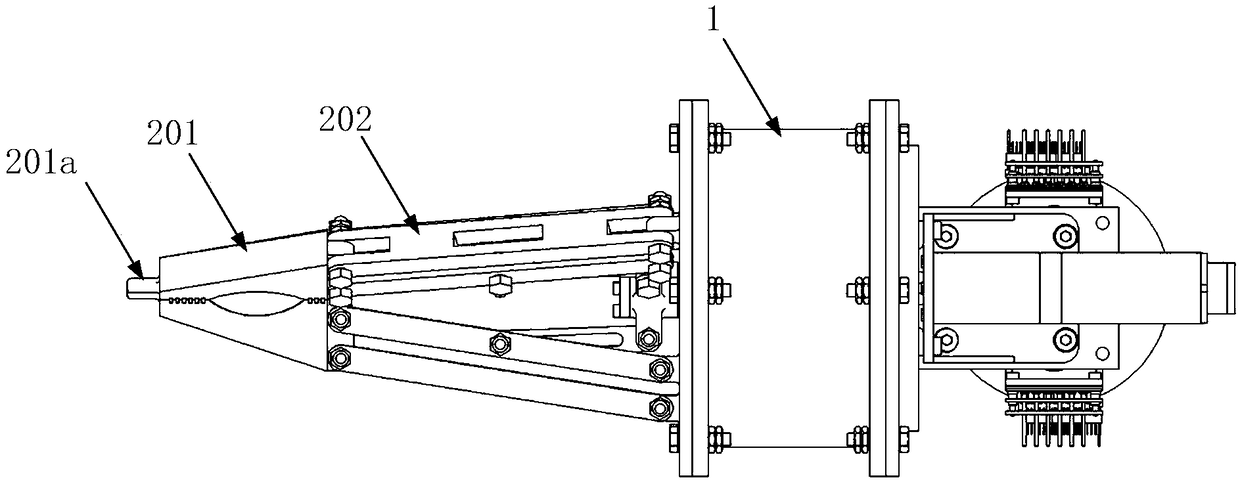

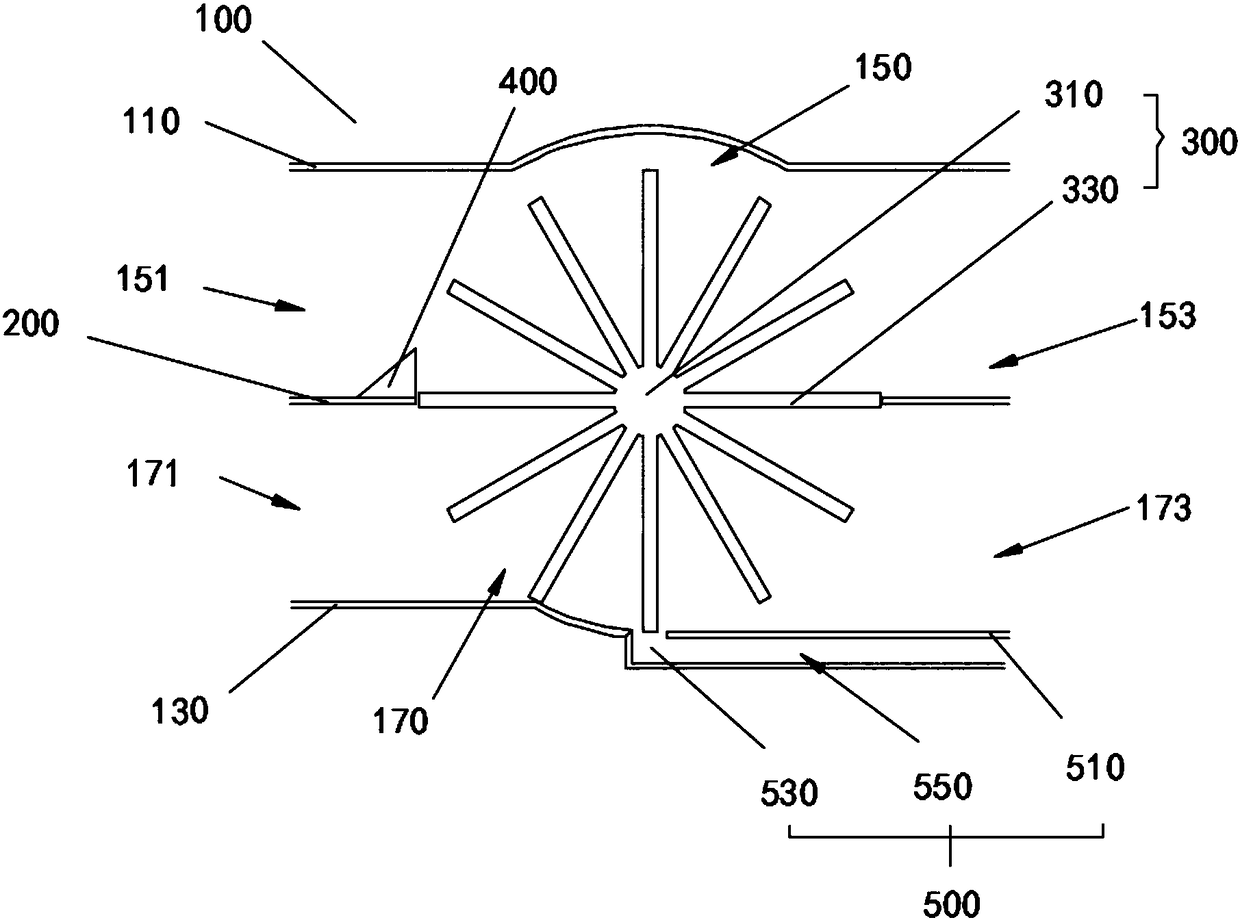

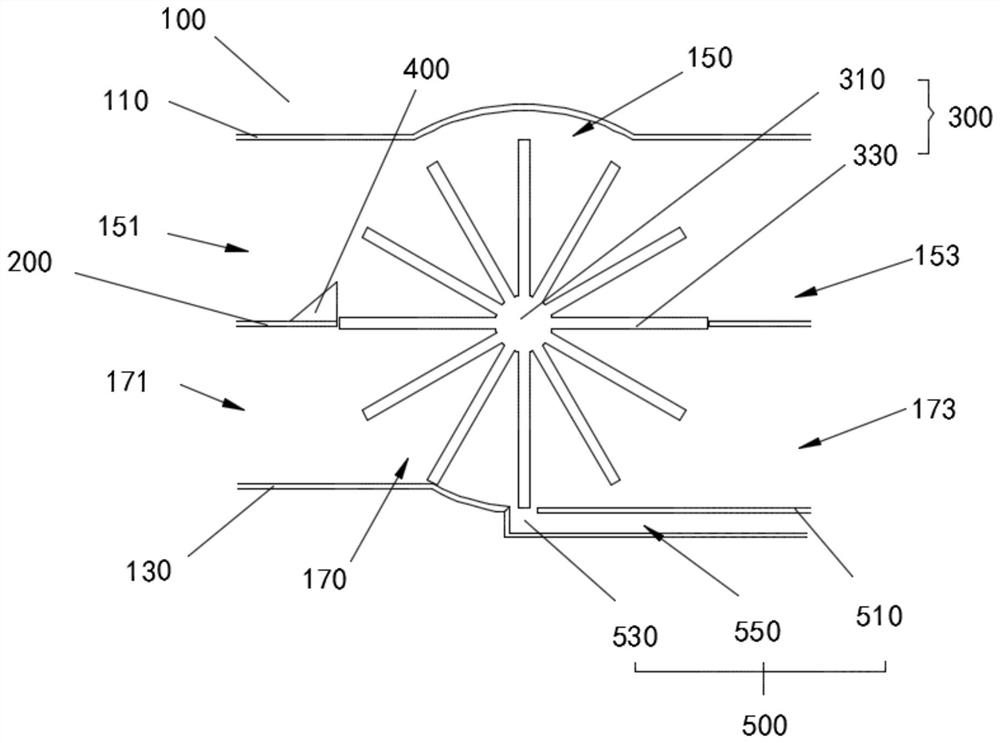

Continuous rotation multifunctional three-finger mechanical paw

ActiveCN108656146AImplement the rotation functionRealize the tightening functionGripping headsControl systemEngineering

The invention discloses a continuous rotation multifunctional three-finger mechanical paw. A physical mechanical structure comprises a wrist part and a paw part. On the basis of the physical mechanical structure, a control system and a sensing system of the three-finger mechanical paw are constructed. The wrist part comprises a rotation freedom degree and is used for rotation of the three-finger paw. The paw part comprises an opening and closing freedom degree and is used for opening and closing of the three-finger paw. The control system of the three-finger mechanical paw comprises two motordrivers. The sensing system is composed of two touch switches, and the paw opening and closing extreme position is detected. Through the finger tip part mechanical structure design, the function similar to the function that an inner hexagon wrench screws an inner hexagon screw can be achieved. The continuous rotation multifunctional three-finger mechanical paw has the beneficial effects that the grabbing, operating and continuous rotating functions are combined, and the operation functions of inner hexagon screw and outer hexagon nut screwing can be achieved.

Owner:BEIHANG UNIV +1

Method for preparing intermetallic compound powder cored filament material for electric arc spraying

The preparation process of intermetallic compound filament with powder core for arc spraying includes the following steps: mixing aluminum powder of granularity 38-44 micron and purity not lower than 99.5 % and iron (nickel ) powder of granularity 53-61 micron and purity not lower than 99.5 % in the atom ratio of 1 to 1; pressing the mixture in a hydraulic press into blank and painting the surface with one thin graphite layer; self-spreading reaction in a vacuum combustor to obtain loose intermetallic compound block; crushing, grinding, sieving to obtain 200-325 mesh granularity powder material and drying; and making Fe (Ni)-Al compound filament with powder core. The present invention has good spraying performance, good coating layer performance, high performance / cost ratio, wide use temperature range, simple technological process and low power consumption.

