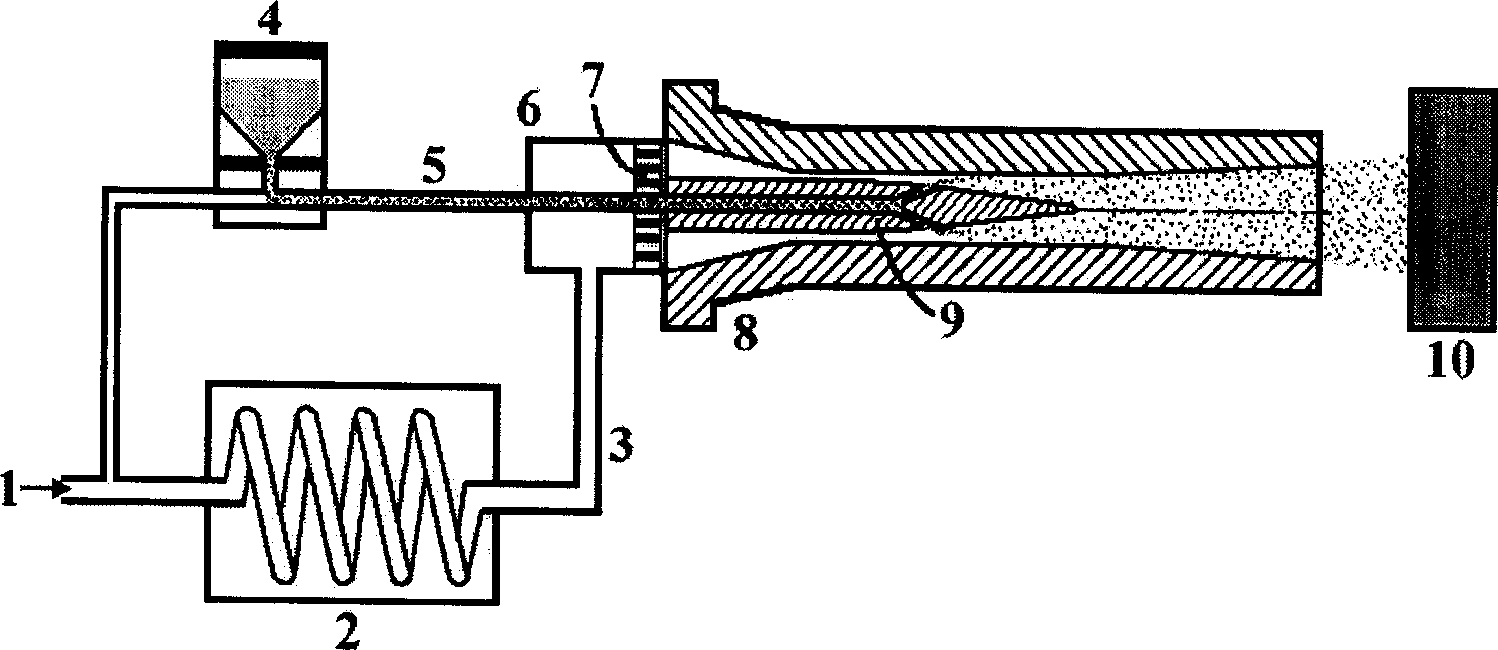

Cold air powered spraying method and device

A technology of cold air power spraying and nozzle, applied in spraying device, liquid spraying device, etc., can solve the problem of powder particle acceleration, and achieve the effect of overcoming blockage, conducive to powder feeding, and continuous cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

