Plastic container structure

A plastic container, container technology, applied in the direction of closure, packaging, removable cover/cover, etc., can solve the problems of deformation of plastic parts, container air leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

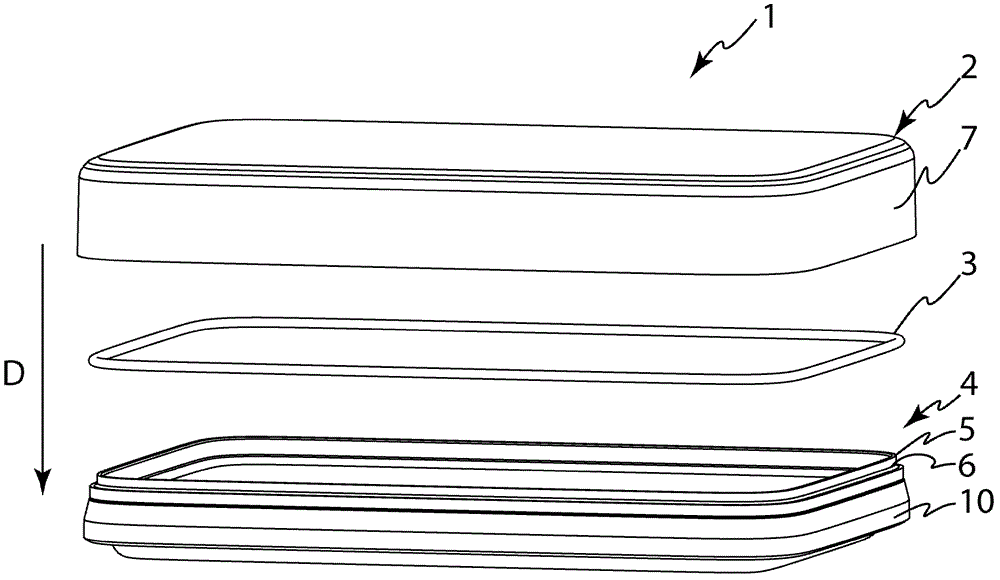

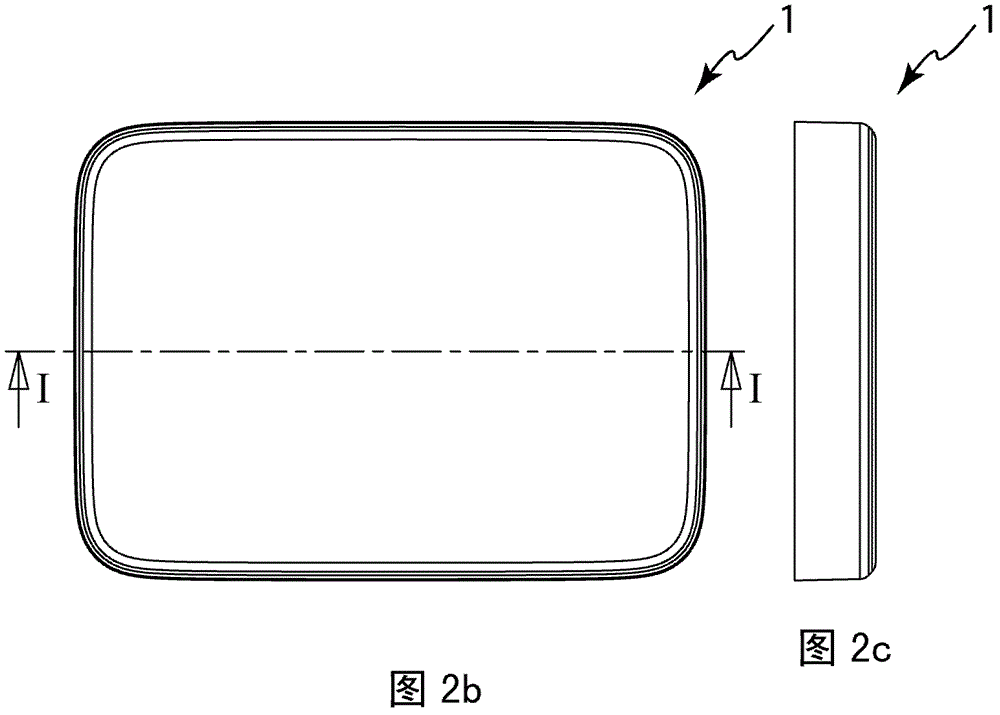

[0021] Such as Figure 1-5 As shown, a plastic container structure 1 according to an embodiment of the present invention includes a lid 2 , a gasket 3 and a container 4 . The lid 2 is configured to be connected to the container 4 by movement of the lid 2 along the joining direction D relative to the container 4 to close the container 4 . The container 4 has an opening defined by a peripheral edge 5 having a peripheral seat 6 for receiving the gasket 3 . Furthermore, the lid 2 has a peripheral wall 7 configured to surround the peripheral flange 5 of the container 4 . The seat 6 is arranged on the outer side of the flange 5 of the container 4 opposite to the peripheral wall 7 of the cover 2, and the seat 6 and the peripheral wall 7 of the cover 2 are configured such that the gasket 3 is compressed between the peripheral wall 7 of the cover 2 and the container 4. Between seats 6.

[0022] The plastic material chosen for the container 4 and lid 2 is a thermoplastic material sui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com