Owner:SHANDONG UNIV OF SCI & TECH

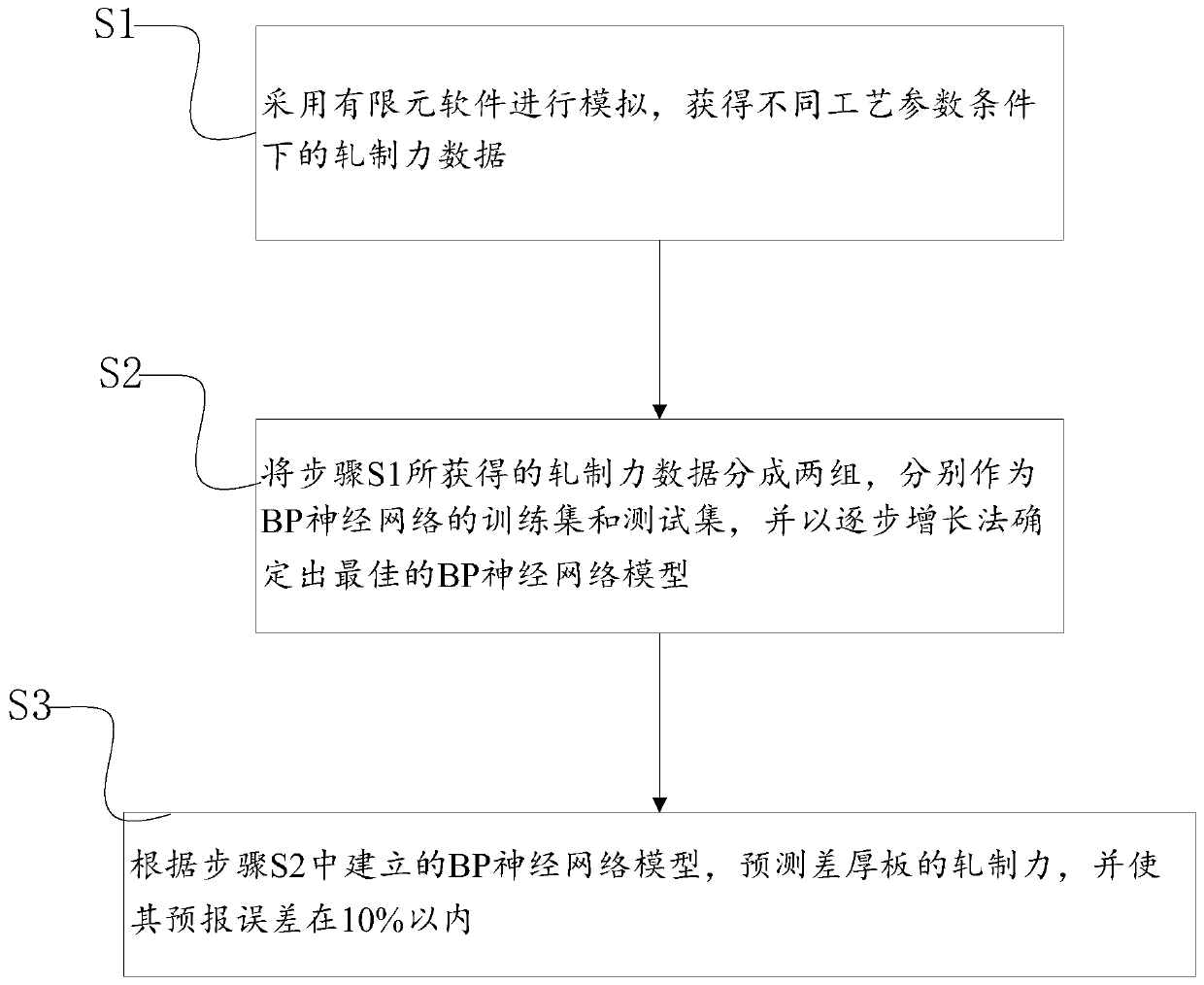

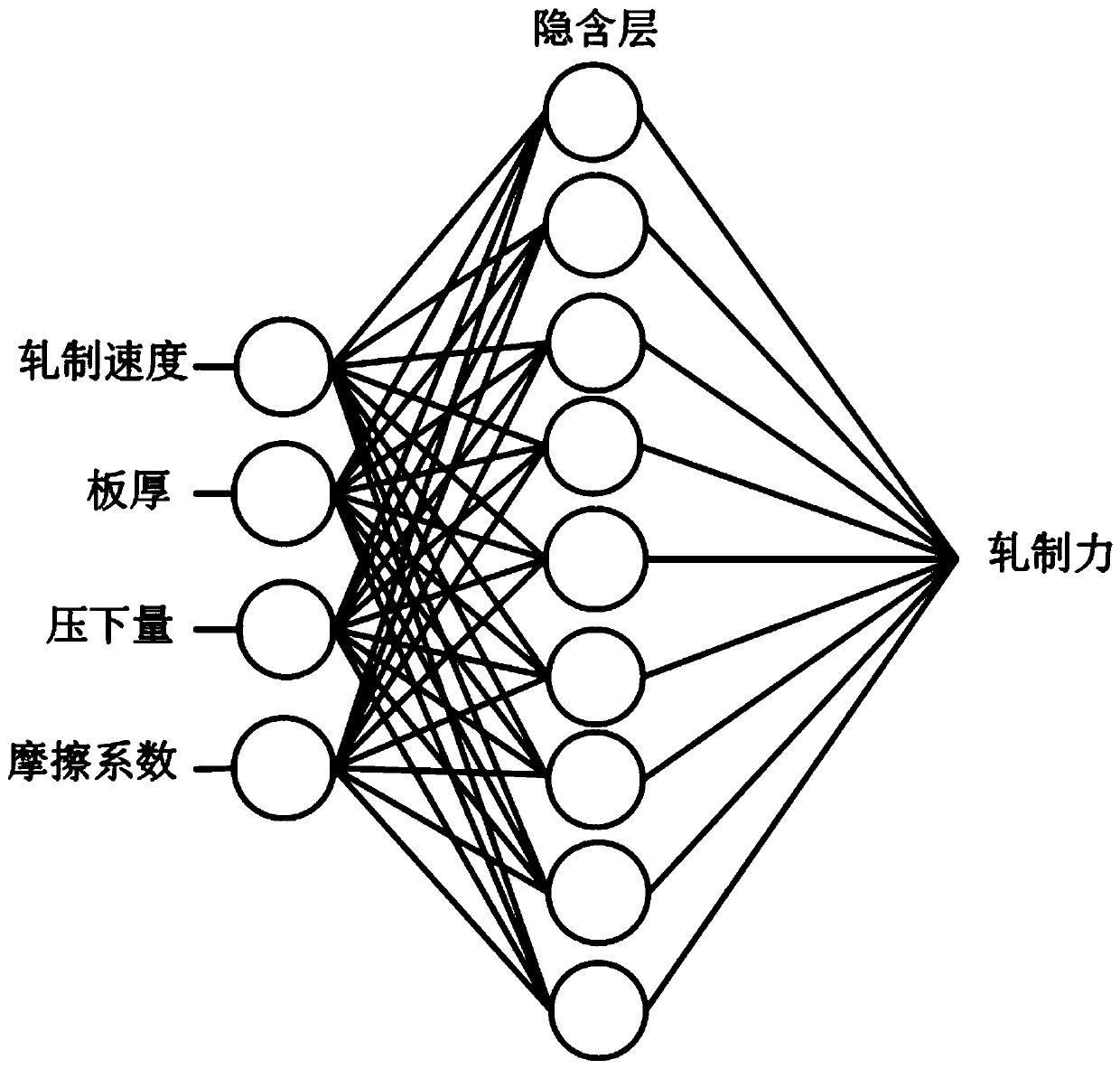

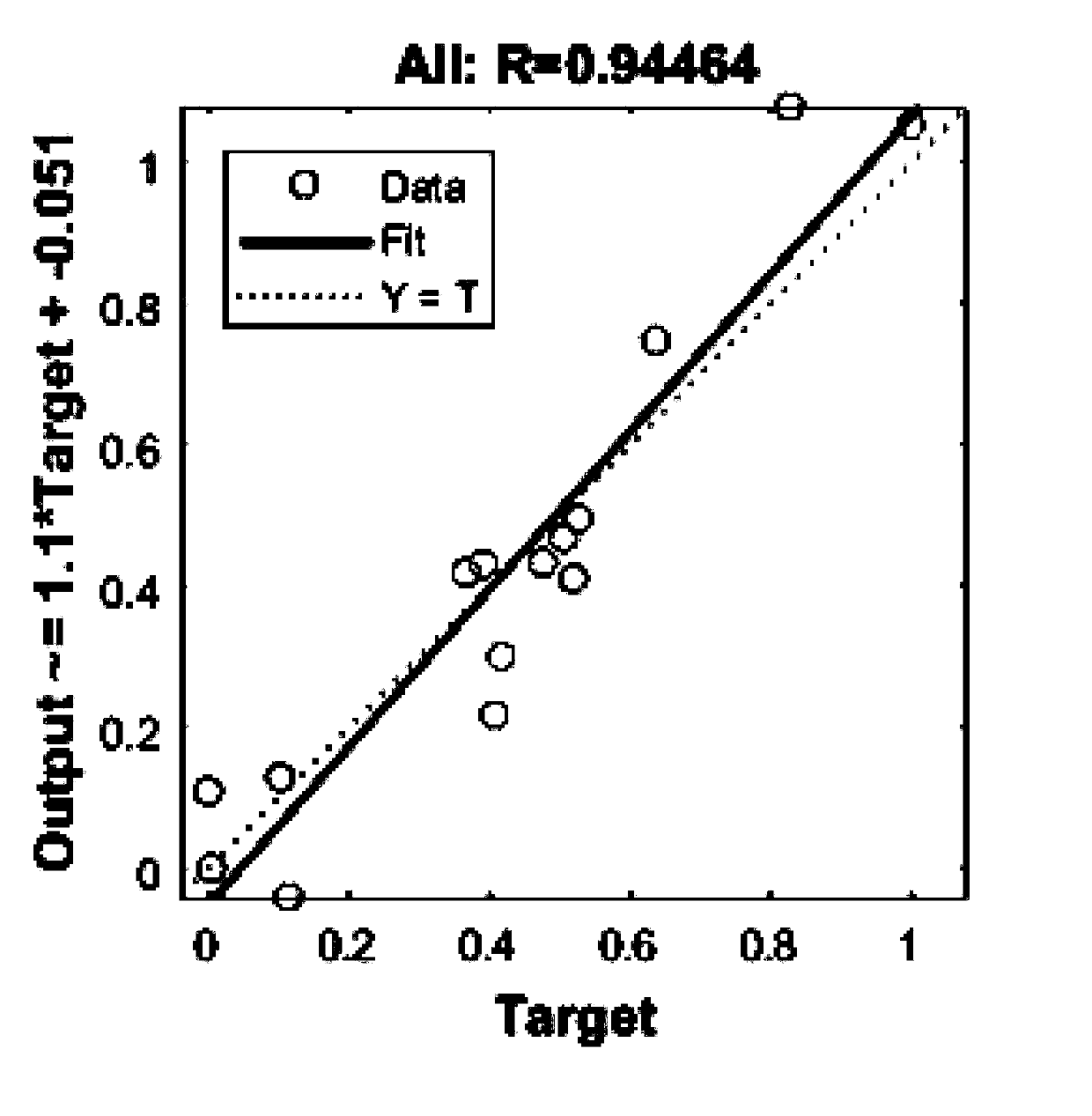

BP neural network-based prediction method for rolling force of different-thickness plate

PendingCN111291513AAccurate predictionSmall error fluctuationGeometric CADDesign optimisation/simulationAlgorithmSimulation

The embodiment of the invention discloses a method for predicting the rolling force of a different-thickness plate based on a BP neural network. The prediction method comprises the steps of adopting afinite element software for simulation; rolling force data under different technological parameter conditions are obtained; dividing the obtained rolling force data into two groups; taking the two groups respectively as a training set and a test set of a BP neural network; and determining an optimal BP neural network model by a gradual growth method. According to the BP neural network model, therolling force of the different-thickness plate is predicted, and the prediction error of the rolling force is within 10%.