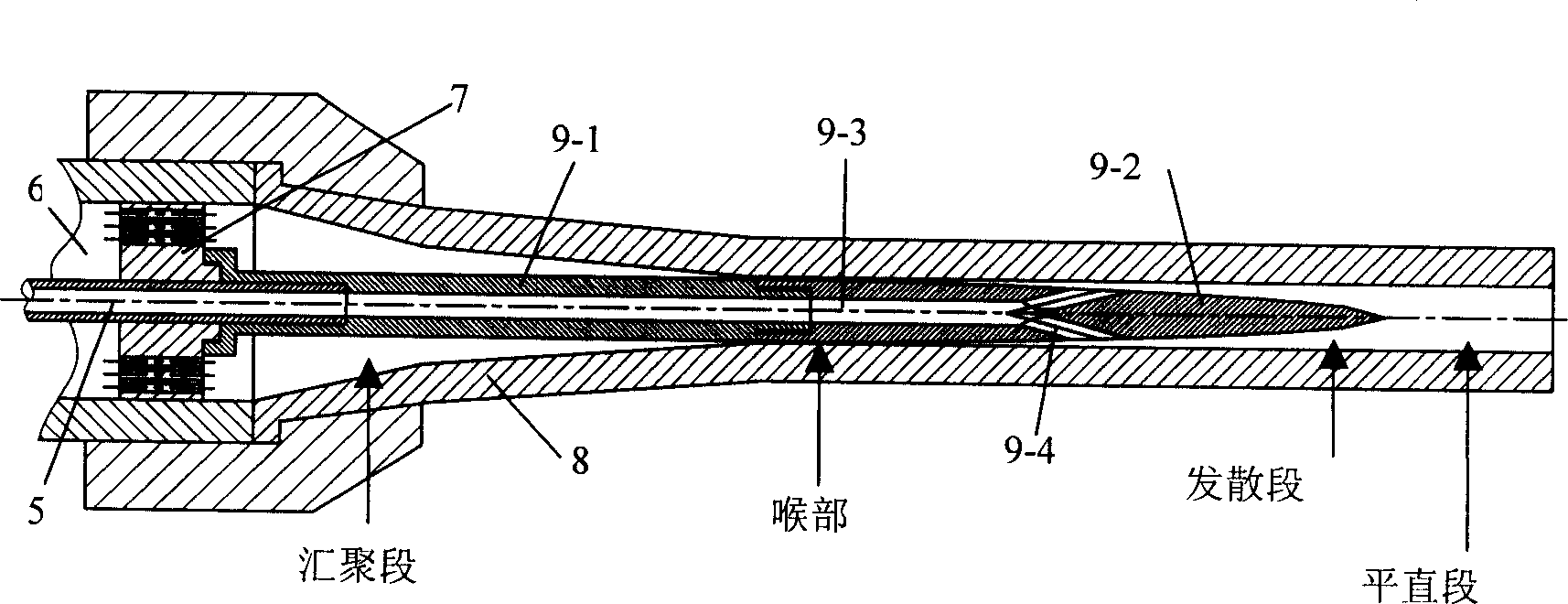

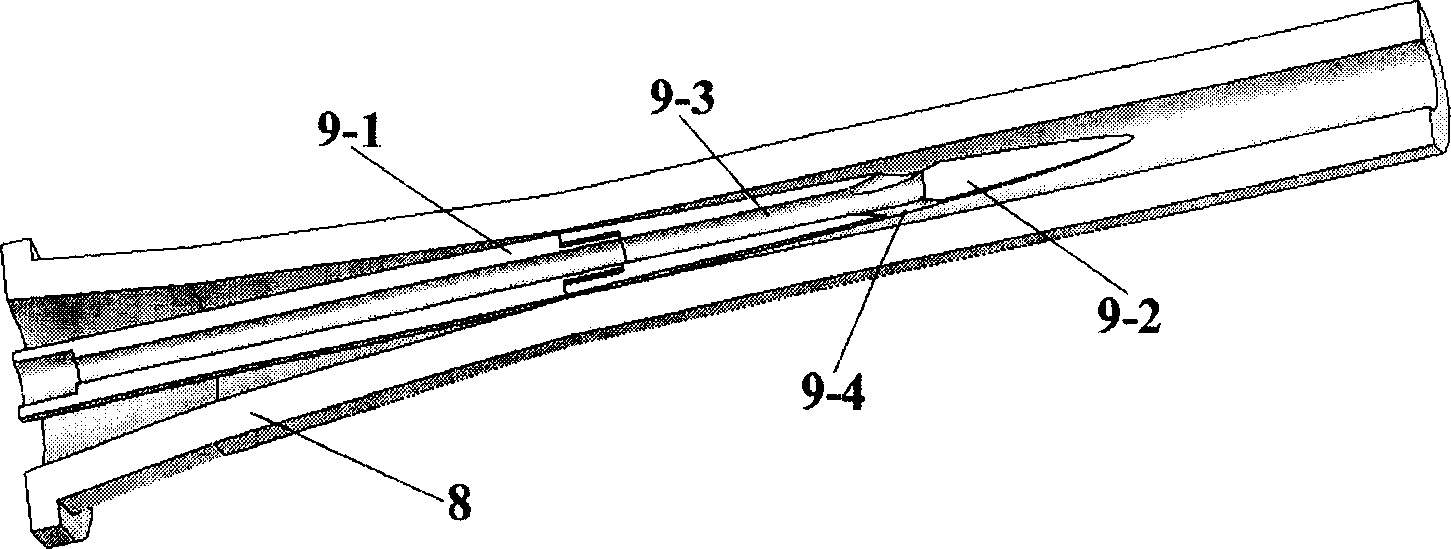

Embodiment 1

[0071] Nitrogen is used as the working gas, the particle diameter of the copper powder to be sprayed is 10 μm to 30 μm, and the substrate is an aluminum plate. The working gas pressure at the nozzle inlet is 2.5MPa and the temperature is 250°C. Nozzles in the form of image 3 As shown, the lengths of the divergent section and the straight section of the outer body 8 are 60mm and 20mm respectively, and the corresponding inner flow channel is straight (cylindrical) with a diameter of Φ7.4mm. The effective length of the nozzle throat is 5mm. The diameter of the guide terminal 9 inside the nozzle corresponding to the cross-sectional circle of the throat is Φ6.7mm, and the annular cross-sectional area of the flow channel at the throat is 7.75mm 2 , the ratio of the cross-sectional area of the outer body 8 cylinder to the cross-sectional area of the diversion terminal 9 corresponding to the throat is 1.22. The diversion terminals 9-1 and 9-2 are respectively made of copper ...

Embodiment 2

[0073] Nitrogen is used as the working gas, the particle diameter of the copper powder to be sprayed is 20 μm to 50 μm, and the substrate is an aluminum plate. The working gas pressure at the nozzle inlet is 2.5MPa and the temperature is 380°C. Nozzles in the form of image 3 As shown, the lengths of the divergent section and the straight section of the outer body 8 are 65 mm and 20 mm respectively, and the corresponding inner flow channel is straight (cylindrical) with