Conveying accelerator

An accelerator and pressure chamber technology, applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of uneven pulverized coal, low transmission power, insufficient combustion, etc., achieve wide application, clean gas, and improve transportation effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

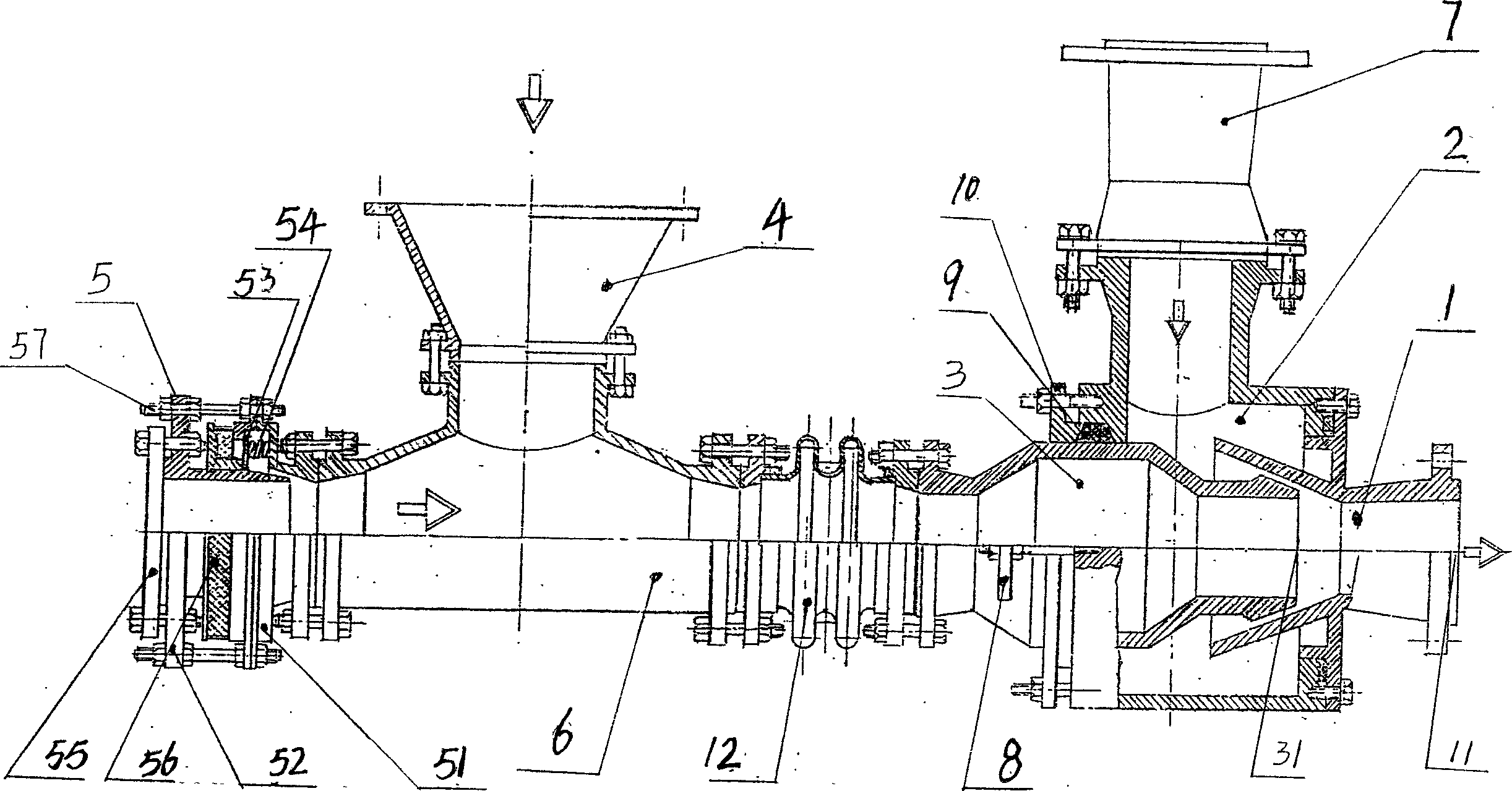

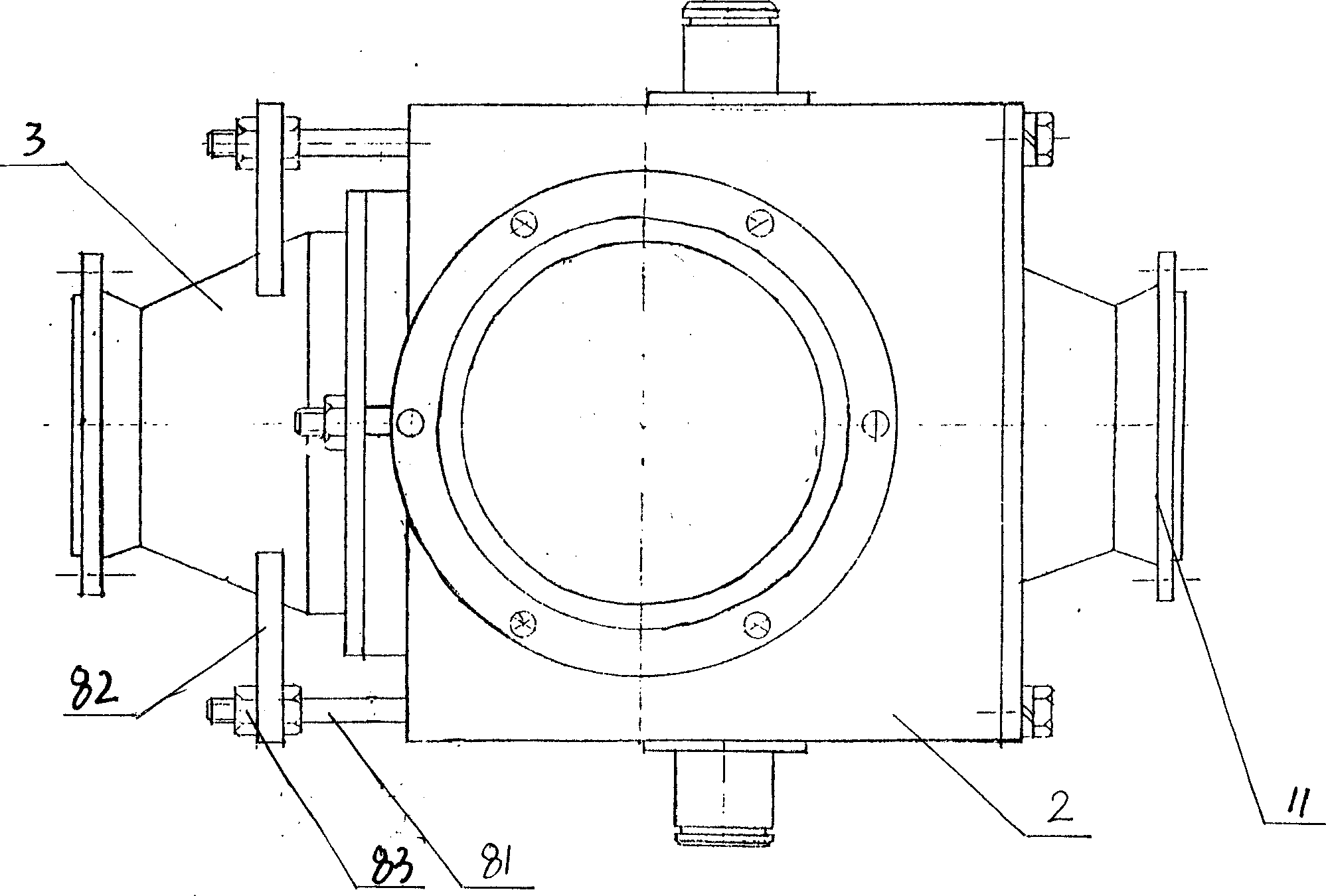

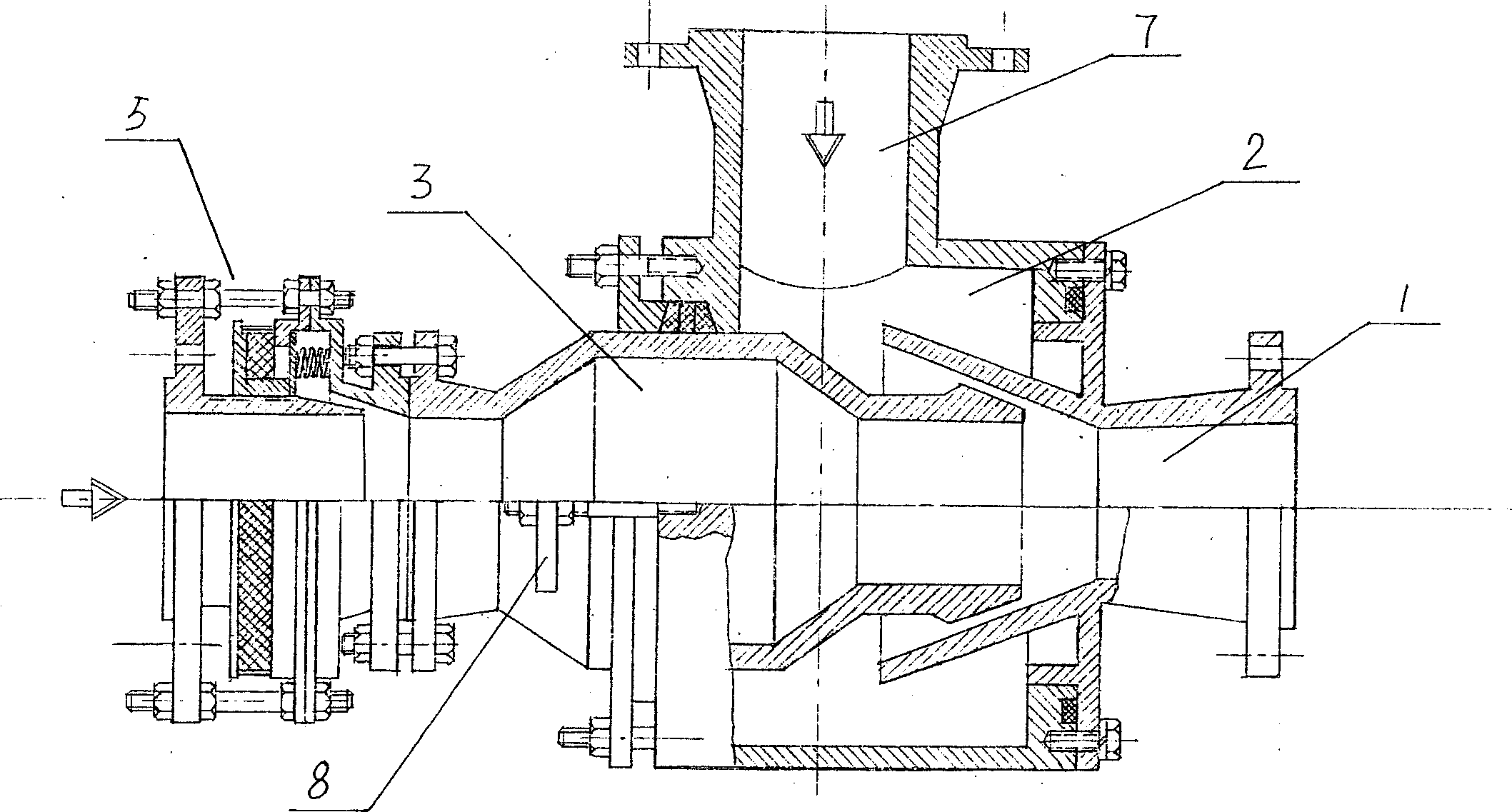

[0021] A conveying accelerator according to the present invention includes a mixing chamber 1 , a pressure chamber 2 , a suction chamber 3 , a feed port 4 and an air inlet device 5 . The mixing chamber 1 is trumpet-shaped and has a conical side wall. The mixing chamber 1 is sealed and fixed on one side of the pressure chamber 2 . The accelerator