Owner:SUZHOU UNIV

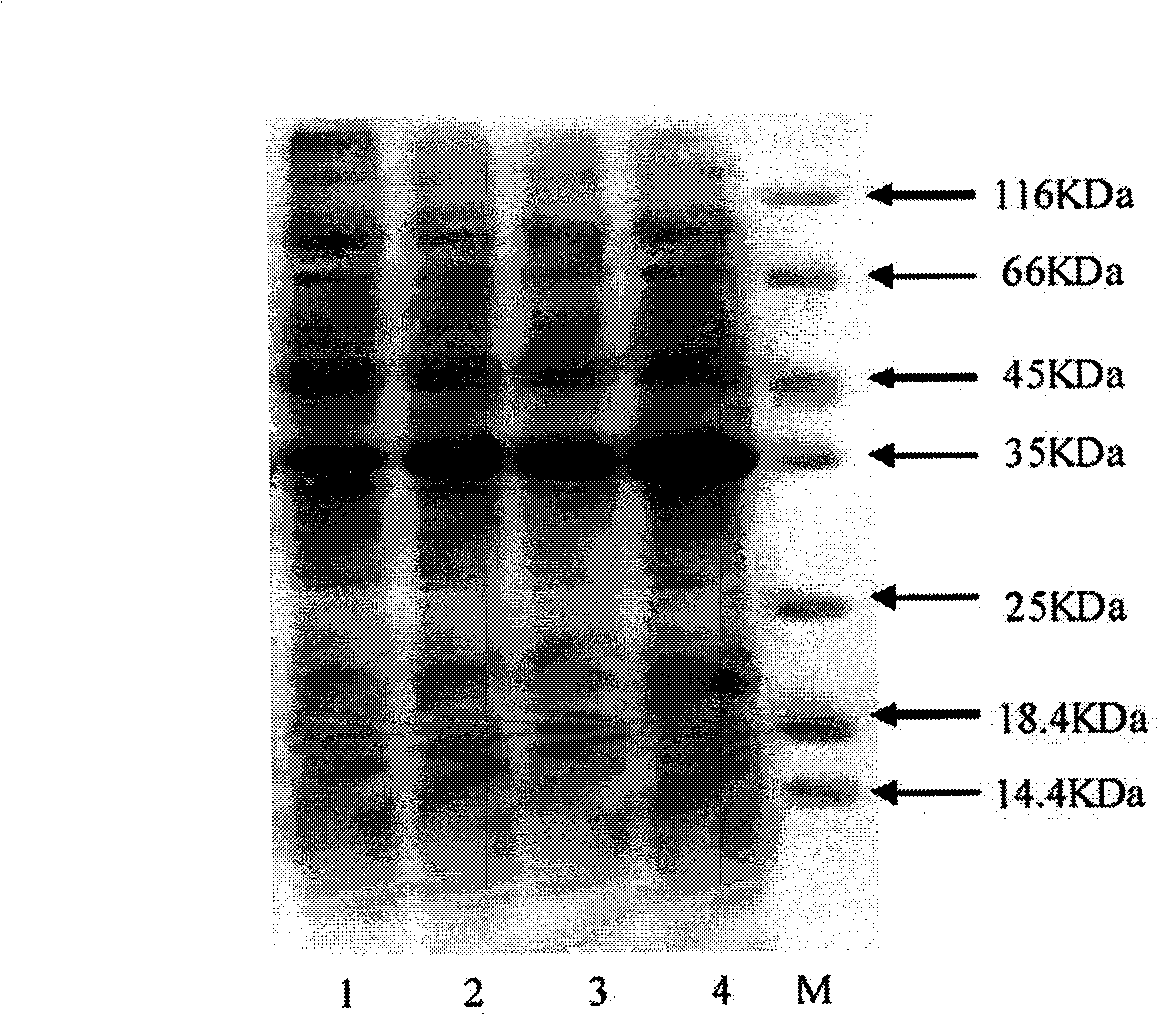

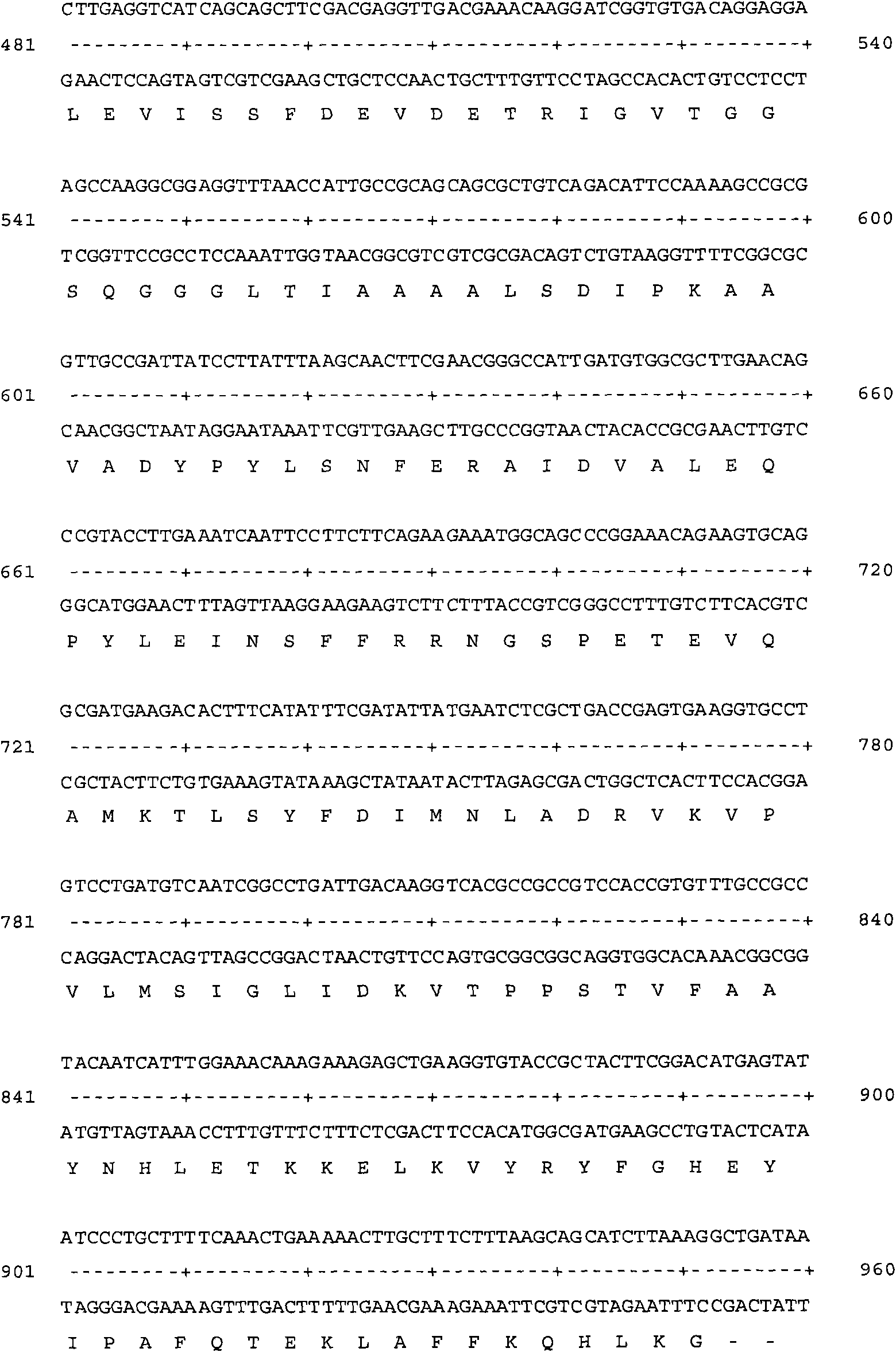

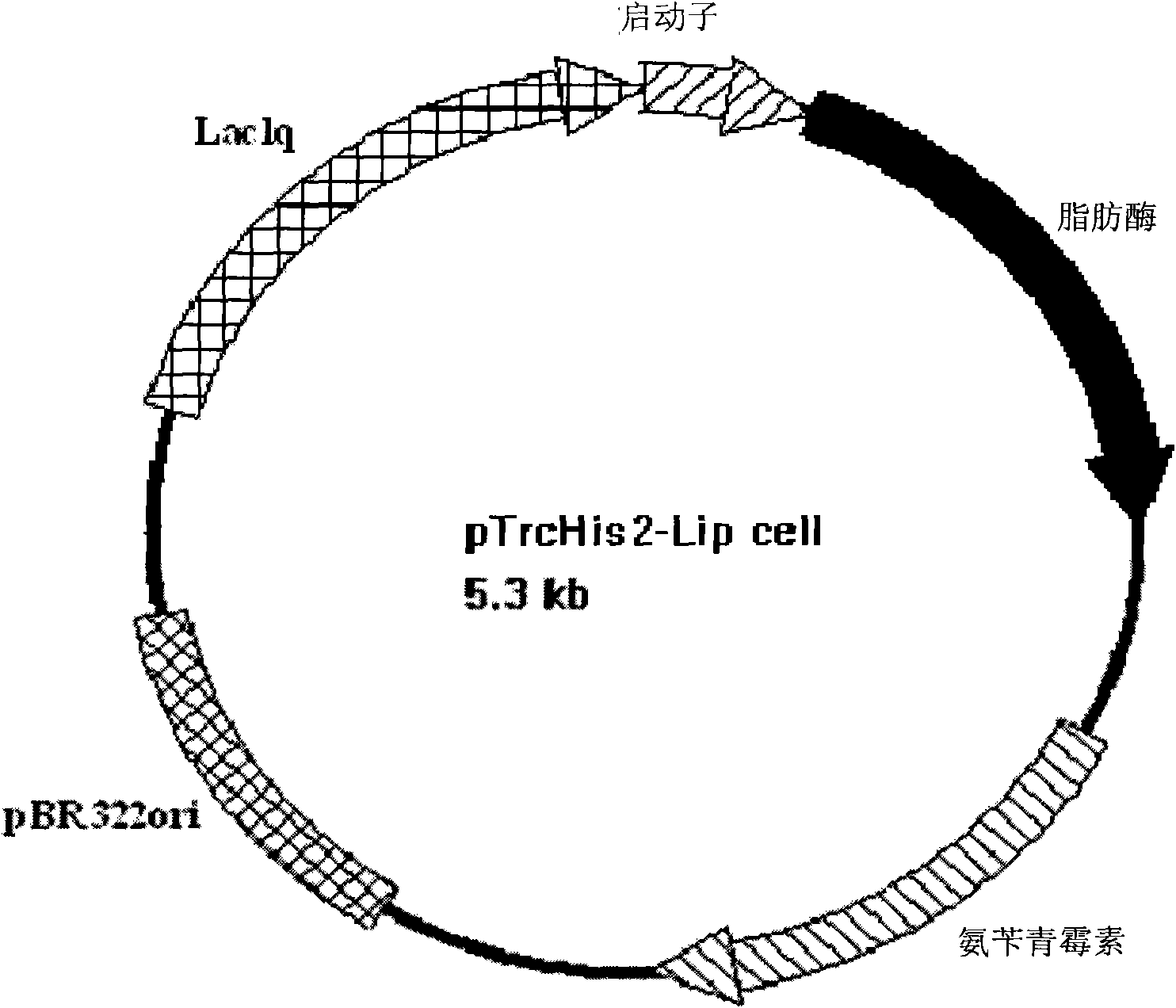

High temperature lipase, preparation for mutants thereof and application thereof

The invention discloses high temperature lipase, preparation for mutants thereof, and application thereof, and in particular discloses a separated lipase with an amino acid sequence as SEQ ID NO:4, a coding sequence thereof, a carrier, a cell and a composition containing the separated lipase, a preparation method for the separated lipase, and application of the separated lipase in catalyzing ester synthesis, performing chiral separation or transforming plant oil into biodiesel.