a diameter of Φ8.1 mm. The effective length of the nozzle throat is 10mm. The diameter of the guide terminal 9 inside the nozzle corresponding to the cross-sectional circle of the throat is Φ7.6mm, and the annular cross-sectional area of the flow channel at the throat is 6.17mm 2 , the ratio of the cross-sectional area of the outer body 8 cylinder to the cross-sectional area of the diversion terminal 9 corresponding to the throat is 1.14. The diversion terminals 9-1 and 9-2 are both made of copper, and...

Embodiment 3

[0075] Nitrogen is used as the working gas, the particle diameter of the copper powder to be sprayed is 80 μm to 120 μm, and the substrate is an aluminum plate. The working gas pressure at the nozzle inlet is 3.0MPa and the temperature is 600°C. Nozzles in the form of image 3 As shown, the lengths of the divergent section and the straight section of the outer body 8 are 100 mm and 40 mm respectively, and the corresponding inner flow channel is straight (cylindrical) with a diameter of Φ8.7 mm. The effective length of the nozzle throat is 10mm. The diameter of the guide terminal 9 inside the nozzle corresponding to the cross-sectional circle of the throat is Φ8.3mm, and the annular cross-sectional area of the flow channel at the throat is 5.34mm 2 , the ratio of the cross-sectional area of the outer body 8 cylinder to the cross-sectional area of the diversion terminal 9 corresponding to the throat is 1.10. The diversion terminals 9-1 and 9-2 are made of stainless stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com