outlet 11 is formed at the narrowing of the conical surface of the mixing chamber 1 . The suction chamber 3 is hermetically installed on the other side of the pressure chamber 2. One end opening 31 of the suction chamber 3 extends into the conical side wall of the mixing chamber 1. The feed port 4 is connected to the air inlet device 5, and the telescopic tube 12 is used to connect the suction chamber 2 and the feed gas mixing tee 6, so that the position of the suction chamber opening 31 in the conical side wall of the mixing chamber 1 can be easily adjusted. Location. The sealed pressure chamber 2 is provided with a boosting inlet 7 ...

Embodiment 2

[0026] A conveying accelerator according to the present invention, in this embodiment, the feed inlet 4 in the present invention is closed, the air inlet device becomes the water inlet device 5 , and the suction chamber 3 is directly connected with the water inlet device 5 . For military industry, the present invention is placed on the bottom of the ship to replace the propeller, the water inlet device 5 faces to the front of the ship, and the accelerator outlet 11 faces to the rear of the ship. The supercharging equipment uses high-power multi-stage pumps to inject water, which generates high pressure in the pressure chamber 2, and the water flow in the water inlet device 5 is sucked, and a siphon phenomenon occurs between the mixing chamber, and the water flow is jetted through the accelerator outlet 11 to achieve high-speed propulsion, making the ship fly go ahead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com