Owner:FUJIAN FUDA BIOTECH

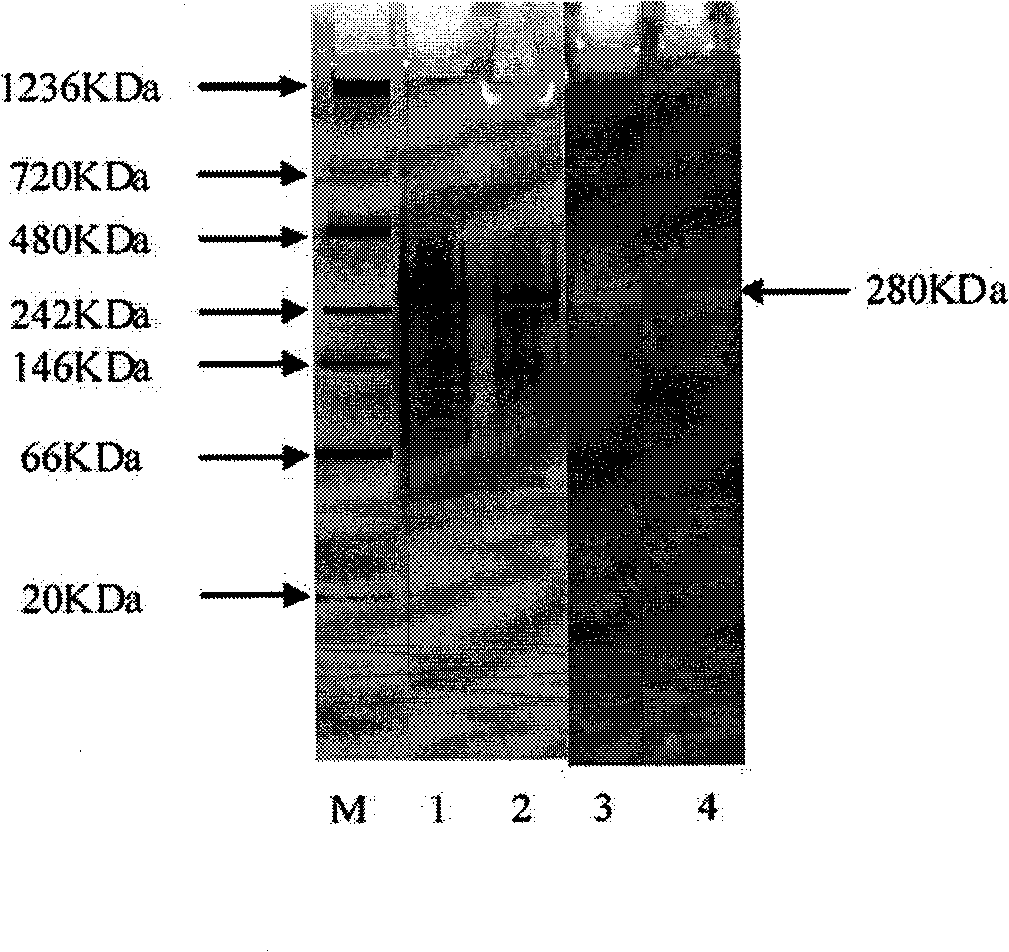

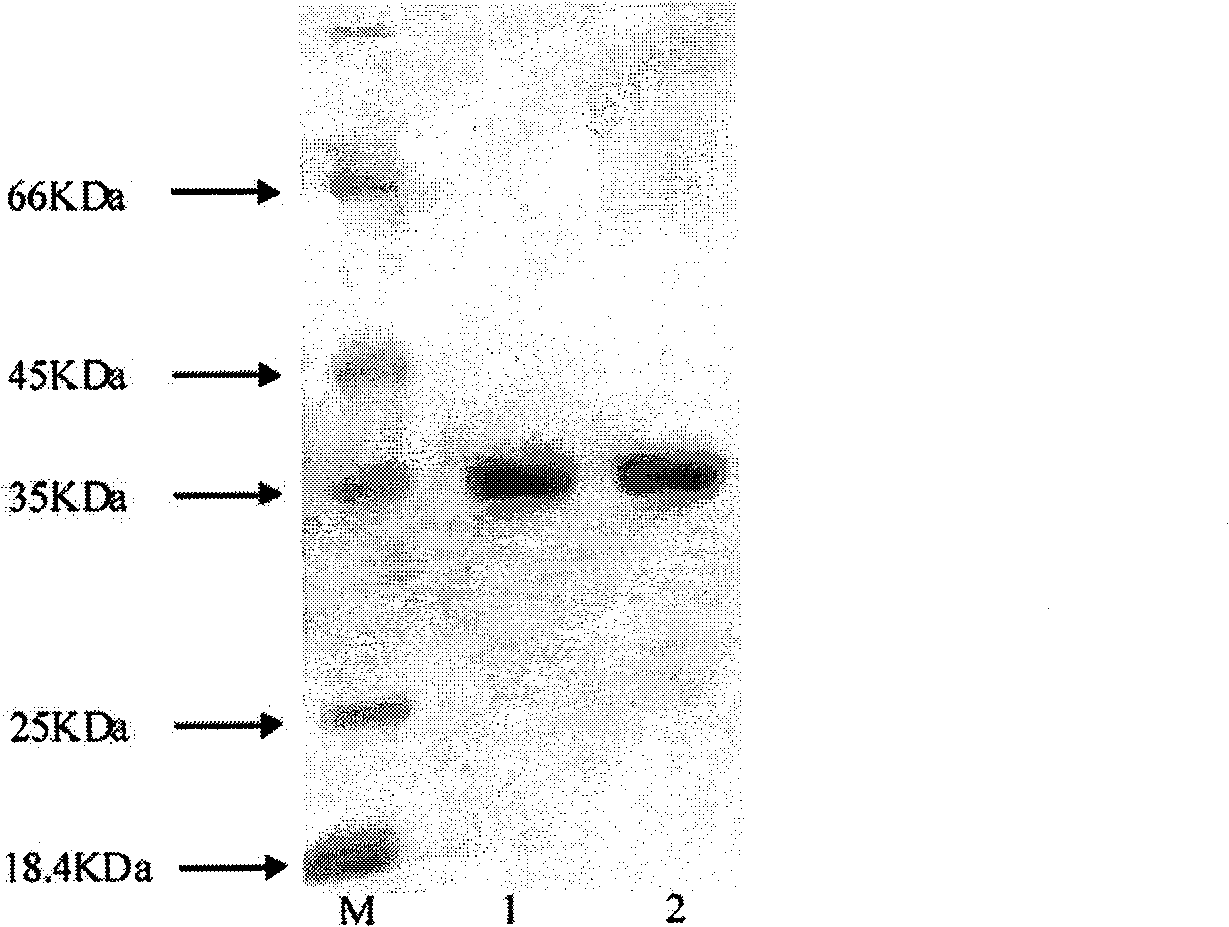

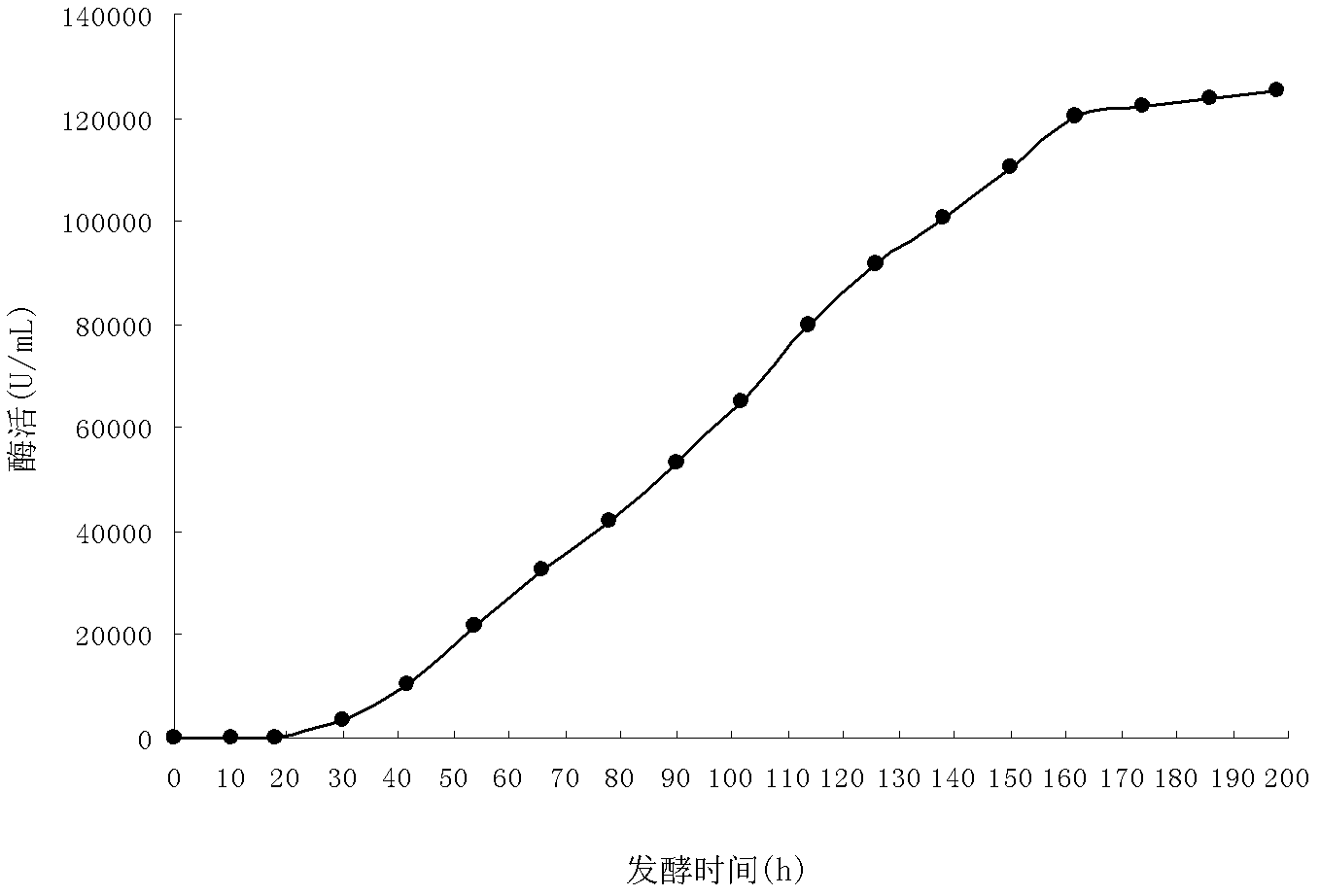

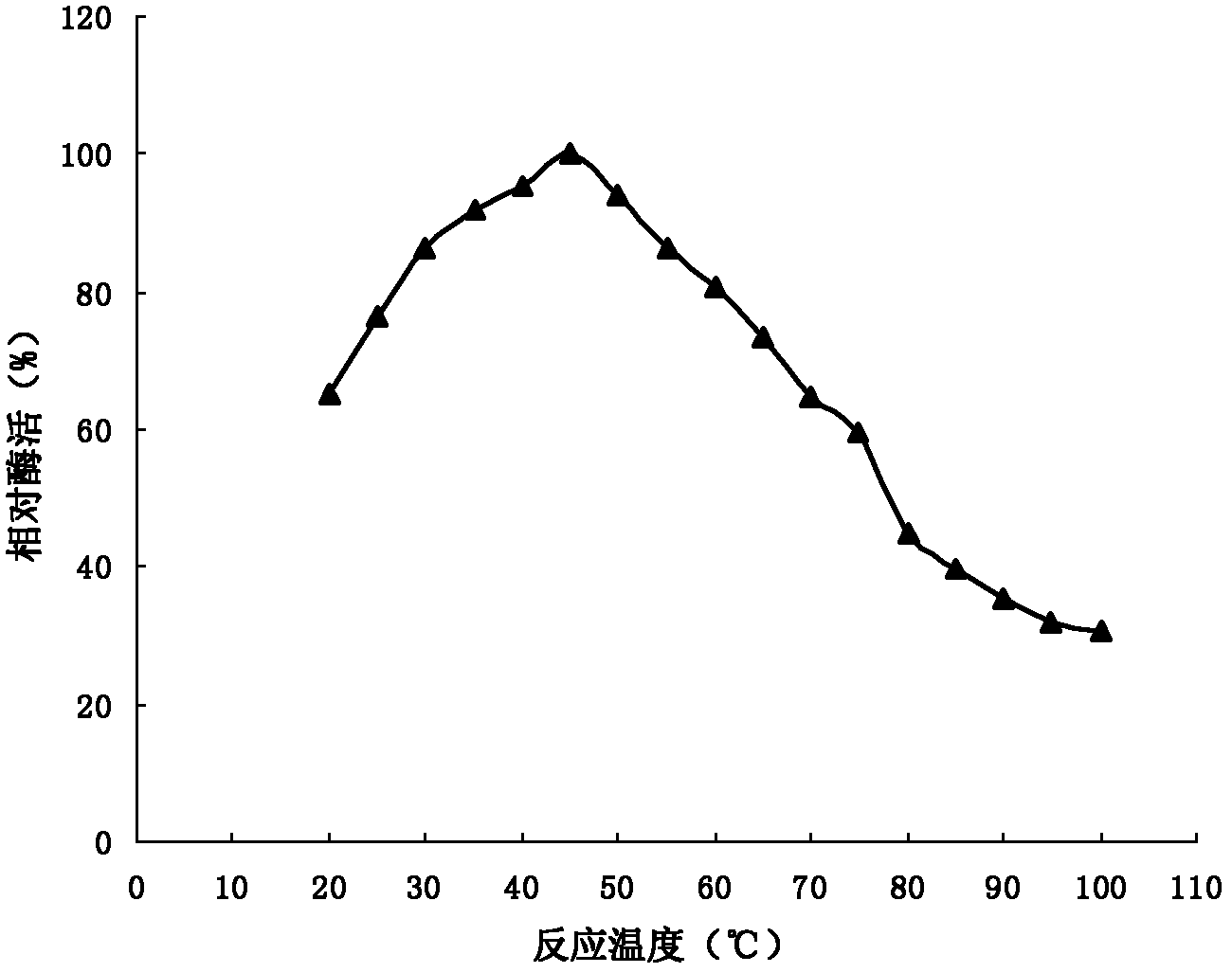

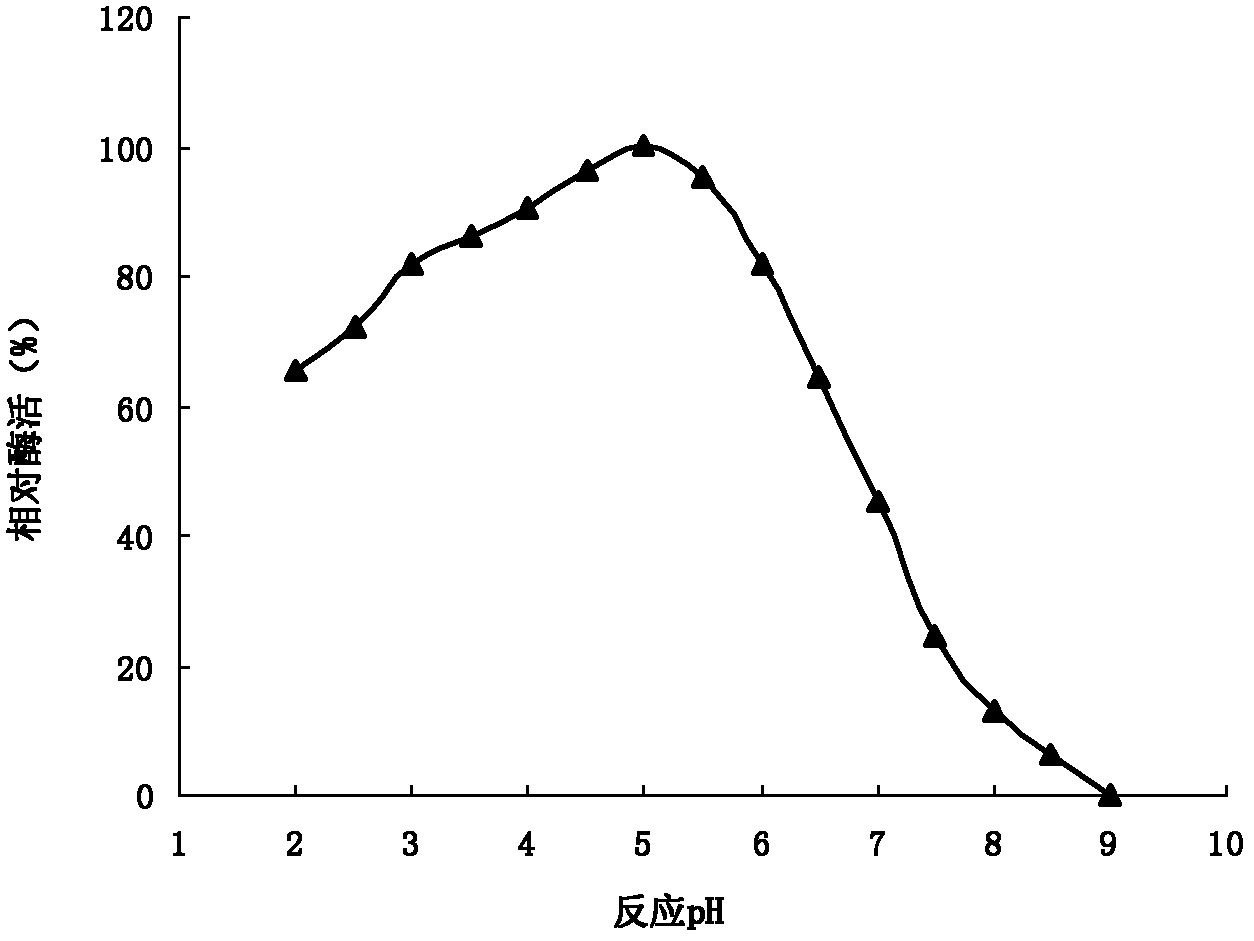

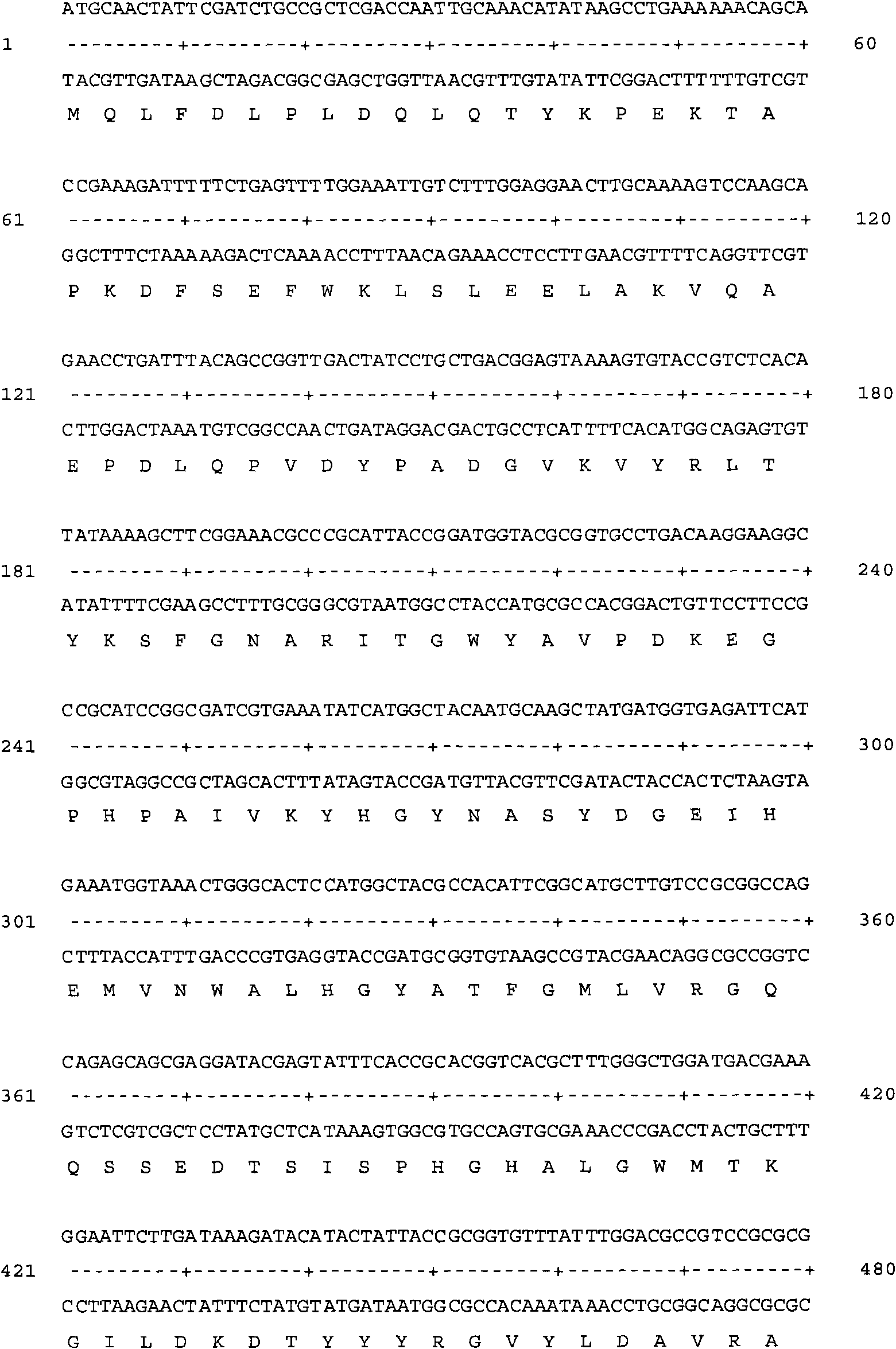

Novel glucoamylase VGA (video graphics array), gene thereof and application thereof

ActiveCN102382807AEnzyme stabilityImprove high temperature resistanceFungiMicroorganism based processesBiotechnologyGraphics

The invention relates to the field of genetic engineering, in particular to a novel glucoamylase VGA (video graphics array), a gene thereof and application thereof. The novel glucoamylase VGA is provided with an amino acid sequence as indicated in SEQ (sequence) ID (identification) NO.1. The invention further provides a gene encoding the novel glucoamylase VGA, a recombinant vector comprising thegene, a recombinant strain comprising the gene and application of the gene, and a nucleotide sequence of the gene is indicated as SEQ ID NO.2. The enzyme activity of the novel glucoamylase VGA is stable under the condition of 2.0-7.5 pH (potential of hydrogen), and the novel glucoamylase VGA is remarkable in amylolysis effect. In addition, the glucoamylase has better high-temperature resistance, and loss of the enzyme activity of the glucoamylase is lower than 15% after the glucoamylase is treated in 85 DEG C water liquor for 10min, so that the glucoamylase completely meets various industrialrequirements and is suitable for being applied as a novel high-temperature-resistant glucoamylase.

