Material binding machine

A binding machine and data technology, applied in binding, printing, etc., can solve the problems of a large number of manual finishing and low work efficiency, and achieve the effect of simple structure, reducing labor intensity, and preventing paper folding or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

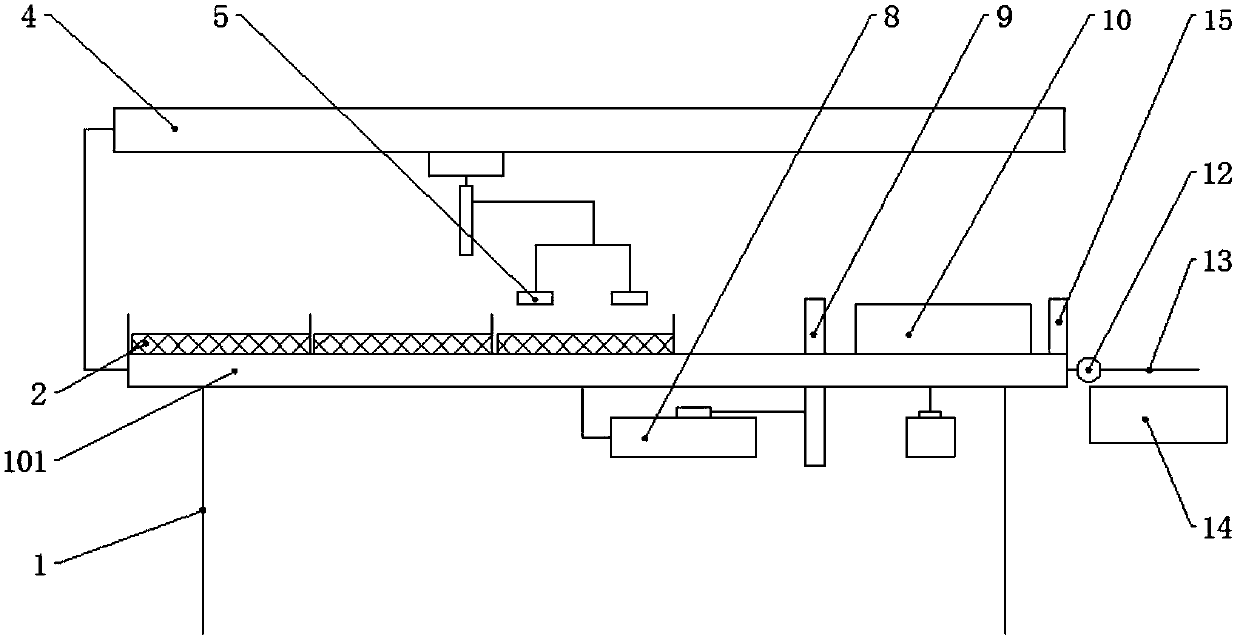

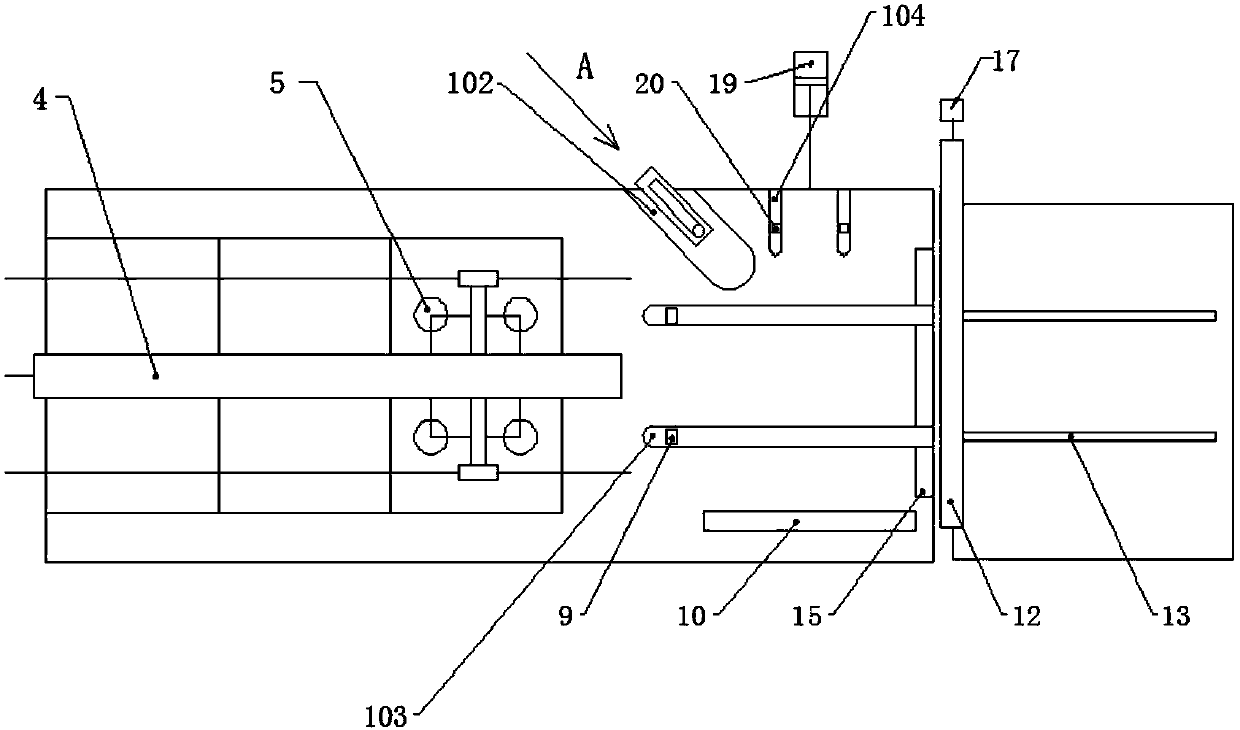

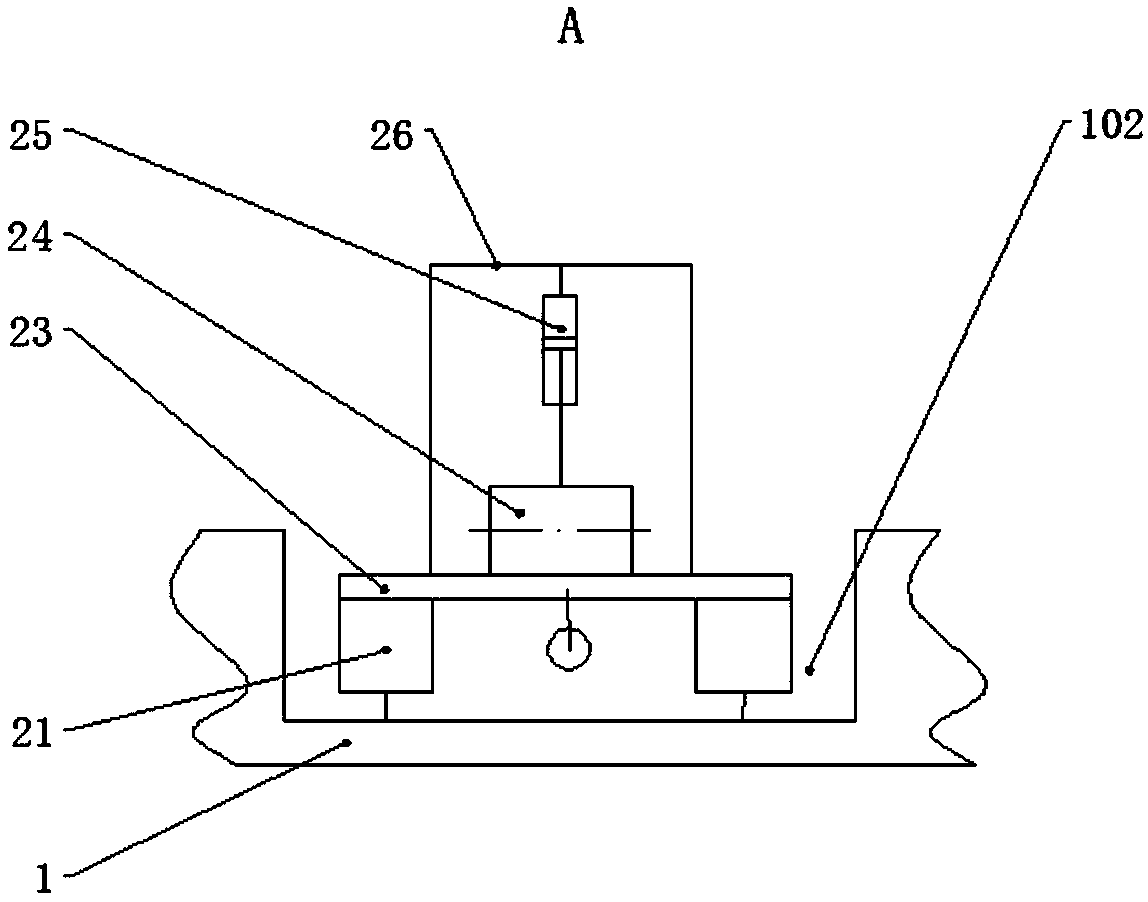

[0034] This embodiment relates to a preferred embodiment of the present invention, in particular to an electrically driven data binding machine, such as Figure 1-4 As shown, the document binding machine includes a paper storage box, a paper picking device, a finishing device, a binding device and a base 1 .

[0035] The bottom plate 101 of the base 1 is provided with a paper storage box, and the paper storage box is a grid area composed of partitions 102 for accommodating paper 2. According to the number of pages of each document, multiple paper storage boxes can be set. box.

[0036] A control platform 4 fixed on the base 1 is arranged above the paper storage box, four vacuum suction cups 5 for absorbing paper 2 are arranged on the control platform 4, and a first driving device for driving the vacuum suction cups 5 is arranged. The first driving device drives the vacuum chuck 5 to move horizontally and up and down between each paper storage box and the sorting area.

[003...

Embodiment 2

[0044] This embodiment relates to another preferred embodiment of the present invention, in particular to a pneumatically driven data binding machine, such as Figure 5-8 As shown, the document binding machine includes a paper storage box, a paper picking device, a finishing device, a binding device and a base 1 .

[0045] The bottom plate 101 of the base 1 is provided with a paper storage box, and the paper storage box is a grid area composed of partitions 102 for accommodating paper 2. According to the number of pages of each document, multiple paper storage boxes can be set. box.

[0046] A control platform 4 fixed on the base 1 is arranged above the paper storage box, four vacuum suction cups 5 for absorbing paper 2 are arranged on the control platform 4, and a first driving device for driving the vacuum suction cups 5 is arranged. The first driving device drives the vacuum chuck 5 to move horizontally and up and down between each paper storage box and the sorting area. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com