Owner:湖南康捷生物科技有限公司

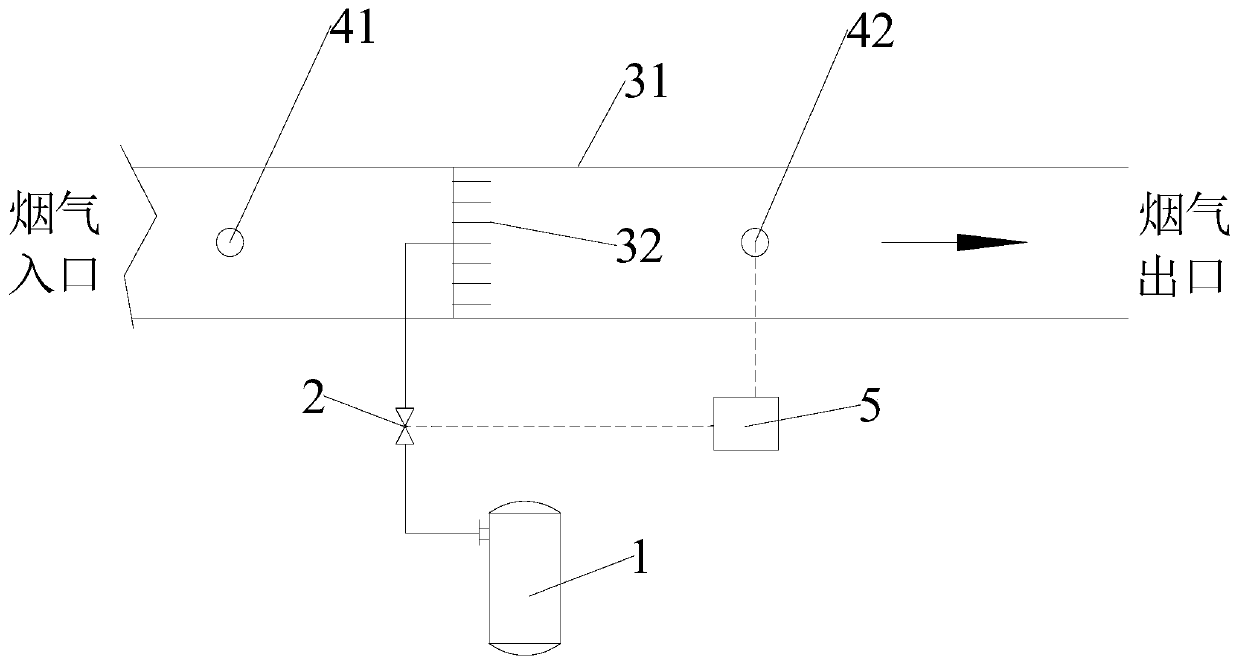

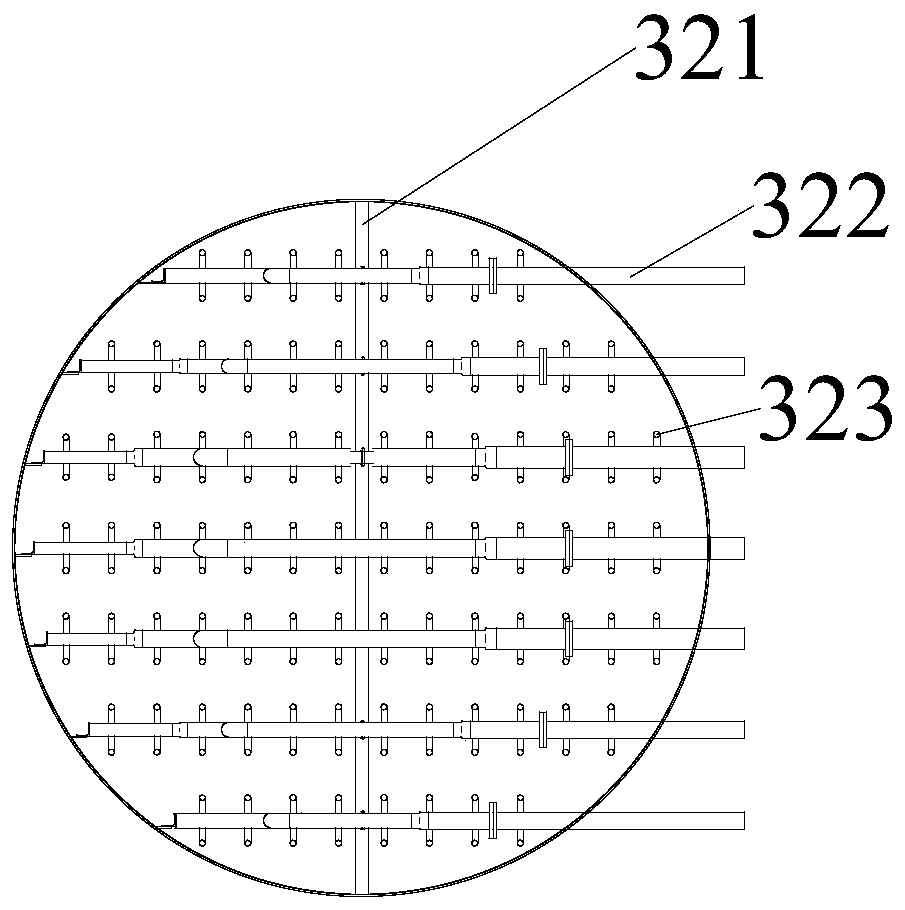

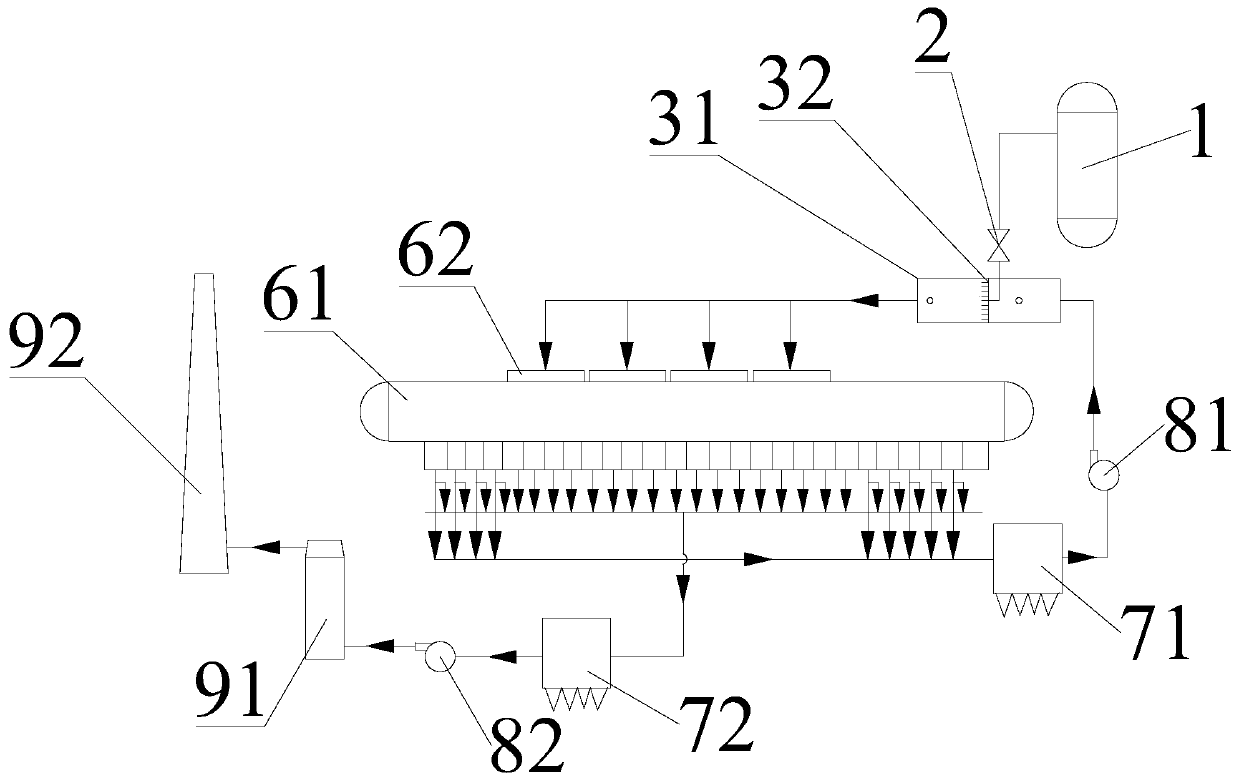

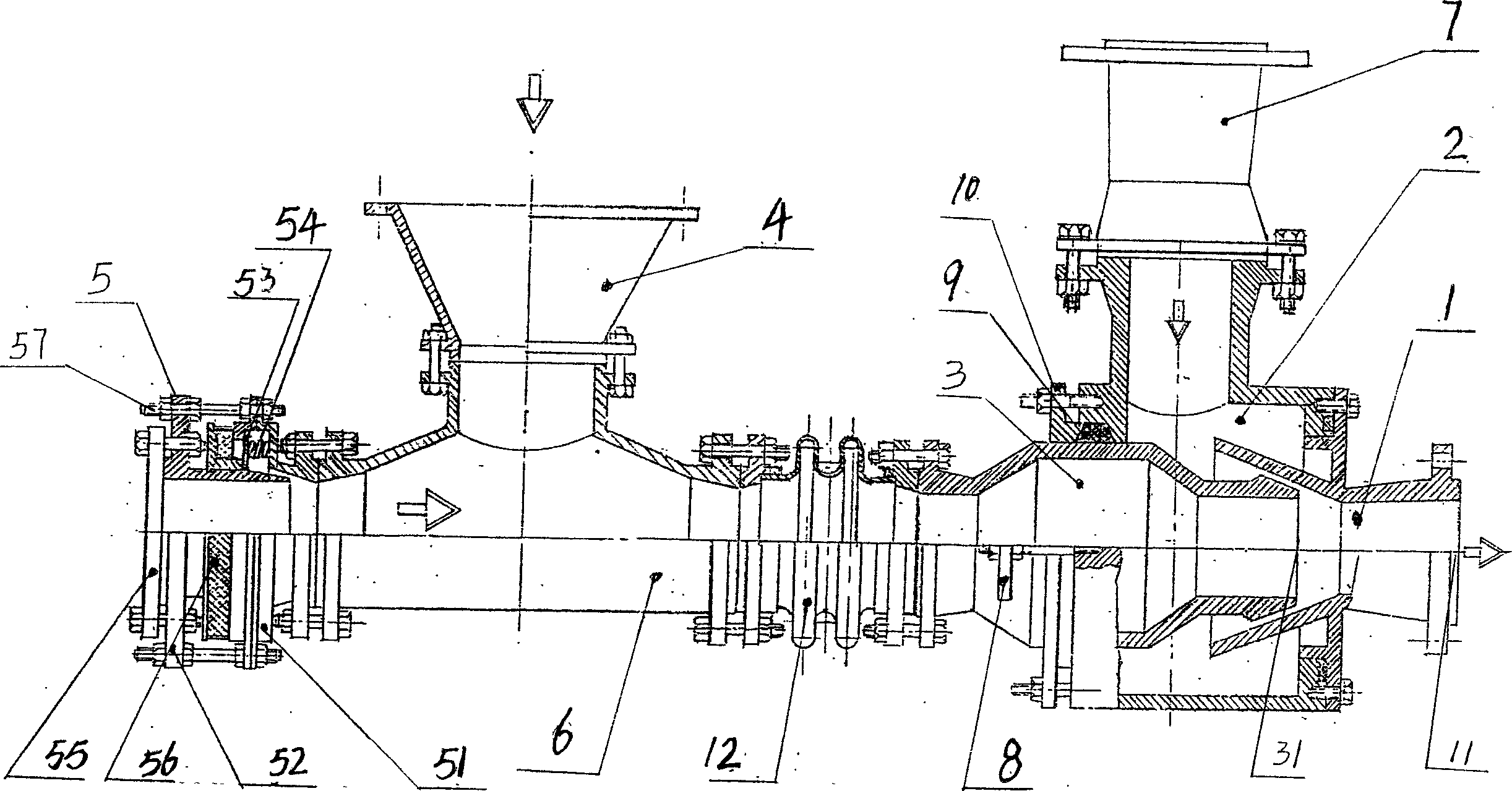

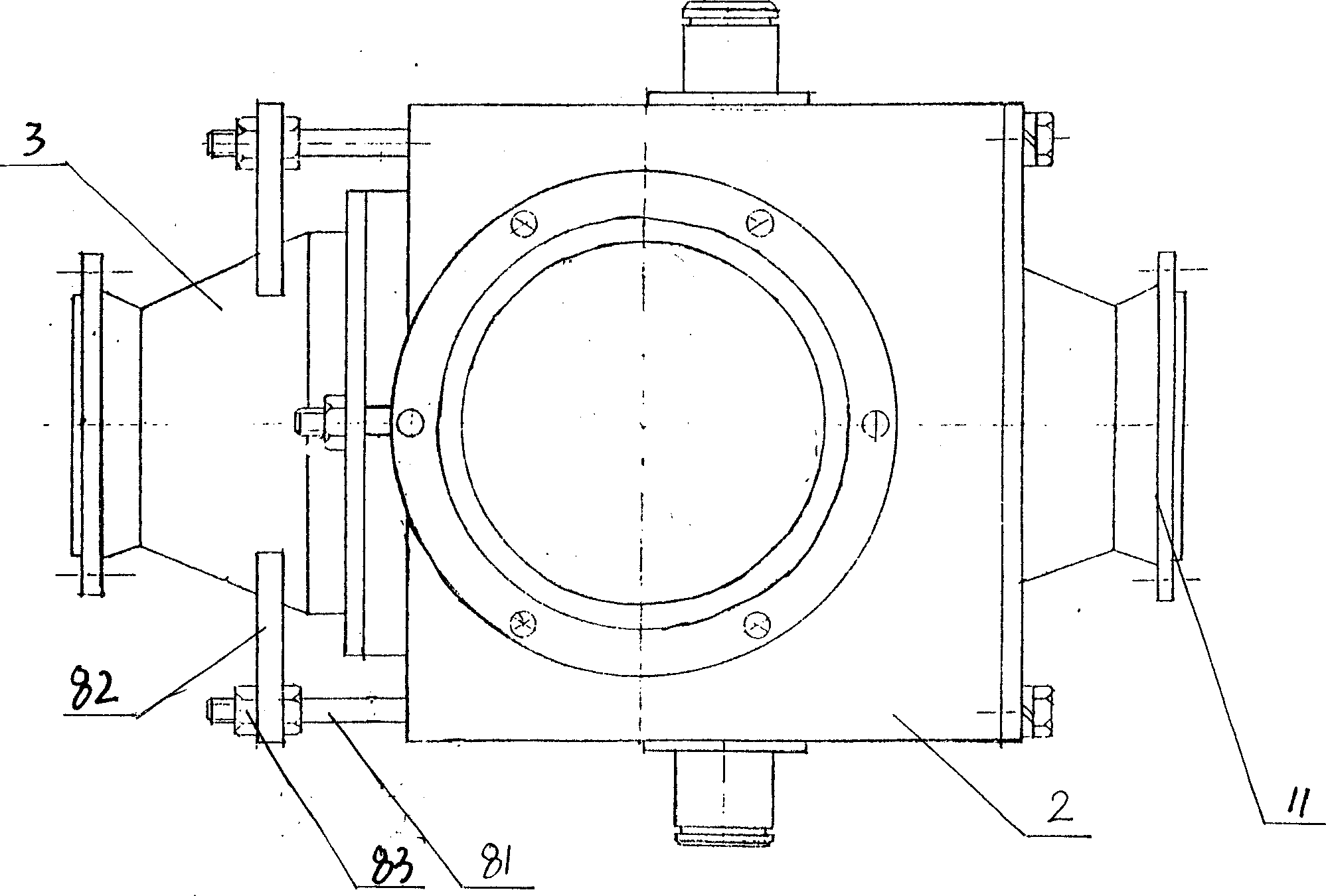

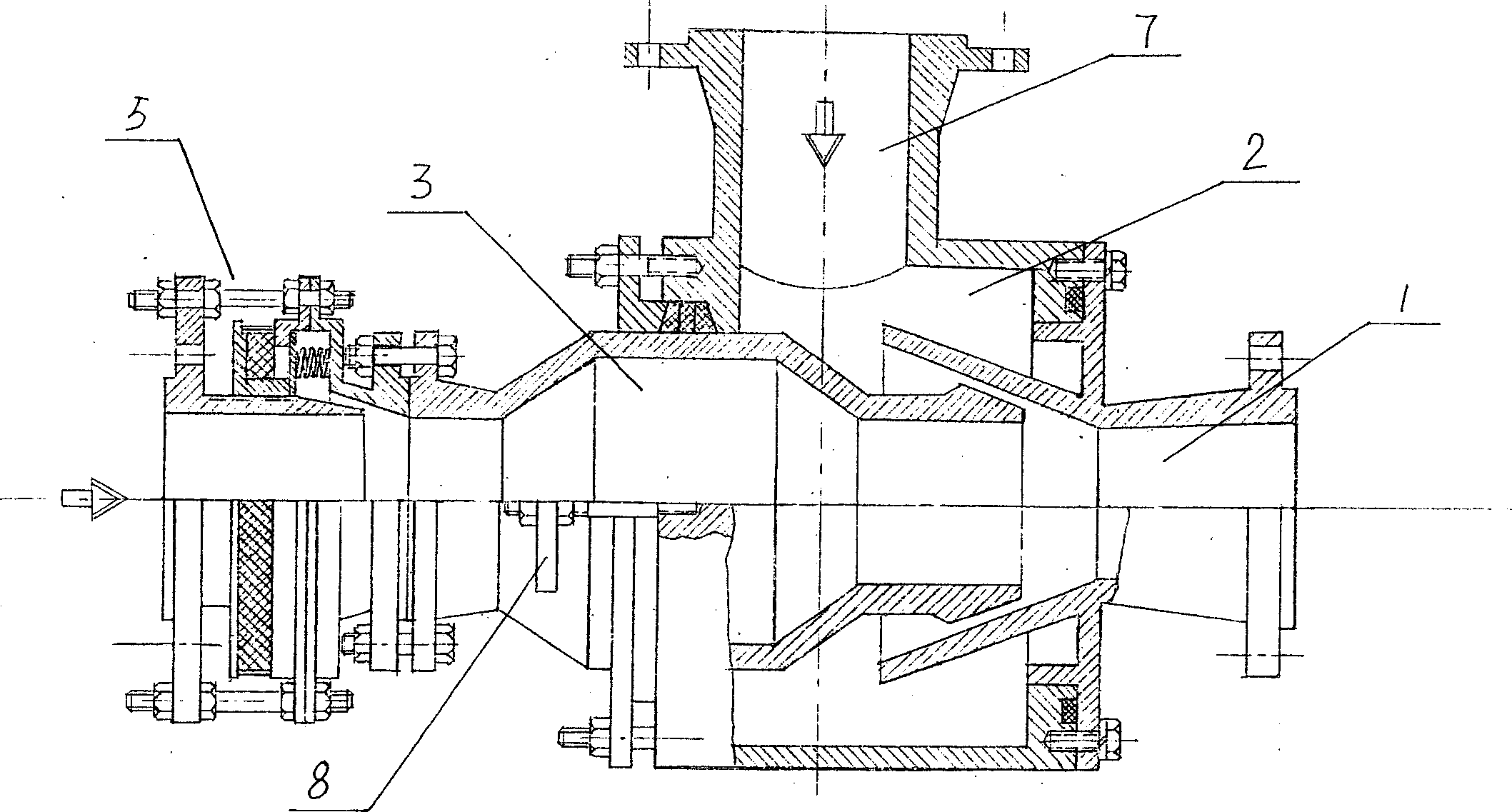

Oxygen-enriched sintering flue gas circulation system and application thereof

InactiveCN110553516ASimple structureEasy to adjustControl devices for furnacesWaste heat treatmentFlue gasExhaust fumes

The invention relates to an oxygen-enriched sintering flue gas circulation system and application. The oxygen-enriched sintering flue gas circulation system involves a sintering machine, a first dustremover, a first fan, an oxygen adding system, a second dust remover, a second fan and a post-treatment unit; the oxygen adding system enables oxygen to be uniformly mixed with circulation flue gas, so that the stability of the sintering yield and the quality is ensured; and a detection unit detects the content of the oxygen in the circulation flue gas in real time, the adding amount of the oxygenis adjusted through a control unit, the content of the oxygen in the mixed flue gas is detected in real time, and the control unit adjusts a flow adjusting device according to the feedback to enablethe content of the oxygen in the circulation flue gas to be 18%-30%. According to the oxygen-enriched sintering flue gas circulation system, the oxygen adding system is simple in structure, the oxygenflow can be accurately and quickly adjusted, the defect that the circulation flue gas flow is reduced due to additionally-added annular cold waste gas or air is avoided, the flue gas circulation ratecan be increased to 60% at the highest, and the flue gas emission reduction effect is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Method for preparing intermetallic compound powder cored filament material for electric arc spraying

The preparation process of intermetallic compound filament with powder core for arc spraying includes the following steps: mixing aluminum powder of granularity 38-44 micron and purity not lower than 99.5 % and iron (nickel ) powder of granularity 53-61 micron and purity not lower than 99.5 % in the atom ratio of 1 to 1; pressing the mixture in a hydraulic press into blank and painting the surface with one thin graphite layer; self-spreading reaction in a vacuum combustor to obtain loose intermetallic compound block; crushing, grinding, sieving to obtain 200-325 mesh granularity powder material and drying; and making Fe (Ni)-Al compound filament with powder core. The present invention has good spraying performance, good coating layer performance, high performance / cost ratio, wide use temperature range, simple technological process and low power consumption.

Owner:SHANDONG UNIV OF SCI & TECH

Thermostable lipase, expression of coding gene of thermostable lipase and applications of thermostable lipase

The invention discloses a separated thermostable lipase of of which amino acid sequence is shown in SEQ ID NO:2, a coding sequence of the thermostable lipase, a carrier with the thermostable lipase, a cell with the thermostable lipase. a composite with the thermostable lipase, a preparation method of the thermostable lipase and applications of the thermostable lipase in the catalytic ester synthesis, chiral separation and convertion from vegetable oil to biodiesel. The name of the invention is ''thermostable lipase, expression of coding gene of thermostable lipase and applications of thermostable lipase''.

Owner:FUJIAN FUDA BIOTECH

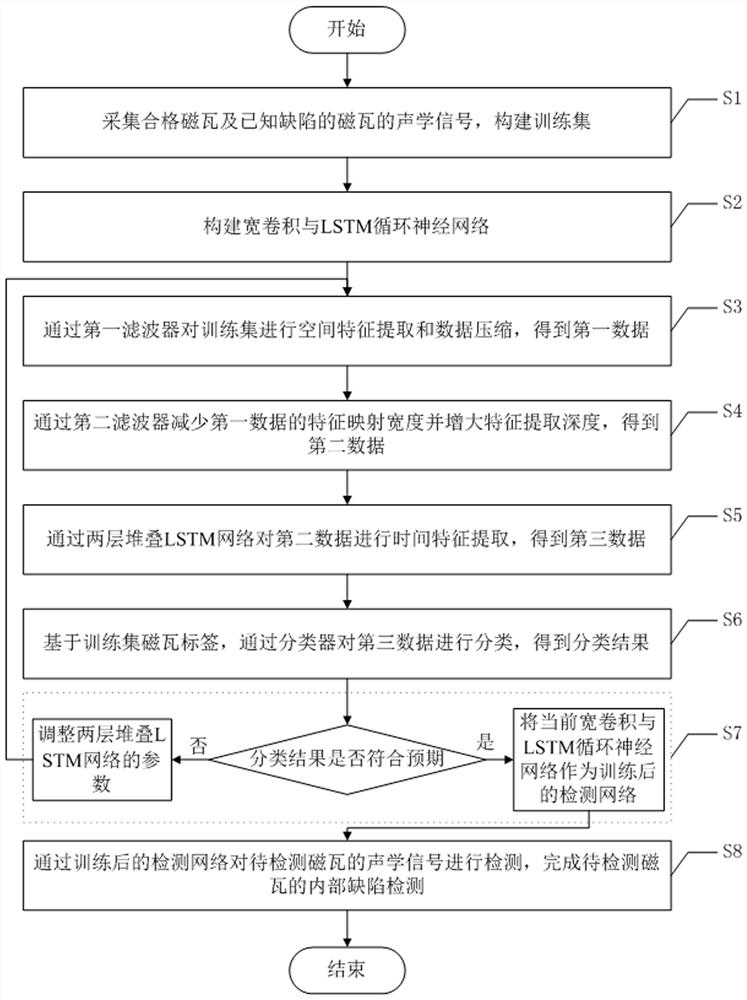

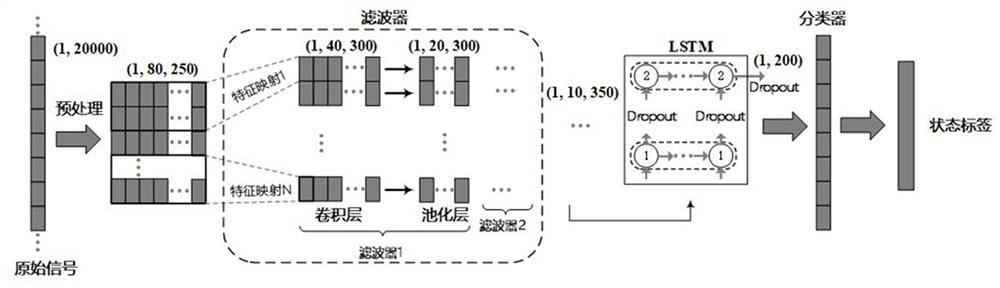

Magnetic shoe internal defect detection method based on wide convolution and recurrent neural network

InactiveCN113252790ARealize identificationReduce computational complexityAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFeature extractionEngineering

The invention discloses a magnetic shoe internal defect detection method based on a wide convolution and recurrent neural network, and relates to the field of magnetic shoe detection, and the method comprises the following steps: constructing a training set, constructing a wide convolution and LSTM recurrent neural network, training the wide convolution and LSTM recurrent neural network, obtaining a trained detection network, and detecting the acoustic signal of the to-be-detected magnetic shoe through the trained detection network to complete the internal defect detection of the to-be-detected magnetic shoe. According to the method, specialist knowledge and complex signal processing and feature selection are not needed, spatial-temporal feature extraction and classification can be directly carried out on original signals in an end-to-end mode by utilizing the wide convolution and the LSTM recurrent neural network, and therefore the target of identifying the internal defects of the magnetic shoe is achieved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Glaze blue-and-white porcelain

InactiveCN104944916AGood colorHigh hardnessCeramic materials productionClaywaresLithiumCarboxymethyl cellulose

The invention discloses a glaze blue-and-white porcelain, a ceramic body is composed of waste porcelain, natural clay, calcined talc, feldspar, alumina micro powder, silicon nitride, black clay and wollastonite; The glaze blue-and-white porcelain is composed of zinc oxide, cobalt oxide, quartz, limestone, lithium feldspar, ulexite, silicon carbide, silicon nitride, ferric oxide, zirconium silicate, zinc borate, montmorillonite, carboxymethyl cellulose sodium and sodium humate by optimizing a porcelain body and a glaze, physicochemical performance of ceramic colouring effect, hardness and stability can be increased, a product class completely accords with industrial and life requirement, and waste utilization effect can be realized.

Owner:广东晖祥陶瓷有限公司

A kind of purification method of electronic grade octamethylcyclotetrasiloxane

ActiveCN103788124BMeet industrial needsSimple methodSilicon organic compoundsBoiling pointDistillation

The invention relates to a method for purifying electronic grade octamethylcyclotetrasiloxane in a rectifying manner. The method comprises the following steps: (1) adding 99% of the octamethylcyclotetrasiloxane into a rectifying tower, and removing little residual hexamethylcyclotrisiloxane (D3 for short) from the top of the tower at 90-96 DEG C under the pressure of 0.02-0.03MPa; (2) enabling the octamethylcyclotetrasiloxane without the D3 to flow out of the tower and enter a reaction kettle of a de-heavy rectifying tower, adding 0.01%-0.1% by weight of a special efficient metal complex ligand, heating to 90-100 DEG C, reacting for 1-10 hours, and performing reduced pressure distillation. The de-heavy rectifying tower is arranged in a superclean room, the reduced pressure operation is adopted in the tower, the pressure of the tower is 0.005-0.01Mpa, the temperature of the top of the tower is 100-110 DEG C, more than 99.99% by weight of the octamethylcyclotetrasiloxane is received, and residues at the bottom of the tower are high-boiling-point impurities; the reaction kettle and the inner wall of the de-heavy rectifying tower and a pipeline receiving container are all wrapped with polytetrafluoroethylene, and fillers of the de-heavy rectifying tower are wrapped with the polytetrafluoroethylene.

Owner:SHANGHAI AIMO JINSHAN PHARM CO LTD

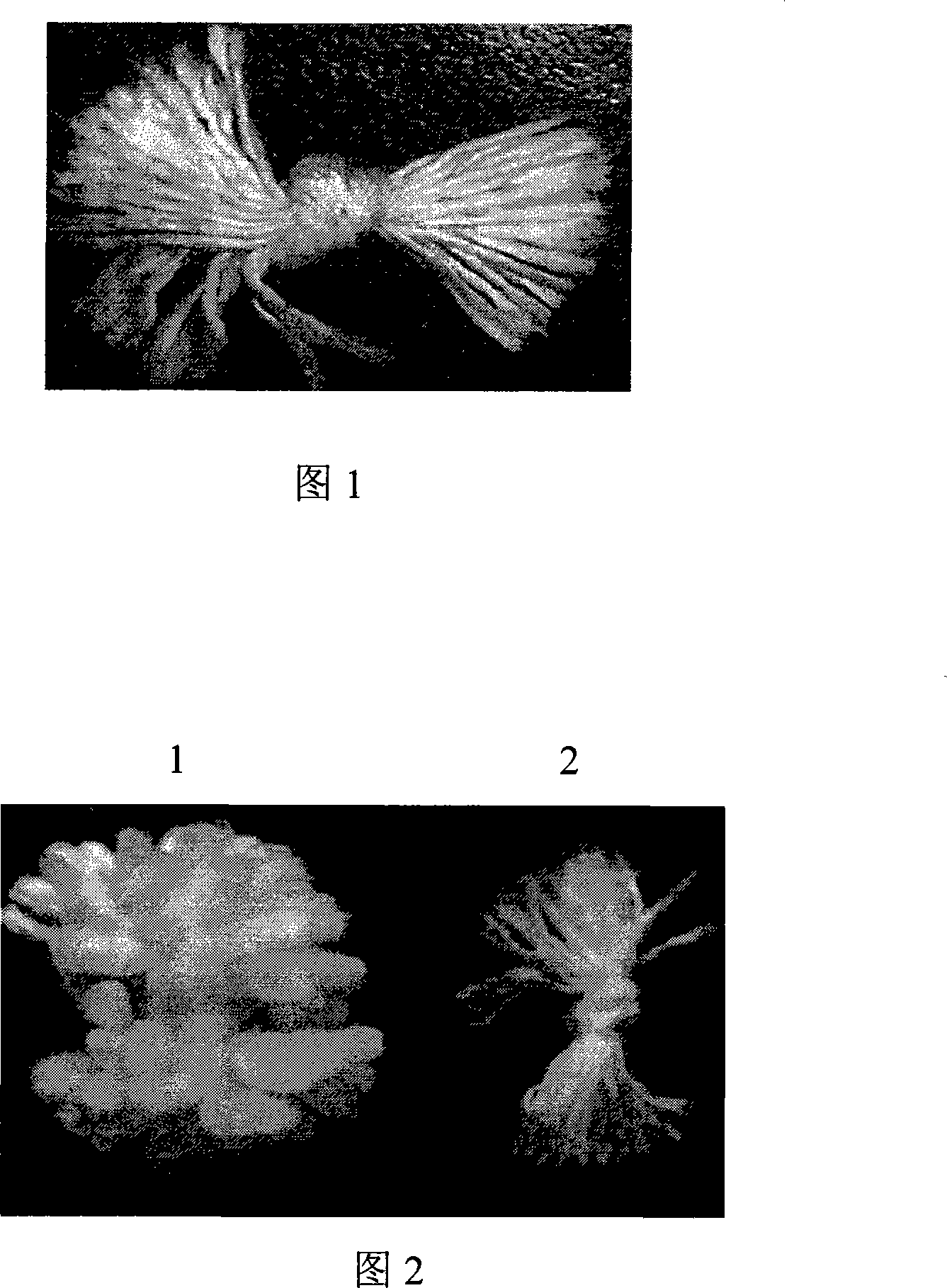

Application of knotting thread for filamentous fungi breeding and breeding method for filamentous fungi

The present invention discloses use of knotted silk thread in propagating filamentous fungi, and the process of propagating filamentous fungi on knotted silk thread carrier. The knotted silk thread may be sunk into water and stretched in water for hypha to attach on easily; and the knotted silk thread is flexible for hypha to be broken and propagated periodically. The knotted silk thread has facile material and excellent use effect, and is favorable to propagation and growth of filamentous fungi.

Owner:TSINGHUA UNIV

Conveying accelerator

A delivering accelerator based on the siphor phenomenon of fluid to generate high sucking force, push force and delivering power is composed of a mixing chamber with conic wall to form outlet of accelerator, a pressure chamber close to said mixing chamber, a sucking chamber installed at another side of pressure chamber in sealing mode, and the material inlet-gas inlet unit connected to sucking chamber via three-way. Said pressure chamber has also a boosting inlet connected to a booster and a regulator for regulating the output pressure of accelerator.

Owner:孙付江

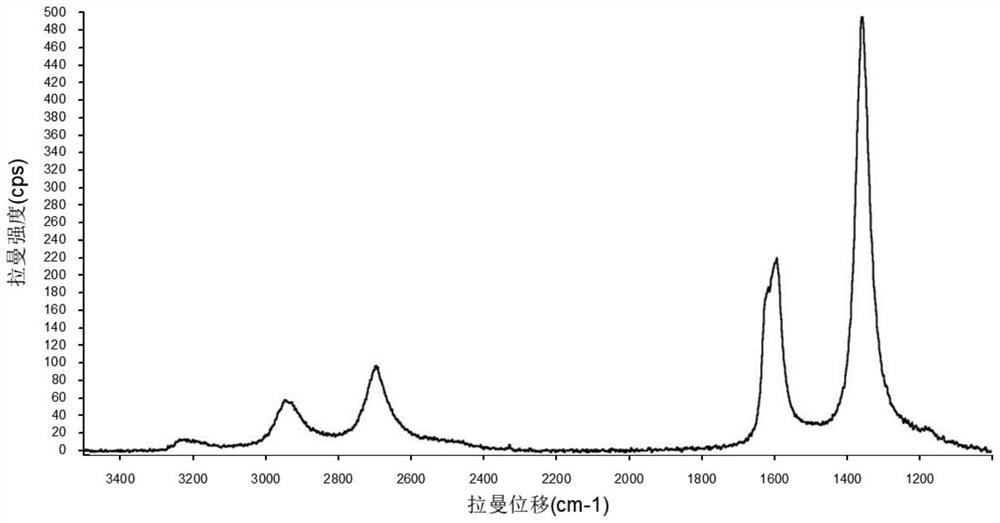

Method for preparing graphene powder material

The invention relates to a preparation method of a graphene powder material. The preparation method comprises the following steps: (1) growing a vertical graphene array on a copper foil through roll-to-roll plasma chemical vapor deposition equipment by using a special process; (2) dripping a proper amount of PMMA solution on the surface of the copper foil on which the vertical graphene array is grown, uniformly spin-coating the copper foil, and heating in a drying oven for curing; (3) directly and completely stripping the cured vertical graphene PMMA polymer layer from the copper foil by using a mechanical stripping method according to the characteristic of poor binding force between the vertical graphene array and the copper foil; (4) soaking the stripped polymer layer in acetone to completely dissolve PMMA to obtain a graphene sheet suspension; and (5) after filtering and separating the graphene suspended matter, putting the graphene suspended matter into a ball mill or a sand mill to obtain the graphene powder material. The graphene powder material prepared by the preparation method disclosed by the invention has a relatively large lamellar area and relatively high conductivity and heat conductivity coefficient, and can be used as an additive material.

Owner:杭州英希捷科技有限责任公司

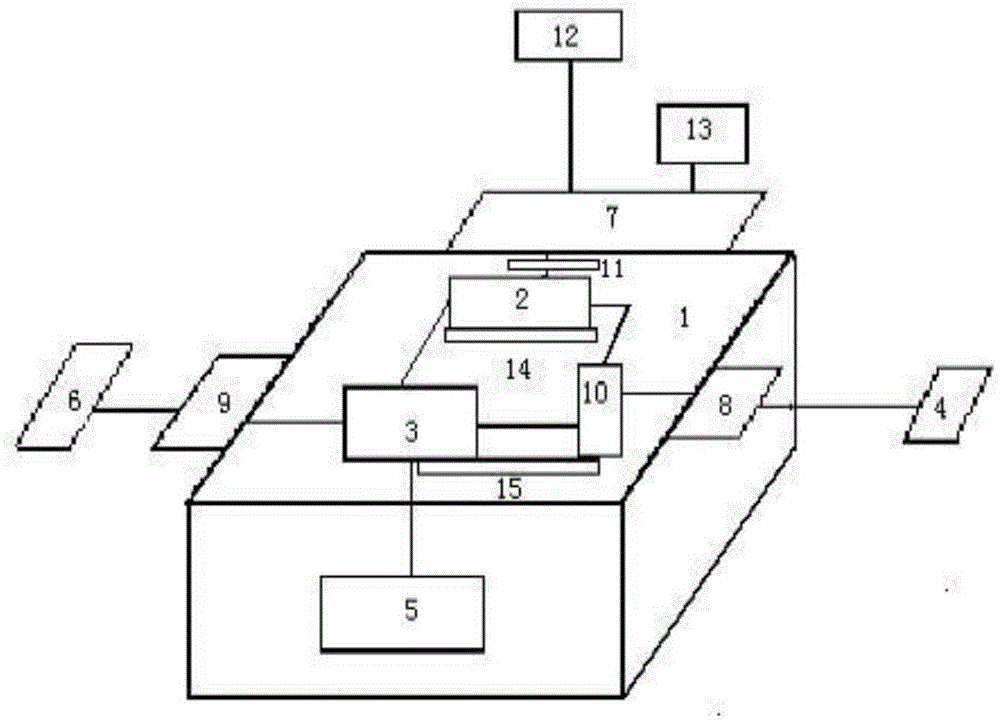

Solar battery laser back electrode window opening end point judging method

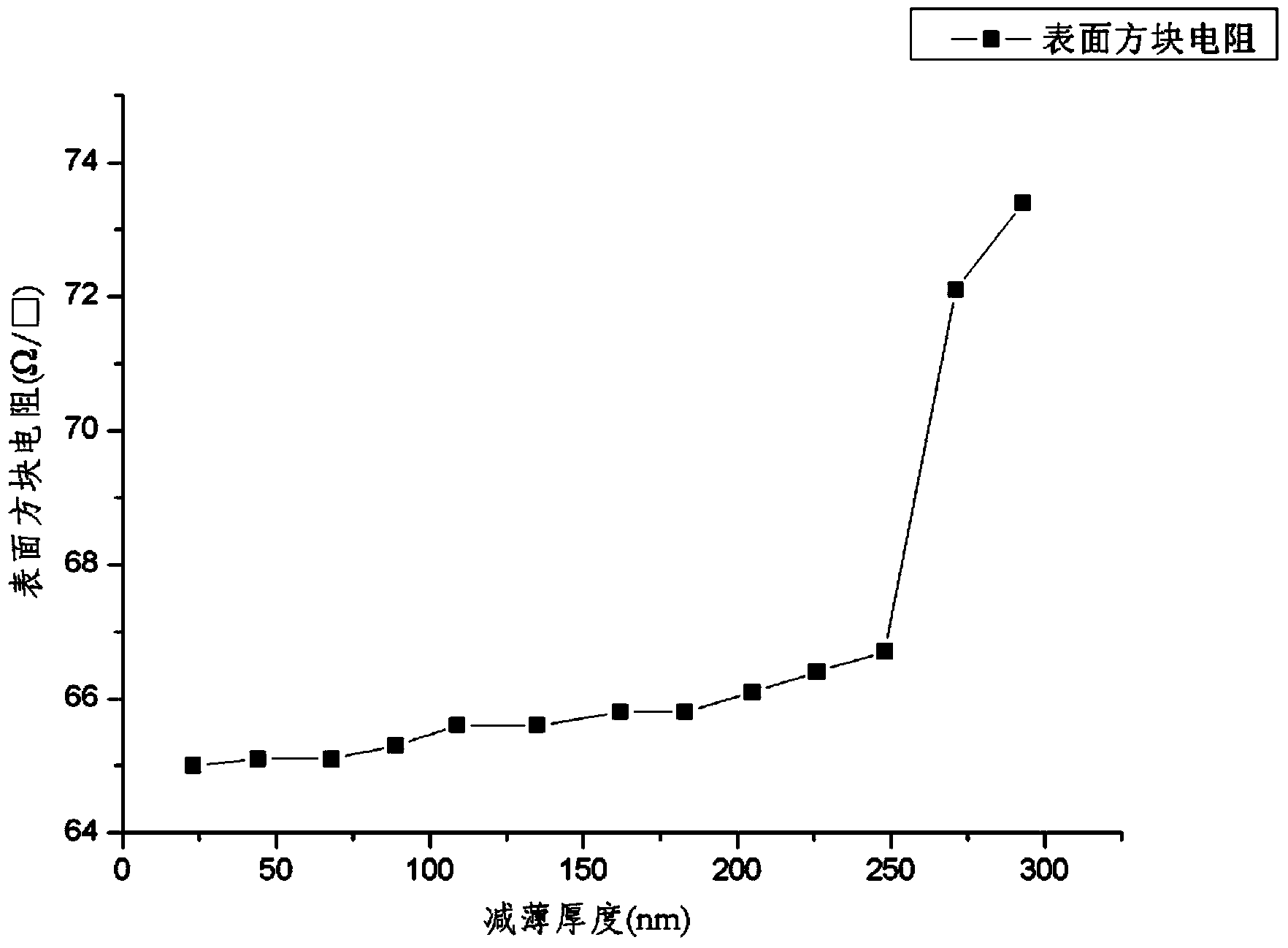

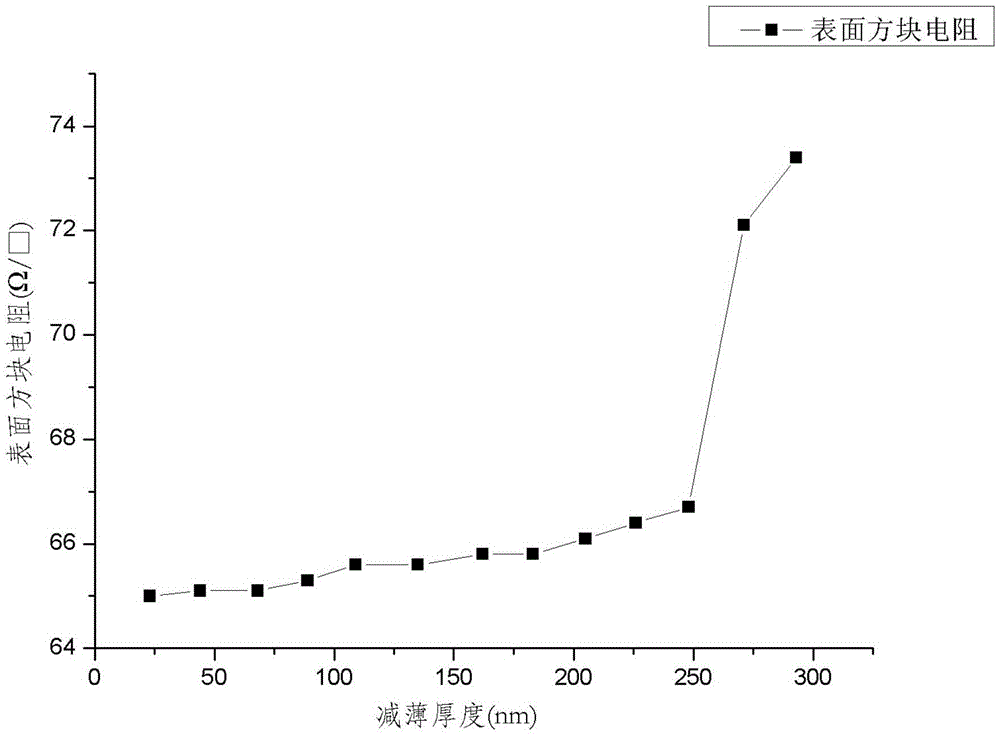

InactiveCN103528558AShorten detection timeIncrease productivityMeasurement devicesSemiconductor/solid-state device testing/measurementEtchingElectrical battery

The invention relates to a solar battery laser back electrode window opening end point judging method. According to the method, the laser with the same wavelength and frequency is used for carrying out continuous etching for many times on the back side of a battery piece, a step-shaped structure is formed at the finally obtained back side of the battery piece, the battery surface resistivity under each step surface is respectively measured, and finally, the corresponding relationship between the laser window opening end point and the laser thinning time number is obtained, so the thinning laser repeating time number required by the etching removal of a back side passivation layer is found. Compared with the traditional method, the continuous proceeding mode is adopted for the thinning of the back passivation layer, and similarly, the continuous proceeding mode is adopted for the surface resistivity measurement, so the detection time is greatly shortened, the production efficiency is improved, and in addition, the state information after the etching in each time can be completely remained by samples obtained after the final etching. The window opening end point judging method provided by the invention has the advantages that simplicity is realized, the implementation is easy, the cost is low, and in addition, the precision is higher.

Owner:NANTONG UNIVERSITY

Windowing terminal point determining method for solar energy cell laser back electrode window

InactiveCN105551990AShorten detection timeIncrease productivitySemiconductor/solid-state device testing/measurementEtchingSurface resistivity

The invention relates to a windowing terminal point determining method for a solar energy cell laser back electrode window. According to the method, a back face of a cell is continuously etched for multiple times by utilizing laser with same wavelength and frequency, and the back face of the cell is finally a step-like structure, cell surface resistivity of each step surface is respectively measured, the corresponding relationship between a laser windowing terminal point and the laser thinning times is finally acquired, and thereby the thinning laser repetition times required for etching a back face passivation layer can be acquired. Compared with a traditional method, the back face passivation layer is thinned in a continuous mode, surface resistivity is further measured in a continuous mode, so the detection time is greatly shortened, production efficiency is improved, samples can be acquired through etching, and the state information after each etching can be integrally kept. The windowing terminal point determining method has advantages of simple and easy operation, low cost and relatively high precision.

Owner:JIANGSU FOX ELECTRIC GRP CO LTD

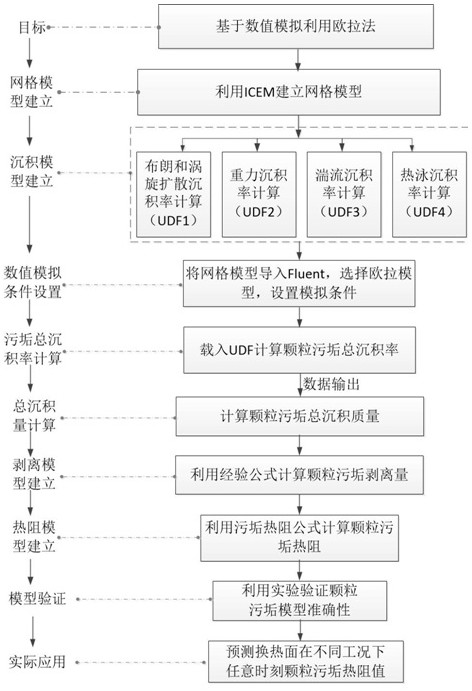

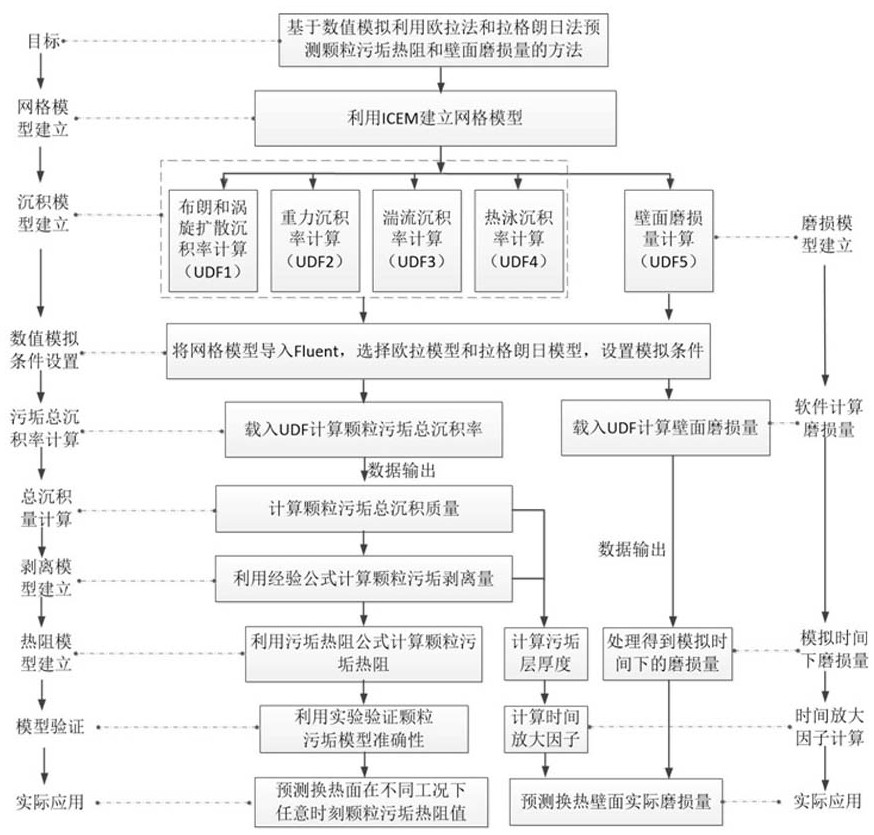

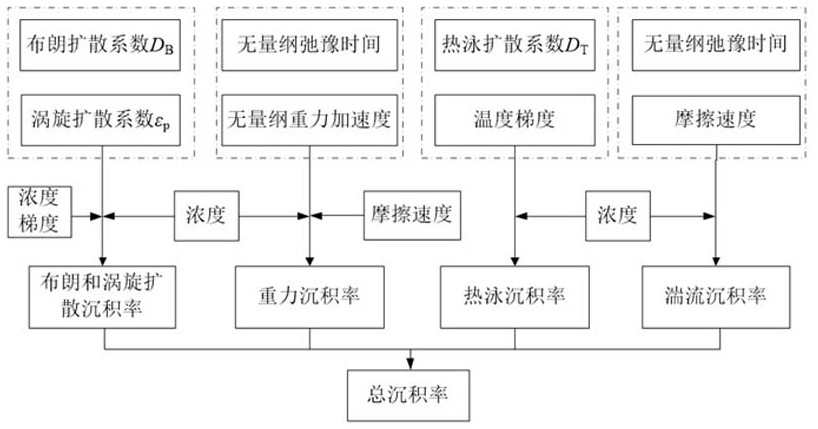

Wall deposition and wall abrasion loss prediction method based on numerical simulation

ActiveCN113723020ALower requirementImprove computing efficiencyDesign optimisation/simulationCAD numerical modellingThermodynamicsEngineering

The invention discloses a wall deposition and wall abrasion loss prediction method based on numerical simulation. The method comprises the following steps of: establishing a grid model, establishing a deposition model, establishing an abrasion model, establishing a fouling thermal resistance model, setting a time amplification factor and the like, namely establishing a granular fouling deposition model from four deposition mechanisms and directly deriving a granular fouling total deposition rate; furthermore, quickly predictingwall surface deposition condition on a heat exchange surface at any time in the future. In the prediction of the wall surface abrasion loss, behaviors of particles are predicted by simulating motion trails of the particles, the abrasion and corrosion conditions of the particles in sewage to a heat exchange wall surface can be accurately simulated, the method has the advantage of high simulation precision, and the actual abrasion result is rapidly and accurately predicted by introducing a time amplification factor; according to the method, the wall surface dirt deposition condition and the wall surface abrasion loss can be predicted, so that the maintenance of heat exchange equipment is timely and effectively guided, and reliable data support and guidance are provided for the design of heat exchange systems.

Owner:NANJING YANGTZE RIVER URBAN AGCHITECTURAL DESIGN

Wear-resistant ceramic

InactiveCN106565205AMeet industrial needsCeramic materials productionClaywaresWear resistantGraphene

The invention relates to the technical field of ceramics, and particularly relates to a wear-resistant ceramic. The wear-resistant ceramic comprises the following raw materials in parts by weight: 3-8 parts of iron oxide, 3-8 parts of quartz, 4-8 parts of anorthite, 3-5 parts of barium sulfate, 12-20 parts of kaolin, 4-6 parts of titanium dioxide, 1-3 parts of graphene, 2-4 parts of fly ash, and 1-3 parts of mineralizing agent. Compared with conventional ceramics, the above wear-resistant ceramic is better in wear resistance and can meet a large number of industrial needs. Meanwhile, the above wear-resistant ceramic has a wider application range and is suitable for more severe application environments compared with conventional ceramics.

Owner:四川金辉卫浴洁具有限公司

Wear-resistant high hardness ceramic and processing technology

InactiveCN108238786AImprove toughnessImprove flexural strengthCeramic materials productionClaywaresIron oxideIndium

The invention discloses a wear-resistant high hardness ceramic and a processing technology. The ceramic is prepared from the following raw materials in parts by weight: 13-16 parts of aluminum hydroxide, 21-26 parts of polycrystalline silicon, 33-42 parts of ferric oxide, 35-42 parts of celestite, 12-15 parts of graphite, 15-17 parts of indium, 20-55 parts of aluminum oxide, 14-29 parts of ceramicpowder, 8-15 parts of feldspar, 4-7 parts of clay, 5-10 parts of Soochow soil, 9-18 parts of zirconium oxide, 3-6 parts of zinc oxide, 2-4 parts of magnesium carbonate, 1-2 parts of crystal stones and 2.4-4.7 parts of spodumene. By adding zirconium oxide into the formula, the whole ceramic has the advantages of high toughness, high bending strength and high wear resistance, excellent heat isolating property, coefficient of thermal expansion close to that of steel and the like, and can meet the massive industrial demands. Compared with common ceramics, the ceramic has a wider application rangeand is suitable for more severe using environments, the whole processing method is simple, and the processing method is low in cost and worth being popularized.

Owner:FOSHAN HUIZHONG SENTAI TECH CO LTD

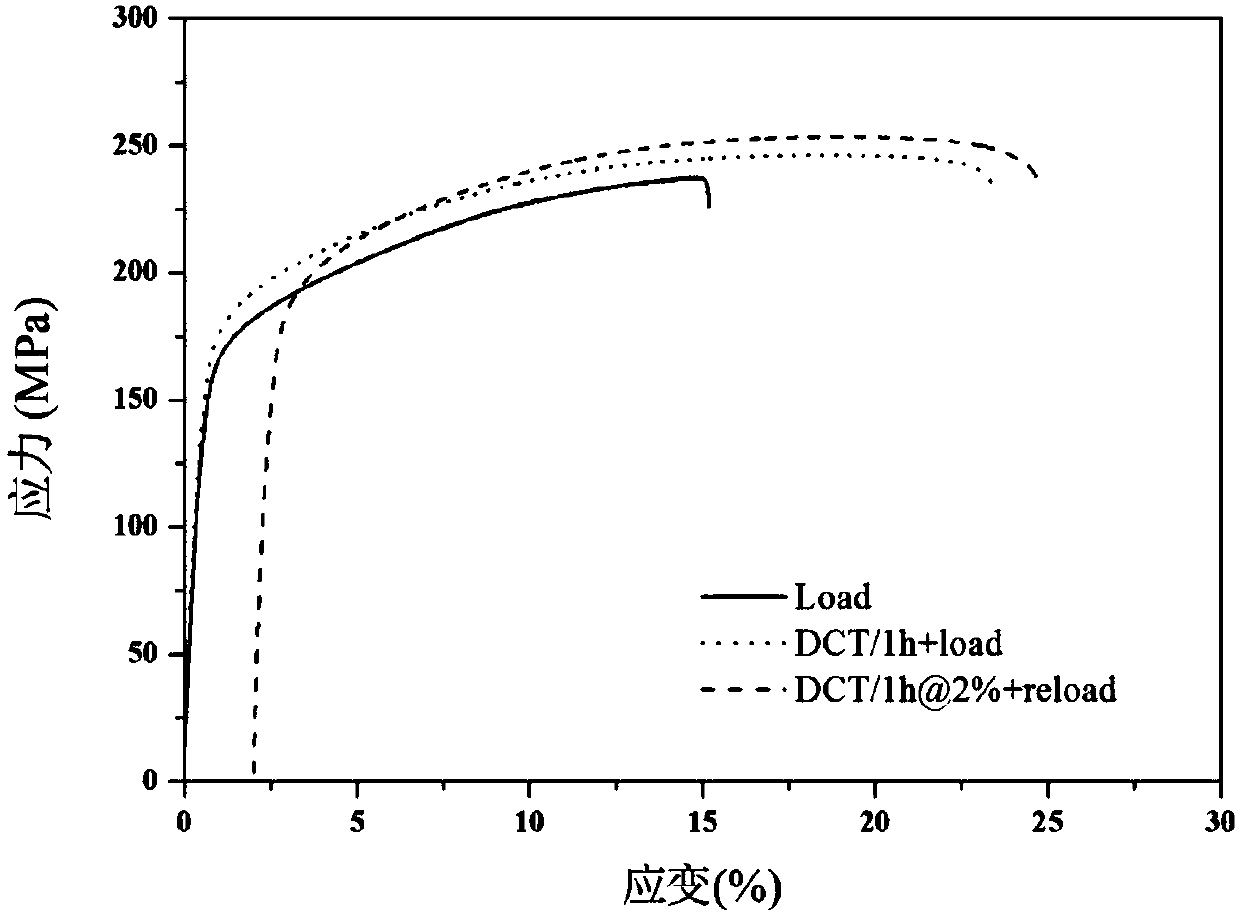

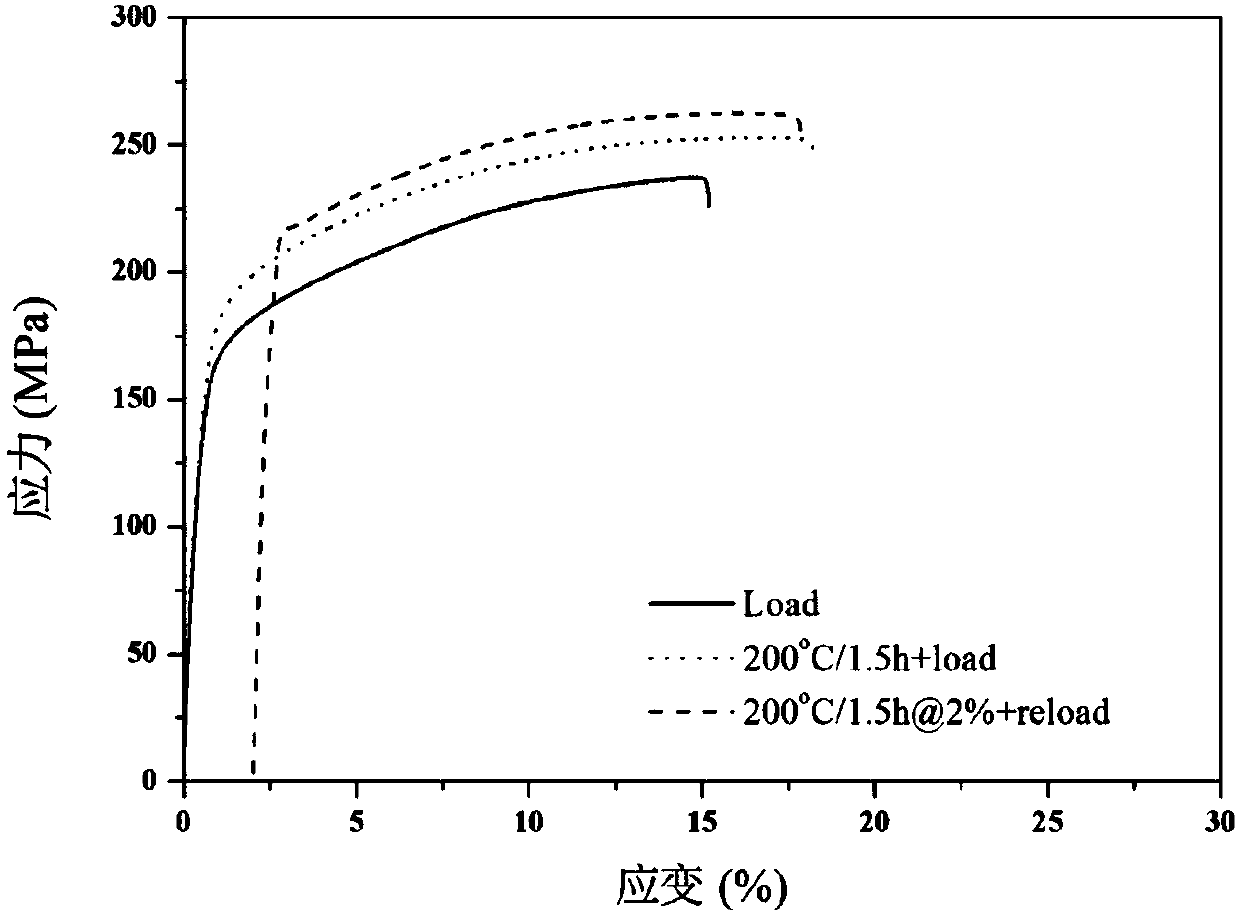

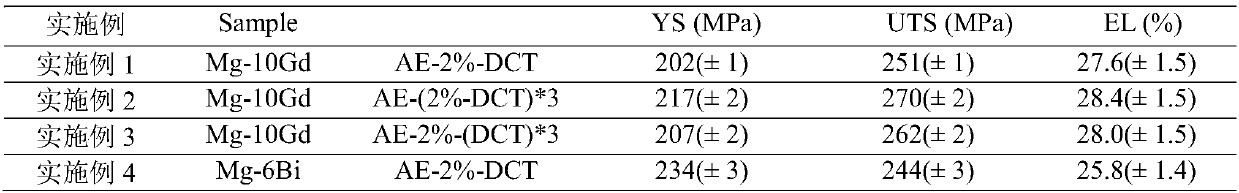

Pretreatment method for improving mechanical property of wrought magnesium alloy

The invention discloses a pretreatment method for improving the mechanical property of wrought magnesium alloy. The pretreatment method comprises the following steps of (1) homogenization treatment and compression deformation; (2) predeformation treatment, wherein bars are machined into tensile test bars, and then the tensile test bars are placed into a tensile testing machine to be subjected to predeformation treatment (stretching or compression), and the amount of deformation ranges from 0.5% to 20%; and (3) subzero treatment, wherein the magnesium alloy tensile test bars subjected to predeformation treatment in the step (2) are placed into a liquid nitrogen environment to be subjected to subzero treatment for 0.5 hour to 24 hours, and the tensile test bars are taken out and placed intoair to naturally recover to the room temperature. With the pretreatment method for improving the mechanical property of wrought magnesium alloy, the purposes of improving the strength and the flexibility of magnesium alloy can be achieved at the same time, and the current situation that the relationship between strength and flexibility is inverted after common annealing treatment or T5 and T6 aging thermal treatment is relieved.

Owner:HEBEI UNIV OF TECH

Paddle type air adsorption dryer, system and air drying method

ActiveCN108479305ASimple structureReduce volumeGas treatmentDispersed particle separationAir volumeBreather

The invention providers a paddle type air adsorption dryer, a system and an air drying method, which relate to the field of air drying. The paddle type air adsorption dryer comprises a breather pipe,an isolation frame, a drain pipe and a paddle machine, wherein the isolation frame is arranged in the breather pipe, and divides an air passage of the breather pipe into an upper air passage and a lower air passage; the drain pipe is arranged on the breather pipe and is located on one side of the lower air passage; the paddle machine is arranged in the breather pipe; one half of the paddle machineis located in the upper air passage; the other half of the paddle machine is located in the lower air passage; the axis of the paddle machine and the isolation frame are located in the same plane; anotch is formed in the lower air passage and is connected with the drain pipe. The paddle type air adsorption dryer is smaller in size, simple in structure, high in air inlet rate, and energy-saving and high-efficient since the paddle machine is driven by wind power, can be adjusted according to the needs, and achieves a drying effect meeting the requirement on different drying degrees.

Owner:碧富(重庆)科技有限公司

A kind of iron-based amorphous alloy composite material

ActiveCN106282848BFacilitate forkingImprove plasticityTransportation and packagingMetal-working apparatusRare-earth elementIndium

The invention discloses an iron-based amorphous alloy composite material. The composition of the iron-based amorphous alloy composite material is: FeaAlbGacY3-dVdInxCoyBzSir, wherein a, b, c, d, x, y, z, r are atomic percentages , 70≤a≤76, 3≤b≤5, the value of c is 0 or 2, 0≤d≤3, 0≤x≤1.86, 8≤Co≤10, the value of z is 4 or 8, 0≤r ≤3. The iron-based amorphous alloy composite material of the present invention has excellent high plasticity and soft magnetic properties, its saturation magnetic induction reaches Bs=1.73T, and the density of the bulk amorphous alloy composite material prepared by powder metallurgy reaches 98.7%, the strength is as high as 2.08GPa, the mechanical properties are good, and can meet the needs of the industry. At the same time, the iron-based amorphous alloy composite material of the present invention does not contain expensive rare earth elements, and the demand for the only relatively expensive indium element is also very small, so its The manufacturing cost is not high, the process is not complicated, and it is easy to realize commercial production.

Owner:南通巨升非晶科技股份有限公司

A mine explosion-proof pneumatic actuator integrating solenoid valve and control unit

ActiveCN103672120BEasy to perform controlReduce application restrictionsOperating means/releasing devices for valvesSolenoid valveModularity

The invention discloses a mining explosive-proof pneumatic executive device integrating a solenoid valve and a control unit, and belongs to the technical field of mine production process automation. The mining explosive-proof pneumatic executive device integrating the solenoid valve and the control unit is characterized in that work equipment with pressure fluid as a power source achieves various motions or rhythms under the control of the control unit, the mining explosive-proof pneumatic executive device integrates the solenoid valve and the intelligent control unit, according to the device, the body portion, the motion portion and the control portion of the solenoid valve are arranged in an explosive-proof box for coal mine explosion-proof certification, the integration of the motions and control is achieved, the control can be executed conveniently, and dust prevention and water prevention are achieved. The mining explosive-proof pneumatic executive device can be applied to any occasion of a pneumatic system, the intellectualization, modularization, serialization and set completion of the solenoid valve and the control unit are achieved under the specific environment of a coal mine, and the device is widely suitable for various control execution devices with the pressure fluid as work media in the coal mine, petrochemical engineering, metallurgy, electric power, environment protection and other systems and industries.

Owner:山西中永通机电设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com